With the onset of the autumn-winter period, owners of summer cottages, country houses and cottages face new problems - how to ensure warmth in the house, as one of the components of a comfortable stay for family members, and to prevent freezing of communications. Modern industry offers a wide range of different types of heating systems, among which is a series of metal heating and cooking furnaces “Professor Butakov” (named by the inventor S.A. Butakov, a heating scientist in honor of his grandfather), the manufacturer of which is Siberian.

The range of stoves is represented by 6 models with original names and designed for heating rooms of various sizes:

- for small country houses measuring 100-150 cubic meters. – “high school student”, “Student”, with a rated power of 6 and 9 kW;

- for a large country house with a larger volume of premises - up to 250 cubic meters. – “Engineer”, power 15 kW;

- for cottages, industrial premises (hangars, construction sheds) 500-1000-1200 cubic meters. – “Associate Professor”, “Professor”, “Academician”, with a power of 25-40-55 kW, respectively.

The Butakova Engineer stove is very popular among owners of country houses, mainly and small industrial premises.

All about stove installation Engineer

To facilitate installation, each Termofor oven comes with detailed installation instructions.

The company has thought out a convenient and simple design that facilitates installation work. To begin installing the Engineer furnace with your own hands, you should begin by determining the location. It will not be unimportant to decide which chimney to use when connecting.

To heat adjacent rooms, a heat sink is installed on air heating furnaces for routing air ducts, and a heating system pipeline is connected to water heating models. After installation, the stove will be able to effectively heat the entire building, and not just the room in which it is installed.

Requirements for placement

The efficiency and uniformity of heating largely depend on the correct location of the stove. For normal operation, the Engineer stove needs a large volume of air and no obstacles in the way of convection currents.

An essential condition is compliance with fire safety rules. Some points that must be followed are contained in the instruction manual. In particular, it states:

- The stove is installed on a non-combustible base.

Protection is provided for walls and ceilings (where the chimney passes) when installed in a wooden house. The section of the wall adjacent to the stove is insulated with non-flammable insulation, and then covered with steel sheet or brick.

The surface of the chimney is heated to a temperature of over 200°C, which, according to the rules of PPB, requires the use of a special passage unit filled with mineral insulation when passing through floor slabs and roofing.

The special design and the use of a special base simplifies the installation of the Engineer furnace and makes it possible to do the connection yourself.

Which chimney is better

Solid fuel heating equipment belongs to the class of furnaces with high flue gas temperatures. During combustion, inside the combustion chamber, the heating intensity reaches 450-550°C. Although due to the use of gas generation, the smoke at the outlet cools significantly, the temperature still remains sufficient to lead to burnout and deformation of a conventional steel chimney.

Additional requirements apply to traction characteristics. Insufficient pressure leads to backdraft, air locks and other operational difficulties.

Reviews from owners and practice have shown that the optimal choice for convection and water heating stoves is a sandwich pipe and a ceramic chimney. An additional advantage of the systems is the simple installation of the chimney yourself. Sandwich pipes and ceramics are assembled like a construction kit and do not require special skills for installation.

On the Internet you can find negative reviews about the stoves of Professor Butakov Engineer, but they are rather the exception to the rule. Basically, owners point out the advantages of Termofor products:

- Affordable price.

Long service life.

A simple design that allows for independent installation of the stove in the house.

Thermal efficiency due to the ability to connect to a water heating system and air ducts.

All of the above factors ensure uninterrupted and comfortable operation of the Butakov stoves of the Engineer series and explain the popularity of the models among Russian consumers.

User manual

Some consumers complain about the rapid combustion of solid fuel in the stove. But experts insist that they install and operate the unit incorrectly. The fuel must not only be placed correctly, but also ignited correctly.

Stack firewood correctly

In order for it to smolder as long as possible, you first need to set fire to a small amount of wood and obtain coals. Then add solid fuel, after which it will smolder for 8-10 hours and give off a large amount of heat.

Basic recommendations:

- Before putting the boiler into operation, it needs to be tested. This will help determine the optimal method for operating the structure.

- To prevent objects from igniting from the hot stove body, it is installed at a distance of at least 40 cm from them.

