Add to bookmarks

One of the skills required for high-quality and quick replacement of pipes at home is accurately determining their diameter using available tools.

Before making measurements, you should understand in what units they are made. It is generally accepted that the diameter of pipes is always measured in inches (1 inch = 2.54 cm).

Whether it's problems with the plumbing or plumbing in the bathroom or problems with the water supply in the kitchen, knowing how to determine the diameter of a pipe using available tools will come in handy.

Of course, there are special tools for measuring, such as a ruler-circometer, laser meter, etc. But everything can be much simpler.

Before making measurements, you should understand in what units they are made. It is generally accepted that such values are always measured in inches (1 inch = 2.54 cm), and the standard size, for example, of steel products is most often 1 or 0.5 inches. By the way, the diameters of plastic, steel and metal-plastic parts vary.

The next step is to select the measured value. External - more important, because It is on it that threads and threaded connections are installed. This diameter directly depends on the thickness of the pipe walls. The dimensions of the wall thickness are determined by the difference between the external and internal diameters of a given pipe.

Taking words to action

In order to correctly measure both diameters, you should take into account the features of all measurement methods, because each of them is suitable for different conditions.

In order to correctly measure both diameters, you should take into account the features of all measurement methods, because each of them is suitable for different conditions.

One method is to measure the circumference of the piece by wrapping it with a measuring tape or tape measure. Then the resulting value must be divided by Pi (3.14).

We will need:

- ruler;

- calipers;

- tape measure (measurement tape).

If access to an area of the part is not difficult and you can measure it before installation, then the easiest way is to use a ruler or tape measure. The outer diameter is determined by placing a ruler over the widest part of the pipe and counting from the first outer point on the scale to the last.

There may be cases where measurements are already indicated in inches (imported deliveries). To convert to centimeters, the size is multiplied by 2.54, and to convert back to inches - by 0.398.

There is another way to determine the internal diameter if the pipe is directly accessible. The walls are measured along the cut using a caliper or ruler, and then the resulting reading is subtracted from the measurements of the outer diameter and multiplied by 2.

What if there is no direct access to the required area? One method is to measure the circumference of the piece by wrapping it with a measuring tape or tape measure. Then the resulting value must be divided by Pi (3.14). This way we can find out the outer diameter of the pipe. This method is also suitable if the length of the caliper or ruler is not enough.

There is a method for determining the outer diameter that excludes all sorts of calculations, but only for those parts for which it is no more than 15 cm. To do this, you will need to measure the readings using only a caliper, on the scale of which the correct results are measured.

One of the most extraordinary ways is to compare the values of a pipe with some object, take photographs and further recognize the measurements. Take a ruler or any object whose length is already known in advance (a coin) and bring it to the area to be measured, then take a picture. Further scaling on the computer will help determine the exact dimensions of the outer diameter. This method is ideal if it is impossible or extremely difficult to get close to the area being measured.

Imagine that you are going to paint the gas pipes connected to your house. How much paint will be needed? One or two cans? As a rule, on paint containers it is written what area this amount of paint is designed to cover. This means that in order to accurately determine how many cans of paint to take, you need to calculate the area of the gas pipes.

Imagine that you are going to paint the gas pipes connected to your house. How much paint will be needed? One or two cans? As a rule, on paint containers it is written what area this amount of paint is designed to cover.

You will need

- - roulette;

- - caliper;

- - strong thread;

- - calculator.

Instructions

To calculate the area of a round pipe, find out the length of this pipe in linear meters. Also for the calculation you will need the outer diameter of the pipe.

Calculate the outer diameter of the gas pipe. There are two ways to do this. The first method is to measure the outer diameter of the gas pipe using a caliper. To do this, spread the jaws of this measuring tool and attach it to the pipe so that the pipe is between the jaws of the caliper. Then move the jaws of the measuring tool: they should tightly grip the gas pipe. Looking at the measuring scale, determine the outer diameter of the pipe. The second way is to wrap a thick thread around the pipe. Then use a tape measure to measure the circumference of the pipe. Substituting the value into the formula D = L / Pi, where L is the circumference of the pipe, Pi = 3.14 (the number “pi”), calculate the outer diameter of the gas pipe. Convert the resulting indicator to

Water supply, heating, sewer, chimney, casing, copper, steel, plastic, metal-plastic, narrow, wide - pipes for various purposes from various materials surround us everywhere. The need to lay new communications or replace old ones arises both during the construction of a house and during ongoing repairs. When drawing up a project for the upcoming work, it would not hurt to arm yourself with a calculator to calculate the weight of the pipe, its mass, volume and other parameters.

Why do you need to calculate pipe parameters?

