Content

Despite all the popularity of natural gas in the modern world, there are still places where its use is still unavailable. In this situation, a person will be helped by a stove in a wooden house, which is heated with wood fuel or coal. You can purchase this fuel at any time of the year.

Classic stove design

In appearance, the potbelly stove resembles an ordinary rectangle on legs. It is equipped with a door and a compartment for fuel, and an ash drawer for combustion waste. In addition, any potbelly stove is equipped with a branch pipe where an exhaust pipe with a length of 5 meters or more is installed. The length of the pipe directly affects the thrust and power of the device. The furnace body is made of steel or cast iron. We also recommend reading about the chimney for a potbelly stove in the garage on our portal.

Potbelly stoves are classified into two types:

- Metal devices.

- Brick buildings.

Brick models fit perfectly into a small country house and can heat several rooms at once. The stove heats the rooms evenly and allows you to retain heat for a long time. The only drawback of a brick potbelly stove is the long heating process. But the brick adds more functionality to the device; for example, during masonry, you can build a place for cooking. Craftsmen can arrange a recess for the oven.

Models of cast iron stoves are compact and easy to install, because they can be placed in any suitable place. The main thing is to fold the chimney correctly so that it can be easily moved thanks to the corrugated pipes.

Difficult climatic conditions are a factor that everyone living in the vast Russian territory has to take into account. With the onset of cold weather, houses, apartments, and industrial buildings are connected to centralized heating systems that supply heat and create comfortable conditions for us throughout the heating season.

Calculation of basic parameters: drawing and recommendations

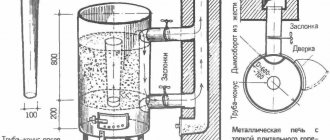

To make an optimally efficient potbelly stove, an all-metal cylinder with a volume of 50 liters is suitable.

A standard 50 liter cylinder will be sufficient

Finding such a cylinder is usually not difficult. They are often used in households and industry.

To equip such a stove with a chimney, a pipe with a diameter of 100–125 mm and a thickness of at least 3 mm is used to make the chimney pipe. The chimney itself should be positioned vertically, but deviation from the axis is also allowed (slope no more than 30 degrees). The slope is made for greater efficiency of heat transfer from the chimney pipe. Although the location of the pipe directly depends on the local conditions for installing the potbelly stove.

For ease of operation, the firebox and ash pan compartments are equipped with doors with a locking mechanism. With the doors closed, the combustion process improves and the risk of fire hazardous particles falling into the room is reduced. And also by adjusting the gap with the ash pan door, you can regulate the intensity of air supply to the firebox.

The doors are made of any shape. The main thing is to take into account the standard size of firewood and the convenience of loading it.

An important part of the potbelly stove is the grate. The grate serves to support fuel (wood) and at the same time helps to separate loose combustion products. The combustion process takes place on the grate

Therefore, the metal from which the grate is made must be strong enough and resistant to high temperatures. It is better to make a grate from reinforcement rods with a diameter of at least 12 mm. Such rods are cut to the dimensions of the inside of the cylinder (width) and assembled into a grid with a gap width of 10–15 mm. The rods are connected by welding

The combustion process takes place on the grate. Therefore, the metal from which the grate is made must be strong enough and resistant to high temperatures. It is better to make a grate from reinforcement rods with a diameter of at least 12 mm. Such rods are cut to the dimensions of the inside of the cylinder (width) and assembled into a grid with a gap width of 10–15 mm. The rods are connected by welding.

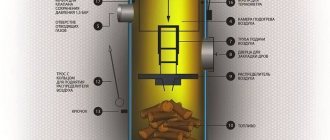

Potbelly stove from a cylinder

The approximate assembly diagram of a horizontal solid fuel stove is applicable to a gas cylinder.

The diagram is applicable for a gas cylinder

The main advantages of stove heating

Installing a stove is not only a simple process, but also quite inexpensive in terms of the cost of materials. Using firewood is the most environmentally friendly way to heat a space and will not harm your family. The installation of a stove can be combined with the installation of a fireplace, then there will be not only a standard type of heating, but also a stylish design element in the room.

Furnace maintenance is a simple and fairly cheap process. The main advantage is the ability to regulate the degree of combustion and the ability to retain heat using special dampers installed in the stove.