- During boiler operation, slag appears on the damper and inside the chimney. To get rid of it you need to use special cleaning agents “Miracle Log” or “Umbrella Pipe”, which increase the movement of the air mass in the chimney.

- It is not recommended to use fuel from coniferous trees, as it emits an unpleasant odor or smoke, while fuel from deciduous trees (birch, aspen, etc.) fill the room with pleasant and environmentally friendly warm air.

- The chimney must be open. Fuel can be placed horizontally or vertically in the firebox.

Design and principle of operation

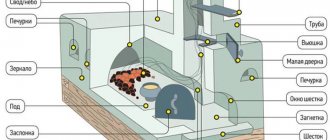

Professor Butakov’s “Associate Professor” stove has a simple but original design, consisting of:

- all-welded 2-chamber body;

- straight and curved convective pipes built into it;

- gas guide screen;

- jets for dosing the intake of secondary air;

- firebox;

- grate;

- ash pan, where there is a special container for collecting ash;

- metal door of the combustion chamber or combined with heat-resistant glass;

- gate welded to the body;

- chimney.

The operation of the furnace is carried out with the simultaneous flow of pyrolysis and convection processes:

- The pyrolysis process is carried out directly in the combustion chamber in smoldering fuel mode. The gas released when wood burns enters the second chamber, where it mixes with oxygen and burns completely;

- the convection process occurs in special air ducts that pass through the firebox and have ends protruding outward. Cold air enters them from below the structure. Then it passes under the influence of natural draft through the combustion chamber and comes out to the top in a heated state.

The firebox door also has a special design. There is a convection chamber inside it, which also participates in heating the room.

How to distinguish a fake from the original?

The “Engineer” model is one of the most popular types of stoves by Professor Butakov. Manufacturers follow construction technology.

How to distinguish a fake? Original designs have oval-shaped nameplates of different sizes not only above the flow door, but also on the door itself.

In all boiler models, the flow door opens to the right. The “Engineer” model has a forced function - using a heat remover, you can change the direction of heat supply. For example, direct heat to another room or to an upper floor. Experts also recommend paying attention to the quality of the seams, the aesthetic appearance of the structure and the set of documentation.

Characteristics

Considering that the Butakov “Student” furnace has various modifications, their sizes and technical characteristics differ significantly. What these devices have in common is the presence of built-in convective channels used to increase heat transfer. Depending on the type, stoves can work both to heat air and provide water heating.

In this mini-review we will look at stoves from.

Wood burning stove

This device is characterized by maximum thermal efficiency and high efficiency, in comparison with coal analogues. It has the following features:

- Tightness of the combustion chamber - the door closes securely, eliminating the formation of cracks.

- Improved control of air supply - the unique design of the gate valve allows you to set gas generation or simply combustion modes.

- High-quality materials - thick-walled structural steel was used to make the body, cast iron was used for the grates and doors.

In addition, the device is characterized by relatively small dimensions, which are:

- 530*780*370 mm;

- chimney pipe diameter 120 mm;

- weight of the entire oven is 77 kg;

- firebox volume 74 l;

- power reaches 9 kW;

- Efficiency is 85%.

The Student stove has an amazing ability to prevent soot from contaminating work surfaces. Even long-term use will not affect the cleanliness of the glass. The burning duration allows you to make bookmarks no more than once every 6-7 hours. The device is equipped with a replaceable grate, which allows air flows to be evenly distributed in the fuel chamber. This eliminates the formation of soot. The design of the ash box allows it to be cleaned without interrupting the combustion process.

Coal furnace

When designing these heating furnaces, the intensity of the thermal load was taken into account. The device has the following characteristics:

- weight – 77 kg;

- firebox volume – 70 l;

- dimensions – 530*370*780 mm;

- Efficiency – 85%;

- Power – 9 kW.

Burning coal requires more oxygen than wood, but produces significantly more heat. Thanks to the 5 mm wall thickness, metal deformation, which can cause rapid breakdown of the furnace, is eliminated. The tightness and thoughtfulness of the design can significantly reduce coal consumption. A similar stove by Professor Butakov “Student”, operating on coal, is an ideal option for systematic heating.