Preliminary calculation of pipe parameters is necessary in many cases. For example, for proper communication of the pipeline with other elements of the system. When working with pipes, designers and installers use indicators such as:

- pipeline permeability;

- heat loss;

- amount of insulation;

- amount of material for corrosion protection;

- roughness of the inner surface of the pipe, etc.

As a result, it is possible to determine the exact number of pipes required for a particular system, as well as their optimal characteristics. Correct calculations eliminate unnecessary costs for purchasing and transporting material and allow the substances in the pipeline to move at a given speed for the most efficient use of the system.

This table provides some useful information about the characteristics of different types of pipes that will help you select the appropriate designs needed to create a pipeline

In heating systems, the diameter of the pipes significantly depends on the permissible speed. An example of this kind of calculation is presented in the video:

Two-pipe circuit in a high-rise apartment

To properly install heating in an apartment in a multi-story building, you need to plan everything from the beginning. One of the key points when planning is calculating the diameter of the heating pipe. The technical part of the matter is called hydraulic calculation. In this case, the choice of the diameter of heating pipes is influenced by the following factors:

- length of the system;

- supply coolant temperature;

- return coolant temperature;

- materials and accessories;

- room area;

- degree of fatigue in the room.

In other words, before calculating the diameter of the heating pipe, you need to determine the hydraulic parameters of the system. You can only make approximate calculations on your own, which can also be used in practice.

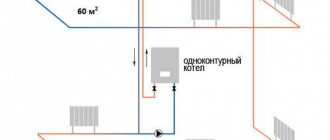

Sealed two-pipe system

The diameter of the pipes for a two-pipe heating system directly determines how quickly the heat from the boiler will reach the end point of the circuit. The smaller the nominal diameter, the higher the coolant speed. Based on this, we can conclude that if the diameter of the heating pipe in the apartment is chosen incorrectly, the speed of the coolant will drop, and along with it the temperature in the last radiator will be lower. After all, water will have time to give off more heat over a longer period of time.

The simplest solution for calculating the diameter of a heating pipe is to adhere to the same nominal passage as in the pipe extending into your apartment from the central riser. This will save you time and nerves, because it is no coincidence that the developer installed a contour with exactly this cross-section. Before the construction of the facility began, all calculations were carried out, including hydraulic ones. If you want to calculate everything using the formula, then use the information from the next block.

Calculations of various pipe parameters

- the material from which the pipe is made;

- type of pipe section;

- internal and external diameter;

- Wall thickness;

- pipe length, etc.

Some of the data can be obtained simply by measuring the structure. A lot of useful information is contained in certification documents, as well as in various reference books and GOSTs.

How to find out the diameter and volume of a pipe?

Some calculation formulas are familiar to every schoolchild. For example, if you need to determine the diameter of a specific pipe, you should measure its circumference. To do this, you can use a measuring tape that seamstresses use. Alternatively, wrap the pipe with another suitable tape and then measure the resulting length using a ruler.

- L is the circumference of a circle;

- π is a constant number “pi”, equal to approximately 3.14;

- D is the diameter of the circle's circumference.

It is enough to carry out a simple transformation to calculate the outer diameter of the pipe using this formula:

Calculation of pipe cross-section

This figure clearly shows indicators such as the outer diameter of the pipe and the thickness of its wall. The difference between the outer diameter and thickness allows you to calculate the inner diameter of the pipe

The formula for the area of a circle looks like this:

S=πR², where:

- S is the area of the circle;

- π—pi number;

- R is the radius of the circle, calculated as half the diameter.

If information about the outer diameter and wall thickness of the pipe is used, the formula may look like this:

S=π(D/2-T)², where:

- S—sectional area;

- π—pi number;

- D is the outer diameter of the pipe;

- T is the thickness of the pipe walls.

Let's say there is a pipe whose outer diameter is 1 meter and the wall thickness is 10 mm. First, you need to agree on all units of measurement. The wall thickness will be 0.01 meters. According to the above formula, we calculate the cross-section of such a pipe:

S=3.14Х(1m/2-0.01m)²=0.75m²

Thus, the cross-section of the pipe with the specified parameters will be equal to 0.75 square meters. m.

As you know, the accuracy of calculations with the number “pi” depends on the number of decimal places that are used when applying this constant. However, in construction there is usually no need for ultra-precise calculations, and the number “pi” is taken equal to 3.14. It also makes sense to round the final result to two decimal places.

How to calculate the volume of a pipe?

