Have a nice day!

As you know, the energy efficiency of a heating system depends not only on the power of the boiler and the number of radiators. This is a rather complex parameter, tied to the climate regime of the region, the materials from which the house is built, the quality and quantity of heating equipment and fittings. And heating pipes play the role of one of the “first violins” in the heating system.

What pipe diameter is best to use for heating a private house so that the coolant circulation in the circuit is as efficient as possible? As a rule, special programs are used for this, however, there are alternative concepts that allow you to perform this operation yourself. We will lift the “veil of secrecy” and tell you as simply as possible about complex calculation schemes that allow you to optimize the heating of your home so that it is warm and comfortable without having to throw money away.

Effect of characteristics on efficiency

A well-designed pipeline design has a positive effect on the performance of the heating system. The throughput of the structure depends on the cross-section of the components. The parameter shows the volume of hot liquid that will pass at a constant speed per unit of time.

Utility network performance is often influenced by factors. The efficiency of the circuit depends on 4 circumstances:

- Throughput and heat dissipation. The characteristic depends on the amount of water in the system.

- Pressure. The parameter in the heating network is associated with temperature and speed.

- Heat loss. At the joints and on the bends there will be a decrease in performance.

- Noise. The faster the fluid moves, the louder the sound.

In a heating system, with a constant flow of coolant and a decrease in diameter, the rate of water movement increases. On lines with a small cross-section, the fluid velocity will increase. Due to the low pressure in large structures, the flow rate is reduced.

Heat pipe diameter Source mastergrad.com

If the diameter of the pipes for heating a private house is too large, then the power of the pump built into the boiler will not be enough to move it. In a large system there will be a lot of coolant, so the equipment will not be able to cope with the movement of such a volume of liquid. Heating excess water will require spending more energy and time, which reduces the efficiency of the network and increases losses. As moisture passes through all rooms, it cools quickly.

The overall section is prohibited from being used in systems with natural circulation. When the speed is reduced, there is a risk of stopping and boiling the liquid in the heating boiler. With a small diameter, moisture can rupture the utility network.

What is affected by the size of parts Source ekaterinburg.kassot.com

When the speed decreases to 0.25 m/sec, air pockets often appear in the pipes. If the flow speed is more than 1.5 m/sec, then noise appears in the heating system. If the background noise standards are constantly exceeded, the inhabitants of the cottage will find it uncomfortable to live.

Installation of heating devices Source realstroyservis24.ru

Heating manifold calculation

To ensure balance and stable operation of the heating system, all its elements must match each other in their throughput. The latter depends on the correctly selected pipe cross-section.

The reservoir calculation is based on this principle. It must have a cross-sectional value equal to or permissibly larger than the sum of the cross-sectional areas of all outlet branches. The cross-sectional size of the prefabricated comb must be no less than the sum of the areas of the supply pipelines.

This condition is described by this formula:

S = S, + S,, + S,,, + … + Sn

Where:

- S is the cross-sectional area of the collector or comb;

- S, ... - Sn - cross-sectional areas of outgoing or incoming branches.

Formula for calculating cross-sectional area

The basis is the formula for calculating the area of a circle, and in this case, the cross-section of the collector (comb). The sum of the cross-sectional areas of the outgoing pipes gives the desired result - the size of the heating collector.

Scall = π × Dcall²/4, then the calculation formula takes the form:

π × Dcol²/4 = π × d,²/4 + π × d,,²/4 + π × d,,,²/4 + …+ π × dn²/4,

Where:

- Dcol — collector diameter;

- π—pi number;

- d, — dn – internal diameters of outlet branches.

To simplify the formula, you need to reduce the number pi and take everything to the square root:

Dcall = 2 × √ (d,²/4 + d,,²/4 + d,,,²/4 +…+dn²/4).

Using this formula, you can calculate a reservoir of any complexity and configuration. If all outgoing heating branches have the same diameter, the formula takes the following form:

Dcall = 2 × √ (dtotal²/4 × N),

Where:

- N is the number of pipes leaving the comb;

- dtotal – diameter of each outlet pipe.

If the calculation results in a fractional number, it should be rounded up. This is necessary to avoid narrowing the cross-section of the collector and reducing the power of the system.

Additional requirements for collector design

When calculating all parameters of the collector, two conditions must be met: the distance between the input and output groups of branches is equal to six diameters, and the heating circuit outlets are three sizes apart from each other.

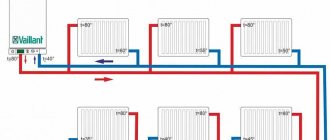

Scheme for connecting the collector to the cottage heating system.