Features of operation

Before installing and starting the oven, pay attention to additional important points:

- for effective heat transfer, you can install a screen by laying brick walls without mortar on the sides of the potbelly stove, at a distance of 10–15 cm from the body: when the brick heats up, it gives off heat for a long time. In addition, this screen will protect the walls of the room from sudden temperature changes;

- It is advisable to use firewood with a humidity of 20%, although this figure is achieved only after 5 years of natural drying (wood will burn with high humidity, but then you will have to clean the stove and chimney from the inside more often);

- during the combustion and smoldering process, it is better not to open the fuel door so that carbon monoxide does not enter the room;

- Lay a sheet of galvanized iron on the wooden floor where the potbelly stove is installed, preventing a fire from accidentally falling coal from the stove. For concrete floors, such arrangement will be unnecessary.

A potbelly stove not only heats a room, but can also become a “warm” decoration for any home if its exterior design is done in a suitable style

Potbelly stove stove design

One of the biggest problems with furnaces of this type is the design itself. Conventionally, the model of a potbelly stove can be imagined as a hearth wrapped in metal and slightly raised above the floor level. Classic cast iron stoves have a firebox and a blower. The design does not provide a gate to regulate the air supply to the combustion chamber, so this is done by opening and closing the blower door. Such an operation is unsafe - when the ash pit is filled with ash, sparks often roll out, which causes a fire. So the “potbelly stove” fully lives up to its name and the appetite is exorbitant and a fire can break out at any minute.

The fuel combustion process also looks specific, which is the reason for the low efficiency of the potbelly stove. When wood burns, the metal shell of the stove body heats up and the heat spreads into the room through thermal radiation. The burning of wood usually occurs irrationally; when burning, the wood simply does not have time to reach the required temperature and therefore some of the combustible gases from the firebox simply go into the chimney. By the way, the pipe itself, like the furnace body, wastes precious heat irrationally - heating of the room occurs due to thermal radiation, and occurs only when the fire is burning in the firebox. As you can see, everything is quite simple - the fuel burns inefficiently in the firebox, while this type of heat energy release such as convection is used irrationally. So it turns out that any improvement immediately allows you to increase the efficiency of the potbelly stove, which means it will allow you to use fuel more efficiently.

Step-by-step instructions for assembling a potbelly stove with your own hands

The first stage is the preparation of the drawing and necessary materials. As for the drawing, it should reveal the design features and subtleties of all elements in as much detail as possible.

For experienced craftsmen, this stage can be skipped, but for those who are just starting the journey of constructing potbelly stoves, it is recommended to assemble a model from cardboard. Modeling, in this case, will cost much less than miscalculations immediately embodied in metal.

The next step is the selection of tools and materials. Here it is recommended to use ready-made components and housings produced industrially as much as possible. This way you can not only reduce the cost of work, but also find new, more effective technical solutions. Another piece of advice regarding this stage is proper organization of the workplace. When working with sheet metal, it is recommended to assemble a jig from wood so that the structures to be welded can be easily installed in the desired position.

During assembly, you need to remember that all connections must be as precise and strong as possible, especially for the body and supports of the potbelly stove. And of course, after assembly, it is necessary to make a test firebox to check the functionality of the assembled structure.

Water heating with wood

This more complexly organized system is a pyrolysis boiler. consisting of two sections. In the lower one, wood is burned, and in the upper one, the gas generated due to combustion circulates. Thanks to the scheme in which gas does not immediately enter the chimney. its efficiency increases, and longer burning requires less wood.

Around the boiler there are thick pipes through which water flows, heated from it. Keep in mind that only dry firewood is suitable for a boiler of this type, so you should always have a good supply of it at home.

There are also systems that use hot air instead of water for heating. It passes through the circuit and is transmitted into the airspace of the house. The cold air, falling down, again enters the boiler for further heating.

How to use the stove correctly

Only dry wood is suitable for use in pyrolysis heating stoves. This is due to the fact that when wet fuel is burned, a lot of water vapor is released, which reduces the temperature in the working area. Of course, in this case, there can be no question of effective combustion of pyrolysis gases. In addition, there are other unpleasant aspects associated with incomplete combustion of volatile components. Firstly, when cooling in the chimney, they fall out on its walls in the form of tar, creosote and other difficult-to-remove substances. Secondly, the content of hazardous chemical compounds at the outlet of the chimney exceeds all permissible standards, which negatively affects the environment and human health. And, on the contrary, when burning well-dried wood, the exhaust gases consist mainly of carbon dioxide and water vapor, and the operation of a potbelly stove from the outside can only be judged by the slight movement of heated air at the upper end of the chimney.

