Options for brick stoves

A brick stove can fit into any interior and become an important part of it. The distribution options are Russian, Swedish and Dutch. There is no need to allocate an impressive space for a Dutch stove; a Russian stove will require a lot of space; a Swedish stove is used mainly for heating a room.

There are several types of stoves. The division is carried out according to the efficiency of wood-burning stoves, the circularity of the firebox, the method of gas movement and purpose.

The main criterion is the purpose.

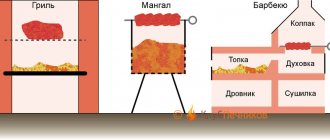

- Heating and cooking stoves are designed to heat space and prepare food. The stove has a heat-generating and cooking surface. The hob must be made of cast iron.

- Heating stoves. From the name it is clear that they are used to heat the space. One stove is enough to heat several rooms; the optimal solution is if the stove is a partition between rooms.

- Cooking ovens. They are used only for cooking, are small in size and are not intended for space heating.

- Universal ovens. Such ovens have a large number of functions. In addition to their intended purpose, they are used for cooking, drying clothes, etc.

Solid fuel stoves

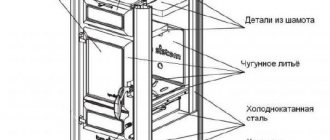

A universal fireplace coupled with a stove can be made from a wide variety of materials, the main requirements for which are strength, long service life, easy maintenance and good tolerance to regular exposure to high temperatures. The most popular and at the same time budget material for making stoves is steel; such designs are characterized by a fairly high efficiency, which can reach 70-85 percent. At the same time, the efficiency of a standard fireplace will not be higher than 50 percent, which does not allow it to fully heat the house, the maximum is one room in which it is located.

We recommend that you further familiarize yourself with all the features and advantages of steel fireplace stoves in this article on our blog.

Fireplace stoves, like simple standard stoves, are often used specifically for heating, since their efficiency is many times higher than that of fireplaces. A feature of simple one-component units is that the combustion compartment of this design is completely closed with a monolithic blind door, which has no glass and is not has an attractive appearance. This option does not create the necessary comfortable and cozy atmosphere in the house, and in order to check the intensity of fuel combustion and the remaining operating time of the stove, it is necessary to open the door.

A modern fireplace stove, unlike traditional bulky brick models with a solid steel or cast iron door, can have not only different sizes, location in the interior of the room, power, functionality, but also the fuel on which such a heating unit can operate.

Also, before you buy a fireplace stove and install it in your private cottage or country house, in your country house, you need to learn more about what types of such heating equipment exist and are offered in the range:

- The main difference between modern fireplace stoves is the presence of a closed firebox, which is equipped with a sealed door, which is based on heat-resistant ceramics or transparent tempered glass. The peculiarities of such heating units include their bulkiness compared to traditional miniature fireplaces. Installation of such equipment would be appropriate if the room has an area of more than 25 square meters;

- Even more bulky and efficient are fireplace stoves, which are equipped not only with a firebox, which is based on high-quality steel or cast iron, but also with a portal or frame, which becomes a kind of battery and a source of additional generation and collection of thermal energy. The frame can be made of brick and lined with stone or tiles, or simply plastered or painted with fire-resistant paint.

Heating of the premises when installing a stove-fireplace of the second variation is carried out due to the fact that the walls of the portal are heated by the firebox, accumulating heat, and begin to slowly and evenly release it into the space of the room.

A stove-fireplace for a summer cottage is also suitable for heating a fairly large two-story cottage, since the basis of such a heating unit is high-quality steel, ceramics, tempered glass and cast iron.

It can also be based on brick, from which fireplace portals are often assembled, and the firebox can be partially lined; combined variations are also very popular, based on steel and cast iron, brick and steel, ceramics and cast iron, etc.