Types of pipes

The selection of the diameter of the heating pipe depends on the material from which the elements are made. The parameters affect not only the cross-sectional dimensions, but also the installation method, the cost of the project and possible heat loss. For heating systems, 4 popular types are used.

Steel

Metal pipes when creating utility networks are an inexpensive and practical option, which have high thermal conductivity and a maximum pressure of up to 30 atmospheres. With proper use, the structures will last 20-30 years. The raw material has no temperature restrictions, so it is often used in a steam system at 100-130 C.

Due to cost and resistance to expansion, property owners often choose carbon steel. Corrosion is the main disadvantage of metal models. During oxidative processes, roughness appears on the surface of the walls, on which deposits accumulate. As plaque grows, the passage for water decreases and the thermal conductivity of the product decreases. When the walls become thinner due to rust, breakouts form. The problem can be minimized by using high-quality coolant in the system and regular flushing of pipes.

Carbon models Source x-teplo.ru

Galvanized steel is a little less capricious. The coating protects the metal from corrosion, thereby increasing the service life of the utility network. The models can withstand loads during water hammer and function perfectly in high temperature conditions.

Stainless steel pipes are superior in durability to galvanized and carbon types. A properly installed structure is inert to aggressive coolant, therefore it is not afraid of corrosion and will last more than 30 years. Elements made by seamless welding are suitable for the heating circuit.

Stainless steel options Source ovknn.ru

The disadvantage of all steel pipes is the weight and complexity of installation. Structures do not bend without special equipment, so at bends it is necessary to use additional parts that reduce the efficiency of the utility network. Now there are options in the form of corrugation, but they are also unstable to the aggressive environment of coolants.

Copper

The maximum operating temperature is 200-250 C, pressure is more than 30 atmospheres. If installed correctly, the heating system will last 90-100 years. The metal has high resistance to corrosion and freezing. According to production technology, copper pipes are divided into 2 types:

- Unannealed. Very strong material will not crack under pressure up to 40 atmospheres.

- Annealed. After heat treatment (annealing), the products become elastic and flexible, while their strength decreases.

Compared to steel, copper has a high density, so the pipes have thin walls and are light in weight. Due to good thermal conductivity, the circuit heats up quickly and evenly. Thanks to the flat surface, the circulating fluid has minimal resistance. There are no growths on the internal partitions, which eliminates the appearance of blockages and a decrease in efficiency.

Heating solution made of metal Source otoplenie-doma.in.ua

Copper pipes are not compatible with other metals. Upon contact with steel, aluminum or cast iron, chemical processes begin in the liquid and gas is formed. The utility network must provide bleed valves for accumulations. Additional parts should be made of copper or brass, radiators should be made of stainless steel.

In a heating system with copper pipes, a well-purified coolant is used. Solid debris can damage soft metal. Additionally, a mechanical cleaning filter is included in the network. The material has high electrical conductivity, so the circuit must be grounded.

Metal structures for a cottage Source kenoll.ru

Polymer

The maximum temperature of the coolant varies between 90-95 C. The structure will withstand 130 C for a short time, but with prolonged contact the polymer pipes are deformed. If the operating rules are followed, they will last up to 30 years. When connected to heating, the circuit is resistant to pressure surges.

Due to the plasticity of the material, pipes are easy to lay without cutting and without additional connections. For welding, a special apparatus is used that heats the parts. The soldering points in the finished structure are not visible to the naked eye.

Plastic models for a private home Source teplomir.in.ua

Plastic is not demanding on the quality of the liquid in the heating system. The raw material does not enter into a chemical reaction, therefore it does not rust or be destroyed by corrosion. Ideally smooth walls do not reduce the speed of the coolant and are not covered with plaque.

Reinforced polymer pipes are used for heating, which can be identified by markings on the surface (PPR-FR-PPR, PPR-GR-PPR). The reinforcing material is fiberglass or aluminum.

Heating solution Source oboiman.ru

Practical recommendations

The wrong choice of product diameters is fraught with many troubles: leaks (due to hydrodynamic shocks or excess pressure in the line), increased consumption of electricity (fuel) due to low efficiency of the system, and a number of others. Therefore, you should not install it according to the principle “like a neighbor (godfather, brother-in-law).”

If the circuit consists of dissimilar pipes, then special calculations will have to be made for each section (line) of the route. Separately - for plastic, metal (steel, copper), apply different coefficients and so on.

Only a specialist can solve such a problem. In such situations, you should not do the calculations yourself, as the error can be quite significant. The services of a professional will cost much less than the subsequent alteration of communications, and even during the heating season.

All devices (expansion tank, battery, etc.) of the circuit are connected using pipes of the same cross-section.

To avoid the formation of air jams (in case of some errors in the calculations), so-called air vents should be installed on each line.

What diameters are there?