Before adding fuel, the piston is removed and put aside, and the space inside the stove is filled with firewood. It should be remembered that the thermal power and duration of operation of the heating device depend on the density of the stacking, therefore all gaps between the logs must be filled with shavings, chips, wood husks, etc. Place a rag soaked in kerosene or diesel fuel on top, install the air distribution piston and close the unit lid.

For ignition, you can use a rag dampened with a flammable liquid.

The stove is ignited with the damper of the air supply pipe fully open by throwing burning rags into it, which have been previously soaked in barbecue liquid or the like. After the wood burns, reduce the air supply.

In order to make the operation of a potbelly stove safe, follow a few simple rules:

- If flammable substances are used to ignite wood (gasoline, kerosene, solvent, special products for wood-burning stoves), then it is necessary to install the piston and close the stove with a lid before throwing a lit match.

- It is not recommended to use plastic, rubber, foam and other household waste as fuel for two reasons. Firstly, this is due to the release of extremely toxic substances that cannot burn even during the process of pyrolytic decomposition. Secondly, during high-temperature oxidation of such materials, a huge amount of soot is released, which means that the chimney will have to be cleaned several times a month.

Often, in order to make a potbelly stove more presentable, its body is primed and painted in the desired color. It should be understood that during operation of the stove the paint will fade, so it is better to use only protective compounds designed for operation at high temperatures.

Despite the fact that pyrolysis decomposition promotes the most complete combustion of fuel, a small amount of soot and ash is still formed during operation of the furnace. To remove carbon deposits, you can use a metal scraper and brush. As for ash, the most convenient way to clean a potbelly stove from a barrel is with an iron scoop with a short handle. There is no need to remove all the ashes. A layer of ash 2–3 cm thick will act as thermal insulation, preventing the bottom of the heating device from burning out.

Modernization process

Potbelly stoves went through a long stage of development before the modern version of the stove turned out. A huge number of modifications are produced, from miniature decorative designs to heating units.

Summer cottage stoves serve as an addition to the existing heating system. There is also the possibility of connecting them to boilers, which will provide residents with hot water. Stove units for cooking are equipped with hobs and ovens. They become a worthy replacement for a kitchen stove. Compact miniature analogues are indispensable assistants on a trip.

Improvement methods

Modern models are highly efficient heating devices.

The appearance of the familiar potbelly stove has undergone minor changes. The main unit of the furnace, the firebox, was subject to modernization. The following changes have been made:

- window made of glass;

- a slow combustion process has been introduced;

- heat-resistant lining added;

- The gas re-burning system is turned on.

Basic models of homemade potbelly stoves

According to its principles, a potbelly stove is practically no different from models of a special solid fuel device.

This is a certain type of very simple stove in the fireplace category. There are also special models that are equipped with hobs and special bath devices. Material used to make the stove Often, a potbelly stove is made of high-quality steel, but in some cases cast iron can be used. For different types of metal, elements made of natural stone are often used. If cast iron is used, then you should count on low heat capacity parameters; it is very difficult to find and it is not easy to cook. Many people prefer steel for this very reason; it is much easier to work with. Moreover, the thicker the material, the longer it will last. If you plan to make a device for rare use, for example, for emergency situations with the heating system, then make it from simple iron, whose thickness is 1 mm. In the process of making a stove, all factory fittings may well be used. This applies to elements such as grates, the necessary doors, burners and valves. Many craftsmen make them with their own hands using steel.

Shape and material for the body If you want to make a potbelly stove using drawings or photos, you must use the method of cutting a metal sheet.

- In addition, the following elements are used:

- Molding profiles;

- Square shaped pipe;

- Special corners;

- Fittings;

- Rod.

Various metal cabinets and boxes can be used as a base. Often these are cylindrical elements, for example, large-diameter pipes, cans, gas cylinders.

In the process of making a stove with your own hands, you will definitely need to use welding

If the metal is not very thick, the furnace can be made using bolts, screws and a drill. Regardless of the chosen model, it is important to use drawings as the basis for manufacturing, because Despite its relative simplicity, certain instructions for implementing the heating device must be followed.

Features of a potbelly stove - pros and cons

A good master can easily make a Bubafonya stove in one day, this is a significant plus. The maximum you have to buy is a cylinder and pipes from scrap metal. Other advantages of a potbelly stove:

- burning duration on 1 load is 6…10 hours;

- omnivory - waste wood, garbage, sawdust, freshly cut branches are placed in the firebox;

- ease of repair, any burnt part can be easily replaced.

