For quite some time now, another type of electrical appliance has appeared in apartments - a storage boiler for hot water supply. It has become very popular because it makes it possible not to depend on the whims of utility services. One of the key elements of the boiler piping is the safety valve. If for older models of boilers it had to be purchased separately, now it is included in the mandatory package. Water periodically leaks from it and many users naturally think about a breakdown.

It should be understood that discharging excess water is one of its functions. Therefore, before taking decisive action to dismantle and replace the device, it is necessary to analyze what volumes of water flow out and with what frequency.

Why is a safety valve on a boiler needed?

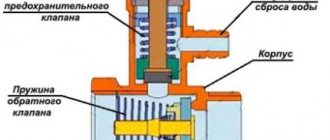

A safety valve device is a direct-acting pipeline version of the valve, which is intended to protect water heating equipment and the pipeline system from mechanical damage under the influence of excess pressure.

The valve element releases excess liquid automatically, and stops the removal of water under conditions of normalization of operating pressure.

Externally, the safety valve device is represented by a brass-plated body. The internal part includes a pair of springs and locking elements.

The starting spring mechanism is located in the inner part of the flow channel. Possessing the function of a check valve, such an element prevents water from flowing back into the pipeline supply system.

When the water pressure increases, the spring device moves away, which ensures the unhindered flow of water into the storage tank. After the tank is completely filled and when the pressure indicators are equalized on both sides, the shut-off device closes the hole, which prevents the backflow of water flow into the main pipeline system.

Safety valve on the water supply to the boiler

The second spring mechanism is located on the outlet part of the device, and the function of such an element is represented by water discharge under conditions of increasing pressure.

In such a situation, the pressure arising in the pipeline is able to overcome the stiffness of the spring, which causes its compression and the opening of the hole for water flow by the shut-off element.

Safety valve installed on the boiler

The use of a safety valve device protects the storage tank from rupture, prevents the reflux of hot water from hot water equipment into the water supply system, smoothes out pressure drops, and ensures the discharge of excess water at critical levels of pressure and temperature conditions. Among other things, the valve drains water during the maintenance and repair of the boiler.

The limit values of water pressure under which the spring mechanism is compressed are established at the stage of manufacturing the valve device and water heating equipment, so the choice of mechanism must be approached very carefully.

Pressure regulator malfunction

The water pressure reducer is designed to adjust the fluid pressure. Stable operation will prevent leaks and damage to plumbing equipment. However, improper operation of the pressure regulator can lead to problems with the boiler. Let's consider two such situations:

- If the fluid inlet pressure is slightly higher than that set by the manufacturer. Some models of flow-through water heating equipment are equipped with a built-in lock: they will not turn on until the pressure returns to normal. In the case of storage devices, the heated liquid will be released from the valve into the sewer system due to the pressure reducer. This will lead to unnecessary waste of water and electricity.

- If the inlet pressure greatly exceeds that indicated in the equipment passport, leaks or breakdowns of not only water heaters, but also other equipment connected to the water supply: dishwashers and washing machines, thermostats are possible.

Is it dripping or flowing?

If water drips from the check valve device during the heating of the boiler equipment, then this situation indicates the normal functioning of the device and the operation of the protective group in normal mode.

During operation of a water heating device, the safety valve must discharge excess liquid if there is an increase in water pressure on the walls of the storage tank as a result of thermal expansion of the liquid. The consequence of water discharge is a noticeable decrease in water pressure inside the tank with heating elements.

Installation diagram of a safety valve for a boiler

To monitor the process of removing excess water, it is necessary to install a regular transparent reinforced plastic pipe on the outlet fitting, the outlet of which is mounted on the sewer system.

The water should not flow in a stream, and the release of droplets should stop immediately after cooling.

If water drips constantly, the problem may be a malfunction of the safety valve device or the liquid is drained due to a worn rubber or silicone seal..

It is imperative to take into account the fact that not all devices are characterized by the presence of a drain for water from boiler equipment, therefore, if necessary, a standard tee tap must be installed.

Purpose

Without exception, all manufacturers of storage water heaters stipulate in the instructions for use a categorical prohibition on operating the device without a safety valve. And the installation instructions describe the installation method in detail. This is due to the ability of water to expand significantly when heated. Since boiler tanks have a certain safety margin, systematic exposure to internal pressure can simply rupture them. This can result in very dangerous injuries as well as significant financial costs. If 50-100 liters of hot water flood several lower apartments.

