A wood-burning stove in a country house or country cottage can be a more than useful acquisition. It is completely autonomous from external networks. Where electricity is often cut off and a centralized gas supply has not yet been implemented, people cook with wood and heat the house with it.

If you decide to provide your home with such a useful device, it won’t hurt to study the types of brick stoves for your home in order to choose the most convenient, efficient and practical option.

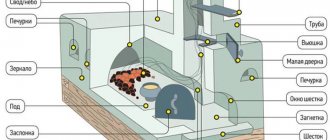

We offer you to understand the traditional design of the furnace, the design and operational features of various heating and cooking units, as well as learn the methods and specifics of arranging a smoke circulation system.

What is the best red brick for laying a stove?

Ordinary red clay brick for the stove, classified as the first grade (GOST 8426-75), is the main material for the construction of stoves.

The standard brick shape is a rectangular parallelepiped with flat edges and right angles. Its surface must be free of cracks and chips. This is the best brick for stoves that will have all the benefits of safe operation. The size of the brick for the stove is 250 X 120 x 65 mm, the weight can vary from 3.5 to 3.8 kg. 380 bricks are placed in 1 m3 of solid masonry. Ordinary red brick of normal firing is divided into seven grades, each of which is designated by a number: 300, 250, 200, 150, 125, 100, 75. The markings indicate the compressive strength kgf/cm2 (1 kgf/cm2 = 0.1 MPa).

What kind of brick for laying a stove is prohibited from being used for the construction of stoves is unburned or burnt ordinary clay material. Unfired brick has a pale pink color. It is a rather fragile material, which is characterized by significant water absorption, so it can often get wet in water. When tapping such a brick, a dull sound is heard.

As a result of firing at temperatures above 1000 °C, the brick becomes burnt. It is distinguished by its dark color. A glassy film is partially visible on top of it, and the surface itself is slightly curvature and covered with cracks. Burnt brick is very durable. It is difficult to trim, but it weakly binds to the solution. This type of brick is called “burnout” or “iron ore.”

For laying arrays of stoves and smoke ducts, it is recommended to use only solid clay bricks. It is prohibited to use perforated, silicate or slotted bricks in such masonry, because they quickly collapse under the influence of high temperatures.

Refractory brick is made from refractory clays, which are characterized by increased strength and fire resistance. Such bricks can withstand temperatures of 900-1000 °C. It is used for laying and lining the fireboxes of furnaces, which are designed to burn fuel with low calorific value (for example, firewood).

The first sauna stove in history with an open heater

This simple, essentially device was invented by people thousands of years ago. The very first baths, discovered by archaeologists in the sites of ancient people, were a hole in the ground, which was lined with straw and brushwood and a pile of stones was thrown on top. Burning brushwood heated the stones, the heat from which the first people used for heating. A little later, inventive humanity came up with a unique innovation of this design: a homemade tent made of branches and skins was erected over a pit with brushwood and stones. Thus, it was possible to keep the heat from the heated stones within one space in which people warmed themselves, were treated and, in fact, steamed. By the essence of its design and operation, this first device can be called an open heater.

Manufacturers of ceramic bricks

The increase in construction volumes in our country in recent years has had a positive impact on companies producing relevant materials.

Fireclay bricks whose technical characteristics meet the requirements of standards and are produced at affordable prices by the following companies:

- TEREX Group of Companies;

- Bogorodsky plant of ceramic wall materials;

- Verkhnevolzhsky brick factory;

- Wienerberger Brick;

- Kerma;

- "Ceramics" (Lomintsevsky brick;

- Brick factory BRAER.

The named enterprises produce fire-resistant bricks in a wide range and of adequate quality. The products of these plants are in demand among builders and the population of both the regions where they are located and in neighboring areas. Competition between manufacturers of building materials has a positive effect on quality and range.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter.

Types by combustion method

The Russian stove is distinguished by its economical consumption of firewood; a small amount of fuel is used to heat it, and the heat is retained for a long time. This feature is due to the special structure of the chamber, especially for a white oven.

According to the method of combustion, three large groups can be distinguished, some are now practically not used, such designs include black chicken ones. White ones with chimneys are more efficient, safer, and can be used for heating, cooking food, and warming up a steam room.

In black

The oldest option is the black-style chicken stove, which got its name for the peculiarity of the firebox. Such structures were built from ordinary clay, not brick, and did not have a chimney. When burning, thick black smoke was generated, which came out through special openings in the walls (wall windows) and a porch above the door. To avoid fire, the fire was always kept low, and strong flare-ups were not allowed. A constant flow of cold air into the house is necessary, but this significantly reduces the efficiency of the structure and increases the consumption of firewood or wood chips.