If you want to achieve maximum results and simultaneously heat not only the room with the fireplace stove, but also those adjacent on the floor, we recommend giving preference to heating equipment that has air convection channels. No less effective are combination furnaces with a water jacket or circuit, which are connected to the pipes and heating system of the house, heating the entire house to the same extent.

For small houses and cottages with limited space, the ideal option would be to install a steel or cast iron corner or wall-mounted stove-fireplace, but if the house has a large area, to fully heat it, you will need to install a massive stove with a firebox built into the portal or even several firebox compartments.

Types of wood stoves

- Cast iron wood stove. The advantage of this stove is that it quickly heats the air in the room and retains heat for a long time.

- A metal furnace has the ability to quickly heat the air, but does not have the ability to retain heat for a long time, since the metal has the ability to cool quickly.

- A brick stove is the best option for heating a space, however, it requires large financial investments.

The advantage of the stove is that it can be used both to maintain room temperature and for cooking.

The best long-burning cast iron fireplace stoves

La Nordica Ghisa Isotta Con Cerchi

The Isotta fireplace stove is suitable for constant heating of homes, as well as an occasional addition to central heating .

The double walls of the firebox are completely sealed, serve as protection against burnout and guarantee long-term operation for many years.

The model is equipped with a hob with a lid for cooking . There is a built-in door on the side that will allow you to load long logs (up to 70cm).

The door is made using special glass with the ability to self-clean; it can withstand heating up to 750 degrees. The standard firewood consumption is about 2.5 kg/hour.

There is an option for simplified ignition and a “summer” operating mode.

The efficiency is more than 82%.

Characteristics:

- power - 11 kW;

- location - wall;

- Efficiency - 83%;

- heated volume of the room - 338 m3;

- hob - yes;

- fuel type - firewood;

- glass door - yes;

- dimensions - 79*83*66cm;

- weight - 216 kg.

Advantages:

- the presence of a convenient cooking surface;

- saving firewood;

- European assembly and quality;

- heating a large area.

Flaws:

- high price.

META Marseille 14

The Marseille 14 fireplace stove produces long-lasting combustion, while the glass remains clean and the fuel is used with maximum efficiency .

High degree of reliability. The door is equipped with heat-resistant ceramic glass. It is not recommended to use any derivatives of coal for kindling.

The unit provides fast and uniform heating of the air inside the room; it will become warm within 20 minutes.

In the long-burning mode, it is possible to maintain the temperature for up to 6-8 hours, which is especially convenient during the night.

Modest dimensions help save usable space.

All components and parts are designed and manufactured in France, except for the glass panel - it is made in Japan.

Characteristics:

- power - 14 kW;

- location - wall/corner;

- heated room area - up to 140 m2;

- hob - no;

- fuel type - firewood;

- glass door - yes;

- dimensions - 113*55*44cm;

- weight - 130 kg.

Advantages:

- affordable price;

- efficient heating;

- strict design;

- large glass door.

Flaws:

- prefabricated body.

META Moscow 12

The model is of the wall-corner type and is complemented by panoramic glazing on the door . Externally, the stove is very similar to a classic fireplace, which has no external decoration.

Not only the front part of the door, but also the side ends are finished with heat-resistant glass. The chimney connection is universal, implying 2 options.

The unused pipe is closed with a secure plug.

The beveled rear walls allow the fireplace to be installed both along the wall and in the corner of the room. The lining is made of modern materials that are resistant to high heat - slabs of fireclay and vermiculite.

High quality steel and imported components are used for production . The high-speed heating mode is due to the presence of convection.

Characteristics:

- power - 12 kW;

- location - wall/corner;

- heated room area - up to 120m2;

- hob - no;

- fuel type - firewood;

- glass door - yes;

- dimensions - 120*88*55.5cm;

- weight - 165 kg.

Advantages:

- heating rate;

- heat transfer;

- external design.

Flaws:

- high fuel consumption;

- Soot forms on the glass.

MBS Thermo Vesta plus

This model is an economical and efficient option for a stove-fireplace for heating a home . The color palette is varied, with a choice of red and cream shades for the body finish.