Hydraulic

Thanks to the unique design of the heat exchanger, the long-burning Student water-heating stove has a fairly high heat output. The usual coils in it were replaced with convective channels, partially recessed into the firebox. Thanks to these features, the liquid is intensely heated and enters the heating system. This large-sized device has the following characteristics:

- weight - 90 kg;

- power - 16 kW;

- firebox – 70 l;

- dimensions – 720*370*770 mm;

- Efficiency – 85%.

In addition, the design provides for the installation of heating elements, which allows you to maintain the temperature of the coolant for a long time.

Features of the “Student” furnace design Hydraulic

Attention! Electric heaters can be installed independently or purchased together with the boiler

Furnace design

Butakov's heating device is very simple. The unit consists of the following elements:

- ash pan for collecting combustion products;

- air outlet pipe;

- two-chamber firebox: one compartment is provided for connecting to gas, the second is for afterburning fuel;

- grate in the form of a damper;

- smoke channel.

The pipes run along the edge of both sides of the furnace, are arranged in two rows, close and cross in the upper part. Thanks to this design, the floor warms up well when cold air moves through pipes located in the combustion zone. Due to them, the heating area increases and the furnace walls do not burn out. Thanks to special jets with hot air inside, located at the top of the firebox, the secondary gas is burned in full. This once again confirms the efficiency of the device: the fuel burns out entirely, and the heat is retained indoors for a long time.

Conclusion

The heating design of Professor Butakov has a long burning time, high-quality construction, high performance and efficiency. Don't get stuck on one type of fuel. The oven is “omnivorous”. It can use different types of solid fuel.

When the glass on the door breaks, don't be upset. It can be purchased for about 3 thousand rubles and is easy to replace. When used correctly, it will fill the house with warmth for a long time during the cold period. And crackling firewood will create a unique comfort in the room.

Advantages and disadvantages of the Butakov furnace

Among the disadvantages it is worth noting the following:

- High temperature of the steel casing may cause burns.

- When the unit is turned off, it cools down quickly, and the room temperature also drops quickly.

Now a little about the advantages:

- The ash box is large enough and does not require frequent cleaning.

- Butakov's oven is not large, but roomy.

- The construction is durable, which is facilitated by the materials used (cast iron, steel).

- Durable, unpretentious in use.

- The upper part of the model can be used as a hob.

- The fuel can be anything, from firewood to peat or paper.

- Externally aesthetic.

- Installation is quick.

- Eco-friendly.

- Fireproof.

Butakov’s heating devices are widely used due to the uniqueness of their design. In the manufacture of such equipment, inexpensive and reliable materials are used, so that such a heating installation is designed for a long period of operation. In this case, the user is only required to periodically remove accumulated ash using a special container. It collects all the slags formed during combustion, so maintenance comes down to cleaning a special container.

The heating installation is unpretentious in terms of fuel - you can use wood waste, coal, pellets, and ordinary firewood. The only thing is that you should not use resinous wood, which leads to increased formation of soot - everything else can be burned in this firebox without any problems.

Butakov's universal models provide a convenient combination of heating and cooking system. The outer surface of the heater, which is in direct contact with the firebox, can be used as a cooking surface. Such a panel will be very hot, in particular, the temperature can reach 350 degrees Celsius, so such an installation can easily replace a hob.

Heating and cooking stoves "Gimnasist"

The low price of heating equipment is a very important factor, which largely determines the popularity of such models. The low cost is due to the simplicity of the design and the absence of expensive materials. The cast iron and steel used in the production process are designed for a long period of operation, so in the long term Butakov furnaces become even more attractive.

Furnace installation

Before installation, you should prepare a place for the heating stove. This does not require the installation of an additional foundation.

The stove is installed on the floor, on a flat, insulated surface (metal sheets on asbestos cardboard can serve as such a surface).

The base of the Butakov stove design is equipped with holes for fixing, so it can be fixed to the floor.

Adjacent walls also need to be insulated to a level 25 cm above the top edge of the stove. Plaster on a metal mesh or asbestos cardboard with a metal sheet serves as thermal insulation.

The distance from the wall to the stove must be at least 38 cm.

A metal sheet must be laid in front of the oven door.

The hole for the chimney should be thermally insulated.

The Butakov heating stove is installed in a prepared place made of non-combustible materials (for example, on a brick stand).

