Today, when furnishing their home, they very often decide to install a fireplace in it. After all, it acts not only as an addition to interior design, but also as a heating device.

In this article I will draw your attention to this type of fireplaces: gas. After all, they are rapidly conquering the market due to their main advantage - ease of installation and operation. A gas fireplace is a heating device with a living flame effect that uses gas as fuel. I will tell you about the main types of gas fireplaces and their features.

Gas fireplaces, their advantages and disadvantages

In order for the fireplace to delight you with cozy warmth on long cold evenings, it should be properly cared for. This means that you need to constantly monitor the combustion process, the moment of cleaning the firebox, etc.

Anyone who owns such a structure understands that its installation requires a considerable investment of effort and money. In addition, the development of a project and installation requires, first of all, coordination with the relevant authorities, and the plan of a country house should already have a prerequisite for arranging such a structure.

However, there is a simple solution to this problem. You can purchase a good model of gas fireplace and install it in your home.

They do not require special care, are easy to use and do not clog the room (with ash, firewood, soot). Apart from decorative models, gas ones can be used as regular heating appliances.

A gas fireplace is a heating device with a living flame effect, using natural gas (methane) or liquefied gas as fuel.

It makes sense to install a gas unit in apartments and country houses to which main gas is supplied.

Although it is possible to organize its operation on gas in cylinders. But in this case, you will need to equip a special room for storing gas containers, and the cylinders will have to be refilled from time to time (which is not very convenient). The combustion temperature of gas (500-650°C) is significantly lower than that of firewood.

Therefore, the requirements for heat resistance of the materials from which the fireplace is made are different. In addition, when burning gas fuel, very little soot is formed - mainly, it breaks down into carbon dioxide and water vapor.

Advantages:

- Much more environmentally friendly than wood-burning fireplaces, fewer hazardous substances enter the atmosphere.

- Gas fireplaces are cheaper in price than wood fireplaces, and their design is much simpler.

Fuel dosing is fully regulated by an automatic system, both electronic and mechanical. This means that, regardless of the degree of modernity of the model, a gas fireplace in an apartment does not require constant adjustments and intervention during operation.

- A live fire like a wood fire, but without ash and soot.

- The heating power of gas fireplaces can reach 8 kW.

Gas has a high specific heat of combustion, which explains the level of efficiency, which is incomparably higher than that of wood. In our case, it can exceed 80%.

- It is easy to use, it ignites quickly and does not require constant maintenance (throw in firewood, adjust the draft, or can be left unattended).

Flaws:

- To install a gas fireplace, permission from the relevant services (gas and fire) is required.

- A gas fireplace should ONLY be installed by a professional. Its first launch is accompanied by permits from the gas and fire departments. The owner, on his own initiative, cannot make any changes to the design or its operation.

- The fuel used is dangerous propane-butane or natural gas, so a fireplace with safety precautions or malfunctions can cause trouble.

Fireplaces are equipped with a pipe that acts as a chimney. If it is located far from the built-in ventilation duct, then a lot of work needs to be done, which must be agreed upon with the fire inspector.

Modern fireplaces are automated by electronic control systems, which means they require electricity. They are small, but installing a fireplace involves installing an outlet in close proximity, which increases the overall amount of work.

A gas fireplace can have an open or closed firebox - equipped with a heat-resistant glass door.

A unit with an open firebox resembles a fireplace using solid fuel. You can light it with matches without much difficulty, but there is also a danger of getting burned by its flame.

The glass door covering the front of the firebox plays a dual role: it protects the burner from contamination and protects users from possible burns due to careless handling.

Gas fireplaces with a closed combustion chamber use heat-resistant glass.

Gas is a flammable substance, but despite this, gas fireplaces are considered one of the safest devices. Thanks to a multi-level tracking system, any emergency situations will be prevented.

Infrared sensors are fireplace position sensors. They react if the device suddenly falls. To avoid causing a fire, the gas supply system is turned off.

A gas fireplace is a fairly powerful source of heat, so this unit can heat large areas of your home.

Gas fireplaces have lower exhaust requirements compared to wood fireplaces, which require a full chimney.

After all, the combustion products of natural gas are steam and carbon dioxide, and the temperature of the exhaust gases at the outlet is much lower. This also increases the appeal of a gas fireplace in the eyes of the modern consumer.

