How nice it is to have a small house outside the city where you can come in spring, summer or even winter. Unfortunately, very often a dacha does not have a full-fledged heating system, this forces the owner to rack his brains over the eternal question - what to do to keep it warm and economical? Indispensable cast iron stoves come to the rescue.

The advantages of such a heating device are very difficult to ignore.

First of all, it's the material. Cast iron is very durable and has a very long service life. It’s not for nothing that many housewives prefer cast iron frying pans. Even at very high temperatures, it holds its shape perfectly and does not float.

- 1 Main types of country stoves made of cast iron

- 2 Average prices and model range - overview of manufacturers

Cast iron stoves for summer cottages are very economical - their efficiency reaches 85%.

Due to its high thermal conductivity, the room warms up very quickly; even after it fades, it still gives off heat for a long time. Thanks to casting technology, the walls of the furnace are very thick, protected from burnout, wear-resistant and not subject to temporary deformation. It is very convenient due to its compactness and mobility. Just by connecting it to the chimney it is ready for use. Installing a cast iron stove does not take much time and does not require special skills. For its full functioning, a foundation and additional cladding are not required—installation on any fire-resistant surface is sufficient. A variety of shapes, designs and models allows you to make an acceptable choice in terms of price and quality. It is possible to install a stove with a horizontal heating surface, then it can also serve as a stove. More modern models have the ability to operate in a slow burning mode, which allows you to maintain heat even while you sleep. Cast iron heating devices are the optimal means of heating in terms of pricing policy.

I would like to note another undeniable advantage - the short heating time; within 15 minutes after laying firewood, the temperature in the room rises by a couple of degrees.

Like any product, it also has some disadvantages. The room where the stove is installed should not be humid, as cast iron is subject to corrosion. To install a stove, you must have a fairly high chimney; the draft and, accordingly, the combustion process depend on its height. Cast iron is sensitive to strong cooling. If very cold water is poured onto the stove, deep cracks may appear.

There are certain technical characteristics that you should pay attention to when choosing a cast iron stove for your summer cottage:

- The power of the stove and its dimensions. One of the most important indicators, since the proportion between the size of the room and the power of the stove must be strictly observed. It is not difficult to calculate this indicator - 1 kW is enough to heat 1 square meter;

- Efficiency and economy. The efficiency of a cast iron stove must be at least 60%, otherwise excessive fuel consumption will occur;

- The type of fuel that will be used in a particular model. What is preferable: firewood, peat or coal;

- Pipe diameter. Another important indicator. The pipe must be wide enough. It is necessary to start from the calculation of 1 kW of power per 8 sq. cm pipe section;

- The thickness of the furnace wall, its solidity. The walls must be thick enough (at least 5 mm), since a housing with thinner walls can quickly crumble under sudden temperature changes;

- If the stove has glass decorative elements, then the fireproof glass must be at least 3 mm thick.

At the moment, there are three main types of cast iron stoves for summer cottages.

Application

Cast iron sauna stoves are very popular, but they cost a little more than classic, simple sauna stoves.

The peculiarity of cast iron is that it has increased resistance to corrosion and high temperatures, which is why many people choose this material.

- However, when arranging a bathhouse with a cast-iron stove, in any case, it is necessary to comply with all fire safety measures.

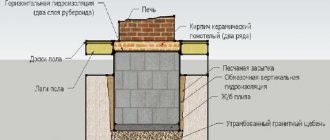

- First of all, you need to take care of insulating wall and floor coverings from hot cast iron.

- For this purpose, brickwork is laid out, on which the stove is located.

The pipe that runs through the roof is also insulated. It is wrapped with insulating material, which prevents high temperatures from affecting the roof finish.

Brick heating panel.

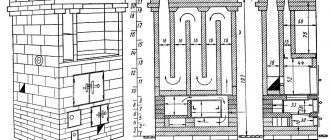

The scheme is as follows. As you can see in the figure, smoke valves are made in the upper part of the shield. The second valve is responsible for the summer flow of gases. The third is the winter mode (it is open, and the gases go into the smoke circuits of the shield, the second valve is closed). While the gases pass through the channels, they cool, giving up part of their heat to the shield, and in a cooled state they go into the pipe. .

