Stove heating of a private home is still one of the most popular in all Russian regions.

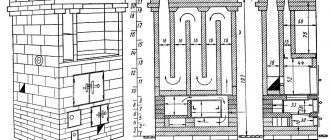

Stove heating of a private house - sketch

Previously, several stoves were used to heat a large house, which were installed in different rooms, but this is not the most economical option, as it requires a large amount of solid fuel.

Today, thanks to the developed modern schemes, as well as the fact that many different modern types of stoves have appeared on sale, organizing heating has become much easier. It comes in different types and using different fuels. To choose the most suitable option for your home, which will suit all parameters, you need to take a closer look at some of the types and find out how they work.

Methods for equipping furnaces with a water circuit

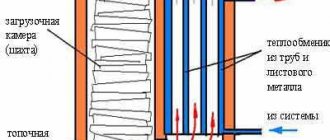

The water circuit can be installed on a ready-made metal structure, which is available for sale in a wide range. A traditional brick oven is also suitable for this. In this case, the role of a water boiler is performed by an ordinary metal pipe or a container made of sheet metal. They are connected to the house heating system.

To increase the efficiency of such structures, water heating from a wood-burning stove can be used to prepare hot water. The designs are convenient due to their high heat capacity, which allows them to maintain heat for a long time after stopping fuel loading. To build a furnace with a water circuit with your own hands, you need to understand all the intricacies of the process in advance. This will save you from wasting time and money, guaranteeing good efficiency of the installed system.

Features of using stoves

The main feature of stove heating is the frequency of combustion. This means that for some time such a system requires human participation in the technological process. This participation is expressed in carrying out work on bringing fuel, starting (igniting) the furnace, and removing residual combustion products (ash). As a rule, the time required to perform these actions is small compared to the duration of the technological period (the time from the start of the fire to the start of the next fire).

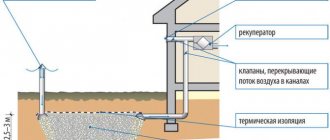

The second distinctive feature is the mandatory location of the stove in a heated room, and this requires compliance with increased requirements for the fire safety condition of the building and for ventilation.

The furnace is laid out of stone or brick. These materials absorb heat during combustion, releasing it within a few hours. To increase the cooling time, a damper is built into the chimney to close it.

Note! The installation location of the damper should be as high as possible in order to use the heat of the furnace more efficiently. However, this height is limited by the possibility of convenient opening and closing.

There are stoves for temporarily heating rooms. They are small and light, heat up very quickly and cool quickly after the fire is stopped. Such stoves are called potbelly stoves.

Main types

When constructing stove water heating, you can go one of two ways:

- If the house already has a stove, then it is necessary to make a coil for installation inside the structure. This technique is used infrequently due to its complexity. In this case, it is quite difficult to make a firebox to fit the existing dimensions of the structure.

- Construction of a heating plant on your own, taking into account the size of the register. If everything is done correctly, the reliability and longevity of the furnace service is guaranteed. The internal dimensions of the shirt deserve special attention. Its thickness should start from 4-5 cm, in order to avoid the threat of boiling water. To protect yourself from problems with coolant circulation, you usually install a suitable pump.

- When choosing wall thickness, the calorific value of the selected fuel is taken as a guide. If it is intended to use exclusively firewood as energy carriers, then 3 mm will be sufficient. If you plan to use coal, the thickness should be increased to 5 mm. The distance from the furnace register to its walls is recommended within 10-20 mm. This will completely neutralize the thermal expansion of metal elements, preserving them from premature destruction.

How to ensure optimal temperature conditions

When heating wooden houses with traditional stoves, obvious uneven heating is observed. The warmest areas in such a house are located in close proximity to the brick heater. It can get quite cool in the far corners. The multi-oven option is very expensive. In addition, this leads to a significant reduction in living space.

