Types of radiators by material of manufacture

If you go to a hardware store and inquire about batteries, you will see a wide variety of radiators. Sometimes stores even present the latest radiators in a cross-section, clearly demonstrating a simple system, thanks to which this miracle of technology supposedly works many times better than old Soviet batteries. However, in fact, the value of modern metal batteries is greatly exaggerated - more on this later, but first, let's look at all the popular types of radiators on the market.

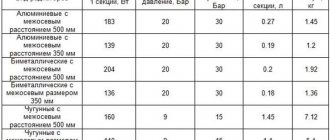

Radiator types:

- Copper batteries. They are rare, but deserve attention. Such radiators have truly unique properties: heat is completely dissipated throughout the room without being retained in the metal, copper does not corrode, and both water and antifreeze can flow in such batteries. Copper batteries are very reliable and durable, however, they are extremely expensive, which is why they have not conquered the market.

- Steel batteries. The most common ones on the market are cheap, quite effective, but much inferior to cast iron ones. They are not that heavy, but they cool down quite quickly after the heat is turned off. In addition, steel batteries dissipate heat quite unevenly, and their appearance is also a disadvantage.

- Aluminum batteries are more expensive than steel ones, but have much higher heat transfer. Aluminum heats up instantly when heat is applied, so the heating turns on faster. There are only two disadvantages - after turning off the heat, they instantly cool down, and with them the apartment, the second is the price, which is an order of magnitude higher than that of steel ones. Another advantage of aluminum batteries is their appearance. They are compact, stylish, and fit perfectly into modern design.

- Bimetallic batteries. These are radiators made from an alloy of two or more metals. Today, manufacturers are testing many combinations, but the most common is steel and aluminum. Steel makes the radiator cheaper and is used as a base; the outer part is aluminum, which achieves some of the properties of all-aluminum radiators. As a result, you get a fairly interesting battery at an affordable price, however, which is still inferior in many respects to purely aluminum or cast iron counterparts.

- Cast iron batteries. Radiators of this type began to be installed in homes more than a hundred years ago, and the first engineers immediately declared that cast iron was much more beneficial for heating than metal. Yes, it is heavy and bulky, but it heats up in such a way that it then accumulates heat and keeps it at the proper level for a very long time. Even if you turn off the heating completely, the apartment will need a couple more days to cool down, since the cast iron will remain warm. The second plus is durability, old batteries in Soviet Khrushchev buildings last 50 years and are replaced during modern renovations only because they are not aesthetically pleasing. Moreover, they are often replaced with modern cast iron batteries, which will again last 50 years or as long as required. In a word, cast iron is reliable and efficient, despite the age of the technology. It's like steel for knives - why make knives from ultra-new materials if there is nothing better than steel?

Different types of radiators and their characteristics

The most common and familiar to domestic consumers is the cast iron heating system - radiators. In the past, such radiators were used everywhere in large quantities. These radiators are heavy and not at all modern in appearance; such devices are unsuitable for use in automatic heating systems. But at the same time, cast iron radiators have many advantages, which led to their spread and popularity in their time. First of all, it is the ability to withstand pressure changes, resistance to corrosion processes, and immunity to those impurities that are in the heat carrier of the heating system.

Steel radiators are lighter, their walls are thinner, so such devices are less inert. If steel radiators are made in the form of panels, then they have high heat transfer, since the heated area is larger.

A radiator heating system with radiators made of a material such as aluminum meets the requirements of many consumers. Such radiators are lightweight, have a high heat transfer rate, and also have a modern and compact appearance.

Radiators can also be made of aluminum with the addition of other materials. If the radiator models are cheap enough, then silicon is mixed in, which will affect the tensile strength of the device material.

More expensive models contain zinc and titanium, these materials give the radiators high resistance to mechanical damage and corrosion processes.

Operational features and advantages of cast iron batteries

Why is cast iron more acceptable in heating systems? Let's take a closer look at its characteristics. The features of cast iron as a metal are very interesting.

Namely:

- It has low thermal conductivity, which means it heats up very slowly. In order to heat the batteries to a temperature of 45 degrees, you need to turn on the water at a temperature of 75 degrees. However, when the batteries get hot, this effect comes to our advantage. Warm cast-iron radiators can hardly be cooled by anything, and walls frozen through in winter do not create problems.

- The second feature is durability and versatility. Due to their bulkiness, cast iron batteries have been written off by many as a “dustbin of the past”, but in vain. After all, alas, there is nothing better than this metal for radiators yet. Some engineers ironically claim that cast iron batteries are generally eternal and it is worth noting that they are not so far from the truth. Not everyone these days has the opportunity to change old batteries, but even 60-year-old cast iron radiators do not break through. Grandmothers living in Khrushchev-era apartment buildings with batteries as old as the world do not even think about their possible replacement. Batteries are perceived as something eternal, unshakable, and their service life can actually be almost 100 years. And now, for comparison, the service life of aluminum batteries is up to 20 years.

