Calculation of the number of sections

Accurately determining the number of sections in a heating battery is a long process.

You need to take into account the region, the material of the walls, what kind of windows and doors there are, how many windows are in the room, what their area is, whether the room below is warm or cold, etc. If you need an exact calculation method, look here, but you can roughly calculate based on the area of the room. It is believed that on average 100 W of heat is required to heat 1 m2 of area. Knowing the area of your room, determine how much heat will be needed: multiply the area by 100 W. Then divide by the thermal power of the selected radiator model. For example, in a room of 12 m2 we will install MS-140M-500-0.9 from the Bryansk plant. Thermal power of the section is 160 W. Calculation:

- Total heat required is 12m2 * 100 W = 1200 W

- How many sections are needed 1200 W / 160 W = 7.5 pcs. We round (always up - it’s better if it’s warmer) and we get 8 pieces.

Advantages of cast iron batteries

Let us list the positive qualities of such devices:

- Cast iron is a metal with high anti-corrosion properties. This feature allows the use of such heat exchange equipment for 50 years, without making any special efforts to maintain. No analog device can even come close to such high performance indicators.

- The design of the cast iron radiator is such that it creates minimal resistance to the coolant. These devices can be installed even where there is minimal hydraulic pressure.

- Cast iron can retain heat for a long time even when the hot water supply stops. Due to its high thermal inertness, the material completely releases its thermal energy.

- The temperature of the coolant is also “radiated” into the space in full, so we can safely say that a cast iron radiator is very effective.

What explains the popularity of cast iron models?

Height, length and width of the radiator

It is too early to say that the era of cast iron radiators has already passed. Such devices will be used throughout the post-Soviet space for a long time. And that's why.

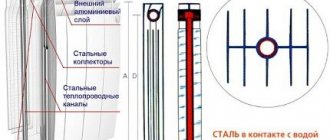

It is this heat exchange equipment that is ideal for operating a central heating system. Aluminum and steel radiators cannot be installed in apartment buildings. They fail very quickly, not even fulfilling the warranty period stated by the manufacturer. The reason is the low quality of the coolant.

Water in most of Russia has an alkaline environment, which is detrimental to “pure” aluminum. Often in central systems, salts and acids are added to the coolant to reduce its heat losses. Alkali, when reacting with aluminum, produces a substance that destroys the brittle metal. Over time, an aluminum radiator becomes like a porous sponge, which can easily break from the first water hammer.

With steel batteries the situation is slightly different. They are able to withstand any quality of coolant, but steel does not tolerate oxygen. As soon as it appears in the system, corrosion processes begin to develop sharply. To avoid this, a steel radiator should always be completely filled with water. If connected to a central heating system, this is difficult to achieve. Usually in summer the water from the systems is completely drained.

The choice remains - either use expensive bimetallic analogues (but due to the high price, not everyone can afford these products), or install time-tested cast iron radiators. And even though they look bulky, and their appearance is difficult to fit into modern interiors, such heat exchange equipment is reliable, efficient and durable.

Designer batteries

These radiators are made in “Retro” style. They are not hidden, but displayed as a stylish decorative element. But such models are not suitable for every interior. They will elegantly fit into the classical style, Venetian, Gothic. Externally, designer radiators look like products of past centuries. Various drawings and bas-reliefs are depicted on their surface. They are often installed on legs. These retro batteries are presented in a wide range: Guratec (Germany), Viadrus (Czech Republic), Demir Dokum (Turkey), Roca (Spain), Rococo (England). Russian companies, for example, Exemet and RetroStyle, also produce designer batteries.

Cast iron radiator in retro style Guratec

Retro radiators have a large range of sizes. The distance between the axes can be from 30 to 90 cm, the depth of the batteries is from 10 to 23.5 cm, and the width of the sections is 4-8.1 cm.