The most optimal solution is to use a combination of a brick stove with water heating. Many residents of our country already have similar experience, having managed to solve the problem of creating warmth and comfort in their homes. To do this, a conventional brick oven is equipped with a heat exchanger that looks like a coil. The place where it is installed is the firebox or the base of the chimney. Thanks to the heat generated, the water inside it begins to heat up, subsequently entering the radiator system. In this way, uniform heating of the home is achieved.

Advantages of a stove with a heating circuit:

- Efficiency and uniformity of heating. This is facilitated by the location of radiators in different rooms and the constant heating of the coolant.

- Absolute independence. These designs do not depend on the presence of gas and electricity in the house. In this case, the owners themselves choose the time and intensity of heating.

- Possibility of independent maintenance of heating systems. To carry out these simple activities, the presence of specialists is not required.

- Economical. Although such a system has to be started every day, due to the cheapness of fuel, the costs of its operation are quite small.

The weak point of such systems is their high fire hazard. For this reason, premises must be additionally equipped with fire protection. You should also take into account the fact that the heating device is static: it will not be possible to move it from place to place. A stove with a water jacket is capable of heating a small one-story house. If a building has a second floor, it is necessary to resort to the construction of another furnace, which results in considerable costs. Disadvantages of the system also include the need for constant human control.

Preventing heating system freezing

Using water as a coolant has one drawback - if the heating system freezes, the pipeline and appliances will be damaged. It is especially difficult to restore in this case the heat exchanger integrated into the furnace.

This problem is relevant for houses that may not be heated for a long time in winter. One way to prevent system damage is to use antifreeze designed for heating systems instead of water.

For residential premises, liquids based on propylene glycol are used as antifreeze, as a non-toxic substance, unlike ethylene glycol.

However, the idea of using antifreeze has its downsides:

- antifreeze based on propylene glycol is expensive (from 80 rubles / liter);

- the specific heat capacity of antifreeze is less than that of water (approximately 15%), therefore a larger furnace power and a large surface area of room heating devices are required;

- antifreeze has a higher dynamic viscosity than water, so a more powerful circulation pump is required, and natural circulation is impossible;

- when heated, antifreeze expands up to 40%, so it is necessary to use a large closed expansion tank;

- propylene glycol is very fluid, so it penetrates through connections in the heating system through which water cannot penetrate;

- propylene glycol is incompatible with galvanized pipes because antifreeze additives lose their properties upon contact;

- when antifreeze boils (which is likely when using furnaces), an irreversible chemical reaction occurs, as a result of which the entire system will have to be drained and antifreeze refilled.

For antifreeze, the heating system must be calculated in advance - its use in projects implemented for water is quite problematic.

Moreover, a project using antifreeze will be much more expensive than a water heating system. Therefore, its use has not yet become widespread in private homes with stove heating, and other methods are used to prevent freezing.

When choosing a liquid for a heating system, it is necessary to keep in mind not only the physical and chemical characteristics, but also its danger to others

Draining water from the circuit and jacket or register of the furnace is the most common solution to the problem when the owners of the house are absent for a long time. In addition to the additional work, the disadvantages of this method include access of air to the metal elements of the system from the inside and, as a result, the spread of corrosion.

Also, as a solution to the problem for a short period of time, they use the integration of a low-power electric boiler into the heating circuit. Its operation at a minimum level of energy consumption is able to temporarily maintain a positive water temperature.

A low-power electric boiler connected to the heating system is capable of maintaining a positive water temperature in case of prolonged absence of the owners

Preparation for construction work

Before you begin laying a furnace with a water circuit, you need to consult with experienced specialists. The optimal place to install the structure is considered to be the central area of the house. The firebox should go into the kitchen or other non-residential premises. On the contrary, it is important to place the housing inside the living room. This layout will ensure efficient heating of several rooms at once.

