Brick stoves equipped with a hob are universal - they allow you to heat the house, as well as heat water and cook food. The designs of stoves vary, from the simplest and most compact, which you can assemble with your own hands, to complex multifunctional ones, the laying of which is best left to an experienced stove maker. For those who are interested in how to fold a stove with a stove for the home, how to properly fold a stove with your own hands, an article will help, which contains a diagram of the stove and drawings with orders.

Classification by material

Heating and cooking stoves (OHS) may differ in size and design of the chimney system. The following materials are used for the manufacture of thermal equipment operating on solid fuel:

Brick heating and cooking stove

Metal heating and cooking stove

Brick

The most common option is a stationary brick structure with a metal hob.

This option may differ significantly in size, the presence of additional elements and the complexity of manufacturing.

Additional elements include compartments for drying herbs, berries and fruits, as well as other functional compartments.

If you have an oven, you can also bake various confectionery products.

Stationary stoves are usually used to heat one room, but there are also models whose chimney is built into the interior walls, which allows you to effectively heat other rooms in the house.

Some models are made in such a way that the hot gases escaping into the chimney heat a large horizontal platform on which you can comfortably sit for rest and sleep.

Note! Brick stoves with a built-in hob account for the majority of those installed in private homes not connected to the gas network. The effectiveness of such structures has been confirmed by many years of operation, but they are not without drawbacks.

Among the obvious disadvantages of brick stoves, the following should be noted:

Large size, weight.

It takes a long time to warm up.

Laying and repair of such a structure must be carried out by a qualified craftsman.

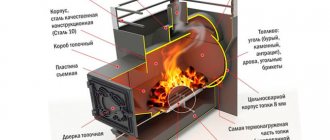

Metal

Wanting to make the room where the dimensional structure is installed more spacious, some owners of private houses dismantle brick stoves and install completely metal products.

The compactness and simplicity of design of metal furnaces is the main advantage of such models.

In addition, they can be relatively easily dismantled, transported to a new location and connected to the chimney in the shortest possible time and used for their intended purpose without the need for preliminary preparation and holding time.

Metal products have not only such remarkable properties as compactness and mobility. Cast iron or steel heats up to a high temperature in a short period of time, so after half an hour of intensive fuel combustion, the temperature in the living room rises to acceptable values. The other side of the coin of fast heating is that the stove cools down quickly after the fuel has completely burned out.

Even cast iron products, which have a high heat capacity, cannot compare with the effect of prolonged heat transfer from heated brick surfaces.

Expert opinion

Alexey Gavrilov

BBQ kitchen and equipment specialist

Which heating and cooking stove design to choose depends on many factors. First of all, you should take into account the fact how often the country house will be used during the cold season. For constant use of housing, brick is better suited. For a dacha that will be visited only from time to time, metal should be used.

Small, but simple cooking stove

Exclusively for culinary purposes, also in the country house or in the summer kitchen, the following design is intended, see fig. Below, a simple cooking oven:

- firebox door;

- blower door;

- oven door;

- hot water tank;

- cleaning

Simple cooking oven

In appearance, it is nothing more than a well-known kitchen stove, but it is made according to the Swedish principle, only without the labyrinth of channels; in the summer they are still inactive. Constructing “rough” in Swedish, we get:

- Although this is a brick kiln, it will take less than 250 bricks themselves, taking into account amateur fire, and the load on the floor will not reach the permissible 250 kg/sq.m. according to SNiP. m. That is, this stove can be built directly in an existing living space. Only the fireproof mat will have to be turned over: put felt on the floor, steel on it, and then build on the steel sheet. Asbestos or basalt cardboard are not suitable, they will not have adhesion to the floor and steel, and the stove may “move”!

- The oven heats up no worse than in a Swedish oven and you can bake bread in it.

- Instead of a hot water tank, you can install the same U- or W- heat exchange register, and in the attic - a hot water storage tank with thermal insulation. Then there will be enough hot water not only to wash dishes and hands, but also for a shower.