In the technical parameters of heating pipes, different types of sections are used. When taking into account the mounting structures and the occupied area, take the outer diameter with the walls. Internal characteristics indicate the size of the gaps, therefore they are suitable when calculating network throughput. The conditional version is an averaging to the larger side of the space inside.

In stores, pipes are marked by their outer cross-section, often in inches (25.4 mm). Internal parameters vary depending on the wall thickness, material and purpose of the part. The external characteristics of steel seam models are 3-4% thicker than those of polymer and seamless structures. Copper types are the thinnest, 1-2 mm smaller than others.

Analysis of popular types Source alchevsk.ua

The size of the heating pipes affects the tasks that the element must perform. Popular diameter parameters range from 16 to 40 mm:

- 16. Used to connect one or two batteries.

- 20. Suitable for installing 1 radiator or a group of up to 5 pieces. The total maximum power is 7 kW.

- 25. Models are used for installing heating structures with dead-end wiring diagrams.

- 32. Used for arranging the utility network of an entire floor or cottage, with a total capacity of up to 19 kW.

- 40. Suitable for 20 batteries, up to 30 kW.

The choice of cross-section of heating pipes determines the throughput capabilities of the system, hydraulic and heat losses. The bulk coolant heats up quickly, and the small size provides better resistance and low noise. Elements of small diameter are cheaper than large ones. Models that are too compact create increased load on the reinforcement, which leads to gusts.

Finding relevant data

As for finding the optimal reference data, almost all websites of manufacturers of heating system components provide this information. In cases where suitable values have not been found, there is a special system for selecting diameters. This technique is based on calculations, and not on average patterns based on processing data on a huge number of heating systems. Calculation of the coolant by pipe cross-section was developed by plumbers with practical experience in installation work, and is used for arranging small circuits inside homes.

In the vast majority of cases, heating boilers are equipped with two sizes of supply and return pipes: ¾ and ½ inches. This size is taken as the basis for wiring up to the first branch. In the future, each new branch serves as a reason to reduce the diameter by one position. This method allows you to calculate the cross-section of pipes in an apartment. We are talking about small systems with 3-8 radiators. Typically such circuits consist of two or three lines with 1-2 batteries. Small private cottages can be calculated in a similar way. If there are two or more floors, you have to use reference data.

Types of coolant movement

The speed of movement of the hot water flow in the pipes is one of the important parameters that allows you to calculate the diameter of the parts. The recommended movement ranges from 0.26 to 1.4 m/sec. Already at 1.5, heat transfer decreases and noise in the utility network increases. There are 2 types that you need to understand.

Pipe size options Source prootoplenie.com

Convection

The natural circulation option is suitable for solid fuel boilers. The operating principle is based on physical laws. The density of a cold liquid is less than that of a hot one. Cool moisture flowing down the pipe displaces warm moisture upward. The speed of movement in such networks is 0.2 m/sec.

A small flow of movement during convection circulation causes the formation of air jams and a decrease in the volume of transferred heat. The expansion tank and Mayevsky taps will help solve the problems.

System with convection movement Source aniko-gas.ru

The diameter of the heating parts with convection circulation must match the boiler outlet pipe. The largest starting section is maintained until the first fork. When laying, the size of the pipes is gradually reduced. In the last node, the characteristics of the elements vary between 16-19 mm.

Forced

Circulation in the circuit is carried out using a pump and a manifold, which are included in the design of the boiler (gas, electric). The user can independently control the speed of the coolant. In engineering networks, parameters are maintained within the range of 0.7-1.2 m/sec.

In options with forced circulation, it is advisable to use pipes of small diameter. In a circuit with a small volume, it is faster and easier to heat water, which increases the efficiency of the design. Installing and masking thin parts is much easier than thick counterparts.

Forced circulation in the system Source eco-kotly.ru

The cross-section of networks with forced circulation often depends on the heating connection diagram. The size for radial connection from equipment to pipes is 19 mm, for single-pipe and double-pipe - 25 mm. The parameter is not final and is calculated based on the characteristics of the boiler and cottage.

Examples

Let's look at examples.

Calculation for a two-pipe circuit

Given:

- Two-storey house with an area of 340 m².

- The building material is Inkerman stone (natural limestone), characterized by low thermal conductivity. → House insulation coefficient = 1.

- Wall thickness – 40 cm.

- The windows are plastic, single-chamber.

- Heat loss on the 1st floor – 20 kW; the second - 18 kW.

- Two-pipe circuit with a separate wing on each floor.

- Pipe material is polypropylene.

- Serving temperature - 80⁰C.

- Outlet temperature - 60⁰C.

- Temperature delta - 20⁰C.

- Ceiling height – 3 m.