The size of the furnace is influenced by the total area of the heated building. According to rough calculations, 1 m2 of stove can heat approximately 35 m2 of a house. Based on this ratio, you can easily calculate the dimensions of the heater in each specific case. There are situations when registers are purchased for ready-made designs. It is more practical to first buy a register, and then design a stove of suitable dimensions for it.

For the manufacture of registers, a pipe or steel sheet with a thickness of at least 3-5 mm is usually used. When using thinner material, there is a real risk of it burning through. In this case, only a complete replacement of the product will help. It is mounted inside the fuel compartment, using the required space between the walls. This precaution allows you to compensate for thermal expansion and increase heat transfer. The gap facilitates cleaning of the firebox, which is carried out on a regular basis.

Increased gas pressure under the throat

A significant obstacle to speeding up the operation of blast furnaces is the insufficient gas permeability of the charge materials column. As the amount of blast increases, the speed and lifting force of the gases in the blast furnace increases. Upon reaching certain speeds, the lifting force of the gases can balance the column of charge materials, and their descent stops.

In order to maintain a smooth flow of charge materials and at the same time speed up the furnace progress, it is necessary to reduce the speed of movement of the furnace gases, maintaining and even increasing the amount of blown air. This is achieved by increasing the gas pressure in the furnace; at the same time, its volume decreases, and consequently, the speed of movement decreases, which makes it possible to increase the amount of blown air.

An increase in pressure is achieved by reducing the cross-section of the gas pipeline by installing a throttling device. This measure can significantly reduce dust removal, which also improves the performance of the furnace.

Switching the furnace to operate with increased gas pressure under the top significantly changes the distribution of gas flows in the furnace; for example, the peripheral flow of gases increases. Peripheral loading allows better use of the reducing power of gases. However, it is necessary to ensure good gas treatment of the central zones of the furnace, that is, materials located along the axis of the furnace must have sufficient gas permeability. Thus, when the gas pressure at the top increases, the preparation of the charge should be improved.

An increase in pressure increases the density of gases, which ensures better processing of charge materials and an increase in the rate of oxide reduction, and the higher the pressure, the greater this effect. Therefore, transferring furnaces to work with gas pressures of 176 - 245 kN/m2 (1.8 - 2.5 atm) is the immediate task for blast furnace workers. At the advanced ones, the Cherepovets Metallurgical Plant, etc.), the gas pressure at the top has already reached 196 kN/m2 (2.0 at).

Increasing the gas pressure under the top made it possible to reduce coke consumption by 1 - 3% and increase productivity by 5 - 10%. The results obtained depend on the smelting conditions - pressure, quality of raw materials, fuel, etc. The practice of operating blast furnaces confirms the advisability of further increasing the pressure under the top.

As the gas pressure in the working space of the furnace increases, it is necessary to further increase the reliability and durability of the structural components and equipment of the blast furnace - tuyere hoses, atmospheric valves, charging apparatus, air and gas pipelines. Thus, the durability of filling devices is currently still insufficient and does not yet exceed 10–15 months.

At the same time, the question arises about using the energy of compressed gases, which, in particular, will reduce the cost of compressing the blast, for example, as a result of installing gas turbines in the place of gas throttling.

What is needed for good performance

The performance of a furnace with a water circuit from a pipe depends on the constant circulation of coolant in the pipes. To do this, it is necessary to provide a mandatory slope. In addition, it is recommended to use a circulation pump, which will guarantee stable circulation and protect the water from boiling. The pumps used for this are compact and have sufficient power. Most often, they are used to equip long-length heating systems. The installation site for such a pump is the return pipe through which water moves into the boiler.

The use of a pump does not relieve the need to arrange the required slope. The fact is that in the event of a power outage, this can lead to water boiling. The consequences of this phenomenon are very sad - breakdown of the pump and failure of the entire system. A good protective option is to use an expansion tank to compensate for the increase in water volume when heated. Thanks to it, despite errors in system maintenance, the heating will continue to operate in a stable manner.

