Residents of private houses do not always connect gas heating. Therefore, an alternative is to install a brick stove for a wood-burning cottage. Some homeowners install the equipment as additional heating equipment. There are several types of brick stoves for heating different rooms and areas.

A Russian stove will not only heat the house, but with its help you can prepare a delicious lunch and bake a loaf Source zen.yandex.ru

Advantages of stove heating

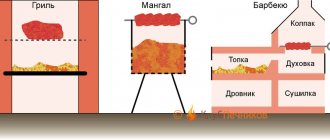

Wood burning stoves heat up quickly and distribute heat over a long period of time. The brick emits radiant energy, which is good for health. A house where a stove is installed is always comfortable and warm. Thanks to draft, natural ventilation is created in the room. The designs often have a hob on which food can be prepared. In addition, such a stove can be used to dry clothes, shoes and food.

A combination oven is a device that has several functions. This includes a fireplace stove, a heating and cooking stove and a Russian stove.

The only significant drawback is poor heating of remote rooms. That is why they try to install the entire structure in the center of the house for uniform heat transfer. In large houses, it is advisable to install several stoves that have a combined chimney. The hob is usually installed towards the kitchen.

Heating equipment differs in appearance and design.

Usually the stove is installed between several adjacent rooms so that they all heat up evenly Source pechnoy.guru

Dutch oven

The design is one of the most popular. Some models are equipped with a hob and oven, which solves the problem of cooking, but the classic “Dutch” is used only for heating.

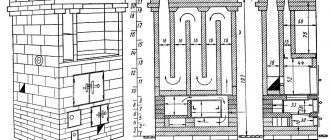

The duct-type firebox heats the walls perfectly. The smoke is discharged through a vertical channel, in which almost all of it burns. Although brick stoves for wood-burning homes are usually large in size, the same cannot be said about the Dutch stove, so it is optimally suited for comfortable heating of a private house - one or two floors. Outwardly, the Dutch woman resembles a column. The shape of the structure can be round, square or rectangular.

Advantages of a Dutch woman:

- After long breaks, you can start firing the stove at full power.

- A small structure can heat a house of 70 square meters. m.

- Economical. Low material consumption. The installation price is lower, as well as saving space.

- The design has thin walls, so it warms up quickly.

Classic “Dutch” stoves take up less space, but they are used only for heating the house Source ar.decoratex.biz

Disadvantages:

- The efficiency is no more than 40%.

- You should not forget about cleaning the stove from ash, as well as soot for normal draft.

- The most effective mode is smoldering. This design is often called a long-burning furnace.

- After heating, you need to close the view, otherwise the stove will quickly cool down.

This equipment can be used to heat small houses that have 2 floors or an attic floor.

Russian stove

It is large in size and multifunctional, and also has smoke channels and an open firebox. It is sometimes closed with a flap. The equipment may have a hob.

In addition to heating the room, this design allows you to cook food and dry clothes.

The efficiency is maximum 60%. In winter, the stove must not be allowed to cool down, so it should be fired regularly. If the structure cools down, condensation may occur. The brick becomes saturated with moisture, and upon subsequent cooling it freezes and cracks.

In summer, you can use the oven in summer mode for cooking. In this case, the smoke is directed directly into the chimney using a damper, and the body of the structure does not heat up.

Modern Russian stove with a stove bench in a wooden house Source yandex.ru

Advantages:

- With timely heating, a comfortable microclimate and temperature are created in the house.

- Multifunctional design.

- A brick stove for a summer house decorates the room.

Flaws:

- High installation cost due to the large volume of bricks.

- Due to the large weight and size, it is necessary to build a solid foundation.

- Low efficiency.

- The ducts and chimney must be cleaned regularly.

Such equipment is suitable for year-round use.

See also: Contacts of construction companies that offer installation services for fireplaces and stoves.

Swedish oven

The stove has a universal design and is designed primarily for efficient operation in small areas. The standard “Swedish” is equipped with an oven, hob, and niches for drying things. Some Swedes have a couch and a fireplace.

The principle of operation of a Swedish stove is approximately the same as that of a bell-type stove - combustion of flue gases occurs under the arch of the firebox.

Design advantages:

- The room heats up very quickly.

- Possibility of cooking both on the hob and in the oven.

- Almost complete combustion of fuel.

- Thanks to the design of the channels, the lower part of the equipment is heated, and, consequently, the floors are slightly heated.

- A heat exchanger can be installed in the design to heat water.

The Swedish brick stove has its own characteristics, but it copes well with heating the house Source mauro-gianvanni.ru

Cons:

- To prevent heat loss through the floor, it is necessary to install high-quality thermal insulation.