Turkish products are in great demand. The designer radiator Alpine Air History 600 with a power of 143 W is popular among the population. It can be used in premises for various purposes. Additional sections can be easily attached to it, increasing the heating power. At the factory it is coated with a layer of primer and high-quality varnish, and tested with a hydraulic pressure of 15 bar. All sections of the radiator are heated evenly. Due to the thickness of the material, the sound of water circulating inside the heating device is practically inaudible. The heater is decorated with an unobtrusive ornament of water plants in the French Art Nouveau style. If desired, you can find models with center distances of 350, 500,600 and 800 mm.

Cast iron radiator in retro style Alpine Air History 600

The Demir Dokum Retro 600 battery impresses with its design. The surface of each section is made in the palace style of the late 18th century. All control and shut-off fittings (taps, valves) are also made in retro style. The heater looks powerful but elegant. It is used to connect to a water or steam heating system. The design feature of this device is the increased diameter of the internal passage holes, thanks to which it is not afraid of blockages and water hammer. How much does such a structure weigh? The battery weight is 76.4 kg, and the heated area is 14.4 square meters. m. The production uses high-quality cast iron, which is resistant to mechanical damage, corrosion and aggressive environments. Demir Dokum Retro radiators are also available with center distances of 500 and 800 mm.

Cast iron radiator Demir Dokum Retro 600

Another stylish Turkish-made radiator is DEMRAD Retro 600. Cast iron forging with intricate patterns evokes associations with rich mansions of the 18th century. With their help, you can create a mysterious atmosphere in a room with a hint of wealth. This radiator is painted in the rich colors of blackened silver or antique gold. What are the technical characteristics of this heating device? The weight of one section is 11.4 kg, volume is 2.6 liters, heat dissipation is 126 W, test pressure is 13 atmospheres. The surface of the battery is painted with high-quality paint that lasts for many years. It can be connected to different types of heating systems. If only part of the structure fails, then you will not have to replace the entire radiator; it will be enough to replace the damaged sections.

Cast iron radiator DEMRAD Retro 600

The domestic company Retro Style also produces vintage-style radiators. They resemble products from the 18th and 19th centuries. The buyer is offered several collections to choose from, each of which has an exclusive design and corresponds to one of the luxurious styles: baroque, empire, classicism, rococo, etc. At the customer’s request, the battery can be painted in the desired color (chocolate, gzhel, red with gold, etc. .).

Cast iron radiator Retro Style

Purpose, advantages and disadvantages of MS 140 radiators

The technical parameters of cast iron radiators of the MC 140 brand allow them to be used in steam heating systems of any buildings with virtually no restrictions: in private houses, country cottages, apartments in apartment buildings, administrative offices, public buildings, industrial, warehouse, and retail premises. The equipment is intended for operation in temperate and cold climates (MCC).

Advantages of heating radiators MS 140

- Long service life. This is one of the most durable types of radiators, with a service life of 50 years.

- Reliability. The hundred-year history of this type of radiator in the heating equipment market has confirmed in practice its high reliability.

- Anti-corrosion resistance. Cast iron does not deteriorate over time under the influence of water.

- Undemanding to the quality of the coolant. Cast iron radiators are not sensitive to the quality of the water used inside them. The presence of sand, dirt, high content of salts, acids, alkalis in water does not have a strong effect on the life of cast iron radiators.

- Simplicity of steam heating systems. Cast iron radiators can be used in networks with natural water circulation, without the use of a pump. They are compatible with all types of boilers - solid fuel, gas, pellet, liquid fuel.

- Thermal inertia. Cast iron takes a long time to heat up, accumulates heat well, and cools slowly. In a heating system, this is considered a great advantage, since after the burner is turned off, the cast iron radiator remains warm for a long time, releasing heat into the room.

Disadvantages of heating radiators MS 140

- Sensitivity to water hammer.

- Tendency to slagging of internal surfaces, which over time leads to a decrease in heat transfer.

- Radiators are assembled from separate sections, the joints of which are sealed with rubber gaskets. The lifespan of gaskets is significantly less than cast iron. To avoid leaks, after several years of operation, failed intersection gaskets must be replaced.

- The appearance of such radiators is not sophisticated enough; the surface requires painting.

