If you are reading this article, then you have already decided to buy a wood-burning stove, so we will not talk about the advantages of such a purchase. Another question is how to choose the right wood-burning stove for your home if you are not an expert, and each seller describes the advantages exclusively of his offer? That's what we'll talk about. In this article we will not incline you to any particular model, but will just share our knowledge. Our goal is to help you understand how to choose a stove that will meet all your expectations and desires.

Type of wood stove for home

— Let's start with a choice based on key parameters.

The first thing you should decide is what type of stove you like best.

Wood stoves are divided into:

- stove-fireplaces;

- heating and heating-cooking;

- cast iron;

- heat storage;

- stoves of the “buleryan” type (in other words, long-burning stoves);

- tiled stoves;

- so-called “potbelly stoves”.

Stove-fireplaces

It’s easy to guess from the name that a feature of such stoves is the presence of a glass door through which you can admire the beauty of a live fire. From an aesthetic point of view, this is certainly the most comfortable option: in the evening, you are lying on a warm carpet, your wife is sitting next to you and reading a book, and a beautiful fire is burning in the stove, crackling...

Furnaces of this type are usually produced with an internal lining.

Koksharov Sergey Manager of the store on the street. Narodnaya, 87

The inner lining in furnaces is the facing layer of the furnace firebox, which is in contact with the open fire. The lining performs the function of protecting the walls from burnout and the function of thermal insulation, reducing heat loss (accumulating heat inside the furnace). The combustion temperature of a furnace without lining can be 300-400 degrees Celsius, and with lining - 500-600. Note that the higher the combustion temperature, the more beautiful the flame will be and the more efficient the combustion. It is for this reason that fireplace stoves are made with a lining.

Fig 1. Meta Rain stove-fireplace

Heating and heating-cooking furnaces

This type combines steel furnaces without internal insulation (without lining). Such stoves, as a rule, do not have glass doors (although some stove models may have small glass, but its dimensions still do not reach the glass doors of “stove-fireplaces”). Heating and cooking stoves additionally have a cooking surface, which is located on top, and can be made of either steel or cast iron. In this case, the burners can be either removable or stationary.

As for appearance, in comparison with stove-fireplaces, of course, these stoves lose. However, if you are only interested in their functionality, then feel free to choose this option.

Fig 2. Heating and cooking stove Vesuvius Comfort 300 (DT-3S)

Cast iron stoves

Cast iron stoves are placed in a separate group due to the characteristics of heating the room, namely, they are characterized by minimal convection. Such ovens accumulate heat inside themselves, after which they distribute hot air in a linear manner in different directions.

Metal stoves, unlike cast iron ones, heat the room by convection - air flows pass through the convection casing. Roughly speaking, cold air from the room enters the oven, from where it comes out hot back into the room. The convection method of heating a room is considered the fastest heating method.

One of the advantages of cast iron wood stoves is that the resulting heat feels more pleasant and soft than the heat received from metal stoves. Cast iron is also a more durable material than steel. The downside is that the room heats up more slowly.

Figure 3. Guca LAVA cast iron stove

Heat storage furnaces

Furnaces with large heat-accumulating mass. Such furnaces have a body made of stone (soapstone, pyroxenite), and their weight can range from 300 kg to a ton. The stoves got their name for their ability to “collect” heat and release it within 8, 16, or even 24 hours, depending on the model.

Fig. 4. Heat storage furnace Kaminiti Lahtila talc

“Buleryan” type ovens

This is a type of heating stoves that are designed to burn for a long time. Please note that “long burn” is their operating mode and not a feature like other stoves. With one stack of wood, such a stove can burn from 8 to 12 hours. The firebox of such stoves is driven to the very top, set on fire, and the wood begins to smolder (burn for a long time). As a rule, “buleryan” type stoves are used in non-residential premises. Let's be honest, such stoves create a lot of hassle for the owner, and besides, they form a lot of condensation, but if you need heat, then you will have a lot of it!

Figure 5. Heating furnace NMK Sibir OV-100

Tiled stoves

The lining of the stove body is made of tile.

A tile is a ceramic element made of baked clay for decorating stoves and fireplaces, internal and external walls of buildings, covered with glaze and often decorated with paintings.

Externally, tiled stoves are very attractive - either with a painted pattern, or the tile itself is a beautiful color. Such stoves become a picturesque element of the interior that attracts the attention of house guests.