The last step in the installation is connecting the chimney to the tee and the stove.

Important! All pipe joints should be treated with heat-resistant sealant. Important! The chimney pipe should protrude 50 cm above the roof ridge

In this case, the part of the chimney located in open space must be insulated with material that can withstand temperatures up to +400 °C

Important! The chimney pipe must protrude 50 cm above the roof ridge. In this case, the part of the chimney located in the open space must be insulated with material that can withstand temperatures up to +400 °C

Be sure to insulate the hole in the roof with special material.

The space around the structure can be equipped with any heat-resistant and non-flammable material.

History of creation

The stove runs on wood, pellets and other solid fuels

The first example of such a stove was made in 2002 in the north of the country, in the Novosibirsk region. Just two months after this, the necessary certificates were received, and by 2004 a patent for the invention was issued. Its developer is a specialist in the field of heating engineering E. Yu. Zubkevich, who named the stove in honor of his relative Professor S.E. Butakova.

A year later, the inventor entered into an agreement with the Termofor company, which mastered the production and production of products. For a number of reasons, cooperation with her was suspended in 2008 and the patent owner remained out of business. To date, the production of these furnaces has been established on an industrial scale.

Characteristics

There are several models of the “Engineer” stove; in this case, we will look at a model of a wood-burning stove from the Termofor company. Its price is approximately 14,250 rubles. (without chimney).

This is what the oven looks like in the photo:

| Heating area, m³ | 250 |

| power, kWt | 15 |

| chimney, Ø mm | 120 |

| chimney outlet | Top/back |

| Height of the chimney, m (minimum) | 5 |

| Firebox volume, l | 120 |

| Door | With glass/without glass |

| Dimensions (depth, width, height), mm | 765*440*895 |

| Maximum load of firewood or coal, l | 40 |

| Maximum length of logs, cm | 45 |

| Boiler material | Metal/steel |

| Firebox material | Metal/steel |

| Unit weight, kg | 113 |

| Manufacturer country | Russia |

Characteristics of the air-heating boiler TMF Engineer Coal ChD, ChK, ZG, TV

| Heated room volume | 250 cubic meters |

| Power | 15 kW |

| Dimensions (WxDxH) | 44*63*77.5 cm |

| Boiler weight | 110 kg |

| Fire door opening | 29*34 cm |

| Combustion chamber volume | 122 l |

| Fuel loading volume, max. | 40 l |

| Log length, max | 46 cm |

| Chimney diameter | 120 mm |

| Chimney height | 5 m |

| Convection pipes, diameter/quantity | 5 cm/14 pcs |

| Guarantee | 1 year |

Furnace design and operating principle

The operating principle of Butakov furnaces is based on the convection process. The heat-resistant cast iron grate ensures a long combustion process and protects the remaining parts of the installation from high temperatures. If the grille fails, you can easily replace it with a new one.

The grate ensures a uniform combustion process over the entire area of the combustion device and controls the air supply. In order to increase the air supply, you just need to open a special window (the faster the combustion process occurs, the sooner the room will warm up).

Through the grate, combustion products enter a special compartment, from where they are subsequently removed. Cleaning can be done directly while the stove is operating, because combustion occurs in another compartment. The ash compartment is equipped with a “window” with which you can regulate the air supply.

Important! The oven is not intended for long-term heat loads. Therefore, overheating above 350 °C is not allowed

The design of the above furnaces consists of:

- welded steel body with built-in pipes, thanks to which the convection process is carried out;

- convection pipes;

- grates.

Various combustible materials are used as fuel: firewood, briquettes, branches, etc.

An important feature is the flat top of the body, which can be used for cooking and heating water

Delivery across Russia

One of the key areas of our work is working with regional buyers: we have excellent prices, even taking into account the cost of delivery. The average delivery time to the nearest regions is 1-3 days, to remote regions – 7-10 days.

Attention! At the terminals of transport companies there are restrictions on the weight and volume of goods sent. For more detailed information, contact the online store managers.