The dimensions of our thick-walled heating panel are 89 x 38 x 224 cm. Weight - 1.2 tons. Heat transfer: one good firebox - 430 kcal/h; two fireboxes respectively - 600 kcal/h. As a rule, the panels are plastered or laid directly from beautiful refractory bricks. Three smoke dampers make it possible to regulate the movement of gases. The operating modes are as follows.

Shield operating modes.

- In winter, the winter valve is closed, the first and second valves are open. Going along all the passages of the shield, the gases lose their heat, giving off their heat to the shield.

- In summer, valves 1 and 3 are open, the second is closed. Gases, bypassing the chimney of the shield, go directly through the pipe. For better ventilation of the room, a special channel is installed in the mounted pipe. It opens with a grille having louvers (valves). Their presence allows the ventilation system to be operated in 3 modes: open, half open and closed. Next we will see the laying of the heating shield.

Material for laying the heating shield:

- refractory brick - 400 pcs.;

- river sand - three to four bags;

- clay mixture - three bags;

- roofing felt for waterproofing - 1-2 m.

- cast iron valves 13 x 13 cm -3 pcs.;

- ventilation draught with valve (15-20 cm);

- cast iron doors 14 x 13 cm - 3 pcs.

When laying the foundation under the shield, it is not brought up to the level of the finished floor by two rows in height. One row of brick is placed on top of the foundation, waterproofing is laid over it, after which the shape of the stove is marked out. Next, the second row is laid, with its upper surface reaching the level of the finished floor. After this, you can start laying out the shield.

- 1st row - made of solid brick.

- 2nd and 3rd rows - according to the picture.

- 4th row - during the laying process, a window is left for entry to the furnace panel and 2 cleanings are installed.

- The 5th row is similar to the fourth, the ligation of the seams is exactly as in Fig.

- 7th row and next. odd, up to the 25th - according to the figure with the formation of three channels.

- 8th row and next. even numbers up to and including the 26th - according to the order in the picture.

- Rows 10, 11, 17, 23 and 24 are similar to the previous ones. However, for the purpose of better reliability, ligation of sutures occurs differently.

The 18th row is placed similarly to the 10th and 24th. A valve is installed in the channel on the right wall. The 21st and 22nd rows are placed with the installation of a samovar. 27th row - during the laying process, the two left channels converge into one and overlap. samovar. 28th row - a cast iron valve is installed during the laying process. 29th row - according to the order

Pay attention to the dressing. 30th row - during masonry, a valve is placed on the right side of the shield, on the left it is crossed

channel. In the 31st and 32nd rows we bandage the seams differently

The top of the shield will be covered in three rows. This can be seen in the figure. This scheme is completely made according to fire safety requirements. 33, 34 and 35th rows - according to Fig. 36th row - during masonry we make a ventilation and smoke passage

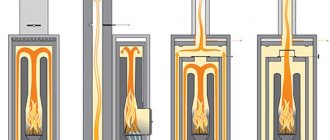

In kitchen wood stoves, most of the heat energy literally goes up the chimney, and only a small amount of heat is used to heat the stove. To trap hot gases and use them to heat your home, you need a heating panel - a brick wall with smoke circulation channels inside. A heating and cooking stove with a shield is ideal for a summer house and summer kitchen - it does not take up much space, effectively heats the room and can operate in winter and summer modes.

Types of cast iron stoves

Cast iron stoves for home and bathhouses have several varieties, each of which is recommended to be used exclusively in the conditions for which it is intended.

Classic heating stove

Can be either small or large. It is a classic cast iron design, ideal for heating small and medium-sized private houses and individual premises.

Cast iron stove-fireplace

Its peculiarity is that it can be used for its intended purpose as a stove, and can also be used as a fireplace. Typically, they have a partially open, safety design with thermally tempered glass inserts.

