What types of shut-off valves for heating are there - types, characteristics

When installing heating in private households, multi-apartment buildings and to organize the operation of central heat pipeline systems, shut-off and control valves for heating radiators and systems are used. It is installed in the circuit, which ensures the highest heating efficiency and its economy.

Purpose and selection of shut-off valves

For heat supply systems, this fittings are used to control the supply of hot coolant and turn off the power to the heating circuit. Basically, a shut-off valve is installed on a heating device in areas where heating devices are connected with pipelines.

A similar solution, in addition to its practical positive qualities, has functional benefits. After closing the shut-off valve of the battery, the home repairman will have the opportunity to repair it without stopping the functioning of the entire heating structure.

At this time, shut-off valves for heating are offered in a wide range on the market in our country, and among the very commonly used products are these devices:

- shut-off valves;

- valves;

- needle valves;

- ball valves.

All of them are made from strong metals that are resistant to corrosion and high temperatures. Shut-off valves protect the heating circuit from the possibility of a dangerous situation, increases the reliability of the heating network, thus helping to minimize the bad consequences resulting from a malfunction of a separate heating device.

Air vents

Air vents perform the task of freeing equipment from air that impedes normal circulation in the network. There are mainly 2 types of these devices:

- Automatic;

- The Mayevsky tap (valve) is manual.

Automatic air vent

The float-based automatic air vent device allows air to be discharged from the system in an independent mode. It is recommended to install them at the highest points of the complex - places where air is most likely to accumulate. They often serve as a standard element of the boiler safety group and have an external thread for connection.

Types of Mayevsky cranes

The Mayevsky faucet is based on a needle valve that opens manually. Most often, these devices are installed on heating devices for periodic release of air.

Ball valves

This product refers to shut-off valves for devices for heating a room. It is designed to regulate the flow of liquid, which is used as a coolant. A valve with a round hole consists of a union nut, an air release device, which is designed to bleed air from the system, and a plug. The product has an internal thread.

When purchasing this type of fittings, you need to look at the material of manufacture and the presence of o-rings that increase the service life of this element in the circuit. As practice shows, brass taps themselves are distinguished by their very high wear resistance and anti-corrosion resistance.

Gate valve

Heating system valve

Valves are designed mainly to completely shut off pipelines; due to the characteristics of the device, flow adjustment is practically not carried out. The actuator element in the valve is a flat oval or wedge-shaped element, which, when the stem is lowered along the thread, blocks the flow of water. The element can be single or double.

The valves are made from carbon steel, cast iron, and stainless steel. The devices are connected via flange connections. Valves usually have large diameters and are most often used on main heating pipelines. The nominal pressure and temperature values are marked on the device body.

Shut-off valves

This type of shut-off valve is used to create the possibility of replacing a heating device without draining liquid for operation from the heat supply system. Taking into account the design features, straight and angular variations of such valves are distinguished.

Certain products are equipped with a drain mechanism prepared for a smooth decrease in pressure in the heating circuit. Shut-off valves are distinguished by the presence of a hose nozzle, which allows the installation process to be carried out as hassle-free and easy as possible.

Needle valves

The functions that a needle tap must perform are distinguished by their diversity. According to the structural device, such a product usually has a shut-off, regulating and balancing purpose.

The needle valve in heating systems is used for heating devices. Due to its presence, a smooth shut-off of the flow is ensured and it is possible to avoid the consequences of water hammer, which have a negative impact on the entire heat supply structure.

Unlike a ball valve, which has two positions, a needle valve can operate in three modes:

These fittings perform exclusively a locking function. Due to the design features of the valve, it is usually located exclusively in two positions, since the mechanism has a closing component located perpendicular to the flow of the coolant. If the valve component is in an open position, the heated liquid enters the circuit, and when it is closed, it does not allow it to circulate.

The valve has a number of special characteristics:

- Provides low hydraulic resistance in the circuit.

- It has a suitable diameter size inside, similar to the cross-section of the pipeline.

- It's easy to install.

- It stands out for its great reliability.

Heat consumption for ventilation

To find out how much heat a private house loses as a whole, you need to add up the losses of all its rooms. But that’s not all, because we must also take into account the heating of the ventilation air, which is also provided by the heating system. In order not to go into the jungle of complex calculations, it is proposed to find out this heat consumption using a simple formula:

Qair = cm (tв – tн), where:

- Qair – required amount of heat for ventilation, W;

- m – amount of air by mass, defined as the internal volume of the building multiplied by the density of the air mixture, kg;

- (tв – tн) – as in the previous formula;

- с – heat capacity of air masses, is taken equal to 0.28 W / (kg ºС).