- For the installation of heated elements, fireclay bricks are used, which have a higher cost.

- Experts recommend leaving the stove always warm in winter. Firing a cold stove can lead to deterioration of the masonry.

Bell furnace

One of the modern designs is such a stove. The equipment heats up well and retains heat for a long time. The design does not have small winding channels, therefore, they are not so susceptible to soot settling.

The principle of operation of a bell-type furnace: smoke rises from the firebox, then remains there until it cools. And then it begins to descend along the walls of the chimney, thus heating it. Such designs are effective because they can have several caps.

Advantages:

- Low cost of material and installation. Simplicity of design.

- You can install a heat exchanger and a hob.

- Heats up quickly even after completely cooling.

- The gas view prevents reverse draft. This is why the oven cannot cool down when the damper is open.

Modern hand-made stoves provide the ability to heat several rooms in the house at once Source mauro-gianvanni.ru

Such a stove can have several hoods, and, therefore, it will be possible to heat 2 floors and several rooms. It is difficult to identify any shortcomings, which is why the bell-type model is popular among homeowners.

Is it possible to build long-burning brick stoves?

Every homeowner wants to install heating that does not require much labor. Arranging this in a long-burning wood-burning home stove made of brick is quite problematic. Industrial furnaces made of metal that operate on this principle produce carbon monoxide. A long burning mode can be arranged in a Russian or Dutch oven. But this method is not 100% effective. Therefore, it is recommended to install a standard brick stove, which retains heat for a long time.

Conclusions and useful video on the topic

Video #1. A video to help independent stove makers, the material presents a visual arrangement of a heating stove:

Video #2. A detailed guide to the construction of a heating and cooking unit according to ready-made procedures, but with some changes from the contractor:

When choosing a design for your own construction of a stove for a summer residence, you need to take into account your own capabilities and skills. It is possible that someone will consider the options we have proposed to be too complex or simple. In any case, the information presented will help you get an idea of the stove structures in order to use it yourself or monitor the actions of hired stove workers.

If you had to build a brick stove for your dacha yourself, please share photos of your own designs. Perhaps you know some subtleties that we did not take into account in our article? Tell our readers about them - leave comments in the block below.

Basic masonry techniques

In production, heat-resistant and fire-resistant materials for the firebox, as well as hardened bricks, are used. It is not recommended to build a stove yourself. It is necessary to contact specialists for high-quality and safe masonry.

Specialists carry out work in compliance with all safety standards and regulations. For laying bricks, cement mortar is used, which is diluted with sand in a ratio of 1 to 3.

For binding material, many craftsmen use clay and sand.

Each row of bricks is laid out in a certain way to form a stove for a given project. Source pechki.net.ru

Selection of bricks, sand, mortar

In order for the stove to serve for a long time, you need to select all the materials correctly. There are three types of bricks:

Advice: when choosing a brick for a stove, you need to completely abandon the hollow types.

The solution is made from clay. Red clay is suitable if the stove is made of red brick; when using fireclay, special fireclay clay is required. Some stove makers still make their own mortar in the old fashioned way from river sand with a grain size of 1–1.5 mm, clay (in a ratio of 2.5:1) and water. It is advisable to use angular quarry sand without foreign inclusions and the so-called fatty clay. However, it is easier and more reliable to buy a ready-made baking mixture in the store, preparing it according to the instructions.

From the accessories you need to purchase grates, blower and combustion doors, soot cleaners, valves or dampers.

What you need to purchase to build a stove

First you need to purchase masonry mortar and bricks. The amount of material will be calculated by a specialist. Do not forget about constructing a separate foundation for installing the furnace. The equipment will require cast iron elements: a door for the firebox, a blower (ash pan door), rings for the burner, a chimney valve, a grate and a hob.

In addition, it is necessary to purchase steel elements: a hot water tank and an oven. When building a structure, you will need strips made of metal of different widths and lengths. A corner made of metal of standard size 0.5 x 0.5 cm. Annealed steel wire with a diameter of 0.2 - 0.3 cm. A sheet of steel must be placed before the firebox.

Some designs may require roofing iron to cover the cooking chamber.

The required amount of material is calculated by a specialist based on the size and type of oven.

Long-burning wood-burning brick stoves for homes are built from fireclay and red bricks, clay and sand. To build the foundation you will need sand and cement, crushed stone, roofing felt, as well as boards for formwork.

Doors and gratings (grids) are mounted along the masonry of the main structure Source extracraft.ru

Choosing the right material

In order for the stove to generate heat more efficiently, not smoke and not be a fire hazard, you need to carefully study the information about the brick and choose it correctly.