- From the Swede I got the side exit to the chimney, i.e. no need to hit the ceiling under the pipe.

- The fire part of the stove is completely Swedish and can withstand a fairly intense fire. In a small house or dacha for household and commercial purposes, inhabited from spring to autumn, a heating panel can be attached to the stove.

Types of ORP and their purpose

Heating and cooking stoves used in residential premises may have significant design differences. Humanity has been using fire for heating and cooking for tens of thousands of years, so it is not surprising that different nations have learned to “encase” it in order to make use more efficient and safe.

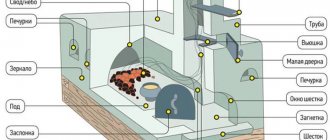

Russian stove

Multifunctional brick oven

Dutch oven

Swedish oven

Despite one common technical feature, the abundance of stove models is due to little communication between different tribes. In the age of the Internet, you can get acquainted within a few minutes with the most common designs of cooking and heating equipment that are used in different countries of the world.

Russian stove

Most of Russia's territory has always been subject to severe winters, so a massive stove was required to heat the house.

The traditional Russian heating device was used not only for this purpose, but also for cooking and baking bread directly in the firebox. On a cozy bed, which was heated by smoke, up to 2 people could comfortably sleep.

In general, the Russian stove was a nurse, a protector from the cold and a health resort, because sleeping on it had a beneficial effect on human health.

A modern Russian stove is made of special refractory brick, but in past centuries this structure could consist entirely of clay.

A significant difference also lies in the presence of a chimney, because previously many huts were heated in a black way, with a full flow of combustion products into the living space.

In ancient times, there was no foundation under the Russian stove.

However, today, according to modern standards for the safe use of heating equipment that uses open fire, the manufacture of a durable, fire-resistant base is a technological norm.

A Russian stove should be installed in a country house or dacha if the building consists of one large room or the living area is divided into sections, with a fence made of thin material.

Only in this case can high-quality heating be achieved.

Traditionally, Russian stoves were installed in wooden huts, so in a house made of natural materials, this type of heating and cooking device will ideally perform its function and look very organic.

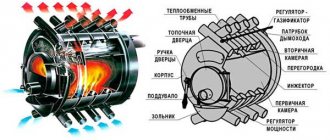

Swedish oven

The Swedish oven is a compact and functional device, and the presence of an oven in the upper part of the structure allows it to be used more efficiently. This cooking and heating device is made from brick. The Swedish stove is used for heating living quarters and cooking.

The most common Swedish breed is in Germany, as well as in the countries of Eastern and Northern Europe. In our country, this design of heating and cooking equipment has been used for less than 100 years. Building a Swedish stove in your home is a good alternative to metal structures. For this reason, in houses the Russian stove is often replaced with a rectangular, tall design with smaller dimensions.

It is recommended to install a Swede in the case where, due to the presence of a small area of the room, the owner of the house wants to keep as much space as possible free.

The compactness of this type of heating device is ensured without compromising its functionality. The Shvedka installation allows you to effectively heat your living space, as well as prepare food.

Dutch

The Dutch oven is intended mainly for heating the room. Its design does not have a cooking section. However, the open fire in the combustion chamber allows it to be heated to a high temperature.

A Dutch oven is made of brick, so once it gets hot enough, the firebox can be used as an oven in which to cook one-pot dishes. You can also bake bread and prepare dishes that require long simmering.

The Dutch style has been used in Russia for more than four centuries. During this time, the design has remained virtually unchanged.

The main feature of such a stove is the movement of hot gases through numerous channels. It is this design feature that the Dutchwoman owes to her high efficiency, which, with proper calculation and installation, can reach 55%.

The Dutch oven should be installed in a house in which the rooms are hermetically separated. In such buildings, a stove of this type is built into the wall between the rooms.