The standard set of modern water heater models includes a safety valve. It is designed to operate at a pressure that is limiting for a particular boiler tank. When purchasing a new device, you must take this indicator into account and under no circumstances overestimate it.

Water dripping at night

It is very important to distinguish between natural water discharge and failure of components. When the water heating equipment is connected to the electrical network, and in the absence of its operation, a small amount of it should flow through the fitting part of the valve device, including at night.

When the appliance operates in an average load mode, including regular washing of dishes and cooking, water flows out of the valve device periodically, in a volume slightly higher than the usual amount. Constant leakage, including at night, may indicate device failure.

Water is leaking from the boiler

The main reason for dripping water at night is that the fitting or the inside of the fitting is clogged with scale or debris. The spring mechanism that opens the valve is not able to close it at the right time, so water flows out even when the water heating equipment is turned off. An equally common cause of water leakage at night is too high pressure in the water supply system. In order to check the working water pressure, it is measured in the main water supply.

The simplest valve devices belonging to the first “protective group” are easier not to clean, but to be completely replaced with a similar device, which is due to the lack of maintainability and a very affordable price.

Main tasks

A safety valve is required for several purposes:

- Dumping excess water from the tank. When the boiler is turned on to maximum heating mode, excess pressure is formed inside, which the safety valve must neutralize. Therefore, sometimes water flows from it.

- Compensation for water hammer. Although this is not a common occurrence in the water supply system, it can seriously damage the boiler tank;

- Leaks are recorded mainly at night. At this time, the intensity of water consumption is reduced to a minimum, and the pressure in the system remains at the same level. This is why the impact on the water heater tank increases significantly;

- The only drawback of nightly discharge of excess water is noise. It can be easily eliminated by putting a plastic tube on the faucet and leading it into the sewer hole.

How much water should the valve drain?

A small amount of water should be dripped from the valve device. The total volume of liquid removed directly depends on the pressure level in the water supply system, as well as the temperature regime used for heating and the volume of the water heating equipment tank. On average, the amount of water released can be about 1.5-3.0% per day.

There are several ways to drain water from a water heater. For detailed instructions, see our website.

Read all about the pros and cons of hygienic showers for toilets here.

You will find options for finishing a bathroom with plastic panels in this topic.

Device and principle of operation

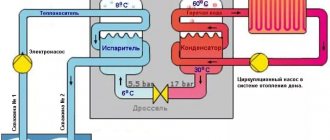

In general, we can talk about three types of devices capable of storing and heating water:

- electric water heaters;

- indirect heating boilers;

- gas water storage tanks.

All of these devices have a similar design and operate on the same principle. They differ only in the heat sources used to heat the water. In this case, the role of a heater can be performed by: a heating element, a coil with a coolant supplied to it (for example, a boiler), or a gas burner. Structurally, all boilers have the form of a wall-mounted tank, the internal surfaces of which are covered with heat-insulating material. Cold water enters it through a pipe located in the lower part, and the heated liquid is taken from the upper part.

The heaters in all boilers are located in the lower part. The water in the tank is heated to the required temperature and then used by the owner for its intended purpose. To maintain and, if necessary, adjust the required temperature regime, a special thermostat is built

. In addition, the boiler is equipped with a temperature meter, with which the user can control the degree of water heating, and a safety valve that prevents the unnecessary leakage of liquid.

What to do?

There may be several reasons for excessive water pouring out through the fitting of the valve device, and the solution to the problem can vary greatly in complexity and implementation technology:

- if an element loses its protective qualities due to wear, including spring stretching and cracking of the poppet device, the fittings are replaced;

- if the valve breaks down as a result of water hammer with a sharp increase in pressure in the water supply system, it is also advisable to replace the element with a new one with similar indicators;

- if the fitting or the internal part of the system is clogged with debris and scale, it is advisable to clean it, partially or completely replace it;

- if the leak is caused by initially incorrect installation of the protective unit, then it is necessary to carry out diagnostics of the safety valves, including measuring the relief pressure using a pressure gauge, followed by replacing the valve if necessary;

- if excessive leakage of water and incorrect operation of the fittings of the water heating device are caused by non-compliance with installation requirements, then the protective unit should be moved to the correct location.