On the left in the photo is the manufacture of a boiler jacket from a bent steel sheet, on the right is an assembled boiler

The disadvantages of Bubafoni are much more unpleasant:

- The stove is difficult to regulate. When working with high-quality dry wood, the damper helps you choose the optimal mode. If you burn with garbage and damp wood, the air duct must be opened completely.

- The potbelly stove's omnivorous nature is a double-edged sword. From burning low-quality fuel, the chimney becomes clogged with soot literally within a day.

- Without good draft, the stove will begin to smoke into the room. Hence the requirement for the height of the chimney - at least 4 m, counting from the grate, pipe turns 90° - no more than two.

- You can’t throw logs “on the go”, unless you pour a handful of sawdust through the air channel. This means we learn to dose the amount of fuel correctly.

- A potbelly stove made from a 200 liter iron barrel is very bulky and inconvenient to use. The piston is too large and heavy, the thin metal quickly burns out. Fortunately, the housing is easy to replace.

Why is “Bubafonya” dangerous: a well-heated firebox cannot be extinguished using a damper. Air seeps through the cracks, and the wood continues to smolder. The heater should not be left unattended or act radically - lift the lid and pour out a bucket of water. Is there a smoke screen in the room?

Setting the register

You can make water heating using a boiler welded from sheet steel or a coil from pipes with your own hands if you have the skills to work with a welding machine.

When making it yourself, you need to take into account that the thickness of the sheet metal or pipe walls must be at least 3-5 mm. Heating of such a coil will occur slowly compared to thin-walled devices, but its service life will be much longer. Burnout of thin metal walls will lead to a major overhaul of the furnace in which the heating element is installed. In self-made coil designs, an old battery (heating radiator) made of cast iron can be used. To use it as a heat exchanger, preliminary preparation is required: the radiator must be disassembled into sections, washed from the inside to remove scale and rust with appropriate compounds and checked for defects (leaks). Reconnect the serviceable sections, using an asbestos cord impregnated with drying oil as a seal between them. The prepared radiator can be installed in the firebox of a brick or metal stove, either on the side or above the flame. In the latter case, the battery must be located in a horizontal plane.

The welded heat exchanger of a water heating system can have different shapes. If the oven is not planned to be used for cooking, the register or boiler can be made in the form of a U-shaped structure from pipes or sheet metal. So the efficiency of a homemade boiler can be increased by increasing the surfaces heated by the flame. To allow cooking on a stove located above the firebox, a different design will be required. In this case, the containers located on the side surfaces of the furnace and the stove, located as it is usually installed in cooking structures, will heat up.

Kuznetsov boiler or stoves for heating greenhouses

Kuznetsov’s heating stoves are of particular interest for greenhouse premises. The brick miracle boiler has good efficiency, approximately 80%. 2 steel registers are built into the furnace body. The brick boiler body must be insulated with basalt fiber. A large number of dome models of stoves have a built-in modern technical solution that ensures afterburning of fuel, which constitutes flue gases.

Such equipment:

- Reliable;

- Durable;

- Effective.

To ensure afterburning, a secondary air supply is organized under the roof of the hood from above or in another place, depending on the modification of the stove. When using wood of the appropriate quality, such a stove will work as a pyrolysis heating structure. The thing is that the installation of stoves according to the Kuznetsov system is carried out using not 1 cap, but 2, which are connected to each other by a vertical channel.

Stoves for heating greenhouses are reliable and durableHigh-temperature combustion products go under the arch of 1 bell and give off heat to the walls. As a result, the gases are cooled and go down under their own weight and the pressure of the upward hot flow from the furnace. A water furnace can also provide watering in a winter greenhouse.

What you will need for work: tools and materials

This model of a “long-lasting” stove can be made in just a few hours. All you need for this is a great desire and proper organization of the work process. You will also need to thoroughly understand the design of the unit and prepare everything you need in advance.

Tools you will need:

- welding machine - a small, lightweight inverter with the ability to adjust the current up to 200 A is best suited for these purposes;

- angle grinder (colloquially a grinder or “grinder”);

- cutting and grinding discs intended for metal work;

- drill press or electric drill;

- set of drills;

- medium-sized hammer;

- blowtorch;

- chisel;

- sledgehammer;

- tape measure and metal ruler;

- core (a device designed for applying marks to facilitate drilling);

- scriber for marking metal surfaces.