The Dutch oven is ideal for budget-conscious owners of houses or summer cottages, because it is possible to maintain a comfortable temperature in a well-insulated building with minimal wood consumption.

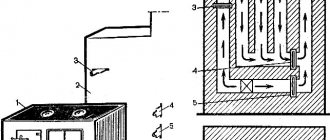

Smoke modifications

When fuel is burned in conventional furnaces, hot gases are intensively removed from the chamber through natural draft. This effect appears as a result of different atmospheric pressure at the entrance to the furnace and at the exit from it.

And during fuel combustion, the movement of gas is enhanced due to the presence of lighter heated air, which tends upward.

The smoke coming out of the chimney has a temperature higher than the environment, this fact indicates that the efficiency of combustion of the coolant does not reach 100%.

It is precisely this imperfection of furnace structures that smoke circulation modifications of furnaces can successfully cope with.

By “forcing” heated smoke to pass through numerous channels, it is possible to cool the gases heated up in the firebox, and therefore increase the efficiency of the stove.

According to the method of channel arrangement, heat exchangers can be of the following designs:

Horizontal

The use of horizontal channels makes it possible to produce large heat exchangers.

In such designs, the smoke moves in a straight line, then rises one “step” up, and then goes in the opposite direction.

The number of motion cycles depends on the height of the building, as well as on the ability to maintain traction at the level necessary for the successful removal of combustion products.

Vertical and combined

A similar design, but only with movement in a vertical plane, are stoves with a vertical chimney. The Dutch oven is a private version of such devices.

In some stove models, the chimney may have horizontal and vertical channels.

Such designs of smoke removal systems make it possible to produce heat exchangers of complex shapes.

Direct flow

In a direct-flow furnace, smoke and heated air from the firebox are removed through a straight chimney.

Heating devices of this design are easy to manufacture, compact, but have a very serious drawback - low efficiency.

Countercurrent

Counter-flow stoves have an original design in which the fuel chamber is located inside a shell, which is filled with combustion products after they rise up.

This stove option is ideal for heating small spaces.

Note! Direct-flow and counter-flow stove models, as a rule, are laid out without the use of a hob, therefore they are used only for heating the room.

The best long-burning cast iron wood stoves

Cast iron models have a high heat capacity: they heat up quickly but cool down slowly. The material is resistant to corrosion and high temperatures. The service life of the equipment exceeds 50 years. Disadvantages include high price and heavy weight: some models will require reinforcement of the floor base for installation.

NMK Sibir

Made of gray cast iron, which is characterized by increased strength and wear resistance. The thickness of the housing walls reaches 10 mm, which ensures long-term heat transfer after combustion is completed. The installed flame arrester protects the chimney and increases efficiency. Cast iron grates do not require replacement during operation.

The model is intended for heating rooms of 45-50 sq.m., can be used for cooking. The hob is equipped with cast iron burners of different diameters. Panoramic door with heat-resistant glass. The heat-resistant cord provides a high level of compaction and tightness of the combustion chamber. Firewood and briquettes can be used as fuel.

Advantages:

- Availability of a built-in chimney;

- Self-cleaning glass;

- Original design;

- Light weight.

Flaws:

- The metal ash box does not fit tightly.

Invicta Mesnil

The heating equipment of the French company is made of cast iron, resistant to temperature deformation. The door is equipped with self-cleaning glass made in Germany. The locking handle ensures the tightness of the firebox, increasing the level of safety. The secondary afterburning function increases efficiency and allows you to work on one load for up to 8 hours.

The vertical format model saves usable space and is easy to install. It is installed on an oval-shaped stand, which adds sophistication to the design. The power of the heating device allows the equipment to be used to heat a room with an area of up to 100 sq.m. The main type of fuel is firewood or briquettes.

Advantages:

- Durable gray cast iron;

- Extended manufacturer's warranty 5 years;

- Island location;

- Large glass area.

Flaws:

- There is no hob.