Free delivery to 10 cities of Siberia and the Urals

When ordering from 20,000 rub. We will deliver free of charge to the DPD terminal in the following cities:

Biysk, Barnaul, Ekaterinburg, Kemerovo, Krasnoyarsk, Novokuznetsk, Omsk, Rubtsovsk, Tomsk, Tyumen

More details

The optimal delivery services for large-sized cargo are Energy, PEK and GDT (Chinese). It is their points that are indicated on the map. We also ship by other services upon request: Business Lines, ZhelDorExpedition, Postal League. Cargo is dispatched from the Fornax central warehouse in Novosibirsk. We will deliver your order to the transport company terminal in Novosibirsk for FREE! After sending the goods, we will send you a tracking number via SMS.

- All orders are insured

. If the cargo is damaged due to the fault of the carrier, the recipient is compensated by the transport company for damages in the amount of the full cost of the damaged part of the goods. - We ship orders without damage

. There is always a note about this in the invoice - “the goods were received without damage.” It happens that TC employees, in order to relieve themselves of responsibility for possible damage to the cargo during its transportation, write “the goods were accepted with damage.” We monitor this and offer to jointly open the packaging of the goods, check its integrity, record it with photographs and indicate in the delivery note that the goods were received without damage. So if suddenly damage occurs during transportation, you have every reason to file a claim. - Free storage for several days after the cargo arrives in your city

. Check with the transport company for the period of free storage of cargo at the pick-up point. This period may vary for different TCs. For example, for TC Energia this period is 3 days, not counting the day of arrival. The average delivery time to the nearest regions is 1-3 days, to remote regions – 7-10 days.

Advantages and disadvantages

The positive aspects consumers include:

- beautiful and original design;

- With a lot of weight, but due to their small size, these ovens take up little space;

- quick heating of the air in the room (as with all metal stoves);

- through the existing air ducts, hot air coming from the side convection pipes can heat adjacent rooms;

- high efficiency, including due to the fact that, due to the design features, all surfaces of the stove participate in heating the room;

- the ability to regulate fuel consumption;

- low price (unlike, for example, the cost of heating equipment running on gas).

Among the main disadvantages are:

- rapid burning of firewood and, accordingly, fairly rapid cooling of the stove and premises;

- despite the presence of a chimney, the stove sometimes smokes, the doors (especially visible on the glass) and the chimney are covered with soot;

- The oven gets very hot, so there is a possibility of getting burns when touching it and damaging the floor and walls.

You might find this article about Finnish stoves and fireplaces useful.

Read an article about making a pyrolysis oven with your own hands here.

Features of installation and assembly

Considering that the surface of the device gets very hot, the installation provides enhanced thermal protection for floors and walls. This can be done in the following sequence:

- A basalt slab is laid on a wooden or other combustible floor, the surface of which should be sheathed with metal.

- Walls located close to the device are protected with basalt insulation. This will reduce the distance between the wall and the stove to 50 cm.

- The presence of supply and exhaust ventilation, both forced and natural, is unacceptable when installing a stove.

- When laying a chimney, you will need to protect the walls from heat. To do this, install a special fireproof cutting and spark arrester.

If you plan to heat adjacent rooms with heated air, you will need to connect thermal extractors and additional air ducts. The oven is installed in such a way as to facilitate the installation of the corrugated pipe.

Installation example

Another installation option (in the corner)

What is unique about the Butakov oven?

Let us consider the design features of the Butakov furnace, which improve the technology of this design:

- The fuel tank of the Butakov stove has the form of a truncated parallelepiped, which allows maximum exploitation of the thermal diagram of the thermal decomposition of the fuel.

- The air duct pipes are in a vertical position, located along the entire perimeter of the firebox. The intersection of the pipes is at the top at an angle that was calculated by the professor, so they are located in a gas-flame environment.

- Air flows freely into the gas generator thanks to the cut-off inlet openings at the convective pipes at a distance of 120 mm.

- Special gas guide shields made it possible to use the gas-flame flow as efficiently as possible with the inclusion of inclined tail surfaces. The combustion chamber door is involved in the heat exchange process, thanks to the use of a converter casing.

- Due to the fact that the design is equipped with an ash pan, it is possible to clean spent fuel without stopping the operation of the furnace.

- The upper part of the boiler has a flat surface, heated by a flame, so it can be used for heating and even cooking.

- Installing a replaceable grate made it possible to achieve uniform combustion of fuel, and also made it possible to change combustion processes and increase the temperature.