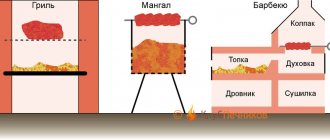

Cooking and heating systems

They are used exclusively for space heating and cooking. For this purpose, they can have several compartments on their surface on which dishes can be conveniently placed.

Long-term heating ovens

This variety is the least common, its task is to retain heat for as long as possible. As a rule, such models are recommended to be installed in houses located in the northern, Siberian regions, where winter is the coldest and most severe.

The best models for a summer residence

The rating is based on customer reviews.

"Vesuvius PC-01" (270)

Country of origin: Russia. The model is designed for heating country houses and cottages with a room volume of up to 150 cubic meters. m. The design is equipped with a hob and runs on wood. The average heating duration is 5 hours. "Vesuvius PC-01" has an attractive design. Its body is decorated with ceramic inserts, and the firebox door has a glass design.

The fireplace stove kit includes a heat exchanger, which is designed to be connected to the heating system of the house. The hob is made of cast iron.

The convection type unit supports two combustion modes: intense and long. The case has several color options. The design is adapted to connect an electric fan, which ensures quick heating.

Characteristics:

- chimney connection type – top;

- dimensions – 821x438x115 mm;

- weight – 141 kg;

- chimney cross-section diameter – 115 mm;

- Efficiency -82%.

Advantages:

- the design has a combined version - steel-cast iron;

- long service life;

- the presence of a hob and a heating boiler;

- Possibility of connection to the heating circuit.

Main disadvantage:

- In intensive mode, fuel quickly burns out.

"Guca Lava"

Country of origin: Serbia. The model is made of cast iron and is intended for heating rooms with a volume of up to 250 cubic meters. m. The attractive design of the unit allows it to be installed in rooms with different interiors. "Guca Lava" is equipped

hob and can be connected to the heating system.

A special feature of this model is the “clean glass” system. The firebox doors of the structure are never covered with soot. The duration of space heating by the unit is 8-10 hours. “Guca Lava” runs on wood and fuel briquettes. The model has a secondary afterburning function.

Characteristics:

- chimney connection type – top;

- dimensions – 540Х493Х946 mm;

- weight – 155 kg;

- chimney cross-section diameter – 120 mm;

- Efficiency -78.1%.

Advantages:

- attractive design;

- rapid heating of rooms;

- spacious ash pit.

Flaws:

- there is no compartment for firewood;

- uncomfortable handles on the firebox door.

La Nordica Ghisa Isotta Con Cerchi

Country of origin: Italy. The cast iron construction has a stylish design. The model is designed for heating rooms with a volume of up to 340 cubic meters. m. The unit has a spacious firebox with double walls that protect it from burning out.

Firewood up to 70 cm long is placed in it.

The model is equipped with a comfortable and spacious hob. The firebox door is made of self-cleaning thermally tempered glass. There is a wood-burning stove-fireplace. They have a well-designed side loading. In an hour, approximately 2.5 kg of dry firewood burns in the stove.

Characteristics:

- chimney connection type – top;

- dimensions – 790Х830Х660 mm;

- weight – 260 kg;

- chimney cross-section diameter – 150 mm;

- Efficiency - 82%.

Advantages:

- availability of primary and secondary gas afterburning systems;

- long service life of grate bars;

- the presence of a convenient handle for safe cleaning;

- comfortable hob;

- volumetric firebox.

Main disadvantage:

- heavy weight.

Kratki Koza K6

Country of origin: Poland. Budget model with stylish design. Designed for heating rooms with a volume of up to 140 cubic meters. m. The unit runs on wood and fuel briquettes. The maximum length of firewood that can fit in the firebox is 35 cm. The firebox door is equipped with comfortable handles.

The model has primary and secondary afterburning. The air supply for simple afterburning is carried out through the firewood grates. For the second afterburning, oxygen is supplied to the upper part of the furnace. This method of burning fuel provides good savings on firewood.