Kratki Koza/K9

The body is made of gray cast iron 200 class, resistant to elevated temperatures and wear. The material provides good heat transfer and soft, comfortable warmth. The power of the equipment is adjustable in the range from 6 to 13 kW, the fireplace can be used to heat a room of 100 sq.m.

The door is equipped with heat-resistant ceramic glass to control the burning of firewood. Secondary combustion technology ensures high efficiency and fuel economy. The supply air can be adjusted to a comfortable temperature. Heated air is used for secondary combustion. The power of the equipment is increased with the help of a cast iron deflector. Maintenance is simplified due to the installation of a retractable ash drawer and a sliding grate.

Advantages:

- Toothed barrier to protect against falling firewood;

- Decorative back panel;

- Manufacturer's warranty 5 years;

- Vertical chimney.

Flaws:

- Not detected.

Design features of ORP

Building a stove in a country house is sometimes the only option for heating a living space.

In remote villages it is not always possible to connect to the gas network, and electricity may be supplied intermittently. We should not forget that firewood is the cheapest coolant. In addition, if you own a plot of land with a large amount of dead wood, as well as if you live in close proximity to a forest, there is an excellent opportunity to provide free heating using a wood stove

Note! Regardless of the chosen model of a solid fuel stove, all structural elements must be of high quality. Only in this way will it be possible to ensure a high level of safety and efficiency of the heating device.

Foundation

Only metal stoves of the “potbelly stove” type can be operated without a foundation; in other cases, the construction of a high-quality foundation is required.

Furnaces that do not require a foundation

The purpose of the foundation is to prevent cracking of the structure as a result of uneven loads. In a wooden house, the importance of making a high-quality base for a stove is explained by the fragility and flammability of wood.

Furnace foundation

When installing the foundation for the furnace, the following conditions must be met:

- The base of the stove should not be rigidly connected to the other elements of the house (primarily the foundation).

- The location for the base of the stove should be selected in such a way that the stove pipe passes through the ceiling at a significant distance from the floor beams.

When calculating the base, be sure to take into account the expected load that the furnace may place on it. The more massive the structure is planned to be made, the stronger the foundation for it should be.

Scheme of row masonry of a heating and cooking "Swedish" with a fireplace

Before starting masonry, a waterproofing layer is laid - 2 layers of roofing felt are placed on the monolith. A sheet of roofing iron is placed on top, then a cake is made from a sheet of asbestos and a sheet of galvanized iron.

The masonry plan looks like this:

- 1st row - bricks are laid out without using a binder mortar;

- 2nd row – the masonry is done in a bond using a binding clay mortar;

- 3rd row - the beginning of the construction of the walls of the firebox and chimney ducts, the base for the oven, the ash door and inspection doors are installed;

- 4th row - the walls of the duct are erected;

- 5th row – laying under the grate;

- Row 6 – the walls of the combustion chamber and the walls of the chimney ducts are laid out, the combustion door is installed;

- 7th row – laying the firebox wall;

- 8 row laying the back wall of the fireplace, the walls of the firebox;

- Row 9 – fixing the door, covering the front wall, installing the oven cover;

- Row 10, covering the oven, installing the hob;

- 11th row – formation of the cooking chamber;

- 12-24 rows covering the cleaning chamber, forming chimney channels;

- 14th row – the fireplace mantel is formed;

- 15-16 rows forming the ceiling of the cooking chamber niche;

- 17th row – overlap of the cooking chamber;

- 18-19 rows the chimney channels are finally removed;

- 20-21 rows – the doors of the cleaning chambers are installed;

- 22 row - a jumper is made between the chimney channels;

- 23 – 24 rows a chimney valve is installed;

- Rows 25-33 are made by combining the chimney channels and creating one channel.