- When burning fuel, conventional gas heaters leave condensation on the walls of the chimney, which manifests itself in the form of liquid discharge and an unpleasant odor. In the Butakov stove, this problem is solved, since it uses a vertical pipe connecting to the chimney. With the help of such a system, condensate flows back into the firebox and burns out along with the fuel.

- The operation of the Butakov furnace after a full load reaches eight to twelve hours of continuous operation.

- This heating system is absolutely safe and is supported by a stable base, as well as holes for its fixation.

Model "Student"

Preparing pipes and parts

The oven has an outlet of 14 convection pipes. The diameter of the chimney outlet is 200 mm; we purchase it ready-made from a corrugated ventilation pipe.

For manufacturing we will need to prepare several parts. From 4 mm sheet steel we cut out:

- 2 side parts measuring 800/950 mm. The second dimension is the height of the structure;

- For the front and rear walls, we use a grinder to cut out parts 1110/670 mm. After final assembly, the protruding metal will be cut off and can be used as reinforcement for the base;

- for the top we cut out a piece measuring 350/950 mm. It is necessary to mark 6 holes of three pieces on the narrow sides and drill or cut them by welding. Pipes with a diameter of 40 mm will come out of them;

- for 2 side jibs, cut the workpiece to a size of 200/950 mm;

- for the base you can use a corner with a 100 mm shelf or a channel. 2 pieces 950 mm and 2 lintels 470 mm each. It is necessary to make holes in the base for the pipes, which must be coaxial with the top ones;

- For convection pipes we use steel parts with a cross section of 40 mm. 6 of them are straight, they run along the front and back walls. There are 4 holes on the jibs. 8 pipes will need to be bent to a certain angle. It is better to do this on a pipe bender.

You will also need to leave a sheet for making a door and an ash drawer. To make a grate, you can use a sheet 10 mm thick, making longitudinal grooves in it with a grinder. You can weld a grid from reinforcement or a rod with a diameter of 8-10 mm.

To install the grate, we will prepare several pieces of corner. It is better not to secure the grate tightly; this will make it easier to replace and maintain the stove. A hole is marked on the top part and made for connection to the outlet pipe. You will need to prepare a section with a cross-section of 180-190 mm and a length of 170 mm.

Furnace installation

The unit can be placed in the center of the room or built into the wall, simulating a fireplace. In this case, two adjacent rooms will be heated at once.

When installing a stove, the main condition is the unhindered flow of air. The material must be fireproof, and for the base it is better to use a concrete screed

The chimney heats up quickly during operation and startup of the stove, therefore it is important to lay a thermal insulation layer between it and the roof

At the dacha, you can heat it with wood scraps, but the best fuel for such a design is pellets with high efficiency. The operating principle of the stove is as follows: smoldering occurs slowly, so the moisture content of the wood is not particularly important. Dry wood will burn the same way.

The combustion chamber must be extremely sealed. Carbon monoxide does not enter the room, so the stove can be placed next to the sleeping place. One bookmark should be enough for 18-20 hours. The Butakov unit will be the optimal solution when installed in a country cottage with a decent area, or in a country house.

Today, more powerful stoves are produced. For example, a new model “Akademik” with a power of 55 kW has appeared. This is a real record among heating devices of this type. Thanks to the modern design, installation is possible anywhere. A large range of models allows us to satisfy everyone's needs.

If you follow all the recommendations described above, you will be able to make an excellent device with a long-burning system without much expense.

Principle of operation

Operation

oven is carried out simultaneously by pyrolysis and convection:

- The pyrolysis process occurs directly in the firebox. In this case, the fuel does not burn, but simply smolders. If you close or open the door vent, you can regulate the flow of fresh air inside. During this process, a large amount of gas is released, which is sent to the second chamber, where, when mixed with oxygen, it is completely burned. At the same time, the air in the room always remains fresh.

- The convection process occurs in special pipes installed in the structure. Through channels mounted in the firebox with protruding ends at the outlet, hot air is directed directly into the room. Heating is carried out naturally. Cold air is taken in from the lower openings of the pipes. It passes through the entire structure and is sent upward while still hot. However, this leads to sudden changes in temperature in the chimney, which is why condensation is possible, which is a significant disadvantage of this design. But the problem can be solved if you install a pipe. Through it, the condensate will not escape outside, but will settle directly in the firebox, in which it will simply evaporate under the influence of heat.