MS-140 - cast iron classic of “Soviet” times

Cast iron heating radiators MC 140 can be called an undying classic. Despite the abundance of different models of heating devices made of the same cast iron, this one - a Soviet-era “accordion” - is still in demand. It is produced in most countries that were formerly part of the USSR. They are precisely produced in Russia, Ukraine and Belarus. Perhaps production has been established in other countries, but why transport goods far away if there are factories nearby.

Characteristics and Features

The secret of their popularity is simple: in our country, the coolant in centralized heating networks is such that it even dissolves or erases metals. In addition to a huge amount of dissolved chemical elements, it contains sand, particles of rust that have fallen off pipes and radiators, “tears” from welding, bolts forgotten during repairs and a lot of other things that are unknown how they got inside. The only alloy that doesn’t care about all this is cast iron. Stainless steel also does this well, but one can only guess how much such a battery will cost.

MS-140 - an undying classic

And another secret of the MS-140’s popularity is its low price. It has significant differences between different manufacturers, but the approximate cost of one section is about $5 (retail).

Advantages and disadvantages of cast iron radiators

It is clear that a product that has not left the market for many decades has some unique properties. The advantages of cast iron batteries include:

- Low chemical activity, which ensures long service life in our networks. Officially, the warranty period is from 10 to 30 years, and the service life is 50 years or more.

- Low hydraulic resistance. Only radiators of this type can be installed in systems with natural circulation (some also use aluminum and steel tubular ones).

- High temperature of the working environment. No other radiator can withstand temperatures above +130oC. Most of them have a maximum limit of +110oC.

- Low price.

- High heat dissipation. For all other cast iron radiators, this characteristic is in the “disadvantages” section. Only MS-140 and MS-90 have a thermal power of one section comparable to aluminum and bimetallic ones. For MS-140, heat transfer is 160-185 W (depending on the manufacturer), for MS 90 - 130 W.

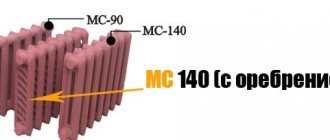

- They do not corrode when the coolant is drained.MS-140 and MS-90 - difference in section depth

Some properties are a plus under some circumstances, and a minus under others:

- Large thermal inertia. It may take an hour or more until the MS-140 section warms up. And all this time the room does not heat up. But on the other hand, this is good if the heating is turned off, or a conventional solid fuel boiler is used in the system: the heat accumulated by the walls and water maintains the temperature in the room for a long time.

- Large cross-section of channels and collectors. On the one hand, even a bad and dirty coolant will not be able to clog them in just a few years. Therefore, cleaning and washing can be carried out periodically. But due to the large cross-section, more than a liter of coolant “fits” in one section. And it needs to be “driven” through the system and heated, which means extra costs for equipment (a more powerful pump and boiler) and fuel.

“Pure” disadvantages are also present:

- Heavy weight. The weight of one section with an axial distance of 500 mm is from 6 kg to 7.12 kg. And since you usually need from 6 to 14 pieces per room, you can calculate what the mass will be. And you will have to wear it, and also hang it on the wall. This is another drawback: difficult installation. And all because of the same weight.

- Fragility and low working pressure. Not the most pleasant characteristics. Despite their massive size, cast iron products must be handled with care: they may burst upon impact. The same fragility leads to not the highest operating pressure: 9 atm. Pressure testing - 15-16 atm.

- The need for regular coloring. All sections come only primed. They will need to be painted often: once every year or two. Thermal inertia is not always a bad thing...

Application area

As you can see, there are more than serious advantages, but there are also disadvantages. If we summarize everything, we can determine the scope of their use:

- Networks with very low coolant quality (Ph above 9) and a large number of abrasive particles (without mud traps and filters).

- In individual heating when using solid fuel boilers without automation.

- In networks with natural circulation.