First, let's figure out what kind of bricks are stoves made of? In the kiln business, high-quality durable ceramic and fireclay bricks are used. The better it is, the longer the stove will last you. The bricks must not have chips or cracks and must be the same size.

The sound of a hammer hitting such a brick should be loud. On the contrary, unburnt, low-quality material will “sound” dull. The “correct” brick is always pink. The overburned one will be purple, and the unburned one will have a red-orange hue.

Typically, fireclay (fireproof) brick is used to lay a firebox. Ceramic - for laying the entire stove. Beginners often have a question: “Is it possible to lay the entire stove out of fireclay bricks?”

There is no particular need for this, since:

- the refractory brick gets very hot, which makes touching the stove dangerous;

- it costs more.

Brick pyrolysis stove

Such heating equipment can be classified as long-burning. Solid fuel burns without oxygen. With the help of wood, volatile gases are saturated, and then burned at a temperature of more than 450 ° C, and they are mixed with the remaining air in the 2nd chamber.

This design has a high efficiency, which can reach up to 95%.

You can install the equipment in a country house, garage or small country house. The pyrolysis furnace consumes little fuel at maximum operation. All solid material burns almost completely. Soot practically does not settle, since coals and gas are burned.

All pyrolysis models work on this principle, but different designs differ in characteristics and appearance.

A pyrolysis oven may not be very different from classic brick ovens Source stop-othod.ru

Preparatory work and selection of installation location

Construction processes for the construction of a brick kiln indoors or on the territory of a summer cottage begin long before the actual laying. At the preparatory stage, it is necessary to perform a number of important actions that will have a positive impact on the functionality and durability of the heat source in the country. These important points include:

- Preparing clay for masonry . You can purchase a ready-made mixture, but if you can find a suitable type of clay in your region, then it must be prepared accordingly:

- 24 hours before the start of laying, it must be soaked in the form;

- a day later, using a drill with a “mixer” attachment, mix the clay with the addition of sand. It is necessary to achieve the consistency of liquid sour cream;

- sift dry sand through a sieve;

- strain the liquid clay through a sieve into a container;

- adding sand to the container with clay, mix the mixture with a mixer. When thickening occurs in the container, add water. You need to achieve such a consistency that the solution slowly spreads on the trowel.

- Preparing bricks. Before starting work, it is necessary to carefully inspect and sort the material. Bricks without cracks or chips will be used for fireboxes. Damaged material is also sorted. These fragments and debris are useful for making halves, three-quarters and quarters.

- Checking and preparing floors . The flooring should be dismantled down to the concrete slab or to the ground. In the second case, it is necessary to compact the soil and lay a thick layer of paper, roofing felt or polyethylene on top. These layers will create waterproofing of the structure.

- Organization of work during the construction process.

- when masonry is being carried out, the stove must remain accessible to each side of the building. For convenience, all building material must be placed no closer than 60 cm to the walls of the furnace.

- the entire structure must first be built without the use of cement and clay, that is, dry brickwork must be made. This will help you accurately select the required quantity and quality of building material.

How does a brick wood stove work?

Brick stoves collect heat and gradually distribute heat throughout the room. A small house is heated from 15 to 24 hours. Smoke escapes through the chimney due to natural draft. The room in which heating equipment is installed should be regularly ventilated. The valve on the main pipe closes to stop the draft.

It is optimal to use dry firewood for the firebox. It is necessary to clean the ash in the receiving compartment. There are usually no problems when using the equipment.

It is not recommended to use various household waste or building materials that are harmful to health as fuel.

Brick structures have some disadvantages:

- Cleaning the chimney about 2 times a year;

- You need to add firewood manually;

It is necessary to build a furnace only from high-quality materials that meet all standards. Otherwise, the equipment may not heat the room well or the smell of smoke may appear in the house.

If the stove is being built from 450 bricks or more, then it is necessary to build a foundation. Heating equipment can be installed on the base of the house if it is made in the form of a whole slab. A separate foundation is arranged without reference to the base.

Basically, the foundation for a brick kiln is made according to a standard scheme Source nastroike.com

According to the house plan, a place is selected for installing the heating structure during the construction of the house. In a house that is already in use, the arrangement of the equipment is designed so that the chimney is located between the floor beams. It should be at a distance of 1 meter from the rafters.

The chimney pipe must be at least 0.5 m higher than the roof. The closer the pipe is to the ridge, the higher it should be.

Chimney pipe

Installing a chimney can be very simple. For this type of stove, a metal pipe with a diameter of 11.5 cm is suitable. It is also worth considering an asbestos cement pipe; this type is most applicable. The height of the chimney itself above the roof is 50 cm.