Russian oven "black"

Today, chicken models are practically not used; they can only be found in some classic Russian baths, and even then extremely rarely. This is due to the need to comply with safety measures, constant maintenance not only of the stove itself, but also of the room, the walls and ceilings of which are gradually covered with a layer of soot. However, there are a number of advantages:

- with their help you can smoke meat or fish;

- the room is perfectly disinfected under the influence of smoke;

- The stove provides the most efficient heat transfer to the room.

In gray

This option has replaced the smoke version; it is safer and more convenient; the smoke does not come out through a glass window, but through a wooden pipe or hole made in the ceiling above the structure. But among the disadvantages is an increased fire hazard - smoke escaping through the roof is accompanied by sparks and high temperatures.

In white

The safest and most convenient are traditional white stoves. A special baked brick is used for the construction, and a pipe is used to remove smoke. The special design of the chimney not only effectively removes combustion products, but also increases draft, increasing the efficiency of the firebox. The design of the pipe has a curved shape, this increases efficiency, allows you to effectively extinguish sparks, which makes the structure safe and protects the house from fires. The curved shape of the chimney ensures rapid heating of surrounding structures - a house with such a stove quickly warms up, becomes warm and comfortable. A minimum of wood is used for heating, which is a big advantage.

Chimney installation

The main task when laying a chimney is to comply with fire safety.

The walls of the chimney should be made of two bricks, and the distance between the chimney and the roof should be about 70-80 cm. All cracks must be carefully sealed to avoid leaks.

Schemes of brick mini-ovens

Small ovens occupy a small area; the dimensions of their bases range from 50 to 70 centimeters in width and up to 65–100 cm in length. The height of the heating structure is from 1.5 to 2.3 meters. A cooking floor, an oven, and a water heating tank are built into the oven. Stove makers have also developed devices intended only for heating a home.

Small heating structure

This is the simplest heating structure. We will analyze the model in the following sizes:

- base width - 51 cm;

- base length (depth) - 89 cm;

- height - 238 cm.

The mini-stove is installed in the middle of the kitchen or against the wall. The optimal heating area is 20-35 meters. Interior partitions are erected around the stove, which allows heating both the kitchen and the adjacent room.

Inside the device are:

- combustion chamber;

- blower;

- smoke channels leading into the chimney.

The combustion door of the mini-stove (cast iron or glass) is selected depending on the aesthetic preferences of the home owners. A door made of heat-resistant glass, through which you can see how the wood is burning, gives the structure a resemblance to a fireplace. Two smoke valves are installed in the middle and upper parts of the furnace. There is one door for cleaning the channels. To build this model of the device you will need:

- 260 pieces of ceramic bricks;

- 130 pieces of fireclay bricks;

- grate (40x23 cm);

- combustion (30x20 cm) and blower (20x14 cm) doors;

- 2 doors for cleaning holes (20x40 cm);

- metal pre-furnace sheet (50x70 cm);

- two sheets of roofing material measuring 60x100 mm;

- sand and clay (or ready-made clay-sand mixture for masonry), clay-fireclay mixture.

Reference. Masonry mortar increases the volume of the device by the thickness of the joints.

The base and top of the mini-oven are laid with ceramic bricks on a clay-sand mortar. The firebox is made of fireclay bricks on a clay-fireclay mixture.

Three and a half bricks fit on the long side of the base, and 2 standard bricks 25 cm long on the short side. The masonry consists of 35 rows in height.

Small heating and cooking stove

This is a mini-oven model for heating and cooking - a convenient and very compact structure. The optimal area for a heated room at sub-zero temperatures is 20-25 square meters.

The device has the following dimensions:

- base length (depth) - 64 cm;

- base width - 51 cm;

- height - 215 cm.

The structure is being erected in the kitchen. The device includes:

- blower;

- combustion chamber;

- smoke channels leading into the chimney;

- cooking floor;

- niche for the oven.

The cast iron cooking floor has a hole that is closed with a disk and a circle. Solid flooring is also available for sale. In the niche for the oven chamber there is a metal oven or a hot water tank with a tap. If the niche is left free, it is used for drying things. To build a stove you will need:

- 222 pieces of ceramic bricks;

- grate (40x25 cm);

- firebox door (20x20 cm);

- door for the blower (14x14 cm);

- cooking floor (35x38 cm);

- metal oven or hot water tank;

- iron pre-furnace sheet (50x70 cm);

- two doors for cleaning holes (20x14 cm);

- two valves;

- a piece of flat slate;

- steel corner;

- clay, sand or ready-made clay-sand mixture for masonry.

Nuances of choosing a heater

When selecting a wood-burning stove, it is necessary to take into account working conditions, the specifics of the material, financial costs and personal preferences. Before purchasing a unit, you should pay attention to the following points:

- Brick structures are characterized by high heat transfer, but require financial investments in construction. Cast iron heats the room well and is installed without a foundation.