However, at the same time, you must understand that connecting a gas appliance involves additional work that must be carried out by specialized services. This procedure also requires documentation in accordance with local legislation. For many reasons, installation sites for gas equipment are limited by safety requirements.

The variety of models of gas fireplaces and fireplaces will allow you to realize any idea of implementing a modern, comfortable fireplace in your home.

You can install a fireplace using one of the existing methods:

- Floor method. This arrangement involves installing the firebox on the floor covering.

- Wall method. The firebox is hung on the wall and has a completely closed design with ventilation channels.

- Embedded method. The firebox is placed on a furnished base and covered with decorative elements.

- Street. The structure is installed outdoors, in a summer kitchen or gazebo.

Where can you see a Russian stove?

We will answer all your questions step by step. In our country, a huge part of the population lives far from civilization. In the 90s, there was a tendency for villages to die out. Young people left their parents' homes and went to the city in search of a better life. Many buildings remained simply abandoned.

Most village houses were equipped with stove heating. In order to dismantle the stove, it is necessary to re-lay the floor covering and seal the hole in the roof under the chimney. Not everyone had the desire and opportunity for this, so the symbols of warmth and comfort in the home, sung in Russian fairy tales, still stand to this day.

Massive brick building

Gasification made it possible to install a burner in the stove and give the structure a second life. But the modern approach to reconstruction implies that it will be converted into a functional, stylish fireplace.

Features of gas fireplaces

Gas fireplace equipment includes the following structural elements:

- A fireplace insert that decorates the room.

- A body made of cast iron or a special metal alloy.

- A high-power burner from which gas is supplied.

According to fire safety rules, such a device must have a high-quality fire-resistant lining, which, in addition, performs a decorative function.

There are fireboxes of different sizes and appearance, i.e. design, so everyone can choose the most suitable insert for their interior style for a gas fireplace.

To comply with fire safety measures, so as not to interfere with air circulation in the fireplace, the firebox must be lined. The cladding can be made of ceramics, artificial and natural stone or ceramic tiles, but the cladding material must have fire-resistant properties.

Inside the combustion chamber there is a firebox, necessarily lined with fireclay bricks, a gas burner, a reflector and a protective screen. All these elements are hidden behind artificial logs.

On the reflector screen, the combustion of fuel occurs, which comes out of the burner onto it. This screen consists of special frames that warm up quickly and release heat.

The reflector, in turn, helps accelerate the heat transfer process. The radiator located in the fireplace releases heat into the room by convection of hot air. The power depends on the number of radiator sections.

The gas fireplace burner is decorated with fireproof ceramic models. They create the impression that wood or coal is burning in the fireplace, and the flames are knocked out between the logs.

The fireplace body is usually cast iron, with possible finishing with stone, ceramics, metal, tempered glass.

The upper part forms a gas collector to which the chimney is connected. A ribbed radiator is installed on the gas collector - the main heating element.

Heat exchange is so efficient that heat loss is only 15%. And for solid fuel fireplaces - 50 - 70%.

The efficiency of a gas fireplace is achieved due to the optimal fuel combustion mode and the special design of the body, which allows the maximum heat from the gases to be transferred to the room air.

Chimneys for gas fireplaces are made of special stainless steel, since combustion produces a lot of water vapor saturated with acids.

Chimneys are enclosed with thermal insulation material that is resistant to heat and oxidation, which prevents water from condensing directly in their lower part.

The upper part of the fireplace is the smoke collector, which passes through the smoke exhaust channel into the chimney itself. The smoke collector has the shape of an accordion, which increases the heat transfer of a gas fireplace.

The fireplace chimney is designed to create draft and remove combustion products outside the room. During the combustion of gas, carbon dioxide and water vapor are released, which have a detrimental effect on the chimney. For this reason, it is made of a heat-resistant material that also has water-repellent properties; steel is most often used for this.

The power of gas fireplaces is usually in the range of 7-12 kW, which is quite a lot, enough to heat the “floor of the house”. At the same time, fuel consumption in heating mode can reach 500 g per hour. And in the flame simulation mode – 180 g per hour, which is comparable to the consumption of a gas stove burner.

The gas device is controlled by a microprocessor. The fireplace is equipped with temperature sensors, so you can set the room to warm up to a certain temperature. Other sensors monitor draft, gas flow and pressure, optimal combustion, etc. In case of violations, the fireplace will be turned off; the safety of operation of this household appliance is guaranteed by the manufacturer.