Place of production - Serbia, which means European quality.

The efficiency is about 80% with relatively low wood consumption. The firebox lining is made of fireclay brick, which retains heat for a long time.

This implies the location of the stove in the corner of the room.

Characteristics:

- power - 11 kW;

- location - wall/corner;

- heated room area - up to 80m2;

- hob - no;

- fuel type - firewood;

- glass door - yes;

- dimensions - 89*45.5*44cm;

- weight - 85 kg.

Advantages:

- high quality materials;

- neat assembly;

- efficiency;

- elegant and discreet design.

Flaws:

- No.

Flamen TENA

The Tena fireplace stove is a classic model of the Plamen brand . Its development was made more than 30 years ago, but it still remains one of the best-selling in the line, since the quality has stood the test of time.

Plamen Tena is a successful competitor to more expensive and modern stoves, and its distinctive design still looks fresh and relevant today.

A fireplace is a decoration for any home, even if there is no fire in it . Despite its affordable price, it will easily become part of any sophisticated interior.

It does not require a special foundation; it can be installed on a sheet of steel or a slab of refractory material. The air supply is carried out exclusively from above, which repeats the structure of the Russian stove.

We can quickly warm up the room using a convection casing . Due to the temperature difference, it “sucks in” cooler air from below, and releases it already heated from above.

Characteristics:

- power - 11 kW;

- location - wall;

- heated room area - up to 80m2;

- hob - no;

- fuel type - firewood;

- glass door - yes;

- dimensions - 75*52*75cm;

- weight - 165 kg.

Advantages:

- nice classic design;

- decent build quality;

- thick metal;

- affordable price;

- economical combustion mode.

Flaws:

- No.

Advantages and disadvantages of brick kilns

Wood-burning home stoves have many advantages:

- High heat accumulation.

- Maintains temperature for a long time.

- Relatively low cost.

- Safety during use, since the outside of the oven hardly warms up.

Disadvantages of such ovens:

- They take up a lot of space.

- It will take a long time to warm up completely.

Best Countertop Mini Convection Ovens

Convection allows you to cook juicy and soft dishes with a crispy crust, so this option is very much appreciated by modern housewives. In a mini-oven with this function, you can easily prepare bread, meat and fish dishes and desserts. In this category, we present four tabletop electric mini convection ovens that have received the most positive reviews.

Oberhof Mofen L24

A stylish, functional mini-oven that can replace three kitchen appliances at once - oven, grill and dehydrator. It is suitable for drying vegetables, fruits, herbs, and preparing various dishes, including bread.

Let's go through the functionality of the device. Cooking is carried out in convection mode. The temperature range is from 60 to 250°C. You can choose one of 10 automatic cooking programs, 4 modes - “Oven”, “Dehydrator”, “Turbo”, “Aerogrill”. Uniform heating is ensured by 2 heating elements.

The case is made of stainless steel. It does not heat up during operation. The capacity is impressive - 24 liters. The maximum power is 1800 W. Control is carried out using an LCD display. Mixer timer for 99 minutes.

Compact model, 45x38x29 cm, weight 8.6 kg. For your convenience, the manufacturer includes everything you need - a frying basket, several baking sheets, a frying pan, and a removable crumb tray. The interior compartment is illuminated.

Advantages

- Good capacity;

- Many programs and operating modes;

- Accessories.

- Convenient control system;

- Durable design;

- Multifunctionality;

Flaws

- Weight.

- Length of cable;

All components are made of stainless steel and are dishwasher safe. With this device you can cook food without adding oil. Heating occurs quickly. Russified control system.

Kitfort KT-1703

This stove is suitable for a country house, small kitchen or bedroom. Kitfort is equipped with two powerful burners, so the appliance can be used as an electric stove, preparing many dishes at the same time. The oven is equipped with a light so you can monitor the cooking process, and action indicators let you know when your dish is ready. There are also four modes: grill, bake, convection and defrost. The internal compartment has a volume of 30 liters, the device heats up to 230 degrees and is equipped with a thermostat to maintain a constant temperature.