After the correct relocation of the protective fittings or complete replacement of the safety assembly has been carried out, the excess flow of water should stop. The opposite effect is observed when the nominal pressure level declared by the manufacturer does not correspond to real indicators.

No less often, the cause of leakage is an incorrectly selected or too high temperature mode for heating water, as well as excess water pressure inside the system, so the purchased water heating equipment must fully comply with all requirements.

Correctly installed boiler

It is very important to remember that the operation of water heating equipment without accessories such as a safety valve device is strictly prohibited. When installing an alternative hot water supply system in conditions of excess pressure in the main water supply, a special reducer must be installed at the inlet, capable of regulating such parameters.

Do you want to save money on boiler installation? How to connect a water heater to the water supply in an apartment - you will find a connection diagram in the article.

We will consider types of plastic panels for the bathroom and repair options in this material.

A prerequisite for comfortable and safe operation of water heating equipment equipped with a safety valve device is the supply of a flexible transparent hose to the drainage hole, the second end of which is discharged into the sewer system or a container specially installed to collect the released water.

Self-diagnosis

You can check the serviceability of the safety unit yourself. To do this you need:

- Connect the boiler plug to the socket.

- Fill the storage tank.

- Shut off the water supply.

- Turn on the water heater using the start button.

- Wait until heating finishes.

- Check the condition of the valve.

You can conduct a self-diagnosis.

If water drips slowly from the drain, then the protective device is working properly. If not, or if the liquid flows in a stream, then most likely you will need to replace it or check the thermostat settings.

Choosing the right model

Usually a safety device of the required model is included with the boiler. But if it is not there, it is faulty, or you replace it after some time of using the water heater, then you will have to choose the right one yourself.

The main parameter after the thread (the size is very easy to select, usually 1/2 inch) is the working pressure. The correct and safe operation of the boiler will depend on the correct selection of this parameter. The required pressure is indicated in the operating instructions that come with each water heater.

There are two problems that may arise as a result of incorrect selection of a safety device:

• constant leakage from the device due to the choice of a lower operating pressure than necessary;

• the device will not work at all if a value greater than necessary is selected, such a safety valve will not save in the event of an emergency;

Repair work

To diagnose and fix the breakdown, you will need to stock up on a set of tools and some consumables.

To work you will need:

- adjustable wrench, plumbing pliers, screwdriver;

- scissors;

- awl;

- indicator;

- FUM tape or tow;

- flexible hoses for easy draining of water from the tank;

- lemon acid;

- box for collecting small parts;

- rags.

Measures should be taken to protect limbs and vision. It is better to carry out repairs wearing protective glasses and gloves.

Valve repair is usually combined with scheduled boiler cleaning, so as not to waste time disassembling the device

First you need to make sure that the cause of the leak is the check valve. It is enough to check whether its body is dry or not. If there is no moisture on it, then you need to start disassembling. This event can be timed to coincide with cleaning the heater and the tank from scale. In any case, the effort will not be wasted.

Dismantling should be carried out in the following sequence:

- Turn off the water. If a walk-through tap is installed in front of the mixer, it is better to turn it so as not to turn off the entire apartment.

- Disconnect the device from electricity. Remove the cover and disconnect the wires from the terminals.

- Unscrew the underwater pipes from the boiler. Remove the ball valve and safety valve.

- Screw flexible hoses to the nozzles, the water will flow in the desired direction.

- If there is a pressure gauge, check the operating water pressure. Ideally, it should be 1.5-2 atm.

- While the liquid is draining, remove any remaining FUM tape and inspect the parts for cracks and dents.

- Clean the tank and heating element from limescale and scale. Rinse the inside of the container using a shower head.

Repair work

To diagnose and fix the breakdown, you will need to stock up on a set of tools and some consumables.

To work you will need:

- adjustable wrench, plumbing pliers, screwdriver;

- scissors;

- awl;

- indicator;

- FUM tape or tow;

- flexible hoses for easy draining of water from the tank;

- lemon acid;

- box for collecting small parts;

- rags.

Measures should be taken to protect limbs and vision. It is better to carry out repairs wearing protective glasses and gloves.