Figure 6. Caminiti tiled stove

Potbelly stoves

Well, you've definitely heard about these ovens. Small stoves, usually on four legs, are designed to heat small rooms (up to 50 cubic meters). Everything is simple here - we throw firewood into a small stove and heat the small room a little at a time.

Fig 7. Potbelly stove Meta Boom

What else is important?

The main fuel for fireplace stoves is wood.

Logs can be of different sizes, and this must be taken into account. The larger their size, the easier and faster it is to prepare firewood and put it in the firebox. The manufacturer usually indicates the maximum allowable log length, and it is better if in your stove this value is not less than 300 mm. If you go to the store, be sure to take a tape measure with you. With it, you can not only estimate the size of the loaded firewood, but also estimate the volume of the firebox, which manufacturers often do not indicate in the specifications. Summary table with furnace models

| Model, country of manufacture | Heated volume, m³ | Features of the line | Price range, rub. |

| 1. Termofor/TMF Fire-battery (Russia) | 100, 150 and 200 |

| 13000-21000 |

| 2. Zhara (Russia) | 100 and 200 |

| 12000-17000 |

| 3. META Ardenfire Marseille (France/Russia) | 150, 200 and 250 |

| 41000-64000 |

| 4. Eco-fireplace Bavaria (Russia) | 90-195 and 105-225 |

| 18000-27000 |

| 5. Thorma Andorra (Slovakia) | 98-200 |

| 69000-77000 |

| 6. Kratki Koza K (Poland) | 135, 190 and 250 |

| 32000-61000 |

| 7. Supra Tomera (France) | 150-320 and 300 |

| 77000 |

| 8. La Nordica Ghisa (Italy) | 172, 200 and 258 |

| 84000-127000 |

Power of wood stoves for home

- choose the type - decide on the power

Power is a parameter that must be indicated in the technical data sheet for the stove and is measured in kilowatts. Many manufacturers claim that 1 kW heats 10 sq.m. premises. It would seem that everything is simple - you multiply the power of the stove by 10 and get the area of the room that this stove is intended to heat.

But wait, because the height of the ceilings in different houses is different, and it turns out that for the same area there can be completely different volumes of the room. Taking this into account, our company’s specialists recommend sticking not to the area, but to the volume of the room. Therefore, you need to proceed from the calculation that 1 kW will heat 20 cubic meters. Therefore, we multiply the power of the stove by 20, we get the volume of the room in cubic meters that such a stove can heat. To calculate your room volume, just multiply the height by the width by the length of the space. On our website, all models of home stoves already indicate what volume they are suitable for:

Koksharov Sergey Manager of the store on the street. Narodnaya, 87

Don't ignore the following two rules:

- The stove only heats the room where it is located. Heat, of course, can flow into adjacent rooms, but only through open doors or specially installed ventilation grilles in the walls.

- You should not choose a stove based on power. Take with a reserve of at least 30% of the original volume of the room. Do not forget that there are many factors that additionally influence the rate of heat loss from the room: the number of windows, the quality of the house’s thermal insulation, etc.

Ghisa (La Nordica, Italy)

The Italian company La Nordica was founded in 1968 and has been present on the wood heating market for the last 50 years. Products are supplied to 50 countries. The manufacturer's range includes ultra-modern, classic and rustic-style models - for heating, cooking, and water heating.

Our selection includes 3 models with female names.

All are made of cast iron and, which is quite rare, Isetta and Isotta implement convective heat transfer: there is space for air circulation between the firebox and the body. Another feature is the side loading door in the Isetta and Isotta models! At the same time, Giulietta is the simplest of the selection, suitable for seasonal use in the country. Main characteristics of Ghisa stoves from La Nordica

| Characteristic | Giulietta | Isetta | Isotta |

| power, kWt | 6 | 7 | 9 |

| Volume of heated room, m³ | 172 | 200 | 258 |

| Maximum log length, mm | 400 | ||

| Chimney diameter, mm | 120 | 150 | |

| Size, mm | 490x710x430 | 660x710x450 | 790x780x520 |

| Weight, kg | 105 | 150 | 190 |

| price, rub. | 84 700 | 105 700 | 127 400 |

Impressions from use. Such stoves are popular for their appearance and ease of use. They are more expensive than alternative options due to their Italian origin, but this is completely justified for those who want to solve the problem of heating a country house for the next 10 years. You can put logs up to 400 mm long into the firebox, and a full load is enough for 4-5 hours to maintain a comfortable temperature at -15°C outside. They quickly warm up rooms: Isotta at 9 kW in an insulated house of 100 m² increases the temperature from +5°C to +25°C in 1-1.5 hours at -5°C outside. Among the disadvantages, one can name only the top connection of the chimney.