How to properly connect a muffle furnace to an energy source

If you have no experience working with electrical devices, it is better to contact a professional electrician. To connect the device to the network you must purchase:

- thermostat;

- large terminal block made of heat-resistant plastic;

- small terminal blocks made of heat-resistant plastic for splicing wires;

- contactor (electromagnetic starter);

- two-core electrical wire;

- electrical plug;

- standard casing for electrical panel.

For this oven, a single-channel thermostat M-1-K was selected, which regulates the temperature of the working chamber up to 1300 degrees. The device is capable of working according to a complex schedule; it is used to set the heating time and temperature.

Reference. The cross-section of the nichrome wire and its length, the diameter of the spiral turn, the cross-section of the connecting wires and other parameters of the electrical circuit are calculated from reference books and selected in advance.

The element has 7 connectors for connection (two terminals for power wires, two for connecting a thermocouple, three for a relay). The device is controlled by four buttons. When the thermostat is turned on, the indicator light is on. The device comes with two brackets for mounting in a panel and detailed connection instructions.

Block installation

The block is installed in the following order.

- The contacts of the thermocouple and the spiral are insulated and connected with terminal blocks to two-core wires.

- A plug is connected to the power cord.

- The thermostat, contactor and large terminal block are mounted in the panel.

- A thermocouple, a muffle spiral, and a power wire with a plug are connected to the thermostat via a contactor and terminal block.

An electric muffle furnace must be grounded.

Technology for installing water heating in a conventional wood-burning stove

The design of a furnace with a water circuit contains instructions on its location and dimensions. It is important to consider how the interior partitions and furniture are located. For large structures of significant weight, a solid concrete foundation is laid. The base of the stove and the finishing material on the floor must be separated by a protective indentation to protect against fire.

To carry out the masonry, a special mortar and high quality bricks are used. Considering the complexity of preparing the mixture and the quality requirements, it is sometimes safer to purchase it ready-made. The foundation requires mandatory waterproofing. Before laying, it is recommended to immerse the bricks in water for a day. Armed with the dimensions of the masonry elements, they select the appropriate order.

A register-coil is mounted inside the structure being constructed: the supply and return pipes are subsequently connected to it. One of them serves to supply hot coolant through the expansion tank into the system. The second pipe is a channel for returning the cooled liquid back to the register. The movement of water is ensured by gravitational forces. The dimensions of the connecting seams are allowed within 4 mm. You need to ensure that there are no sharp corners inside the firebox and chimney. It is better to use rounded connections that do not affect the efficiency of smoke removal. This will significantly reduce the amount of soot formed in the firebox.

Disadvantages of combined models

- Modern manufacturers produce only floor-mounted universal gas-wood boilers. They weigh quite a lot, so transporting and installing them yourself is quite difficult. Under them it is necessary to build a solid foundation, and this is an additional expense.

- For installation of combined installations, you will have to allocate a separate room. And this is not always possible in conditions of cramped, compact housing.

- The more powerful the hardware, the fewer functions it can provide. For example, a high-efficiency boiler does not have a frost protection system. A second circuit for supplying hot water is not installed everywhere.

- “Sophisticated” models are quite expensive. They are difficult not only to buy, but also to maintain later, using service advantages.

- You can obtain the required performance in one single case - by correctly calculating the power of the unit. Experts recommend using the following formula for this: 1 kW of power is spent on heating every 10 square meters. For double-circuit boilers this figure increases by 30%.

Recommendations for carrying out construction activities

When constructing a stove with a hob and a water circuit, the following standards must be adhered to:

- The stove and nearby surfaces must be separated by a safe distance. For these purposes, a metal sheet is additionally installed in front of the firebox to protect the floor and partitions.

- To make the masonry as strong as possible, every 4th row of bricks is reinforced with metal pins.

- A clay mortar of medium plasticity is used as a mounting mixture. A small ball rolled from it should not crack or crumble when it hits the floor.