Gas fireplaces are produced both for main gas and for liquefied propane in cylinders, and this is an option for a remote dacha.

In any case, the gas unit is connected by the gas service master, according to the gas supply project, for which the relevant documents are issued.

But before purchasing and installing a fireplace, you need to obtain permission to install it. This is easier for a home or cottage, but problematic for an apartment.

Facing

When the structure is completely dry, you can move on to decoration. There are different methods for cladding a fireplace; the material must be resistant to high heat.

Brick finish

Old brick can be given a more fresh, decorative look if treated correctly.

First, excess cement-clay mixture is removed from the seams and bricks with abrasive paper. It is necessary to treat the seams, for example, with a colored mixture, to give them a convex shape.

The bricks must be coated with heat-resistant paint. The final coating is a varnish that can withstand high heat.

Plaster coating

A simple finishing option is plaster. To perform the cladding, complex installation work is not required, as, for example, with tiles.

It is necessary to make the solution more durable; you can use salt or crushed fiberglass. To give the coating a tint, add lime paint.

Before you start plastering, the fireplace is heated until the outer surface becomes warm. The plaster is applied in layers, the first layer eliminates minor irregularities, the second is decorative.

Stone covering

An impressive finish can be made with artificial or natural stone. In both cases, environmentally friendly material will be used, the difference is in weight and density of raw materials.

Artificial material is much cheaper, you can make it yourself. The natural analogue is better due to its natural properties.

Natural raw materials are characterized by increased resistance to any changes in temperature, humidity, and mechanical damage, in contrast to artificially created materials.

The cladding is complex, and it is difficult to attach natural raw materials to ordinary mortar. It is recommended to consult a mason.

Tile surface

Not all tile models are suitable for decorating the outside of stoves and fireplace devices: clinker, porcelain stoneware, terracotta, majolica.

Clinker tiles have become widespread due to their stability. There are many colors, imitation of natural stone. Models are produced with the addition of stone chips, which enhances performance characteristics.

The tiles will require adhesive that will not dry out when exposed to high temperatures.

Making a fireplace from scratch, or remaking an old stove is not very difficult, the main thing is to work out the diagram and prepare the materials. You cannot replace the material with a similar one; the structure will become very hot.

Step-by-step algorithm for remodeling the furnace:

Gas fireplace safety

Modern gas fireplaces are equipped with several automatic safety systems:

- Checking gas pressure.

The gas supply system provides and maintains constant pressure, and the built-in sensor monitors the process and automatically stops the gas supply in case of any violations.

- Air analyzers.

Another sensor is atmospheric. They constantly check the condition of the air in the room, determining the level of carbon dioxide formed during combustion, and if the norm is exceeded, they automatically issue a command to turn off the gas supply.

- Infrared sensors.

Their task is to monitor the position of the fireplace. If for some reason it unexpectedly tips over, infrared sensors will detect this and instantly stop the fireplace from working.

Device structure

Different manufacturers provide numerous options for gas fireplaces to choose from. But if you understand their structure, you can identify single key nodes that perform strictly defined functions.

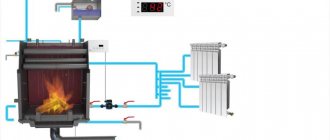

Suspended version of the fireplace system

- The gas combustion process occurs in the furnace. It is this that determines the type of fireplace and can be open or closed.

- The smoke collector concentrates combustion products before they enter the chimney. Its purpose is to ensure that carbon monoxide evaporates without loss and does not remain in the room.

- Do not forget that the main purpose of such a fireplace is heating, so the heat exchanger is a mandatory part. With its help, heat is released from the increased area.

- The gas supply to the direct place of its combustion is provided by a gas burner.

- Dummy firewood.

- Flame control system.

With this configuration, it is not difficult to imagine the operating principle of the fireplace. After switching on, which is done from the control panel, gas supply begins. At the same time, automatic ignition occurs, which works thanks to the piezoelectric effect. Temperature sensors send a signal to the controller and “monitor” the air condition in the room. When a certain temperature is reached, the gas supply decreases and the flame intensity drops.