Characteristics:

- chimney connection type – top and rear;

- dimensions – 630x578x490 mm;

- weight – 118 kg;

- chimney cross-section diameter – 150 mm;

- Efficiency - 71%.

Advantages:

- attractive design;

- the presence of panoramic glass on the firebox doors;

- fast heating;

- long service life.

Flaws:

- no hob;

- inferior to other models in terms of efficiency.

EdilKamin Aqua

Country of origin: Italy. The model is designed for heating rooms with a volume of up to 360 cubic meters. m. The design has a steel water circuit that can be connected to the heating system of the house. This can only be done with forced ventilation.

The side walls of the unit body are made of heat-resistant ceramics. The cast iron hob has a lid. The combustion chamber of the model is covered with fireclay bricks. The firebox door is equipped with panoramic glass. The unit runs on wood.

Characteristics:

- chimney connection type – top and rear;

- dimensions – 520x950x520 mm;

- weight – 154 kg;

- chimney cross-section diameter – 150 mm;

- Efficiency – 72%.

Advantages:

- the presence of a convenient hob;

- quick heating of the room;

- stylish design;

- long service life.

Main disadvantage:

- not very high efficiency.

Advantages

Cast iron stoves have a large number of advantages that allow them to maintain one of the very first positions among heating systems for private homes.

- The most important advantage of cast iron structures is the durability of the material. For 25-30 years, it is able to resist corrosion, which can appear on other materials due to exposure to cooled condensate during operation. In this case, the appearance of the material does not actually change.

- Also, the cast iron walls of the furnace are not destroyed due to exposure to cooled condensate and ash, which contains alkalis and acids that can negatively affect other materials.

- Wood-burning cast iron structures designed for heating private homes are distinguished by a beautiful and aesthetic appearance. Often, when using such a stove, the interior is stylized as an old rustic one with elements of modern technology. The result is a very unusual and unique interior, which is based on environmental friendliness and convenience.

- Long-burning cast iron stoves will allow you to heat a house or a separate room virtually around the clock. Thick cast iron walls help retain heat for a long time, which is very slowly released into the room. Thus, having lit the stove once, all that remains is to maintain the optimal flame level so that the level of heat transfer is maintained.

However, it is worth considering that in order to achieve the optimal level of heat transfer, you need to spend a lot of time to heat the stove to the desired level.

How to use?

Proper operation of the stove is no less important than its installation. When using the device, the following fire safety rules must be observed:

- When lighting the stove, it is advisable to use charcoal, dry logs or tree branches.

- Adjust power

- Don't overheat the room

- Do not use too much fuel at once,

- Be sure to close the stove damper after igniting the fuel,

- Leaving the heater unattended for a long time,

- Make sure that flammable items, aerosols, and explosive substances are no closer than 80 centimeters from the stove.

- Make sure that all windows and doors are closed while the device is operating; blowing in air from the street will worsen the operation and eventually cause the chimney to fail.

Flaws

Like any heating structure, cast iron stoves have several disadvantages, which in some cases can be critical, so you should carefully study the design and its features.

- The most obvious drawback, which scares off most potential buyers, is the cost of the stove. Even small classic heating stoves are significantly more expensive than stoves made from other materials. The increased price is due to the fact that cast iron is a very stable material with a service life of 25-30 years. In fact, it is better to purchase an expensive but high-quality furnace that is unlikely to ever need to be repaired or replaced. Rather than buying the cheapest designs every year.

- The second disadvantage is the heavy weight of the structure. Cast iron is a fairly heavy material, and given the thickness of the furnace walls, the total weight can be quite large. That is why it is recommended to install such stoves exclusively on the ground floor of the premises, or in the bathhouse. If installed on the second floor, there is a possibility of deformation of the slabs, in addition, there will be an increased effect of temperature on them, combined with cooled condensate.