Potbelly stoves and many pyrolysis units operate in approximately the same way, but there are still some differences. Among them the following are noted:

Pipes in the furnace are not installed arbitrarily, but at an angle

It is important to set the exact angle when arranging the structure yourself. The doors are not just hung on hinges, they contain a convection chamber, which contributes to faster and more uniform heating of the room. The oven, unlike some pyrolysis models, is quite easy to maintain. The ash pan is easy to remove and quick to clean

Among similar designs, it is the Butakov unit that is considered the most efficient, simple, and has high heat transfer.

Self-production

Before you start building a device with your own hands, you need to study its diagram:

The assembly sequence of this unit is no different from the installation of gas generator furnaces. The basis of the device is a metal barrel.

To get a high-quality unit with safe, economical and efficient heating, follow the instructions below:

- Using a grinder, you need to cut off the top of the barrel, smooth out the sharp edges with a hammer and bend them down.

- It is necessary to cut a circle with a diameter of 1.5-2 cm in a steel sheet. This is much smaller than the corresponding size of the barrel itself.

- In the cut out element you need to make a hole with a diameter of 10 cm and weld a steel pipe of the same size to it.

- You will need to attach channel sections to the bottom of the product using a welding machine and install them so that they can move freely inside the barrel. During operation of the unit, metal beams will put pressure on the fuel.

- A damper is mounted on top of the pipe, and the pin is installed strictly vertically.

- This element must be fixed by welding. A hole needs to be drilled at the edge of the valve, cut from steel with a diameter similar to the corresponding pipe size. After installation, the pin should cover the product.

- The damper is screwed on with a nut. Installing this element allows you to further monitor the volume of incoming air, as well as the intensity of the device’s operation.

- The side of the lid must be leveled with a hammer. The edges need to be bent outward to ensure a tight fit and adherence to the base.

- You need to make a hole in the lid with a diameter of 10.5 cm. To do this, you need to stock up on a chisel.

- The pipe needs to be welded to the pancake and brought out through a hole made in the lid, which then needs to be welded.

- For the base of the furnace, you can prepare a not too deep brick platform.

- In the upper part of the device body, you need to cut a hole with a diameter of 15 cm. A smoke channel will pass through it, which is 1.5 times longer than the body itself. A previously measured section of pipe is welded to the hole on top of the structure.

- You need to make a small square hole at the bottom of the device, then weld the door to it. This will be an ash pan - a hatch for collecting ash, where a box is installed for convenience and ease of cleaning.

- The lower part of the chimney pipe is carefully welded. It is desirable that the product stands on legs.

- An elbow is welded to the channel and the furnace is connected. The structure is fixed with a clamp. A fiberglass base is preliminarily placed under this device to ensure the tightness of all connections.

If there is no barrel, then you can use a fire extinguisher for the base of the stove, from which you need to remove the body. A gas cylinder is also suitable for these purposes. The device is assembled in a similar way.

Advantages and disadvantages

Today, the modern “Engineer” boiler has been improved. Specialists have increased the diameter of convective pipes, and the pipe walls have become thinner. This change contributes to an increase in the open section, and heat flows improve heat transfer. Therefore, the main advantage of the stove is the cost-effectiveness of the model.

Main advantages:

- Increased efficiency. Each structural element is aimed at fulfilling its functional load. It helps heat the room and food.

- Eco-friendly. The firebox is designed in such a way that almost all the fuel burns. Therefore, ash does not emit harmful substances.

- Reliable and fireproof. The design is equipped with a sealed firebox that protects the room from open fire.

- Affordable and durable. The low price goes well with the quality.

- Design. The stove is not bulky, has an aesthetic appearance and fits into any interior.

Main disadvantages:

- Oxygen can enter the furnace through the ash pan.

- For cleaning, the pipe is disassembled into sections.

- The front part of the structure deforms over time.

The lineup

Today there are many models of the Butakov stove on the market. Below we will consider the main ones.