A gas fireplace without a chimney, despite its obvious advantages, involves additional work. In its natural form, it can only be used outdoors, for example, in the country. Working indoors, he still needs to remove combustion products.

Relaxation area in the apartment space

The fireplace deserves its name due to the fact that there is no need to install a chimney or maintain its height to ensure the required draft. The burnt gases are discharged through a special pipe through the wall to the street. It is also possible to equip an apartment with such a fireplace, but this requires permission from the management company.

Good to know: Permits for installing a real fireplace in an apartment

Gas fireplaces without chimney

The principle of operation of chimneyless fireplaces is the complete combustion of fuel, which leads to the absence of combustion products.

They are used as decorative elements and are manufactured in several modifications:

- Floor-standing fireplaces for a home on gas without a chimney look like a regular island fireplace.

A small gas cylinder is installed inside the case, the capacity of which is sufficient for full operation for several hours.

Floor-standing models are often equipped with wheels or can simply be moved to any convenient place. A convenient option because it does not require special tricks during installation and can be used even outdoors, verandas and cafes.

- Hanging and built-in fireplaces. Easy to install outdoors, creating a cozy and comfortable atmosphere.

Installing stationary built-in devices is more difficult, but the result is more aesthetically pleasing. The front panel of the fireplace is flush with the wall, the device does not hide the space of the room. You can also “hide” gas supply lines in the wall. In addition, such a fireplace can be decorated with a wall, then the flame can be observed from two or even three sides.

The models are completely safe; no toxic combustion products are released during combustion. To install a chimneyless fireplace, there is no need to obtain permits. To ensure proper operation, the room should be ventilated before turning on the device.

Advantages of gas fireplaces without a chimney

When choosing, most buyers are guided by the ratio of positive and negative properties of heating equipment.

Comparing the pros and cons, they make a certain choice and make a purchase.

Gas fireplaces for apartments without a chimney have a number of distinctive features:

- Quick ignition.

While wood or charcoal takes a long time to ignite effectively, the gaseous mixture ignites immediately and within minutes you will feel the temperature in the room increase.

- Additional properties.

Many models are supplemented with devices that simplify the operation process. For example, a thermostat can control the level of heat generated to optimize fuel consumption.

- Simplified operation.

Installation requires a minimum of effort and time; you do not have to constantly move logs, chop wood and look for coal.

- Environmental Safety.

Gas-powered structures emit minimal pollutants into the atmosphere. An alternative option may be to use biogas obtained from waste processing - when burned, it emits significantly less carbon dioxide.

Installation Requirements

You can build a gas fireplace with your own hands in two main stages: arrangement and connection. It is logical to note that all this is intended for the street version of the structure. And first you need to accurately determine the location that the fireplace will occupy, its size, shape and general appearance. It is necessary to take into account the convenience of passages and the location of furniture next to this decorative element. They are often built as an element of a patio, near a summer kitchen, a swimming pool or on a terrace. In various photos, such devices look quite modern and beautiful.

Gas fireplaces on a cylinder

When installing, the first thing you need to do is decide on the location of the fireplace, make a marking of where exactly the structure will be placed, and only then get down to business.

And although gas cylinder fireplaces are modern safe designs, precautions must be observed.

There are certain rules for installing a gas fireplace that must be strictly followed.

Remember that by neglecting these rules, you risk not only your own health, but also that of your loved ones. After all, due to carelessness and negligence, a fire, explosion, or, at best, equipment damage can occur.

Basic Rules:

- A gas fireplace or stove should be mounted exclusively on a stable, flat surface. Such a surface must be made of fire-resistant materials or can be lined with fire-resistant tiles.

- The load-bearing floors must support the weight of the fireplace. The bearing capacity of concrete slabs is 750 kg/m2, for wooden floors - no more than 300 kg/m2. If the load-bearing capacity is less than the mass of the heating device, then it should be distributed over the entire surface, increasing the support area.

- Remove all flammable furniture and structures from the heating surface of the fireplace to a safe distance. As a rule, this is indicated in the device passport.

If the wall is not insulated, a distance of 60 cm is considered safe, for a ceiling - 130 cm. If for some reason you need to reduce this distance, this can be done by using sheet steel cladding.

The steel sheet is laid on top of a layer of mineral or basalt wool or asbestos, the thickness of which must be at least 8 mm. It is worth noting that asbestos material itself is not environmentally friendly, and for this reason its use in residential premises is not advisable.