As for materials, there is no need to follow the list exactly. The beauty of homemade structures lies precisely in the fact that they will use any iron that can be found in the backyard or in the corners of the garage (workshop).

Any large container, for example, an unnecessary metal barrel, is suitable for making the furnace body.

So, the list of necessary materials:

- steel pipes with a diameter of 80 to 250 mm, which will be needed for the manufacture of an air supply riser and a chimney;

- a suitable metal container with a diameter of 300 to 600 mm with a wall thickness of at least 2.5 mm (you can use a used gas cylinder, a fuel barrel or a piece of pipe at least 120 cm long);

- a metal sheet with a thickness of at least 4–5 mm from which the air distribution piston will be made;

- durable metal hinges, which will be needed to secure the firebox and ash door;

- asbestos cord (it is needed to seal the loading window and other operational openings);

- corners with a flange from 50 mm, channels and profile pipes - for the manufacture of air distributor blades, support legs and other structural elements;

- a round metal pancake with a thickness of at least 5 mm and a diameter of 120–150 mm (you can take any suitable gear or sprocket from a motor vehicle);

If you plan to equip the heating device with a water jacket, then you should additionally prepare sheet steel with a thickness of at least 2 mm and pipes for connecting the liquid circuit to the heating main (hot water supply).

The pipes are also used when assembling a potbelly stove with a water circuit. Step-by-step instructions are given in our article:

How to make a stove for a greenhouse with your own hands?

Almost any stove for heating a greenhouse space consists of a fuel compartment, a second bottom (located above the specified compartment), an opening with a door and a blower. In addition, we must not forget about the organization of the chimney (it must have a metal valve and a lid). Wood chips, sawdust and small firewood are often used as fuel, so we suggest considering a homemade version of such a stove.

Preparatory work

To construct a long-burning furnace, in the simplest version, you will need the following tools and materials:

- a sealed barrel with a volume of 200 liters;

- a thick metal circle (with a diameter slightly smaller than a barrel);

- 4 corners or the same amount of channel, slightly shorter than the radius of the pancake;

- a piece of metal pipe for blowing with a diameter of 100 mm (5 cm longer than the barrel);

- a piece of metal pipe for a chimney with a diameter of 150 mm and a length of 5 m;

- welding machine;

- Bulgarian;

- sledgehammer;

- chisel;

- pliers;

- hammer.

When finished, a sawdust or small wood stove should look something like this:

The finished brick oven will look something like this:

Sequencing

A homemade long-burning stove is an economical option for a factory design, which often has a long working life. However, you can achieve the most positive results from its work only if you design it correctly.

Therefore, we propose to consider the sequence of actions for manufacturing the simplest, “barrel” heating system:

- Take a barrel prepared in advance, cut off the weld on its upper end and straighten the sharp ends with pliers. The result is a cylinder with a lid.

- Using a sledgehammer, bend the edges of the cylinder inward, and, on the contrary, leave the remaining side outside.

- Turn the lid over and put it on the prepared cylinder, just so that it sits tightly on it and does not slip off.

- Using a chisel, carefully cut a hole with a diameter of 102 mm in the center of the lid (later the blower pipe will be inserted into it, which should move freely up and down).

- In the upper part of the future firebox, mark a hole for the chimney and cut it out (a part of the chimney, no more than 30 cm long, will be welded to it).

- When the installation body is almost ready, you can work on the air supply device. To increase the rigidity of the previously obtained pancake, it is advisable to bend its edges, but if you use part of another barrel as a lid, then the existing plug hole will have to be welded.

- Weld corners or channels on the inside of the cover, and install a damper in the upper part of the pipe hole (it is better to fix it with a wing nut; by loosening or tightening it, you can adjust the amount of air supplied.

- Install a chimney made of a pipe with a diameter of at least 150 mm, otherwise the smoke from the firewood will not be completely discharged outside. To ensure good draft force, the length of the chimney must be at least 5 m.

- In addition to the already manufactured device, you can weld a ball valve, which is suitable for draining accumulated condensate from the inside of the installation.

- The ignition point should be at the bottom of the barrel, so cut a rectangular hole in it and make a drawer or tray to clear the stove of unburned wood. Above the door level, install a perforated partition with a hole in its central part (it should correspond to the lower end of the blower pipe).