- The third thing that makes cast iron batteries so interesting is the lack of headaches regarding maintenance. Cast iron batteries will almost never require repairs or even preventive measures; they are the only type of radiators in which rusty, dirty water can easily circulate without any consequences. Unfortunately, our realities are such that the water in the pipes is really far from crystal clear, so in this regard, cast iron batteries provide insurance.

And the last significant advantage of cast iron batteries is that they can easily withstand water of any temperature. The maximum temperature that a cast iron radiator can safely withstand is 150 degrees. This means that you can even run boiling water and nothing will happen to the batteries.

Features of the option with bottom pipe connection

As a rule, connecting a radiator with a bottom connection is carried out in cases where unpresentable heating pipes need to be hidden in the floor or wall so as not to disturb the interior of the room.

On sale you can find a large number of heating devices in which manufacturers provide a lower supply to the heating radiators. They are available in various sizes and configurations. At the same time, in order not to damage the battery, it is worth looking at the product passport, which describes the connection method for a particular model of equipment. Typically, the battery connection unit has ball valves that allow it to be removed if necessary. Thus, even without experience in such work, using the instructions, you can connect bimetallic heating radiators with a bottom connection.

The circulation of water inside many modern radiators with a bottom connection occurs in the same way as with a diagonal connection. This effect is achieved due to an obstacle located inside the radiator, which ensures the passage of water throughout the heating device. After this, the cooled coolant enters the return circuit.

Cast iron battery: what are the disadvantages

Unfortunately, cast iron batteries also have their disadvantages. Therefore, before buying such a radiator, you should carefully weigh the pros and cons.

What are the obvious disadvantages of cast iron compared to other materials:

- Heat loss . Quite a large part of the heat goes to heat the metal. Yes, it then takes a long time to cool down, but if it’s warmer outside and this effect doesn’t help you, then it turns out that you wasted some of the energy on heating. Aluminum, for example, cools quickly, but has a low level of heat loss.

- Low threshold pressure . Modern bimetallic batteries can withstand a pressure of 30 atmospheres, while their cast iron counterparts can withstand only 15. Cast iron is generally an inherently fragile metal, which is why batteries have to be made so massive.

- Heavy weight . Each battery section weighs about 7-8 kg, that is, the entire battery without water weighs about 50 kg. Installation or installation of such radiators is difficult.

Elimination of fistula

For any breakdown there are a number of reasons accompanying it. A fistula on heating system pipes or on a radiator is no exception. If a small brown spot appears on the elements of the heating network, you should not think that it is paint coming off. In fact, this is the beginning of an often irreversible process, but knowing how to repair a fistula in a cast iron battery, you can stop the destruction and extend its service life. Causes of corrosion:

- Taking into account the frequent increases in the cost of utilities, some craftsmen are cunning and, in order to save energy, connect a neutral cable to the heating circuit. The currents that begin their “journey” through the pipes through the coolant are what cause the formation of corrosion. You can identify a dishonest neighbor if there are several fistulas and they appear with a certain regularity. Calling the appropriate service to identify the intruder and repairing cast iron batteries yourself will help save the situation.

- Too much acidity of water can harm even corrosion-tolerant cast iron.

- The batteries have expired or deposits on the battery walls have damaged the metal. In this case, even a small fistula or crack under the influence of water pressure can cause the battery to burst and a stream of hot water to flow from it.

Any of the options requires urgent intervention. If the cast iron battery leaks only slightly, then you can do without disconnecting the circuit and dismantling it. A clamp can save the situation. If the water only drips, then a one-sided clamp will do, but if it runs in a thin string, then it is better not to risk it and use a double-sided clamp.

In the event that the coolant ruptures the place where the fistula was located, the question immediately arises whether it is possible to weld a cast-iron battery. As a rule, cold welding becomes an emergency solution, but even if it has restored the tightness, it is necessary to call specialists from the heating network to check the condition of the heating system.

Sectional design of a cast iron heating battery

Any cast iron battery consists of separate chambers, each of which is cast from gray cast iron at the factory.

If you cut the battery, you will see that the chambers are connected together using nipples, and the joints are also additionally sealed - rubber gaskets are usually used for this.

Cast iron radiators can be single- or double-channel. As for water, each section holds about 1.2-1.4 liters of water. With a section weighing 7 kg, it turns out that together with water it weighs more than 8 kg.

DIY installation

It is not necessary to invite specialists for installation - you can do the work yourself, but additional help may be required, because the products are heavy. You shouldn't put too much stress on yourself.

Required tools and materials

Products are mounted on different surfaces, which should be taken into account before starting work. The main requirement is that the surface to which installation will be carried out must be smooth and clean. Therefore, the wall is carefully prepared before installation work. It is cleaned, impregnated with liquid glass and covered with a heat-reflecting shield, which will increase the performance of the system. Instead of shields, a special composition can be used that gives the same properties.