Manufacturers, models, technical specifications

MS-140 is produced by the following factories:

- Nizhny Tagil Boiler and Radiator Plant (Russia);

- Minsk Heating Equipment Plant (Belarus);

- Lugansk Foundry and Mechanical Plant (Ukraine);

- JSC "Santekhlit" Bryansk region (Russia);

- LLC "Descartes" Novosibirsk (Russia).

The product has some features and differences; there are models with center distances of 300 mm and 500 mm, as well as a smaller depth option MS-90.

Nizhny Tagil Boiler and Radiator Plant

The plant's products are certified according to the ISO 9001:2008 standard in the Russian Register certification, there is a certificate from the GOST R System and IQNet.

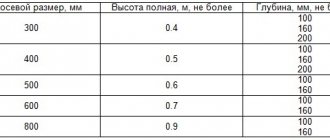

Overall dimensions of MS-140 produced in Nizhny Tagil

Coolant temperature up to +130 oC, operating pressure up to 12 Bar, other technical characteristics are given in the table.

| Model name | Center distance | Dimensions | Section thermal power | Section volume | Section weight | ||

| width | depth | height | |||||

| MS-140-M2-500 | 500 mm | 94 mm | 140 mm | 580 mm | 160 W | 1.45 l | 6.65 kg |

| MS-140M-300 | 300 mm | 104 mm | 140 mm | 388 mm | 117 W | 1.11 l | 5.4 kg |

| MS-90 | 500 mm | 90 mm | 90 mm | 580 mm | 130 W | 1.15 l | 5.475 kg |

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to take into account technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

- There is a fireplace and air conditioning in the room.

There are other important features that need to be taken into account. How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional insulation of the walls done and what kind of insulation (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of space. You can take into account not the volume, but the area of the room. For a 10 sq.m standard room with one door and one window, one door and an outer wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- In the premises of panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Methods for calculating paint coverage area

You can find the necessary information about the paint coverage area in the technical description for the model. Usually for domestic equipment it is indicated as “heating area” or otherwise if it is an imported radiator.

The most popular type of heating device is MS-140. This is a classic for most older apartments. The length of one section is 9.3 cm, height is 58.8 cm. The area is 0.24 m². Based on this, you can find out the total area of the battery. The area of the section is multiplied by their number. The result is a number equal to the area of the painted surface of the cast iron radiator. It is better to always round up the result and take into account paint consumption with a small margin for taps, couplings, adapters, etc.

A more modern or modified model of the heating device has a painting area of cast iron radiators of approximately 0.208 m2. Accordingly, less coloring material will be needed.

Now many Internet sites have special online calculators. With their help, you can independently calculate the required indicator. To do this, you just need to enter the following parameters in the appropriate lines:

- radiator marking according to technical documentation;

- number of sections, their length and height.

After this, the program will make the necessary calculations of the paint area and give the desired result.

As you can see, calculating the area of heating radiators for painting is not at all difficult. After this, you can confidently begin the reconstruction of one of the main interior elements.

There are many types of heating equipment - these are steel, aluminum, metal, bimetallic, cast iron radiators, each section of the radiator has its own characteristics - all of them have both their advantages and disadvantages.

Heating Devices LLC, which produces refurbished cast iron radiators, retains all standard characteristics in its products that meet GOST 31311-2005. The manufactured products are distinguished primarily by their lower cost compared to similar products.

Each radiator section has a thermal power of 160 W. Long-wave thermal radiation enters the room, which makes up 35% of the total heat flow, due to which the lower part is uniformly heated, and the resulting convention with the help of the other 65% of the heat flow prevents the high temperature from rising in the upper part of the room.

The corrosion resistance of cast iron suggests the increased durability of cast iron radiators. Cast iron heating radiators can be used for up to 50 years, which is also not a limit for them. Gravity circulation systems can use such radiators.

Disadvantages of heating cast iron batteries:

The production and installation of such batteries is a rather labor-intensive process; the weight of a section exceeds 7 kg. It is impossible to adjust the amount of heat transfer from the radiator using thermoregulation heads; this is due to the fact that cast iron has a large heat capacity, and the sections have a large capacity. The increased heat capacity will allow you to retain heat for a certain period of time even after the heating is turned off.