- The Gymnasist device, with a power of only 7 kW, is capable of heating up to 100 m² of area. The height of the chimney is 5 m.

- The Student stove (9 kW) can heat a room up to 150 m². The maximum fuel volume is up to 20 kg. The height of the chimney is 5 m.

- Professor Butakov’s “Engineer” unit (15 kW) will heat a room up to 250 m². The maximum fuel volume is 40 kg. The height of the chimney is 5 m.

- The Docent stove (25 kW) will heat a home up to 500 m². The design can hold up to 100 kg of flammable substances. The height of the chimney is 6 m.

- The “Professor” device (40 kW) is capable of heating up to 1000 m² of housing. The maximum fuel volume is 200 kg. The height of the chimney is 8 m.

- The Akademik unit (55 kW) can warm up a house with an area of up to 1200 m². The stove can hold up to 240 kg of flammable material.

Each model has its own dimensions. The larger the fuel space and firebox, the larger the dimensions of the stove.

The optimal choice of device depends on its purpose and the area of the premises requiring heating.

The compact stove “Gimnasist” can heat up to 100 square meters. meters. Its chimney goes up, so this unit is suitable for country houses and garage buildings. For other models, the chimney exits to the top or is located at the rear of the structure. They are mainly installed in large rooms.

Range

The most interesting thing about Butakov’s stoves is the names that he used when creating the model range of heating equipment - Student, High School Student, Engineer, Professor, Associate Professor, etc. We will get to know each of them separately.

- High school student. Power parameters - 6-7 kW. Nowadays it is not in great demand; it is purchased mainly to order. A high school student is able to heat an area of up to 20 square meters, using 20 liters of fuel.

- Student. The power of the Student stove is 9 kW, and its weight is only 70 kilograms. The Student model is quite old, but the most common. The heated area does not exceed 100 square meters. At the same time, the Student has a cast-iron grate and a retractable convenient ash pan. The student allows you to heat the house and cook food.

- Engineer. The Engineer weighs 113 kg, but the power is 15 kW. The Engineer model is designed for heating rooms up to 250 square meters. The maximum load of the firebox is 40 liters. The Engineer stove is distinguished by the presence of a glass screen on the door. The door itself can be made of steel or cast iron. The engineer is in great demand for private homes.

- Assistant professor. An impressive 164 kilograms of weight gives 25 kW of power. The firebox of this stove model holds 100 liters of fuel. But the Associate Professor is also capable of heating an impressive area - 500 square meters.

- Professor. The highly efficient Professor stove weighs 235 kilograms, but also produces 40 kW of power. The Professor model copes with heating rooms up to 1200 square meters. To heat such an area, the Professor will require 240 liters of solid fuel to be loaded into the firebox.

- Academician. The most powerful representative of the Butakov stove series. Weighing 300 kilograms, the power of the equipment is 55 kW. Unlike the Professor model, the Academician heats up to 1000 square meters, using 200 liters of fuel.

Advantages and disadvantages

Diagram of the Butakov furnace

What unites the models Student, Professor, Gymnasium Student and other stoves made by Butakov? Their advantages and disadvantages.

The strengths of the furnaces of the Soviet developer include:

- High level of fire safety. In Student stoves and other models, combustion does not occur, but the process of smoldering occurs. Therefore, there is no open fire;

- Functionality. Despite its small dimensions, the same Student model has heating and cooking capabilities. Due to the high efficiency, there is enough power to efficiently perform each function;

- Environmental friendliness. The fuel burns almost completely, so there is no waste hazardous to humans;

- Long service life. At its attractive price, Butakov’s equipment guarantees long-term operation.

But Butakov stoves have certain disadvantages.

- The stove body actively heats up, so touching the surface of the stove can lead to burns. You just need to be careful when using the stove.

- When the combustion process is completed, the chamber cools down quite quickly. Because of this, the indoor temperature drops. But since the furnace is capable of operating for 8-12 hours, it is difficult to call this a serious drawback of Butakov’s equipment.

- When the furnace operates, the air inside the room becomes very dry. To avoid this, you need a humidification system or effective ventilation.

The stoves made by Butakov cannot be called ideal in all respects. But these stoves have their undeniable advantages, allowing them to compete on an equal footing with gas boilers that are objectively more attractive to many.