Preparing for furnace installation

At the first stage, you need to select high-quality materials for building the stove. Ceramic, silicate, and refractory bricks are suitable here.

Fireproof materials are the optimal solution, but it is more often used for exterior decoration.

The next step is to prepare the solution. You will need clay for the solution. It must be remembered that red clay is required for red colored bricks, and appropriate clay for fireclay bricks. The best solution is to purchase a special mixture.

- When installing the stove, it is necessary to take into account that it is not advisable to place it next to an external wall.

- A stove located in the middle of the room will divide the room into zones.

- The stove located between the rooms will serve as a partition.

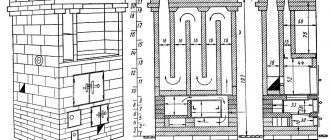

Using drawings

In order to avoid significant mistakes when installing a long-burning wood stove, it is necessary to use drawings.

It is not advisable for beginners to draw up drawings on their own, as this can lead to irreversible consequences.

- There are several types of masonry, but the main stages are repeated almost everywhere.

- It is recommended for both beginners and experienced layers to first lay out the layout without mortar in order to accurately follow the diagram and take into account all the nuances.

- This is necessary for proper installation of the chimney, and, therefore, for proper draft.

Laying the foundation

Before installing a wood-burning stove-fireplace, you need to take care of laying out the foundation. There are cases when there is no need to install a foundation and install the stove directly on the ceiling, but in this case, it is necessary to take into account the load on the ceiling.

For the foundation can be used:

- Solid brick.

- Reinforced concrete slab.

- Solid concrete.

It is extremely undesirable to lay on sand-lime brick, as it is destroyed in a damp environment.

How deep the foundation will be laid depends on the natural qualities of the soil. It is advisable to lay it below freezing point. A cushion of sand and gravel is laid under the foundation.

Principles of laying bricks

All voids must be filled with mortar: horizontal joints - no more than 5 mm in width, vertical joints - no more than 3 mm in width. The laying must be carried out strictly according to the scheme and pre-selected without mortar. The door is fixed with steel wire.

Steel parts have different abilities to conduct heat, so they need to be laid at a distance that is filled with asbestos. A solution of clay and sand is prepared in advance in proportions of 1 to 1.5.

When choosing bricks, it is especially important to pay attention to its quality. It is not recommended to use insufficiently fired bricks or materials with cracks. This rule applies to the installation of any stove, be it a wood-burning stove for a summer cottage or a stove for a home.

Main selection criteria

The stove must be powerful to heat the air in remote rooms to the required temperature. It is better to choose universal models. The heating stove-stove is simple, affordable, and runs on any fuel. For bath structures, the problem remained in the huge overall dimensions. The combustion process is not controlled or automated. There are always combustion products.

When heating at the same time, the location of the furnace plays a big role. The firebox, in which fuel is loaded and ash and coals are removed, is located in the accessible part of the dressing room. The other part goes into the greenhouse, the washing compartment. Maximum heating necessarily occurs in the greenhouse portion. The temperature of this part is higher than all other places. The location of the water supply depends on the design of the bathhouse. The heated water disperses throughout the bathhouse and goes into other rooms to warm the walls and air.

The following can be used as an energy source:

- wood;

- solid fuel;

- gaseous fuel;

- electricity.

note.

The most environmentally friendly fuel is firewood. It is expensive to burn with wood alone; it is combined with coal.

Purchase, installation, installation of electrical equipment is more expensive. During operation, it does not form combustion products, takes up less space, and is controllable.

A simple option for laying out the oven

This option is suitable for beginners. The size of such a furnace will not exceed 0.5 m2.

- There is no need to lay a foundation for it - you will need a strong board.