Heating cast iron radiators of the MS-140-500 series - they heat residential, public buildings, industrial premises, the coolant has a temperature of up to 130 degrees C, the operating excess pressure is within 0.9 MPa.

Cast iron radiator - sectional two-channel type. The section has a length of 93 mm, a radiator height of 588 mm, and a depth of 140 mm. One section has a heating surface area of 0.244 m2, and a nominal heat flux of 0.160 kW. One section has a capacity of 1.45 liters. and weight including nipples and plugs of 7.1 kg. The nipple hole has a thread - G1 1/4.

The MS-140-300 series of cast iron heating radiators is intended for heating residential, public and industrial buildings with low window sill heights, the coolant temperature is 130 degrees C, the operating excess pressure is 0.9 MPa.

Radiator Specifications:

Radiator of sectional two-channel type. The section has a length of 93 mm, a height of 388 mm, and a depth of 140 mm. The heat flow has a nominal value of 0.120 kW, and the capacity of one section is 1.11 liters, weight is 5.7 kg. Threaded nipple hole - G1 1/4.

Heating cast iron radiators MS-90-500 - heat industrial, public, and residential premises. Their technical parameters:

Sectional two-channel type. The section has a length of 78 mm, a height of 571 mm, and a depth of 90 mm. Heat flow - 0.160 kW. The capacity of one section is 1.45 liters. Nipple hole thread - G 1/4-B.

Russian (Soviet) cast iron radiators

Most Russian manufacturers make cast iron batteries of a classic look. They were developed back in the USSR and turned out to be quite successful. There are two main classifications - MS and WC. Outwardly, they are practically the same, but have different characteristics.

Weight of the radiator section ChM1, ChM2, ChM3

Without water

- World Championship 1-70-300 – 3.3;

- World Championship 1-70-500 – 4.8;

- World Championship2-100-300 – 4.5;

- World Championship2-100-500 – 6.3;

- ChM3-120-300 – 4.8;

- World Championship3-120-500 – 7.0.

With water

- World Championship 1-70-300 – 3.95;

- World Championship 1-70-500 – 5.7;

- World Championship2-100-300 – 5.2;

- World Championship2-100-500 – 7.25;

- World Championship3-120-300 – 5.75;

- World Championship3-120-500 – 8.4.

ChM radiators are produced in three versions - single-channel (ChM1), two-channel (ChM2) and three-channel (ChM3). The size and number of channels directly affects the weight of one section.

Weight of 1 section of cast iron radiator series MS 90, 100, 140

Without water

- MS-90/500 – 6.5;

- MS-100/500 – 4.9;

- MS-140/300 – 5.7;

- MS-140/500 – 7.1.

With water

- MS-90/500 – 7.4-7.7;

- MS-100/500 – 5.8-6.1;

- MS-140/300 – 6.5-7;

- MS-140/500 – 8.4-8.9.

Model designations indicate the dimensions of the MC series radiators. The first number is the depth, the second is the height in millimeters. We also note that each manufacturer has its own configurations and section design. For example, the weight of one section of a Soviet cast iron battery MS-90 with a height of 500 mm can fluctuate between 6.3-6.7 kg.

Why is cast iron so in demand?

Cast iron radiators have advantages over other heating devices. They differ:

- Highly resistant to corrosion. This property is explained by the fact that during operation the surface of the battery becomes covered with “dry rust”, which is unable to enter the corrosion stage. Cast iron is wear-resistant and will not be affected by various debris from heating pipes.

- Good thermal inertia. While steel radiators retain 15% of their heat after the boiler is turned off, the cast iron analogue of the MC 140 can radiate up to 30% of heat even after an hour.

- Long service life. High-quality models of cast iron radiators can reach a hundred-year operational period. But manufacturers are reducing these periods and promising reliable operation in the interval between 10-30 years.

- Large internal cross-section. Thanks to this technical characteristic, the cast iron radiator MC 140 500 rarely needs cleaning.