- Despite the fact that the material is quite resistant to moisture, alkalis and acids, it is also very fragile, so you need to be very careful when operating the stove. The stove can crack from a strong impact, so it is not recommended to hit the walls when cleaning in order to knock down soot and deposits.

Features of organizing a heating system with your own hands

Connecting heating in a private house with your own hands begins with installation work on installing and piping the boiler. If the power of the device does not exceed 60 kW, it is allowed to be installed in the kitchen. More powerful heat generators will require a special boiler room. Heating devices with an open combustion chamber, designed to burn different types of fuel, need a good air flow. In addition, you will need a chimney to remove combustion products. In order for the water to move naturally, the boiler return pipe must be lower than the level of the batteries on the ground floor.

When installing a heat generator, it is necessary to take into account the minimum permissible distances to walls and other devices. Most often, these instructions are included in the instructions supplied with the product.

In the absence of special instructions, the following rules are used when installing the boiler:

- The width of the passage on the front side of the boiler must be at least 1 m.

- If there is no need to service the device from the side and rear, then a gap of 70 to 150 cm is left there.

- Adjacent devices should be located no closer than 70 cm.

- If two boilers are installed side by side, then there should be a passage of 1 m between them. If the installation is carried out opposite, the distance increases to 2 meters.

- Hanging installation makes it possible to do without side passages: the main thing is that there is a gap in the front for ease of maintenance.

Photos of cast iron stoves

Loft

This year the style remains in demand. It is often used to equip kitchens combined with a living room. This combination gives more free space, which will only emphasize all the details of the loft.

For loft, rough and heterogeneous surfaces and rough materials are selected. In apartments decorated in this style, wall lamps are installed. In this case, the light is directed along the walls.

Due to this, shadows fall so that uneven surfaces look three-dimensional. At first, loft was viewed with caution, but it quickly became popular. Designers do not hide finishing materials and even fake them. To imitate a concrete surface and smudges, decorative plaster is used.

Aluminum alloys

Aluminum alloys are generally not used to make furnaces. Some craftsmen make such stoves from milk cans. The only advantage of such a can is its large capacity, sufficient for the oven.

But, unlike steel, aluminum has a significantly lower melting point. It begins to melt at a temperature of 660°C.

For wood to burn effectively, a temperature of 400°C is required. And to prevent the formation of harmful gases, it is necessary to ensure a temperature of 600°C. Accordingly, aluminum is not suitable for making stoves.

Drawing up an order

By ordering we mean a certain scheme that helps facilitate the construction of the furnace. Do-it-yourselfers or people with minimal experience can do the work.

Furnace order:

The instructions are prepared by master stove makers. As a result, a person spends a minimum amount of time and money on equipment. Ordering helps increase the efficiency of the process. Documentation is drawn up before the start of bricklaying. Specialists will write down each step, the exact sequence, and the necessary materials.

The procedures are distinguished by their clarity and accessibility. You can easily and quickly build a stove without the help of craftsmen. Advantages of detailed orders:

- Minimizing financial costs. If a person uses an ordering diagram compiled by a qualified master, then he can save money on the services of specialists. Even people with minimal training and construction skills can create a functional stove in a short time.

The many variations of oven arrangements will help you create the oven that is right for you.

- Access to a wide and varied selection of design options. In the specialized literature you can find a huge amount of photographic material for creating a simple order. Users will be able to choose their own construction option. Ovens can be traditional or specialized (oven and cooking).

- Save time. If you plan to build a furnace of complex design, then thanks to the correct arrangement you can save time on construction. As a result, time and money are also saved. Specialists will be able to quickly build a stove in a country house, in a country house, or in a bathhouse.

- Clarity and ease of use. Master stove makers create a detailed ordering diagram, so even novice specialists can understand it.

- Availability of an exact sequence, a detailed inventory of materials. The order will not allow specialists to make mistakes, so the result can be high-quality work.

Heating stove:

Ordering helps improve quality and build structures of various types. A free project for a heating and cooking stove made of brick can be found in specialized literature.