Using the finished product is easy: insert a blower tube into the prepared hole, fill the barrel with sawdust and remove it so that the hole remains. Next, throw firewood into the lower firebox and set it on fire so that over time the fire spreads to the layer with sawdust.

Designing a long-burning potbelly stove

The starting point in the process of designing a long-burning potbelly stove is the need to ensure a comfortable temperature in the room with minimal expenditure of time and effort. The next stage is the search for the optimal design option. To heat a residential house, you can use a Burelyan or rocket stove circuit. But for a greenhouse, garage or industrial premises where there are no high requirements for cleanliness, you can use bubafonya - a stove with vertical fuel loading.

In practical terms, the following is taken into account:

- Location of heating devices;

- Purpose of the premises;

- Dimensions of the heated room;

- Availability of necessary materials and tools;

- Availability of skills to work with tools.

Each of these points is important in its own way and it is simply irrational to discard it during design. The installation location must ensure complete safety of the premises, both in terms of fire safety and safety during use. In addition, it is important to place the stove in such a way that it does not interfere, the chimneys do not take up much space, and the heat from it is evenly distributed over the entire area of the room.

To efficiently heat a room, you need to choose the right dimensions of the structure itself. In a garage or workshop, it is enough to construct a stove of standard sizes, but for a greenhouse you will need a stove from a 200 liter barrel.

The idea of building a long-burning stove with your own hands is often put off until later due to the lack of necessary materials or tools. But on the other hand, if there is no metal sheet 5 mm thick, this does not mean that the idea should be abandoned completely, because there are many successful stove designs created from old cylinders, channels, angles or thick-walled pipes.

How to choose a heater for a summer house

Previously, we found out that a convection cast iron oven is suitable for periodic heating and is not afraid of long downtimes

Like any potbelly stove, it is “omnivorous”, that is, it can burn wood of different species, sizes and humidity, which is very important for dacha owners. It remains to understand which stove from the offered range to choose based on operating conditions

The selection criteria are as follows:

- thermal power of the unit;

- its dimensions and purpose;

- additional functions.

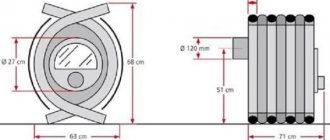

Power is an important characteristic indicated in the technical data sheet of any heater. It needs to be correlated with the size of the room where you plan to install the stove. For example, the technical characteristics of the Russian-made Bavaria PK 004 cast iron stove shown in the photo indicate a power of 12 kW and the cubic capacity of the room for which it is designed is 90 m3. This data should be relied upon when choosing a heat source.

Bavaria stoves PK 004 and PK 153 of the Russian brand Ecofireplace

Before choosing a stove for a country house made of cast iron, we suggest that you familiarize yourself with our recommendations in this regard:

- For a small house or a cabin located on a summer cottage, it is worth buying a small-sized, or better yet, collapsible model of the stove. Then it can be loaded and taken away in a car, so that the wood-burning heater is not stolen in your absence.

- If you need to heat 2-3 rooms, then it is better to take a stove with a water circuit and connect it to radiators installed in adjacent rooms. But you need to understand that this is due to increased consumption of firewood and constant monitoring of the operation of the heat generator.

- In a country house you can purchase and install a beautiful stove - a fireplace with wide panoramic glass.

- To cook and heat up food, look for a stove with a cast iron hob.

Modifications of “Bavaria” with a water heat exchanger (left) and with natural stone trim (right)

Among the many different cast iron stoves, you can also choose a unit with an oven, various additional drawers and original cladding made of natural stone.

Basic rules for lighting a stove from a cylinder

The furnace is started according to a certain scheme. It is important to take this into account in order to achieve an optimal result and ensure an ideal level of safety.

- You should do the following:

- For effective kindling, you initially need to completely remove the existing lid and then remove the special device for supplying air masses.

- The fuel used is added, but its volume should not be greater than the chimney line located below.

- If a potbelly stove or bubafonya operates on wood, then in a vertical position it can accommodate much more than if it is laid horizontally.

- It’s worth sprinkling the top part of the firewood you’re using with a small amount of wood chips and putting paper on it.

- The damper opens and paper or rags are thrown into the pipe. After the fuel is completely ignited, the damper closes.

In this position, the oven is able to operate for a day or more, that is, constant human intervention is not required.

Solid fuel heating stove Professor Butakov Student

Modern solid fuel equipment is constantly evolving, improving its appearance, design and technological processes. Despite this, simple metal stoves remain quite popular among ordinary consumers. The Professor Butakov series of stoves, named after its designer, is one of the few examples of domestically produced equipment that has created full competition with foreign analogues, and in some respects, surpassed them.