- Region – Crimea (south).

- The average temperature of the five coldest days of winter is (-12⁰C).

Calculation:

- 340×3=1020 (m³) – volume of the room;

- 20- (-12) = 32 (⁰C) – temperature difference (delta) between indoors and outdoors;

- 1020×1×32/860≈38 (kW) – heating circuit power;

- Determination of the pipe cross-section in the first section from the boiler to the branch. According to the table below, pipes with a cross-section of 50, 63 or 75 mm are suitable for transmitting thermal power of 38 kW. The first option is preferable, because provides the highest speed of movement of the carrier.

- To distribute the media flow to the first and second floors, reference books prescribe pipes with a diameter of 32 mm and 40 mm for powers of 18 and 20 kW, respectively.

- On each floor, the circuit is divided into two mains with an equivalent load of 10 and 9 kW, respectively, and a cross-section of 25 mm.

- As the load decreases due to cooling of the coolant, the diameter of the pipes should be reduced to 20 mm (on the first floor - after the second radiator, on the second - after the third).

- Reverse wiring is carried out in the same sequence.

To calculate using the formula D = √354x(0.86xQ/∆t)/V, we take the carrier speed to be 0.6 m/s. We obtain the following data √354x(0.86×38/20)/0.6≈31 mm. This is the nominal diameter of the pipeline. For implementation in practice, it is necessary to select different pipe diameters in different sections of the pipeline, which on average will be reduced to the calculated data according to the algorithm described in paragraphs 4-7.

Determination of pipe diameter for a single-pipe system with forced circulation

As in the previous case, the calculation is made according to the indicated scheme. The only exception is the action of pumping equipment, which increases the speed of movement of the medium and ensures uniformity of its temperature in the circuit.

- A significant reduction in power (up to 8.5 kW) occurs only on the fourth radiator, where the transition to a diameter of 15 mm is made.

- After the fifth radiator there is a transition to a cross section of 12 mm.

Important! The use of pipes made of a different material will make adjustments to the calculation, because... Each material has a different level of thermal conductivity. It is especially important to take into account the heat loss of a metal pipeline.

Heating systems

To correctly calculate the diameter of the pipes, you need to take into account the wiring diagram. Resistance affects the parameters of heating equipment and the characteristics of parts (section, material). The cottage uses 2 types of heating systems.

Two-pipe

The heating option with a vertical riser for the placement of pipes can be either upper or lower. Two elements are connected to each radiator: for supplying hot moisture and removing cold moisture. Horizontal wiring is:

- dead end;

- parallel;

- radial (collector).

Rabbits sleep

Watching a sleeping rabbit is a real touch! When animals sleep, their faces and ears are in constant motion. It's funny to us, but in fact, this is an important natural feature. Thus, pets pick up various smells and sounds around them, trying to smell a predator.

It is no less funny and interesting to watch their posture in their sleep. For example, when animals are relaxed and satisfied, they sleep on their tummy or side, stretching out their hind legs. Some people like to sit down when they sleep, covering their face with their ears.

Boiler power

In a country house, rooms are heated using gas or electric equipment, less often - solid fuel models. Based on the size of the heated space, the power is calculated. For high-quality home heating you need 0.1 kW of thermal energy per square. Parameters may change due to climatic conditions or gentle regime up to 1.3.

The power of the boiler is affected by the material from which the walls are made and the presence of thermal insulation. Increased thermal conductivity, combined with the thinness of the partitions, increases the heat loss of a country house. Even the most efficient model will not cope with heating the building.

What to look for Source eco-kotly.ru

The quality of heating is affected by the presence of a second circuit in the boiler. When hot water is turned on for domestic needs, the performance in the utility system decreases. Designs with this option should have higher parameters than their single-circuit counterparts.

The boiler power depends on the type of fuel. Gas equipment is considered the most practical. The most expensive are electric, the most inconvenient are solid fuel. Pumps are used to optimize coolant circulation and solve the problem of air locks.

Two-pipe circuit

More equipment is needed to design the wiring of a two-pipe type of heating. Additionally, more financial resources and installation work are required.

In such a scheme, hot water is distributed evenly and at the same time it is possible to easily regulate and customize the functioning of the system.

The coolant is heated by a double-circuit boiler using gas energy.

When installing a two-pipe distribution system, it is necessary to install special self-bleeding valves in the upper positions. In a one-story house, such elements are installed on the very last battery.

Temperature is regulated using thermostats.

It is better to equip large rooms with a two-pipe type of wiring and a circulation pump. With an area of less than 100 sq. m single-pipe type with natural movement of fluid in the system can fully provide heating of the room.

To avoid mistakes, it is recommended to entrust the creation of the project and installation of the heating system to professional plumbers.