- Functional heating and cooking models are equipped with several burners and an oven.

- Pyrolysis devices ensure complete combustion of fuel.

- The optimal wall thickness of a furnace with a water circuit is from 75 mm.

- A unit with automatic fuel loading is loaded with circular sawn timber 10-15 cm thick.

- Due to their low efficiency, cooking and heating structures are suitable for rooms up to 25 m2.

- If you have a sauna or bathhouse, opt for a heater.

- The safest type of firebox is closed.

- It is easier to connect an expansion tank and heat exchangers to modifications with an oven.

Wood stoves require careful maintenance and compliance with operating conditions.

How are the different types different?

The variety of brick products for heating is very large. They can run on wood, coal or other fuels. Act as a heating device only, or can also be used for cooking.

Products can be folded into a variety of shapes: round, square or complex architectural designs. In terms of size, products range from very small models to large-scale multifunctional structures.

Only a good craftsman can put together such a design.

Various stove options mainly differ in the design of the chimneys:

- Models with horizontal smoke channels.

- Products with vertical channel design.

- Counterflow chimneys.

- Bell systems.

- Combined options.

Stoves can be used only for heating, or have additional functions:

- Hobs make it possible to cook food while the stove is on. But this design requires a smaller fuel compartment. In addition, the heat capacity of this model is much lower - a lot of heat is lost through the surface of the stove, the stove cools down faster.

- The presence of an oven compartment makes the design more heat-intensive. Hot gases can only heat this compartment, or pass directly through it. In the latter case, you can use the oven only after all the wood has burned out.

- Water pipes can be built into the stove. This design allows for heating throughout the entire house.

Variety of brick stoves

Carved brick stoves can decorate any home

Two-story brick ovens

You can combine different types of stoves, combine them with fireplaces, or pair them with a stove bench or heating panel. There are often two fuel compartments, each serving a specific purpose.

Main types

To decide on a modification to solve specific problems, it is important to familiarize yourself with what types of stoves there are.

There are currently 4 main types of brick stoves for home use:

- Heating . As the name suggests, the main task of these devices is to effectively heat a private house or other building. The sizes of heating stoves vary, which directly depends on the parameters of the heated room. Fireboxes can also vary quite a bit. In general, the main task of this type of construction is to efficiently heat the home, which is facilitated by fairly rapid heating of its walls. The appearance of such structures is usually not particularly sophisticated. The fireboxes of this type of home stoves have a large volume and strong walls, because... It takes quite a lot of fuel to heat a house. Most often this is high-quality and well-dried firewood.

- Heating and cooking . The most popular type of stove, which allows not only to heat the room, but also to cook food. Designs of this type usually have numerous additional elements, such as an oven, heating panel, grill, etc. The fireboxes of heating and cooking structures are quite diverse: this allows you to choose the optimal set of device functions for yourself. The dishes cooked on this type of brick ovens, with their unique taste and aroma, deserve special mention. As for the efficiency of heating a home, it is at a very high level: in this way it is possible to equip both private houses and country houses. The durability of structures is guaranteed by the use of high quality refractory bricks for their construction.

- Cooking

. This type of stove can only be used to cook food: it is not intended for heating rooms. Designs of this type are found in many modifications: the fireboxes in them are also different. Inside the appliance there is usually a kitchen hearth, a grill, a burner for a cauldron, etc. The functions of the cooking types of the oven are quite numerous, which allows you to prepare a wide variety of dishes. The construction does not require a lot of building materials: the work itself is often carried out independently by the owners of the home. If such a cooking device is installed in a small room, then it will heat the surrounding space during cooking. - Specialized

. These include stoves for baths, garages, greenhouses and other specific premises that need heating. Their construction will also require high-quality fireproof material. The dimensions of such structures are usually not very large. Efficiency and safety are at the highest level here.

Materials and tools

In order to build a stove, you will need construction tools:

- a trowel necessary for laying and removing the mortar that holds the bricks together;

- a mason's hammer (pick) for shrinking bricks laid on the mortar;

- metal jointing for marking seams between bricks;

- electric saw “grinder” for cutting bricks into pieces;

- construction electric mixer for mixing the solution;

- metal bucket (capacity 10–12 l);

- shovel and large metal container for mixing mortar;

- a metal mesh sieve for sifting sand and cement with a mesh size of no more than 2 mm.

You will probably be interested in reading about how to build a swimming pool, sauna, toilet, barbecue, cellar and veranda.

Required measuring tools:

- plumb line to check angles for verticality;

- corner level for checking the corners of the structure;

- construction metal or fabric tape measure;

- meter “rule”, with the help of which the wall surface is checked for evenness;

- cardboard templates of all openings provided for in the design;

- water level to check the masonry horizon;

- flexible level.