- This material cannot cause electrochemical corrosion. That is, cast iron comes into excellent contact with steel or plastic pipes.

Summarizing

There is no clear answer to the question “Which heating radiators are better?” It all depends on the conditions under which the batteries will be used and the budget. For a new private house with an individual heating system, you can purchase a new type of foreign-made battery. It will fit into a modern interior and will last a long time. For houses with a classic interior, if you can not save money, you can choose a designer model that will fit well into the interior and will favorably emphasize the taste of the owners. For apartments with central heating, it is recommended to install old-style domestic radiators. The best option is a cast iron radiator MS-140M-500, the technical characteristics of which speak for themselves. Such a heating device is inexpensive and will last for many years even in difficult conditions.

Peculiarities

All heating radiators, regardless of the materials used in their creation, as well as regardless of shape and size, are equipped with an inlet and outlet. In the bulk of commercially available devices, these holes are duplicated to allow both bottom and top connections.

Not all available technological holes are used during the installation process. To ensure the tightness of the device, special plugs are used that are screwed into unused holes.

The standard package of the heating battery does not include the necessary plugs (plugs) and fittings (connecting elements for joining with the pipeline). As a result, you will need to additionally buy a special kit for installing radiators.

Typically, these kits are universal and suitable for cross or side connections. But there are devices designed for the lower supply of the inlet and outlet pipes. In such a situation, along with the main installation kit, it will be necessary to purchase a special unit for connecting to closely spaced pipes.

Main characteristics

MS-140M-500 is a cast iron radiator, the characteristics of which must be carefully studied before purchasing the product. This equipment is a convection-type device that has elliptical or round sections. The radiator releases approximately 25% of the heat flow transmitted by the coolant into the room. The remaining 75% is transmitted by convection.

On sale today you can find sectional cast iron radiators, the construction depth of which is 90 and 140 mm. If we are talking about the MS-140M brand, then we can say about it that the distance between sections is 300 or 500 mm. One section has a heat transfer surface of 0.208 m2. One section holds 1.45 liters and weighs 6.7 kg.

MS-140M-500 - a cast iron radiator, the characteristics of which may be useful to you, is equipment whose specific metal consumption is 42 kg/kW. Experts are sometimes also interested in the linear heat density of the flow; it is 1.48 kW/m. One section has a power of 160 W. For Russia, such devices are traditional today. Their main advantage is their ability to be used in open systems.

Cast iron heating radiators: technical characteristics

: 11-09-2017

Cast iron is a classic material for the manufacture of heating appliances. It was from this that the first radiators of the pre-revolutionary era were made, some of which continue to function properly to this day. For a long time, cast iron radiators had no alternative in the USSR - steel radiators-convectors began to be actively installed in the central heating system only in the 70s. Cast iron batteries are made by casting.

Improvements in technology have made it possible to improve the surface quality and a modern mass-produced heating device looks no worse than popular batteries made from other materials. But the most aesthetically pleasing is the appearance of cast iron products made using artistic casting technology - such batteries can become the highlight of the room. Let's consider the technical characteristics of cast iron heating radiators and their features.

Cast iron batteries Retro

Types of cast iron radiators and their design features

When choosing cast iron radiators, first of all pay attention to their dimensions. If we are talking about reconstructing the system, then the heating device must fit the existing pipeline according to the distance between the connection holes. It must be installed under the window sill in compliance with the requirements regarding the gaps between the radiator and the window sill board, on the one hand, and the floor, on the other - it is important to ensure effective circulation of heated air. Its heat transfer depends on the dimensions and correct installation of a cast iron battery.

Design of cast iron radiators

Cast iron heating radiators from different manufacturers differ in the following parameters

:

- center-to-center distance (the space between the centers of the holes for connecting the pipeline) – from 220 to 900 mm;

- depth – from 85 to 200 mm;

- width – from 45 to 108 mm;

- height – from 330 to 954 mm.