- It must be isolated from water with a special solution.

- A layer of sand is applied to the board, after which you can begin laying.

- The first row is laid, then the asbestos cord is wrapped and the door is installed.

- To lay out the third row, fireclay bricks are needed. Then the ash pan and grille are installed.

At the final stage, the chimney is laid by laying bricks on an edge and installing a pipe.

Read more about the benefits

Metal is much softer than ceramics, but is comparable in strength. It can be melted, cut and bent, forged and drilled, after which it does not require additional energy expenditure for firing. There are many ways to process metal with a broad scientific basis, and this is another plus in favor of the material.

When creating a metal furnace, you can use various design innovations that improve technical characteristics. As a result, the efficiency of a brick kiln is on average 70%, and metal kilns have an indicator of 85-90%.

Comparison

Again, if we compare metal and ceramics, the strength of brick decreases with decreasing thickness, while that of metal, on the contrary, increases. As a result, the weight and cost of heat of metal furnaces is 10-20 times less than that of equipment made of bricks. On the modern market, good heating equipment made of metal for a house of 100 m2 can be purchased for $300, and second-hand equipment can be purchased for $50-100.

In addition, it is a one-piece design - it is easy to transport, resistant to shocks, impacts, and falls. Its mobility is combined with the absence of the need to build a foundation. The entire installation boils down to installing the chimney into the smoke channel. If the stove is no longer needed, it can be easily dismantled and stored.

Another plus is the high thermal conductivity of the metal. Because of this, the heat capacity of the stove is small, and the house heats up quickly. This factor gives high efficiency.

For example, in a brick structure, almost 20% of the heat goes into the chimney during the combustion process until the heat exchange in the furnace is leveled out and it does not release energy.

Household use and certification

Also, the metal product is more homogeneous than brickwork and does not have a porous structure. It is not afraid of dampness and heating breaks, it does not need accelerating heating. It is easier to integrate a hob and water heating equipment into this design due to the high thermal conductivity of the metal and the rapid combustion of flue gases.

If a metal stove is produced at a factory, then it can be certified in terms of fire safety as a completely ready-to-use product. Permission from the fire inspection is much easier to obtain than for another furnace building. Some models of factory-made metal stoves do not require paperwork at all - you only need a chimney separate from the ventilation.

Drying the oven

It may take from 3 to 8 days to dry the oven. To dry, you need to heat the oven for a short period of time. All doors must be open during drying.

After a few days, when the stove turns grayish-brown and the seams have dried, you can move on to a more intense fire.

Cleaning and restoration

If used frequently, the oven will need to be cleaned approximately once a month because the oven will gradually fill with ash.

If smoke breaks into the room, you need to find all the places where the seams are of poor quality and seal them with cement and liquid glass. Although most often a stove made by a professional has a long service life.

How to choose metal for the stove

Technical characteristics depend on the material from which the stove will be made. Therefore, you need to pay special attention to this nuance. Most often, craftsmen make a device from what is already in the utility room or barn.

However, this is not an entirely correct approach; the following options must be taken into account:

- Structural steel - can withstand temperatures up to 400 degrees, it is better to choose sheets of at least 4 mm. It won’t be possible to use it often, as it can easily burn out in one winter. If it is used for a bathhouse that is heated once a week, it will last a long time.

- Heat-resistant steel - this option can withstand 30 years of operation. The thickness should be at least 1 cm. Many stores sell a ready-made structure that only needs to be assembled; no welding is required, which is very convenient and profitable.

- Cast iron takes a long time to heat up, but retains heat well and heats the room. They have a long service life; such stoves can provide heat every winter for 30-40 years. The material is quite expensive, but fully justifies itself. Self-production is a rather complicated process. Such a device is often used to heat greenhouses and outbuildings. It is advisable to choose thick material, since sheets up to 1 cm will crack at the first temperature change.

Based on these recommendations, you can choose a good material for making a metal stove with your own hands.