To determine the heat demand for the entire building, it remains to add the value of QTP for the house as a whole with the value of Qair. The boiler power is taken with a reserve for the optimal operating mode, that is, with a coefficient of 1.3. Here you need to take into account an important point: if you plan to use a heat generator not only for heating, but also for heating water for domestic hot water supply, then the power reserve must be increased. The boiler must operate effectively in 2 directions at once, and therefore the safety factor must be taken at least 1.5.

Shut-off and control valves

Apart from the locking function, which helps prevent dangerous situations in the circuit, the fittings usually perform the task of regulating the flow of coolant. Control valves for heating radiators and systems are used to smoothly adjust the temperature of the heated liquid, in order to stabilize the pressure, and also to control the direction of movement of the working environment.

These devices are demonstrated by the following types of valves: balancing; reverse; rechargeable; thermo-; waste; bypass

Balancing valve

During the installation of heating systems, it is used to regulate the operation of several hydraulic circuits. Installing a balancing valve makes it possible to increase the efficiency of the heating structure, as it helps control the possible volume of coolant consumed.

Properly installed, this type of fittings, whose operating principle is to distribute the heated liquid evenly across all segments of the heat supply system, can work in very difficult conditions. This device can withstand significant pressure drops in the circuits and high speeds of movement of the coolant through pipelines.

The balancing valve, the price of which for direct-acting modifications is not small, consists of the following important elements:

- housing made of steel, aluminum alloy or brass;

- pipe section;

- position lock;

- membrane septum;

- measuring diaphragm;

- shutter indicator.

Check Valve

The use of this type of control valve makes it possible to prevent water hammer and thereby helps to increase the reliability of the entire heating structure. The valve prevents reverse circulation of the heated liquid through the system. In order for the device to be acceptable in combination with the circuit, it must be selected taking into account the diameter inside.

The main element of a check-type valve is a spring, which serves to hold the rod and closes it if a dangerous situation occurs in the circuit.

Make-up valve

To ensure effective circulation of the operating environment in the system, there must be a suitable volume of coolant in the circuit - water, antifreeze, etc. Thanks to this, the make-up device is one of the necessary elements of every heating structure.

This type of valve makes it possible to compensate for fluid losses resulting from leaks in heaters and the use of bleed valves and air vents.

The main purpose of this recharge element is to control the amount of coolant in the circuit, and if necessary, it should replenish its losses. It is best to choose an automatic device equipped with a reduction mechanism and a membrane fabric, which is located under the pressure of the working environment.

If the pressure in the circuit is reduced, the liquid does not affect the membrane tissue, the rod pushed by the spring falls, opening a gap in the seat. Eventually, the circuit begins to be fed from the water supply pipe until pressure is established in the system.

Types of shutters

Types of pipeline valves can be classified in different ways; The easiest way is to rely on differences in the configuration of the locking unit. The classic option in the post-Soviet space is the wedge valve. Another name for the mechanism is a parallel (double-disk) valve with the following device:

- There is a rod (spindle) located vertically, which is driven by rotation of the steering wheel.

- At the bottom of the rod there is a paired shut-off element (cheeks, plates) that shuts off the water. The cheeks are made of cast iron and have a round shape, and are equipped with brass mirrors along the edge. The same mirrors are located in the housing.

- When we lower the rod (to block the movement of fluid), the wedge located in the lower part of the body rests against the rod, pushes the cheeks apart, and they are pressed tightly against the mirrors in the body.

- The tightness of the valve is ensured only by tightly rubbing the metal mirrors on the cheeks to the mirrors on the body.

Sectional view of a wedge valve Source santehkomplekt.ua

Thermal valve

It is considered the most effective control valve for heating radiators. This device increases the practicality of the circuit and makes the heating process simple, good, and most importantly, healthy. The thermal valve can be mechanical or automated. Products of the first type consist of thermal and valve.

Automated models have a more complex design; they consist of similar elements:

- temperature sensor - built-in or remote;

- programmer;

- automatic control systems.

An automated type mechanism is designed to regulate the temperature regime in the circuit in accordance with the settings that are pre-set by heat energy consumers. This device is sold at a high price, but it is fully justified, since with its help you can maximize the functioning of the heat supply system.

Exotic

Several other devices are used relatively rarely and are little known to the general public.

- The thermoelectric radiator valve actuator can be used with any throttling valves. It is an externally controlled servo drive powered by batteries or AC power.

The photo shows a closed thermoelectric valve.