The best long-burning stoves with a water circuit

The easiest way to ensure uniform heat distribution in the house is to install a water heating system. Radiators are connected using pipes through which coolant circulates to a source of thermal energy. Its role can be played by a long-burning furnace with a water circuit, which can easily replace a solid fuel boiler. The difference between these models and conventional stoves is the presence of a heat exchanger.

Stoker 120 Aqua-C

A universal model that can be used as a backup heating device for a home with an area of 60 sq.m. A special feature of the design is the presence of a water jacket for connecting the battery and the possibility of additional installation of a heating element. The firebox ensures complete combustion of fuel due to the combustion of gases. Working time on one bookmark is up to 6 hours.

A door with heat-resistant glass will allow you to control the combustion process. Fine-tuning the power helps create a comfortable atmosphere in the home. The design of the housing makes it possible to increase efficiency due to the convection effect. The fins increase heat transfer and improve air circulation. The model is characterized by a high rate of heating of the room.

Advantages:

- Increased volume ash pan;

- Hob;

- Precise adjustment with microslides;

- Economical.

Flaws:

- Not detected.

Guca Lava Thermo

The Serbian company offers an inexpensive option for the heating system of a house with an area of up to 90 sq.m. The model is made of gray cast iron and boiler steel and has good heat transfer. The flue gas afterburning system has increased efficiency to 78%, thanks to which fuel is consumed economically and heating occurs quickly. Two air flow regulators help you fine-tune the room temperature. You can change the power for both primary and secondary afterburning.

Door with glass that can withstand high temperatures. The water circuit for connecting radiators ensures rapid heating of the coolant. The hob may have one or two burners. This makes it possible to use the oven for cooking.

Advantages:

- Good heat dissipation;

- Spacious ash drawer;

- Comfortable handles made of heat-resistant material;

- Vertical chimney.

Flaws:

- The paint takes a long time to burn during the first fires.

Ecofireplace Bavaria Prismatic

The Russian company offers to buy a model with a water circuit for owners of cottages with an area of up to 130 sq.m. The equipment is made of heat-resistant boiler steel and gray cast iron. The firebox is lined with cast chamotte to increase its service life. The body is lined with tiles. A French-made hob allows you to cook food.

The heating device has one of the highest efficiency in its class - 80%. This is achieved through a secondary combustion system with a constant air supply. Power is adjustable in the range from 9 to 16 kW. One stack of firewood or briquettes can work for up to 5 hours. The door with heat-resistant self-cleaning glass has a large glass area.

Advantages:

- Volumetric firebox for large logs;

- Adjustable clear glass;

- Slide valve with rigid rod;

- Side opening door for added safety.

Flaws:

- Heavy weight.

Preparing the necessary tools

During laying, you need to control the verticality of the walls and the horizontality of the rows. To do this, use a building level, a plumb line, and a carpenter's square.

Other tools:

- trowel, pickaxe;

- tape measure, pencil;

- drill with whisk;

- grinder with cutting wheel for stone.

For even masonry, use a device called ordering. This is a wooden or steel strip on which the installation locations of each brick are marked with marks or notches.

A cord is used, which is pulled after installing the corner elements; it outlines the top of the stones of each row.

Popular mistakes

It is better to wet the bricks before laying.

Inexperienced craftsmen put dry bricks into the masonry, but it is better to wet the material. It holds better and adheres more firmly to the solution. This results in more accurate and even masonry joints. Use a wide bucket of water, where the elements are placed for 2 - 5 minutes before installation.

Narrowing the smoke channel in relation to the standard size reduces draft, and damp wood will not burn. When installing the fire chamber door, they often do not leave a 0.5 cm gap around the perimeter to compensate for expansion. After installation, the gap is filled with asbestos cord or sand mortar.

Iron partitions are placed inside the furnace, but it is better to use bricks placed on edge. This is explained by the different expansion of ceramics and metal.

The oven cavity cannot be placed close to the firebox; it is better to place it above the heating chamber through the decks. This will heat the bottom evenly, and the baked goods will be baked equally on all sides.