Watch a short video of the Isotta model in action:

Furnace firebox material

— this must be taken into account

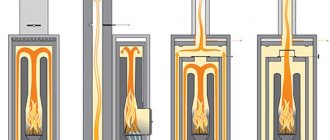

Steel firebox

As a rule, furnaces are made of structural steel 3-4 mm thick, rarely thicker. Steel furnaces include heating furnaces, heating and cooking furnaces and long-burning furnaces. The peculiarity is that in such furnaces, for the most part, there is no lining. Everything is logical, the higher the combustion temperature (and the combustion temperature of stoves with lining, as previously written, can reach 500-600 degrees Celsius), the faster the firewood burns, which means it is not entirely suitable for stoves of this heating group.

The advantages of steel wood-burning stoves include, respectively, the duration of combustion. And the disadvantages are the service life of such stoves, which is the shortest in comparison with stoves made of other materials. Also, the disadvantages include the low quality of firewood combustion, which leads to greater condensation formation. These ovens therefore require more frequent cleaning than others.

Steel firebox with lining

The most common type of material is a steel firebox with an internal lining (insulation). Fireclay brick is most often used as a lining (although today it is a slightly outdated material that has obvious disadvantages: it is heavy, porous, and not durable.

More modern materials include vermiculite and cast fireclay (white, smooth, non-porous). Some manufacturers use their own unique lining material, for example: Acumotte, Termotec, Reallit, etc. Such materials are based on cast fireclay, to which various substances are added that increase the strength, self-cleaning and durability of the lining.

The advantages of steel stoves include the beauty of combustion (especially important for fireplace stoves!), and the best quality of combustion of the wood itself.

The disadvantages include the fact that sooner or later (every few years) the lining will still have to be changed, since it is a consumable material.

See how Acumotte material even withstands a blow from a poker!

Video testing of Acumotte lining in Kratki furnaces and fireboxes

Cast iron firebox

As we wrote earlier, cast iron stoves are produced without lining. The advantages of cast iron stoves include their durability and soft heat. The disadvantages of such stoves include their heavy weight and fragility due to temperature changes (if you splash cold water on a heated stove, the stove may crack).

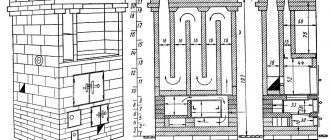

How to properly heat the second floor

Supplying heat to the second floor of a house is a rather difficult task. As an option, you can consider installing a fireplace equipped with additional equipment. The fireplace has a number of advantages. Among them are the following:

- ease of operation;

- small sizes;

- use of almost any fuel.

How to properly heat the second floor

In fairness, it should be noted that most of our people consider it a luxury item, but this design is capable of combining democracy, aesthetic properties, and excellent performance of its main task - heating the room.

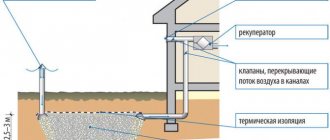

Heat supply to the second floor due to air convection. That is, passing by a heated fireplace wall, the air receives thermal energy and continues to move upward through a special box. Warm air is supplied to rooms located on the second floor through air ducts, which must be covered with thermal insulation. This is necessary to minimize heat losses and ensure fire safety.

Furnace location

Everything is simple here, because... everything determines the place where the stove will be installed.

Wall . Such stoves are installed near the wall. The chimney outlet can be either from above or into the wall.

Angular . Corner stoves are installed in the corner of the room, for which they have an angular shape of 90 degrees.

Central . Stoves with a central location have only an upper chimney outlet. Accordingly, such stoves can be placed anywhere in the room without being tied to any wall. Often such ovens have a round shape.

Fig. 8. Corner stove-fireplace Vesuvius and wall-mounted stove-fireplace Brandenburg

Fire safety rules during installation

Sheets of steel to protect wood from fire

Before installing a stove in your home, you need to protect the walls and floor from possible fire. Particular care is needed when installing metal units. For protection, mastics and impregnating compounds with fire retardants are used, as well as sheets of non-flammable insulating materials installed on the walls, ceiling and floor in places of contact with the stove. Load-bearing elements, beams and all areas close to the unit are treated with chemical compounds. Impregnations are good because they do not stain materials, but mastics have better protective properties.