- The internal spring valve for the radiator is a stainless steel valve with a spring that closes the manifold of the first section when the passage plug is screwed into it. The purpose of its installation is to limit circulation through the lower collector of the device, ensuring its uniform heating throughout the entire volume. (See also the article Manifold pipe routing: features.)

The damper restricts circulation through the lower manifold.

The valve for the lower connection of the radiator is equipped with a thermostatic head.

Relief valve

Exceeding the normal pressure in the system leads to dangerous situations, damage to the integrity of the circuit and, in some cases, to an explosion of the heating boiler. Due to this, when installing heating systems, a pressure relief valve is installed.

When choosing a location for such a device, it is necessary to take into account that very often an increase in pressure during overheating of the liquid occurs in the boiler. Even very modern units equipped with a gas valve are not completely protected from dangerous situations.

Experts advise placing the relief valve very close to the heating boiler and on the supply pipeline. When choosing a model of this device, you need to pay attention to additional options such as the presence of a device for determining the pressure value and a Mayevsky valve. Valves with them are more practical and reliable.

What is needed for installation

Installation of heating radiators of any type requires devices and consumables. The set of necessary materials is almost the same, but for cast iron batteries, for example, the plugs are large, and they do not install a Mayevsky valve, but instead, somewhere at the highest point of the system, they install an automatic air vent. But the installation of aluminum and bimetallic heating radiators is absolutely the same.

Steel panel ones also have some differences, but only in terms of hanging - they come with brackets, and on the back panel there are special arms cast from metal, with which the heater clings to the hooks of the brackets.

These are the arms that hook the hooks

Mayevsky crane or automatic air vent

This is a small device for releasing air that may accumulate in the radiator. Placed on the free upper outlet (collector). It must be on every heating device when installing aluminum and bimetallic radiators. The size of this device is significantly smaller than the diameter of the manifold, so you will also need an adapter, but Mayevsky taps usually come complete with adapters, you just need to know the diameter of the manifold (connection dimensions).

Mayevsky crane and method of its installation

In addition to the Mayevsky crane, there are also automatic air vents. They can also be installed on radiators, but they are slightly larger in size and for some reason are only available in a brass or nickel-plated case. Not in white enamel. In general, the picture is unattractive and, although they deflate automatically, they are rarely installed.

This is what a compact automatic air vent looks like (there are more bulky models)

Stub

The side-connected radiator has four outputs. Two of them are occupied by the supply and return pipelines, on the third they install a Mayevsky valve. The fourth entrance is closed with a plug. It, like most modern batteries, is most often painted with white enamel and does not spoil the appearance at all.

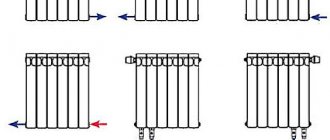

Where to install the Mayevsky plug and tap for different connection methods

Shut-off valves

You will need two more ball valves or shut-off valves that can be adjusted. They are placed on each battery at the input and output. If these are ordinary ball valves, they are needed so that, if necessary, you can turn off the radiator and remove it (emergency repairs, replacement during the heating season). In this case, even if something happens to the radiator, you will cut it off, and the rest of the system will work. The advantage of this solution is the low price of ball valves, the disadvantage is the impossibility of adjusting heat transfer.

Radiator taps

Almost the same tasks, but with the ability to change the intensity of the coolant flow, are performed by shut-off control valves. They are more expensive, but they also allow you to adjust the heat transfer (make it less), and they look better externally; they are available in straight and angular versions, so the piping itself is more accurate.

If desired, you can install a thermostat on the coolant supply after the ball valve. This is a relatively small device that allows you to change the heat output of a heating device. If the radiator does not heat well, you cannot install them - it will be even worse, since they can only reduce the flow. There are different thermostats for batteries - automatic electronic ones, but more often they use the simplest one - mechanical.

Related materials and tools

You will also need hooks or brackets for hanging on walls. Their number depends on the size of the batteries:

- if there are no more than 8 sections or the length of the radiator is no more than 1.2 m, two mounting points on top and one on the bottom are sufficient;

- For every next 50 cm or 5-6 sections, add one fastener at the top and bottom.

You also need fum tape or linen winding and plumbing paste to seal the joints. You will also need a drill with drills, a level (preferably a level, but a regular bubble one will do), and a number of dowels. You will also need equipment for connecting pipes and fittings, but it depends on the type of pipes. That's all.

https://youtube.com/watch?v=nnQz2VA7C_M

Bypass valve

This type of control devices is used to normalize the difference in pressure between the supply and return pipes. The use of a bypass valve in heating systems in which thermal valves are connected to the circuits is considered mandatory, since they create pressure differences in specific areas and thereby reduce the efficiency of heating.