Valve repair is usually combined with scheduled boiler cleaning, so as not to waste time disassembling the device

First you need to make sure that the cause of the leak is the check valve. It is enough to check whether its body is dry or not. If there is no moisture on it, then you need to start disassembling. This event can be timed to coincide with cleaning the heater and the tank from scale. In any case, the effort will not be wasted.

Dismantling should be carried out in the following sequence:

- Turn off the water. If a walk-through tap is installed in front of the mixer, it is better to turn it so as not to turn off the entire apartment.

- Disconnect the device from electricity. Remove the cover and disconnect the wires from the terminals.

- Unscrew the underwater pipes from the boiler. Remove the ball valve and safety valve.

- Screw flexible hoses to the nozzles, the water will flow in the desired direction.

- If there is a pressure gauge, check the operating water pressure. Ideally, it should be 1.5-2 atm.

- While the liquid is draining, remove any remaining FUM tape and inspect the parts for cracks and dents.

- Clean the tank and heating element from limescale and scale. Rinse the inside of the container using a shower head.

Installation instructions

Installing a drain valve is a mandatory step in piping a water heater. The minimum set of required parts: polypropylene pipe and safety valve. But there is another installation method, where in addition to the elements described above, there is an American valve, a drain valve and a tee. In addition, PP fittings will be needed to move the pipeline to the wall.

A complex node for organizing a security group is not used all the time. Some experts argue that one safety valve is enough. This is the basic minimum for proper installation of a water heater.

If tees or other adapters are not used, the fuse is attached directly to the water heater pipe. It can be located behind the body or lowered a few centimeters, which is much more convenient for connection.

Then you need to organize the drainage of water using a hole in the valve; for this, use a plastic elastic tube of the required diameter. One end of this tube is put on the fuse pipe, the other is passed into the tee of the sewer system.

Some people put a drainage tube into a jar or bucket - this should not be done. If a bucket can save you, it will only be from being dug under. In an emergency, the amount of water that moves through the tube increases in volume, and a regular jar is simply not enough. The only correct solution is to drain the drain into a sewer pipe by inserting it into a separate inlet or tee.

How to check a water heater thermostat

To check the serviceability of the thermostat, you need to measure its resistance using a household ohmmeter or multimeter. To do this, you will need to remove the thermometer and connect the tester to its contacts, setting the handle on the device to the maximum value.

This thermostat will need to be replaced with a new one. You can choose a new thermostat based on the brand of water heater, tank volume, size and power of the heating element.

In addition, when choosing, you will need to consider:

- The amount of current for which the thermostat is designed;

- Device functions (adjustment, protection);

- Type of thermostat (rod, capillary, electronic).

When choosing a regulator in a store, you should show the consultant the passport from the boiler. This will allow you to choose the most suitable device.

Main causes of leaks

There are several reasons why water drips from the boiler:

- manufacturing defect;

- poor-quality installation of the device;

- the anode is destroyed;

- the heating element is faulty;

- the valve has deteriorated;

- the gasket is worn out;

- blockage

For repairs you will need:

- adjustable wrench (large);

- Screwdriver Set;

- tubular keys;

- a set of simple keys;

- drain hose;

- rags;

- pad;

- cutter.

Knowing how to fix a leak in the boiler yourself, we get to work. In order to determine why your water heater is leaking, you must:

Turn off power.

- Shut off the water supply

- Wait several hours for the water in the boiler to cool down.

- Remove the heater.

- Conduct an external inspection. If he has not identified the cause of estrus, proceed to analysis.

- Remove the protective cover using a screwdriver. You'll have to use force.

- Drain the water.

- Check the inlet and outlet pipes. Touch the insulating gasket. If dry, proceed to the next steps.

- Check valve. If it is not damaged during installation, the search for the cause of the leak continues.

- If the spiral or blockage is to blame, you will have to open the thermos.

- Remove the wires after taking a photo of the connections.

- Unscrew the fastening elements of the heating element and thermostat.

- Inspect the heating element.

- Clean the inside of the tank from dirt.

If it is not clear why the water heater is leaking, its use is stopped and the device is sent in for repair.

Possible manufacturing defect. If there was an error during installation, you will have to correct the problem at your own expense.