The installation process itself largely depends on the wall material:

- If the surface is made of wood, then a plank and stand will be additionally useful.

- If it is a brick plastered surface, brackets and a niche are used.

- In the case of a wall that has a lightweight structure, you will need a solid support.

First comes the fitting of the location, after which you can proceed to the fastenings. You need to understand that the weight of a cast iron radiator is impressive, so it is recommended to prepare a model from cardboard or plywood. This will help you install the equipment on the brackets more correctly.

Installation and connection to the system

First of all, install the brackets.

The process is as follows:

- The points where the fasteners will be inserted are marked.

- Holes are made in the surface.

- Dowels or wooden plugs are installed.

- Brackets are inserted and fixed with concrete mortar.

- Before hanging the radiator, you need to make sure that the fastenings are secure.

To install cast iron batteries you will need 4 brackets. If this is a sectional model, then fastening elements may also be required to build additional sections.

After the device is hung on the brackets, the following components are installed:

- Every modern system has an automatic or manual air vent. This element must be screwed into the adapter and installed on the upper manifold opposite the place where the supply pipe is connected.

- Free collectors must be closed with plugs. Their diameters may vary, so you will need adapters, which are already included in the kit.

- Shut-off and control valves are installed. Ball valves are placed on the inlet and outlet openings, which will allow, if necessary, to service and repair heating equipment. If you have shut-off valves, you won’t have to turn off the entire system; you just need to close the taps.

- Using control devices, such as a thermostat, you can set the desired heating temperature. In general, this element is optional.

- Inlet and outlet pipelines are connected. There are several schemes. The type of connection depends on what pipes and fittings are used.

- The last stage is pressure testing of the system or battery. When filling with water, taps should be opened slowly, without rushing. If you open the tap too quickly, there is a possibility of water hammer, which will negatively affect the condition of the system.

The installation and activation procedure is not complicated. The only problem that many beginning craftsmen face is the heavy weight of the equipment.

Operational features of cast iron batteries (video)

Well, cast iron batteries have come a long way and have been used in our homes for more than a century. They are heavy, rough and do not have the best heat loss properties, but they offer a long-lasting heating effect and an extremely long service life. Cast iron radiators do an excellent job of warming up the house and preventing it from cooling down quickly, so they still deserve their place on the market. The main competitors of cast iron radiators are aluminum, steel and bimetallic.

Comments

-1 Dima 07/13/2017 06:09 As for me, cast iron batteries are the best, both in quality and in terms of operating time.

Yes, they weigh a lot and don’t look very good, but these are minor things, and the appearance can be changed through the screens. Quote

Update list of comments RSS feed of comments for this entry

Prices: summary table

| Model | Dimensions, mm | Working pressure, atm | Heat dissipation, W/section | Section price, rub. | Price 1 kW, rub. |

| Konner Modern 500 | 600/60/96 | 12 | 130 | 1 000 | 7 500 |

| STI Nova 500 | 580/80/60 | 12 | 124 | 850 | 6 850 |

| Viadrus Bohemia 450/220 | 540/225/86 | 10 | 100 | 7 650 | 76 500 |

| Viadrus Hellas 470/218 | 540/218/50 | 10 | 108 | 11 000 | 101 000 |

| RETROstyle TOULON 500/160 | 580/160/60 | 10 | 157 | 2 700 | 17 200 |

| Exemet Romantica 510/350 | 660/215/74 | 10 | 172 | 4 000 | 23 500 |

| RETROstyle WINDSOR 500 | 650/95/80 | 10 | 163 | 7 050 | 43 000 |

| Iron Lion Pion 600 | 600/180/65 | 10 | 118 | 3 900 | 33 000 |

Based on the price analysis, we can conclude: most of the products belong to a high price category, which makes them in demand by a narrow circle of buyers.

Radiators are an important part of the heating system in private houses and multi-storey housing. The microclimate in the house and the safety of operation depend on their correct choice. Cast iron radiators satisfy many parameters, but it is worth studying the manufacturer’s technical documentation and consumer reviews when choosing a specific battery model.

How to calculate the number of sections for a bedroom

There are several methods for determining the number of segments. The simplest option involves using the formula: N = (100 x S)/Q

How to calculate the number of radiator sections - online calculator

Explanation of values:

- N – number of sections;

- S – room area;

- Q – section heat transfer indicator.

The calculations use an average value of 100 W. This is exactly the power of the device required to heat 1 m2.

You can get a more accurate result by taking into account factors such as:

- ceiling height;

- wall thickness;

- number of windows;

- climatic features of the region;

- on which side is the room located, etc.

All these are called correction factors. They are assigned the designations K1...K10. The formula with their participation is as follows: N = K1 x K2 x...K10 x (100 x S)/Q. This option is considered the most accurate.