For heating small areas up to 150 m#179, an excellent option would be to install a wood-burning stove, Professor Butakov Student, with a power of 9 kW. Despite the modest thermal power, the room is heated in the shortest possible time, no more than 2-3 hours from the moment of startup. The speed of heating is ensured by the special design of the air heat exchanger, which ensures uniform convection heating.

Furnace structure and operating principle

The heating stove Professor Butakov Student is equipped with a combustion chamber capable of burning wood and afterburning pyrolysis gas generated as a result of combustion of the main fuel. The use of this technology made it possible to obtain a significant increase in efficiency and increase it to 90%, which is an excellent indicator for stoves operating on conventional wood.

To obtain the maximum effect and the largest volume of pyrolysis gas, it is necessary to use natural, as dry wood as possible.

The heat exchanger of the heater is made of steel pipes surrounding the firebox. In essence, the fire tube heat exchanger is the body of the combustion chamber, absorbing the maximum heat generated as a result of wood combustion. The lower air intake ends of the pipes are located almost parallel to the floor, this allows cold air to be drawn in. Air entering the heat exchanger pipes quickly heats up, leaving through the upper free ends of the pipes, creating constant draft and convection flow.

To ensure long service life, the bottom of the firebox is equipped with a cast iron grate that is resistant to long-term thermal influences. Through the grate, residual combustion products in the form of ash, ash, and unburned fuel fractions enter the ash box, which allows the stove to be cleaned of debris directly during its operation.

The upper plane of the oven is a cooking surface that allows you to heat or cook food on it.

Some model differences

Currently, this heater model is available in three configurations:

- Heating stove Professor Butakov Student with a cast iron door and glass. Glass makes it possible to observe the living flame in the firebox.

Heating equipment with a blind damper. Butakov Student stoves with the possibility of a rear chimney connection. Compared to the classic design, where the chimney pipe is located on the upper plane, the rear connection increases the area of the cooking surface and ensures the connection of the stove to the chimney built into the wall.

Advantages and disadvantages

Despite a number of disadvantages inherent in such equipment, solid fuel heating stoves by Professor Butakov Student have a wide list of advantages.

Wood is a natural fuel that does not pollute the environment during processing.

The use of a fairly simple design and reliable materials, steel, cast iron, ensures long service life. Wood is the most economically advantageous fuel for many regions. Increased efficiency rates of at least 90%. Easy to use. Possibility of cyclic use only when necessary, unlike most heating devices that require constant operation at minimum power. Low cost.

Among the disadvantages of the equipment, Professor Butakov Student’s heating stove is not equipped with automation, therefore it is necessary to constantly monitor the presence of fuel in the firebox and, for safety reasons, it cannot be left unattended for a long time.

Installation

The entire line of heating equipment by Professor Butakov does not require lengthy preparatory work during the installation process. The stoves are installed and attached directly to the floor. One of the mandatory conditions is maintaining an air gap between the stove body and the nearest surface, especially important for wooden houses. The heaters can be equipped with any suitable chimney system with a height of at least 5 meters to ensure normal draft and, accordingly, a constant fuel combustion process.

Design and principle of operation

A distinctive feature of the design of a long-burning potbelly stove compared to a conventional one is two combustion chambers separated by a partition. In the first (it is a fuel receiver) slow smoldering occurs under a small air flow. During this process, coal and unburned pyrolysis gases are formed, which, under the influence of draft, rise and burn out in the second chamber with an additional supply of oxygen.

Unburned gases mixed with air burn out at a very high temperature, thereby increasing the efficiency of the stove. The remaining coal also gradually burns out, transferring heat. Together, these processes form such a high heat transfer.

A long-burning potbelly stove does not require additional intervention during heating, as it operates without access to oxygen

Installation of the system in a finished oven - all the nuances

If the house already has a stove, then only a certain part of it is disassembled and a register is installed. In this case, more frequent fuel supply will be required.

If desired, you can change the number of smoke channels or their direction. However, this is only allowed in the most difficult situations.

All work must be carefully thought through, since after the actions taken it is important to maintain good traction. When dismantling the structure, it is recommended to sketch the location of the masonry

In the future, using this scheme it will be possible to easily disassemble the oven

When dismantling the structure, it is recommended to sketch the location of the masonry. In the future, using this scheme it will be possible to easily disassemble the stove.