This diagram clearly shows the use of data such as the cross-sectional radius of the pipe and its length to determine the volume of the pipe

Calculating the volume of a specific pipe section is also not difficult. To do this, you must first find the circumference of the pipe based on its outer diameter using the formula given above:

S=π(D/2)² or S=πR²

In this case, D is the outer diameter of the pipe, and R is the outer radius, i.e. half the diameter. After this, the resulting value must be multiplied by the length of the pipe section, obtaining the volume, which is expressed in cubic meters. The formula for calculating pipe volume may look like this:

- V—pipe volume, cubic meters. m.

- S—external section area, sq.m.;

- H is the length of the pipe section, m.

Let's say there is a pipe with an outer diameter of 50 cm and a length of 2 meters. First, all units of measurement must be agreed upon. D=50 cm=0.5 m. Substitute this value into the formula for the area of a circle:

This table provides reference weight data

of various types, taking into account their sizes and features of production technology

Middle school students are well aware that the mass of an object can be found by multiplying its volume by the density of the substance from which the object consists. Builders are spared from tedious calculations of the mass of a specific pipe section, since various construction reference books contain information on the weight of a linear meter of a wide variety of types of pipes. The easiest way is to calculate the mass of the pipe using the relevant GOSTs, using information about:

- the material from which the pipe is made;

- its outer diameter;

- wall thickness;

- internal diameter, etc.

Having found out the weight of one linear meter of pipe, you should multiply the resulting value by the total number of linear meters. The complexity of the task corresponds to the level of the fourth-fifth grade of a general education school.

The occurrence of problems in the water, gas or sewer system often involves pipe installation - replacing a fragment of an old pipe or installing a new one. When performing such work, you will need the skills to determine the diameter of the pipes of your system using improvised means. When installing a new water supply system, it is also necessary to accurately determine the dimensions of old pipes in order to determine the choice of new plastic or metal-plastic pipes.

Of course, there are special tools for carrying out such measurements, for example, a laser meter, a ruler-circometer and others. But what if you are not a professional specialist, and your home tool kit does not include such high-precision instruments? How to measure the diameter of a pipe in another way?

Before answering this question, it is useful to know in what units these indicators are measured. Pipe diameter is usually measured in inches. One inch is equal to 2.54 centimeters.

When working with a pipe, both its internal and external diameter will be measured. The external diameter of the pipe is important due to the fact that it is its value that is taken into account when applying threads and creating threaded connections. The outer diameter is directly dependent on the thickness of the pipe walls. The wall thickness size is the difference between the outer and inner diameters of the pipe.

What are calculations for?

Bernoulli's law, known to many since school, says that the speed of fluid flow in a pipe depends on pressure and diameter. Accordingly, if the diameter of the pipe is small, the pressure will be too high, which can lead to pipe rupture. And if the pressure is lowered, the speed of movement of the liquid will also drop, and as a result, the pressure with which water flows from the taps.

Today, several types of pipes are used to create a water supply system:

- Metal (from alloys of copper, cast iron, steel).

- Plastic (made from thermoplastic polymers - polyethylene, PVC, polypropylene).

- Composite, or reinforced (in them layers of polymer and metal mutually reinforce each other).

The strength characteristics of these materials differ significantly, and therefore the parameters of the pipes used to create a water supply system differ from each other.

The weight also differs. Therefore, taking a pipe “with a reserve” may also not be justified: it will cost more, weigh more, make installation more difficult and require more reliable brackets. However, the gain in throughput may not justify all these shortcomings. Therefore, in order for pipes to be optimally suited to the plumbing system, it is necessary to calculate the outer and inner diameter, length and thickness of the pipe walls. To find out how to choose the right plastic pipes for sewerage: selection, dimensions, read this article.

From words to deeds

There are several ways to measure pipe diameters, differing in their characteristics depending on the conditions that are important to consider in order to avoid mistakes. The choice of a specific measurement method often depends on accessibility to the measurement object. Let's look at some of them.

Most often, the well-known caliper is used to measure the diameter of a pipe. But you may not have it, or if you do have it, it may not be possible to measure a large pipe diameter with it. In this case, the simplest set of tools and knowledge is used:

- flexible ruler (similar to the type of measuring tape used in sewing);

- roulette;

- school knowledge of the number Pi (it is equal to 3.14).

Using a similar set of tools, you can measure the diameter of not only a pipe, but also any other round object - a rod, column or garden bed.

We only need to make one measurement - determine the circumference of the pipe using a tape measure or flexible ruler. To do this, a measuring tape or tape measure is placed on the surface of the pipe in its widest part. The resulting circumference value should be divided by 3.14. For more accurate dimensions, use the value 3.1416.

It should be noted that imported supplies of pipes are accompanied by documentation that already indicates the pipe diameters in inches. To convert these values to centimeters, they are multiplied by 2.54. Similarly, to convert centimeters back to inches, multiply by 0.398.