If the treatment is carried out by homeowners themselves, they must first obtain a certificate from the Ministry of Emergency Situations confirming that the installation of the stove complies with fire safety requirements.

The ceiling is protected from fire by gypsum fiber boards treated with putty for painting. A basalt cardboard covering is installed on the walls, and steel shielding is installed on top. Other options are covering with a thick layer of plaster (more than 3 cm) and lining with brick.

Door type

Pay attention to this factor, because... Ignoring this little thing can ruin a lot. In fact, everything is simple here...

With glass : with fireplace door or with small glass

The fireplace door, as you already understand, is the first sign of fireplace stoves. A small glass is intended only to control the amount of firewood in the firebox without opening the door.

Without glass - just “solid” stoves with a metal or cast iron door.

Making a bath unit

One of the best options for a heating device for a bath is a metal stove made of sheet steel, lined with brick.

Such a homemade sauna stove is not mobile, but it is fireproof, which means it can be installed in a residential building and even in a wooden sauna building. To build it, you will need the following tools:

- welding equipment;

- Bulgarian;

- diodes 3-4 millimeters.

You also need to have sheets of iron 2–3 millimeters thick, and reinforcement 8–10 millimeters.

An important point is that when arranging such a stove, it is necessary to choose the correct cross-section for the chimney, since the draft force depends on this, which is also influenced by weather conditions: the warmer and more humid the air, the weaker it is.

If the chimney is not wide enough, gases and air will begin to mix before they have time to escape. This creates a smoke plug. If the diameter of the pipe is too large, then the gases in it will move too slowly, and the surface of the inner walls will quickly become clogged.

Do-it-yourself iron sauna stoves are built like this:

- First of all, the foundation is laid out. For it, a wooden formwork 20 centimeters high is built so that a square measuring 1x1 meter is formed.

- The reinforcement is mounted in one layer, making a mesh of rods with cells measuring 20x20 centimeters. It is necessary that the reinforcement does not touch the ground, so it is supported on pre-installed pegs and tied in weight.

- Prepare a cement-sand mortar in a ratio of 1:3. For it, take 1 part of cement no lower than grade M400 and 3 parts of fine river sand. To add strength, some crushed stone is added to the mixture.

- The solution is poured into the formwork, covered with polyethylene film and left to dry for 4 weeks. Once a day, the concrete must be sprayed with cold water and covered again, otherwise it will begin to crack.

- Next, you need to take the rear wheel rim and weld all the holes on it, leaving only the central one.

- The convex top is cut off from the second rim, the first one is inserted into it and welded. The main thing is to create a tight connection, because there will be hot liquid inside.

- On the inside of the second rim, at an equal distance from one another, reinforcement is welded on three sides. It needs to rest against the pipe to give the structure rigidity.

- A round 25 mm hole is created at the bottom of the first rim and a pipe of the appropriate cross-section is welded to it. A faucet is screwed into it to drain water.

- Next, exact copies of the two rims are made. A copy of the second of them is placed on the pipe, the copy of the first rim is turned over and welded to the end of the pipe. A second copy of the second rim is attached to the top and reinforced with reinforcement for rigidity.

- When the foundation mortar has hardened, the formwork is removed and bricks are laid using a clay-based mixture.

- The location of the furnace is completely covered with bricks to protect against fire.

- The base is made of brick, and from the second row they begin to lay out an ash pit with a blower. By means of it, ash is removed and thereby ensures the flow of air inside, which helps the appearance of good draft. The length of the ash chamber should be less than that of the firebox.

- Install the blower door, line it with bricks and lay another row. A grate is placed on the ash pit shaft.

- After the grate, two rows of bricks are laid out, leaving space for the firebox door. Two more rows are created on top.

- The masonry is allowed to dry for 2 weeks, ensuring air circulation. Then the stove needs to be heated with wood chips for 1.5 - 2 hours.

- The finished pipe is installed on the brick structure. There is a heater and a container for hot water on it.

- The weight and dimensions of the stove are quite large, so it is better to divide it into its component parts and assemble it inside the bathhouse on site.

- The top of the chimney is reinforced with reinforcement rods, welding one end to the pipe and resting the other against the wall. To attach it to the wall, use a metal plate or a steel angle.

Chimney outlet location

This parameter is determined by the room where the stove will be installed and your wishes.

With top outlet . Stoves in which the pipe is located at the top, respectively, the chimney will go up.