- The chimney must have a height of at least 5 m: the presence of a head is a prerequisite. This element is designed to protect the chimney from climatic precipitation and blockages. In addition, it helps to increase traction and decorate the building.

Building a home stove with a boiler with your own hands usually does not cause any particular difficulties. Quite often you can find metal structures that are not inferior to brick ones in terms of external aesthetics. Such a product can greatly decorate a home interior. For the construction of brick kilns, a special building material is selected. The best option is fired ceramic red bricks. They are distinguished by their uniform color and metallic sound when tapped.

It is not recommended to take risks with burnt and unburnt elements, because... in this case, there is no guarantee of quality and operational safety. In fireboxes with very high heating levels, it is recommended to use a refractory refractory material, which usually does not cause problems during operation.

Voting: which modern stove is the best?

| Photo | Name | Rating | Price |

| The best factory models of Russian-made potbelly stoves | |||

| #1 | Potbelly stove POV-57 | 99 / 1005 – votes | Find out more |

| #2 | Termofor Fire-battery 5B | 98 / 100 | Find out more |

| #3 | META Gnome 2 | 97 / 100 | Find out more |

| #4 | Stove Potbelly stove Teplostal | 96 / 1003 – votes | Find out more |

| Popular potbelly stoves from world brands | |||

| #1 | Keddy | 99 / 100 | Find out more |

| #2 | Guca Lava | 98 / 100 | Find out more |

| #3 | Vermont Castings | 97 / 1001 – voice | Find out more |

| #4 | JOTUL | 96 / 1001 – voice | Find out more |

| #5 | Brunner IRON DOG | 95 / 100 | Find out more |

Which of the modern stoves would you choose or what would you recommend purchasing?

Brunner IRON DOG

Save your voting results so you don't forget!

To see the results you need to vote

After the stove is installed and ready for use, it is necessary to install a chimney that can function properly, retain heat in the room and at the same time prevent combustion waste from entering the air of the room where the stove is installed. To do this, you need to correctly calculate the diameter of the pipe, its length and think about how it will exhaust the smoke into fresh air.

The pipe outlet above the roof should be located according to certain rules:

- The chimney is located from the roof ridge at a distance of up to 1500 millimeters, which means the pipe outlet should be located at a height of 50 centimeters above the top of the ridge,

- With a distance to the canopy of 150-300 centimeters, the pipeline outlet can be positioned at the same level with it,

- If the chimney is located near the edge of the roof, then its outlet should be slightly lower than the ridge, or at the same level with it,

The second option for the pipe to exit is through the wall, and not through the roof. In this case, the end of the chimney should be located just below the top of the roof ridge.

Do-it-yourself installation work should begin with choosing the place where the outer and inner elements of the furnace should be connected. An attic or roof space is perfect for this purpose. The first element of the future chimney is installed on the potbelly stove itself, on which the second, third, and so on are then placed (depending on how many sections the chimney will include).

The chimney pipe must be extended until it reaches the previously determined location at the junction of the two elements.

You need to make a hole in the ceiling, the diameter of which will be 5-10 cm larger than the diameter of the pipe: this will be required in order to cover the pipe where it passes through the ceiling with heat-insulating material. If there are insulating materials or other easily flammable objects in the cracks between the ceilings or near the pipe, they must be removed: when the pipe is heated by smoke and its temperature rises, the risk of fire of the insulating material will also increase.

A passage glass is inserted into the cut hole in the ceiling, through which the chimney pipe must be passed. Then you need to connect the pipe coming from inside the room to the outside of the chimney. The chimney should end above the roof level, approximately 10 cm above it. The place in which the hole for the pipe outlet will be cut is equipped according to the same principle as the place where the pipe exits inside the building:

- the hole must be larger than the chimney pipe itself;

- A layer of heat-insulating material must be placed between the roofing materials and the pipe.