Measurements are taken using a caliper without any mathematical calculations. The condition is complete accessibility to the pipe. This method is suitable for measuring accessible pipes of small diameter (no more than 15 cm). To take measurements, the legs of the caliper are applied to the end of the pipe and clamped tightly on the outer walls. The resulting value on the caliper scale, accurate to tenths of a millimeter, will be the outer diameter of the pipe.

If the end part of the pipe is inaccessible for measurement, that is, when the pipe is a mounted element of an already existing water or gas supply circuit, then for measurements a caliper is applied to the side surface of the pipe. In this case, an important condition for taking measurements is that the length of the caliper legs must exceed half the diameter of the pipe.

Large diameter pipe measurement

We have already mentioned a formula with a value above. The circumference of a large pipe can be measured using a cord or tape measure, and then its diameter is determined using the formula D = L: 3.14, where: D is the diameter of the pipe;

L – pipe circumference.

For example, if the length of the pipe circumference you measured was 31.4 cm, then the diameter of the pipe will be D = 31.4:3.14 = 10 cm (or 100 mm).

How to calculate cross-sectional area

Formula for finding the cross-sectional area of a round pipe

If the pipe is round, the cross-sectional area should be calculated using the formula for the area of a circle: S = π*R2. Where R is the radius (internal), π is 3.14. In total, you need to square the radius and multiply it by 3.14.

For example, the cross-sectional area of a pipe with a diameter of 90 mm. We find the radius - 90 mm / 2 = 45 mm. In centimeters this is 4.5 cm. We square it: 4.5 * 4.5 = 2.025 cm2, substitute it into the formula S = 2 * 20.25 cm2 = 40.5 cm2.

The cross-sectional area of a profiled pipe is calculated using the formula for the area of a rectangle: S = a * b, where a and b are the lengths of the sides of the rectangle. If we consider the cross-section of the profile to be 40 x 50 mm, we get S = 40 mm * 50 mm = 2000 mm2 or 20 cm2 or 0.002 m2.

Measuring pipes using photography (copy method)

This non-standard method is used when there is complete inaccessibility to a pipe of any size. A ruler or any other object is applied to the pipe being measured, the dimensions of which are known in advance to any master (often in this case they use a matchbox, the length of which is 5 cm, or a coin). Next, this section of the pipe with the attached object is photographed (in addition to a camera, in modern conditions it is also possible to use a mobile phone). The following size calculations are made from photographs: the visual thickness in mm is measured in the photograph, and then converted into real values, taking into account the scale of the photographs.

Drafting

The design documentation of the heating circuit is carried out in compliance with general requirements. The entry and exit points from the gas boiler are considered the main ones. The initial section of the pipeline, even when using a polypropylene pipe, is made of metal (approximately 1.5 m from the exit point) until the first branch of the system.

Then the entire branch of plastic or polypropylene pipes is laid out. In this case, the sections depend on the length, but usually each subsequent branch is made smaller than the previous one. The schematic diagram for connecting the pipe system with the coolant is the same, only it is connected to the inlet of the heating boiler.

Monitoring pipe parameters in production conditions

The outer diameter of water or sewer pipes in large production conditions is controlled and checked using a more complicated formula: D = L: 3.14 - 2∆p - 0.2 mm.

In this formula, in addition to the already known values, the symbols ∆p mean the thickness of the tape measure in mm, which you use to measure the diameter, and “0.2 mm” from the formula are the permissible deviations that take into account the fit of the tape measure to the pipe. The permissible deviation value for pipes with a cross-section of 200 mm is ±1.5 mm.

When measuring large diameter pipes, permissible deviations are measured as percentages. Example, for products ranging in size from 820 to 1020 mm, permissible deviation = 0.7%. For such measurements, an ultrasound-based measuring system is used.

In large production conditions, the wall thickness of pipes is measured with a caliper with a scale division of 0.01 mm. The permissible deviation from the nominal thickness towards reduction should not exceed 5%.

The values of pipe curvature are also subject to control, which should not be higher than 1.5 mm per linear meter of pipe length. The total curvature of products in relation to its length should not be more than 0.15%. The ovality of the pipe ends is determined by the ratio of the difference between the largest and smallest diameters to the nominal diameter of the pipe.

The value of this parameter should not exceed 1% for pipes with a wall thickness of up to 20 mm and not higher than 0.8% for walls above 20 mm.

The ovality of the pipe can be determined by measuring the diameter of the pipe end using an indicator clamp or bore gauge in two mutually perpendicular planes.

Simple school knowledge and careful use of simple tools will significantly simplify your task - how to measure the diameter of a pipe using improvised means.