If the brick remains in good condition after dismantling the masonry, it can be reused

If it is necessary to replace the material, it is important to select bars of the same quality and shape as the previous ones

Furnace design, its specifics

The important elements of a potbelly stove are:

Furnace compartment. It is located approximately in the middle third of the oven. Designed for burning fuel - wood or coal. Equipped with a door on the side wall of the oven for loading. An ash pan is necessary to collect solid residues after burning wood or coal. It is disconnected from the part for the firebox at the top by grates, which are cast iron rods of a specialized shape. Ash awakens in the gap between them and penetrates into the waste collection tray. At the bottom of the ash pan, a bottom is made of sheet metal 1.2–1.5 mm thick. The container with the coolant is a tank made of sheet metal, filled with water or the rest of the heating agent. This device requires absolute tightness. At the top of the tank there is a hole for the outlet of water, at the bottom there is a return pipe through which the coolant cooled in the heating system is returned. The smoke exhaust duct is installed on top of the stove body; it can be vertical, horizontal or inclined. It is brought out through the wall. For potbelly stoves, in most cases a pipe diameter of 150 mm is used. The supporting part is legs made of profile metal, providing a clearance between the body and the floor of at least 20–25 cm. Under them it is necessary to install a protective sheet of metal with an asbestos backing

This is very important if the heating unit is placed on a floor made of combustible materials.

Pipe coils

The design of this unit depends on the design of the furnace. There are different types:

- With right angles. Such thermal units are made of sheet metal up to three millimeters thick. Naturally, the most technologically advanced pipe coil is made in the form of a jacket located around the combustion chamber. The distance between the walls of the jacket and the furnace body depends on the volume of the heat exchanger. The higher it is, the very slowly the heating of the coolant in it occurs. Often containers are installed on top of the combustion chamber, but in this case the surface for cooking the stove becomes inaccessible.

The quadrangular shape of the stove is most suitable for a potbelly stove

Cylindrical vertical potbelly stove is very cheap

A potbelly stove can be made from a metal pipe needed for a high-pressure pipeline

Lining can be compared with thermal insulation

You can also heat the room with sawdust

What is a potbelly stove with a water circuit? The advantages and disadvantages of a popular stove

A potbelly stove is characterized by high heat transfer and fuel burning rate. These qualities are given to it by the materials from which the firebox is made (cast iron, steel, iron). The potbelly stove quickly flares up and heats up, and if a water circuit is connected to it, then the warm flue gases along the way also manage to heat the water for domestic needs.

When choosing the material from which it is best to make a potbelly stove, you need to be guided by the following indicators:

- Thermal conductivity is the property of metals, liquids and gases to conduct heat through themselves. The faster heat is transferred, the faster the object heats up or cools down. Foam plastic has low thermal conductivity - 0.036–0.050 W/m*C. Taking it in our hands, we will immediately feel that it is warm, because the foam does not transfer heat, but accumulates it. If you take a metal bar, you will feel the cold due to the high heat transfer.

- Heat capacity is the property of a material to accumulate heat. Water has the highest heat capacity, air is in second place, and cast iron, steel and iron are at the end of the list. Therefore, a metal stove heats up quickly and cools down just as quickly. In city houses, central heating radiators are filled with water, which gives off heat for a long time, heating the home.

List of materials used to create a potbelly stove:

- Steel.

- Cast iron.

- Iron.

- Brass.

- Aluminum.

- Copper.

Copper is the most thermally conductive material of all those listed in the table. Its disadvantages are cost and melting point. Aluminum and brass have the same limitations. At high temperatures, a cast iron or steel stove will only turn red, but will do its job, while a copper, aluminum or brass stove will melt.

Potbelly stoves are most often made of steel because it has a high melting point and the highest heat capacity among all available materials

Making a stove from steel, iron and cast iron is justified due to the prevalence of these materials. From the point of view of thermal conductivity and heat capacity, they need fine-tuning. It is more expedient to use the thermal energy of the stove to heat water, otherwise it will simply go down the chimney

To limit heat loss, it is also very important to achieve complete combustion of the fuel.

The ideal way for a potbelly stove to work is when barely warm air comes out of the pipe, and all the energy is directed into hot water supply and heating the house.

Table: advantages and disadvantages of a potbelly stove

As can be seen from the table, a potbelly stove has a lot of disadvantages, so if you decide to install this design, you will have to take into account all its weaknesses.