- The gas main is supplied through metal pipes, as well as special gas fittings. This type of work must be entrusted to specialists. Only gas cylinders are allowed to be connected by yourself, but if you are not confident in your abilities, do not take risks, invite a specialist.

- Gas fireplaces using bottled gas without a chimney are not permitted.

The chimney for removing processed gases must be made of resistant materials. Ceramic and stainless steel chimneys are suitable; they will be resistant to acids.

They mainly buy sandwich chimneys made of stainless steel, which have high corrosion resistance and good thermal insulation. Prefabricated ceramic chimneys are also reliable, but they are more expensive.

In addition, you can use a coaxial chimney with a built-in recuperator and air duct.

- For combustion efficiency to be high, air must flow into the firebox without obstruction. The intake can occur either from the room through air ducts or through special air channels in the chimney system.

- Make sure that the room with the fireplace is always ventilated. Fireplace models with an open firebox should be placed so that the flame is not directly exposed to air.

- When installing a built-in type of firebox in a casing, make channels in it in advance so that air can circulate freely in both its upper and lower parts. The convection flow must pass freely between the casing and the heating chamber, and at the same time be able to remove heat from its walls.

Street option

If you are going to install a gas fireplace in your country house, on the territory of your summer cottage (alternatively, it could even be a garage), then it is recommended to choose an outdoor option. As you might guess, it will be installed outdoors. For example, this could be a gazebo or a secluded place in the garden.

As for the shape and method of construction, such a fireplace is very similar to a home one. They are usually made from the same brick, but you can choose another building material. The most important thing is that it can withstand various natural influences.

Burners for flueless water heaters

Two types of burners are installed in flueless gas water heaters:

- Variables with automatic power adjustment;

- Constants in which the power changes in steps.

A stepped burner makes it possible to adjust the fire power, which ultimately affects the temperature regime of the water heater. This solution may seem convenient, but only at first glance. In practice, it often turns out that the temperature of water heating during the operation of the column fluctuates within a fairly wide range.

The degree of heating can be affected by changes in gas pressure, air pressure or inlet water temperature. The last factor often occurs if the heater was set up with warmer water, and then colder water from the street began to enter the system.

When the required power level is set, the water temperature can be changed by the degree of opening of the tap. However, excessive efforts in this case will not lead to the desired result - if you tighten the tap too tightly in an attempt to get extremely hot water, you can simply get a completely cold stream. Trying to change the outlet water temperature by adding cold water from the tap is strongly discouraged.

How to serve

A fireplace without a chimney is easy to use.

To maintain an electric fireplace, you need to know a few simple rules - wipe off dust on time, change the water in the tank if we are talking about a fireplace with the effect of a real flame, and clean the tank from limescale if you use unfiltered water. In this case, with bio-fireplaces everything is somewhat more complicated - you must adhere to safety rules so as not to get burned or start a fire. You need to carefully pour fuel into the tank using a special watering can. Be careful not to spill fuel. Use long matches or lighters with a long handle to prevent possible burns.

Calculation methods

Exact method + formula

Calculating a chimney for a stove is not a task for beginners. It is better to entrust such work to professionals. But if you decide to calculate this parameter yourself, you will need knowledge of basic data and several formulas:

To determine the volume of exhaust gases, it is important to know the power of the heating unit. For calculations we use the formula: , where:

- B is the combustion rate coefficient of solid fuel. This value is determined based on the data in table No. 10 of GOST 2127;

- V – level of volume of fuel burned. This value is indicated on the tag of the industrial device;

- T – heating level of exhaust gases at the exit point from the chimney. For wood stoves - 1500.

- The total area of the chimney. It is calculated based on the ratio of gas volumes, this value is designated “Vr”, and the speed of their movement in the pipeline. For a household wood-burning stove, this number is 2 m/sec.

- The diameter of a round pipe is calculated using the formula - d² = (4 * Vr) / (π * W), where W is the speed of gas movement. It is better to perform all calculations on a calculator and carefully enter all values.

Calculating the optimal amount of thrust

This operation is performed to control the calculations of the optimal height and cross-section of the chimney. This calculation can be carried out using 2 formulas. We will present the basic, but complex formula in this chapter, and we will present the basic, simple formula when performing a trial data calculation:

, Where:

- C is a constant coefficient equal to 0.034 for wood-burning stoves;

- the letter “a” is the value of atmospheric pressure. The value of natural pressure in the chimney is 4 Pa;

- The height of the chimney is indicated by the letter “h”.