Shut-off control valves for heating devices and heating circuits on the market today are provided with a large selection of valves of any design. It is necessary to purchase certain devices in accordance with the design documentation for the improvement of the heating system, which is calculated and created for a specific home or building, depending on its purpose.

This approach can be explained by the fact that different types of pipes and heating devices are installed in each building. Taking them into account, the choice of fittings is made.

Types of shut-off and control valves

To begin with, let us say that in this topic we are considering only the details of heating circuits of private apartments and houses, since in general the range of fittings used is very wide. It will be difficult to review it in one publication.

Types of heating taps

So, shut-off and control valves are parts of a system designed to control the flow of a coolant by partially or completely blocking the flow area of pipelines.

By and large, all flow control parts installed in heating systems of private houses can be divided into the following groups:

- constipation;

- shut-off and regulating;

- mixing and regulating.

You should not mix concepts such as shut-off and control valves and control and measuring instruments (thermometers, devices for determining pressure). Also, various safety and air vent valves, filters - non-flushing filters and metering devices have nothing to do with managing the coolant.

Shut-off valves

A fairly popular example of a shut-off device is a simple tap with a round hole. It has only 2 working positions: “open” or “closed”. Thanks to its own design, when open, the valve allows a flow of liquid through itself without changing its direction or flow area. It is a brass body with a built-in spherical element with a hole, rotating with a rod and handle, as shown in the diagram:

Section of shut-off valves

The polished steel ball is sealed with polymer and is capable of rotating 90?. As can be seen from the diagram, the design of the control valve also allows the flow to be closed not completely, but this control method is not used. Firstly, it is excessively rough, and secondly, the hole of the ball, rotated at some angle, provides high hydraulic resistance to the flow of fluid.

Stopcock with filter

For reference. Modern ball valves are produced in universal versions: with a built-in drain fitting, an air vent, a strainer and even an electric drive. Moreover, there are three-way ball valves that can switch flows in different directions. The last 2 variations are used very rarely in individual systems.

Three way valve

In traditional heating systems, ball valves are used in the following places:

- disconnecting heating devices from the system for the purpose of their periodic maintenance;

- to turn off branches and risers;

- blocking the flow to remove or repair heating and pumping equipment, expansion tanks;

- for emptying and refilling the system.

Electric crane

Shut-off devices also include check valves and various shut-off valves with electric drive. It must be said that in systems of private apartments and houses, shut-off and control valves with an electric drive are not so often installed, is it really only in complex and branched circuits controlled by automation.

As for check valves, their task is to allow the coolant to pass in full in one direction, and to close tightly in the other. Installation location of components - boiler piping diagrams and other private situations when it is necessary to avoid the reverse movement of water.

When is the best time to replace batteries?

So, let's start, first let's look at the simplest case when the batteries need to be replaced during apartment renovation.

It is best to replace batteries at the stage of finishing the rough finishing, that is, when the walls have been plastered and the screed has been poured. It often happens that an old heating device (convector or cast iron radiator) prevents you from plastering the wall behind it; in this case, you need to plaster wherever possible around the old radiator, so that the radiator installer understands what level the wall is at and installs the radiator as the required distance from the wall and parallel to it. Plaster the space behind the radiator by removing the new radiator after installation. You should also understand the technological process that first the radiator is installed on the brackets, blanks of new bends are attached to it on the union nut of the ball valve, and only then the bends are welded to the riser. And not vice versa. The reason is the need for clear alignment of the radiator outlets and collectors. An example of a job I reworked that did not follow the required workflow.

Shut-off and regulating parts of systems

These include the following devices:

- balancing valves;

- automated differential pressure regulators;

- thermostatic radiator valves.

The listed types of shut-off and control valves are designed to implement quantitative control of the coolant. In other words, by partially closing the flow section of the pipeline, such elements provide a specific consumption of water entering the system section or the radiator. Balancing valves are installed both at the outlet of the batteries and at the beginning of a branch or riser of the system, mainly on the return line.

With a large number of batteries, the disposition may change and the installation of shut-off and control valves is carried out using automated differential pressure regulators. They are installed simultaneously with the valves and are connected to them by a capillary tube. The balance valve provides the required flow of coolant to the branch or riser, and the regulator adjusts it accordingly with the operation of the radiator thermostatic valves.

Using an Automated Valve

Automated automatic radiator valves are fittings for heating devices that reduce or increase the flow of hot water through the radiator depending on the room temperature.