Necessary materials:

- The material for the construction of the stove is heat-resistant and fire-resistant red brick, smooth and solid. Broken or poorly dried bricks with voids and cracks are not suitable. A well-burnt brick produces a clear and clear sound when tapped. A dull sound means incomplete heat treatment or burning of the brick.

- Mortar for fastening bricks - cement mortar is not suitable in this case. A mixture of sand and clay with a viscous consistency is used as a binding solution.

Make a stove - a potbelly stove for heating your dacha.

Checking the solution for quality

Before starting work, it is important to check the quality of the resulting solution of sand, water and clay. To do this, take a small amount of solution from the mixture and roll it into a ball. After the clay ball has dried, check to see if it has cracks.

If there is, this means that there is too much clay in the solution, and a little more sand is added to the next batch to make the solution more elastic. There is another way to check the suitability of the mortar for masonry

After the clay ball has dried, check whether there are any cracks on it. If there is, this means that there is too much clay in the solution, and a little more sand is added to the next batch to make the solution more elastic. There is another way to check the suitability of the mortar for masonry.

A dried ball from a solution should not crack when dropped from a height of one meter onto a hard surface, and after calcination at high temperatures (in a stove, oven) it should not crumble into dust. If the clay ball resisted all tests, then the ratio of clay and sand for mixing the solution was chosen appropriate. Such a solution can be safely used for laying out a future heating structure; it will not fail and will not spill out of the seams of the furnace.

Important! If the sand is carefully sifted and cleared of coarse foreign impurities before starting work, the builder will not have to waste time removing small stones and other unwanted objects from the brick mortar.

Features of building arches and vaults with your own hands

When constructing arches and vaults, they also use do-it-yourself drawings of a brick kiln for a summer house or other building. The bricks are laid using the gradual overlap technology, with a thickness of at least two rows.

The thickness of such an overlap cannot be less than 2 rows. For the opening of the firebox, a “lock” layout or masonry using the “lintel” method is used - the bricks are installed vertically on a metal corner. A metal product can be replaced with a wooden frame.

To construct the pipe, silicate brick is used, which can withstand temperature changes and precipitation. It is resistant to the acidic environment formed when smoke and water vapor come into contact

It is important that there are no unevenness or chips in the chimney. When the stove structure is ready, a control fire is carried out after 2 - 3 weeks.

Large and small DIY brick stoves are popular in private homes. But the main thing is to build the unit correctly so that it lasts for decades.

Operating rules

A fireplace, a small sauna stove or a wood-burning model with a steam generator should not create fire situations. The operation of wood heaters involves:

- Installation next to the combustion chamber of a metal sheet 2 mm thick. The length of the protective product is 30 cm, the extension beyond the brick structure is 15 cm.

- Installation of smoke exhaust systems for metal structures made of acid-resistant materials.

- Use for burning dry firewood stored indoors.

- Dense fuel laying - thick lumber is on top.

- Use thin dry twigs for ignition.

- Laying firewood with a gap of 1/5 of the height of the firebox to the roof.

The second batch of fuel can be added after at least 1 hour, for long-term combustion models - after 3-4 hours.

Tunnel stove options

Tunnel brick ovens can be made with vertical or horizontal smoke channels.

Horizontal smoke channels

Hot gases in this type of stove give off their heat along the way to the chimney. It is necessary to provide a cleaning door on each channel, since soot and ash settle on the horizontal surface in large quantities.

Scheme of gas movement through horizontal tunnels

To increase the heat transfer of gases, you can also make special heat pockets. By increasing the internal area of the channel, the speed of movement of hot air through them is reduced. Consequently, the stove becomes more heat-intensive.

Scheme of gas movement through horizontal channels with pockets

This chimney system is not particularly popular.

Vertical smoke channels

A design with this arrangement of channels prevents the free movement of gases inside the chimney. This often leads to overheating of the first channel. In addition, in this case it is necessary to build a higher chimney than with a horizontal scheme.

Air movement through vertical tunnels

But this option has serious advantages: due to the large height of the structure, it is less susceptible to air blowing. This way the stove becomes more heat-intensive.

Scheme of gas movement in a counterflow stove

The main difference between counterflow designs and models with vertical channels is that the hole where the gases fall has a wider cross-section. They move at a lower speed, managing to transfer more heat to the brick walls.

Combined smoke exhaust systems

Combinations of different systems are often used. This makes it possible to use all the advantages of each design and get rid of its disadvantages for individual design. There are a lot of options for this combination.

Scheme of gas movement in a combined system

Scheme of direct-flow air movement

Movement of gases in a chimney with cuts

Not all designs are suitable for heating stoves. Some of them are used to construct simple fireplaces.