Fixing the pipe

The smoke exhaust pipe is passed through a hole in the roof and fixed with a sheet of tin or other metal. As an alternative to tin, you can use another non-flammable fixative - bricks, which are installed in the gap between the chimney and the roof. However, in order for the bricks to hold the pipe tightly, a stand needs to be built for them from the inside. All cracks in this place are covered with ordinary clay.

Sealing seams

After the entire structure has been assembled, you need to take the sealant and, sparingly, lubricate all joints and seams to prevent smoke from entering the living room from the chimney

The sealant for these purposes must be selected with special attention - only one that is not afraid of high temperatures is suitable

Unfortunately, some sealants will simply “melt” on a hot pipe, while others will dry out easily. One way or another, a sealant that is unstable to high temperatures will lose its properties and will not be able to protect the room from smoke.

Bottom line

To provide heating for a home, several options are usually considered. Popular gas or electric equipment runs on expensive energy resources. The most economical type is heating and cooking furnaces with a water circuit. They are easy to build yourself, which results in noticeable financial savings. This type of heating involves a combination of traditional brick construction and modern technology. As a result, the home receives the necessary warmth and comfort. In addition to brick ones, they often make metal stoves with a water circuit with their own hands. By ensuring proper maintenance of your heating system, you can guarantee a suitable microclimate in your home for many years.

DIY gas fireplace

Another convenient option for heating rooms is a gas fireplace. Purchasing such a device will cost a hefty sum, although the most savvy can independently assemble and arrange a fireplace in their box without a particularly large investment.

This kind of fireplace can be powered either directly from a gas pipe or from a gas cylinder.

You can find a wide variety of designs for gas fireplaces on the Internet. Also, some users can purchase prefabricated structures, lay out the brickwork themselves and assemble a fireplace from pre-prepared parts

The design consists of the following main elements:

- an ordinary fireplace insert or a decorative one that decorates the room;

- fireplace body made of refractory metals - cast iron or other alloys;

- burner that supplies gas;

- gas supply system.

After determining the place where the structure will be installed, it is necessary to prepare it to begin the construction of the brickwork. There must be a solid foundation. You also need to install the chimney. After the fireplace is erected, it can be decorated with a variety of decorative elements to suit the taste of the owners.

The fireplace is laid only from refractory bricks. When erecting a structure, care should be taken to ensure passage to the gas valve. After the internal elements of the masonry are installed and communication is connected to the gas burner, you should make sure that the entire system is tight.

With the help of a valve, in the future it will be possible to regulate the strength of the gas supply and, consequently, the amount of heat generated. Gas workers advise turning the burners with their holes facing down - this will protect them from contamination and moisture.

The burner should also be reinforced with protective mesh elements. This will reduce the load on the burner from the decorative material.

A pipe covered with refractory materials is supplied to the fireplace firebox, supplying gas. The gas burner is installed with the holes down and masked with artificial refractory material

The introduction of some modern devices will allow you to slightly automate the operation of the fireplace. This way you can connect a gas supply control system, depending on the level of heat generated, or an automatic gas supply shutdown system. All modifications are freely available on the market, and their acquisition depends on the desire and ability of the owners.

Beautiful decoration of the fireplace bowl is made using a variety of stones, glass, and ceramics. In addition to interior decoration, the outside of the fireplace can be decorated with tiles or in another way. The main thing is that it is a fireproof material.

It is easy to assemble a gas stove yourself with your own hands. To do this, you need to adhere to the design and safety instructions.

If you follow all the requirements and recommendations, assembling the stove will be a fun and inexpensive activity. Self-assembly of such a design will save significant money.

First of all, before installing a gas stove to heat a room, it is worth carrying out a number of preparatory measures. If you do not insulate the room, then even the most powerful equipment will not give a serious result

Therefore, it is important to carry out external and internal insulation procedures, as well as equip reflective surfaces