Valves with thermal heads

It is installed on the supply line and can be additionally equipped with a thermal head and a remote external water thermostat for more precise control of the heat carrier flow. It is an integral element of modern circuits and one of the main means of saving energy sources.

Direction of coolant circulation

The lower saddle connection of the batteries using a lower vertical collector allows you to not depend on the direction of coolant supply. This cannot be said about the lateral and diagonal leash, as well as when radiators with a bottom connection point are used: here the supply must be clearly adjusted. Otherwise, the heating of the device may stop completely, or it will heat up very weakly. A lateral or diagonal connection involves the use of a top feed (the return pipe in this case comes from below).

When installing a bimetallic radiator with a bottom connection, it is important to clarify in advance which of the inputs will be connected to the supply. Usually this information is indicated in the passport

It is important not to confuse the directions, because... The supply in such heating devices is equipped with a tube extending upward from the inlet assembly. With its help, the coolant is brought to the upper collector. After this, it spreads over the radiator.

Mixing and control valves

The brightest representative of this group of devices is the thermostatic three-way valve. Its function is good control of the coolant, that is, by temperature, and not by flow. A three-way valve does not act like a shut-off valve; it functions as a mixing unit. Configured to produce a coolant of a specific temperature, the component mixes the two flows in the required proportions.

Heat supply mixing unit

The device is a brass body with three pipes, in the middle of which there is a rod controlled by a thermostatic drive. The rod goes through 2 seats, regulating the flow of the required amount of water through them from 2 nozzles in order to obtain a mixture of a given temperature in the third.

Working principle of three way valve

It must be said that not every heating system needs similar fittings. The area of use of mixer devices is maintaining the temperature in underfloor heating circuits, some radiators or entire groups of devices for heating a room, and also in small circulation circuits of solid fuel boilers. In general, it is very difficult to list all the specific situations of using mixing valves, since there are very, very many of them in modern traditional heating schemes.

Heating wiring diagrams

They are distinguished by the following characteristics:

- The number of pipes - single or double pipe. With a single-pipe distribution, hot water sequentially passes through all the radiators of one riser. It is clear that the first of them receives more heat, the last - less. Ensuring uniform heat distribution is achieved by using a tap at the battery inlet and a bypass - a pipe of smaller diameter that creates a path for water to bypass the radiator.

- The location of the risers is vertical or horizontal.

- Organization of circulation - natural or with an installed circulation pump.

When organizing a heating system for an apartment in a multi-story building, you have to rely on the already installed wiring. For example, in Soviet-built houses, single-pipe vertical distribution with a natural coolant circulation was used. When renovating such premises, you have to adapt to this, although it has more disadvantages than advantages. Strictly speaking, there is only one advantage - the length of the pipes is half that of the two-pipe version.

In modern construction, attention is constantly paid to saving energy resources. You can save heat, including by quickly regulating its output and choosing the optimal heating mode

Therefore, new buildings are often initially equipped with a two-pipe heating system. With higher initial costs, it opens up opportunities for effective management of energy consumption.

Types of shut-off heating valves for a private house

A modern heating system is a complex of various equipment, pipes and other additions. To guarantee safety and control over all fundamental processes, shut-off valves for heating of a new generation are used today. At points of sale you can find a considerable number of taps, valves, taps and other options for these products.

Now shut-off valves for heating a private house are unique devices used to limit or completely stop the supply of coolant. Very often, taps and valves fall into this category. When choosing, you need to look at the following points:

- 1.

Geometric specifics of the device: diameter of the inlet and outlet holes, dimensions, and so on. - 2. Temperature mode. In other words, depending on the materials used, the faucet will operate at absolutely different temperatures.

- 3. Pressure. The devices must maintain critical pressures, which are produced by circular pumps.

Based on the presented parameters, in technical terms, an appropriate device is selected for a particular purpose. For the comfort of consumers, all technical properties are applied to the valve body, which greatly facilitates the search and selection of parts. Control valves are used to guarantee safety in the heating system. In other words, it can control pressure, be used to mix different water flows, and so on.

Modern control valves for heating are equipped with electronic control units, which allows them to operate automatically. The main criteria when selecting these devices are the following parameters:

- The degree of operation of the mechanism. In other words, the device must be sensitive and should turn on at the slightest deviation from the norm.

- Effectiveness of flow mixing. This is of great importance, for example, if you need to mix cold and hot water.

- Ease of use. There are mechanical, semi-automatic and automated units, so it is necessary to select much better models.

Each type of equipment and devices provided has its own specifics, pros and cons. Shut-off and control valves for heating systems are purchased in accordance with the individual requirements of the upcoming project. This will make it possible to cope with all technical tasks very effectively.