- Т0 – average level of atmospheric temperatures;

- Ti is the amount of heating of the exhaust gases as they exit the pipe.

Example of calculating the cross-section of a chimney

We take as a basis:

- the potbelly stove runs on solid fuel;

- within 60 minutes, up to 10 kg of hardwood firewood burns in the stove;

- fuel moisture level – up to 25%.

Let's look at the basic formula again:

The calculation is carried out in several stages:

- We perform the action in brackets - 1+150/273. After calculations we get the number 1.55.

- We determine the cubic capacity of the exhaust gases - Vr = (10*10*1.55)/3600. After calculations, we obtain a volume equal to 0.043 m3/sec.

- The area of the chimney pipe is (4*0.043)/3.14*2. The calculation gives a value of 0.027 m2.

- We take the square root of the chimney area and calculate its diameter. It is equal to 165 mm.

Now we determine the amount of thrust using a simple formula:

- Using the formula for calculating power, we calculate this value - 10 * 3300 * 1.16. this value is equal to 32.28 kW.

- We calculate the level of heat loss for each meter of pipe. 0.34*0.196=1.730.

- The level of gas heating at the exit from the pipe. 150-(1.73*3)=144.80.

- Atmospheric gas pressure in the chimney. 3*(1.2932-0.8452)=1.34 m/sec.

Important! Using the data from your furnace, you can perform the calculation yourself, but to be on the safe side, it is better to consult with specialists. The safety of your home and the economical operation of heating devices depend on the correctness of the calculation.

Swedish calculation method

The size of a chimney for a stove can be done using this method, but the main purpose of the Swedish method is to calculate the chimneys of fireplaces with an open firebox.

In this calculation method, the size of the combustion compartment and the volume of air in it are not used. To determine the correctness of the calculation, use the following graph:

What is important here is the correspondence between the area of the combustion chamber (“F”) and the opening of the chimney (“f”). For example:

- firebox dimensions 770/350 mm. We calculate the area of the compartment - 7.7 * 3.5 = 26.95 m2;

- chimney size 260/130 mm, pipe area – 2.6*1.3=3.38 m2;

- We calculate the ratio. (338/2695)*100=12.5%.

- We look at the value 12.5 at the bottom of the table and see that the calculation of length and diameter was made correctly. For our stove it is necessary to build a chimney 5 m high.

Let's look at another example of calculation:

- firebox 800/500 mm, its area is 40 m2;

- chimney cross-section 200/200 mm, area 4 m2;

- We calculate the ratio (400/4000)*100=10%.

- Using the table, we determine the length of the chimney. In our case, for a round sandwich pipe it should be 7 m.

Pipe material

There are four non-combustible options to choose from what the pipe for the furnace will be made of - brick, metal (steel), concrete or modules with ceramic cores.

Most often, stove owners still prefer to install brick pipes, which in turn consist of the following elements:

- neck is the part of the pipe between the furnace body and the groove in the thickness of the ceiling;

- cutting - thickening the pipe in the body of the ceiling;

- a riser is a pipe located in the attic space;

- cutting near the roof (also called “otter”);

- pipe head.

For the pipe, you will have to use only special high-quality bricks designed for laying heated structures. The solution on which it will be laid must also be heat-resistant and plastic.

Is it profitable or unprofitable to heat a dacha with bottled gas?

An approximate estimate of the cost of heating with bottled gas can be determined from the following calculations:

- The calorific value of a cubic meter of firewood with 12% humidity is on average 2300-2500 kW/h, while for propane this characteristic is 6710 kW/h;

- The efficiency of a gas fireplace is 97%, the wood-burning version provides no more than 25-27%;

- The cost of a cubic meter of firewood is 1,600 rubles; for propane, the price of a cubic meter will be 19 thousand rubles.

As a result of the most approximate comparison, it turns out that to obtain an equivalent amount of heat from wood and propane, you will need 1.2 and 1.1 rubles, respectively. It turns out that heating using bottled gas will cost at least no more than wood in terms of fuel costs. If you take into account the transportation tariff and losses when cutting wood, then bottled gas may turn out to be more profitable.