The pipe is a stove element, approximately 5 cm high, on which the chimney is installed.

Please note that with this arrangement, the chimney can be led into the wall, but you will first need to install about 0.5 m of vertical pipe, and then make a 90-degree outlet from it into the wall.

With rear exit . Ovens with a pipe located at the rear. This is a convenient option if you immediately want to move the chimney into the wall.

When is it profitable to burn with wood?

It’s good when there is a gas main within reach of a country house. In this case, the question of choice does not arise for most owners; If wood heating is present, it is for comfort, in the form of a fireplace or a small decorative stove. If there is nothing to connect to and the house is large, the best choice would be a solid or liquid fuel boiler, since electric heating will cost much more and can only be considered as an additional (backup) option.

It’s another matter if the country house is small in area. For a building with two or three rooms and a kitchen, the number of heating methods is greater, but the most common is still the use of wood. In country cottages, wood heating is beneficial in the following cases:

- Seasonality of residence. Heating with wood is especially beneficial if people do not live in the house permanently, but use it for seasonal recreation. Even if there is a gas main nearby, it is not always cost-effective to carry gas.

Wall-mounted method of arranging a modern wood-burning stove for heating a house Source kamine-streubel.de

- Availability of fuel. If there are no problems with the procurement of firewood in the area, heating with wood will be the most economical way for a house of any size.

- Modern design. For a small house, a modern, economical wood-burning stove and well-designed heating will be the best solution.

Presence or absence of a long-burning system

So that you don’t get confused, let’s immediately define this: there are long-burning stoves (we wrote about them above), and there are those with a long-burning function.

Almost every modern stove has a long-burning function. Its principle is that we cover the supply of combustion air to the maximum (we remember from school that the combustion catalyst is oxygen - the less of it, the longer and less intense the combustion). Considering that the task of the stove is to generate heat, all modern stoves are equipped with this function (only “stove stoves” lack it).

Advantages and disadvantages

Using a wood-burning stove for home and garden (the modern version) in many cases has significant advantages:

- Easy to install and operate.

- Efficiency and economy. A high level of efficiency and careful consumption of firewood is ensured by various technological methods, from the shape of the exhaust pipe to the long-term burning mode.

- Quick effect of work. The heat from a working stove spreads quickly, a comfortable temperature is established within half an hour.

- Compactness. This quality is especially valuable in small country houses. Such a heating device can be installed in any room (if there is a chimney).

Do you need a drawing?

Drawings “how to build a stove with your own hands correctly” are not required in this case, especially if a specialist is working. A clear and detailed description allows you to do without them. It is the simplicity of the designs and minimal costs that make it possible to save yourself from complex and lengthy work.

A high-quality and detailed drawing is only necessary if you are building a large stationary stove for heating your home and cooking food. But even in this case, an experienced specialist can do without it.

Multifunctional large oven Source i.ytimg.com

Video description

For a clear overview of laying and applying mortar, watch the video:

- Duplicate row, but the stones are laid flat.

- The brick is on edge, the walls are wiped with a wet rag.

- The brick is laid flat, and on the back side - on the edge.

- Next, the firebox is closed, 2 bricks should hang over the chamber (if the structure is planned to be used as a fireplace and the firebox is not covered), the flame will be directed to the middle of the structure.

- The stones are moved a little to the back side, they will support the door. Before laying the brick, wet strips of asbestos are laid to seal it. The panel cannot be placed on the mortar - cracks will appear due to the difference in thermal expansion.

- A pipe is formed to remove smoke. A smooth expansion is made towards the back. Stone is used for the base; light metal is used for everything else.

- A valve is installed, it is necessarily sealed with asbestos, first coated with a solution. This completes the construction of the structure.

Decorated stove for cooking and heating Source mainavi.ru

At the end, several tiers of the chimney are made, and a pipe is inserted into it. The brick (installed without mortar) and all debris are removed. The joint of the structure near the floor is closed for decoration with metal. The structure will dry completely after 1-2 weeks.

How to build a simpler type of oven if you don’t have the time, necessary materials or skills? Take advantage of the following structure, which can be erected in just a few hours. It has the simplest operating principle.

Fuel is placed below, which burns there, and where it settles. The draft is created by temperature changes. This design is characterized by a minimal amount of smoke and almost complete combustion of fuel. For this option, two half stones and 20 whole bricks are enough. There are five rows in the stove, the stones are tied together with mortar, but you can lay out the stove without using it - it will be a temporary structure.