To a certain extent, the dimensions of a heating device depend on the style in which it is made. The usual “accordion” is produced in Russia and the Republic of Belarus according to certain standards, which differ slightly from each other. Designer models from domestic and foreign manufacturers vary greatly in height and the presence of legs. In this case, the standard interaxle distance is observed.

Please note: unlike standard ones, designer radiators cannot always be expanded with additional sections. Manufacturers of designer radiators can also offer models designed for bottom connections.

Low radiators. This category includes heating devices with a height of 330 mm to 400 mm. The center distance for such models is 300 or 350 mm. Representatives of low cast iron radiators are the standard “accordion” MC-140M, as well as the designer BOLTON 220, Viadrus Hellas 270.

Device Specifications

Cast iron radiators of this type have the following technical characteristics:

- The service life of cast iron radiators of the MS 140 brand is at least 50 years.

- The coolant temperature can reach +130 degrees.

- Warranty period - 2 years.

- Working pressure - 9 atmospheres. And the maximum test pressure applied to radiators of this type is 15 atmospheres.

- The inlet diameter is 1 ¼ inches.

- The material of the intersection gaskets is high-temperature resistant rubber.

- The heat output of one section is 175 W.

- Sections and plugs are made of gray cast iron grade SCh-10.

- Cast iron radiators can withstand pressures up to 15 bar when performing pressure testing.

- The number of channels in 1 section is 2 pcs.

- Country of origin: Russia.

In the factory configuration, MC 140 radiators can consist of 4 or 7 sections. These types of devices are supplied without brackets, so do not forget about this element when purchasing.

Features of the MS-140-500 radiator

Cast iron radiators MS-140 with a center distance of 500 mm are designed for heating buildings of any purpose, from private residential buildings to industrial and production buildings. They have good heat transfer and resistance to aggressive coolants. Cast iron “accordions” stubbornly do not want to leave the heating equipment market, since they are considered the most unpretentious type of radiators.

Cast iron batteries are among the most durable. This is due to the physical and chemical properties of the metal.

The main advantage of cast iron batteries is their long service life. Cast iron reluctantly reacts with water and aggressive compounds, resisting corrosion well. The top layer, protected by primer and paint, is also not susceptible to it. Even in the absence of external protection, cast iron practically does not deteriorate or become thinner. It gets to the point that in some cases these radiators can outlast the building itself in terms of service life.

The heat output of MS-140 cast iron radiators with center distance ranges from 140 to 185 W per section. This is a pretty decent indicator, which allows cast iron to successfully compete with other types of heating batteries. Today, cast iron batteries are produced by many domestic factories and are not going to leave the shelves of plumbing stores.

Thanks to modern cast iron casting technologies, the finished products are especially durable and do not require too frequent maintenance.

Differences in the technical characteristics of cast iron heating batteries from other popular types of batteries.

What are the advantages of cast iron radiators MS-140-500?

- Resistance to aggressive coolant - centralized heating systems do not spare even the most durable modern radiators. Cast iron practically does not react with caustic and aggressive compounds;

- Large internal capacity - thanks to this, radiators almost never become clogged or clogged. Also, the internal volume helps reduce hydraulic resistance;

- Long service life - manufacturer's warranty reaches 10-20 years. As for the actual service life, it is up to 50 years and even more, you just need to properly care for the batteries and tint them on time;

- Long-term heat retention - if the heating is turned off, cast iron will retain and release heat for a long time, heating rooms and rooms;

- Affordable cost - the price for cast iron radiators MS-140-500 starts at 350-400 rubles per section (depending on the manufacturer).

Let's list a few disadvantages:

One of the main disadvantages of cast iron batteries is their instability to water hammer; here they are inferior to their bimetallic counterparts.

- Heavy weight is perhaps one of the most important disadvantages. One section weighs over 7 kg, which is why the weight of a 10-section battery is over 70 kg;

- Difficulty in installation - if you can install aluminum or steel radiators yourself, then two or three people will have to work on a cast-iron radiator. In addition, for fastening to the wall you need good, durable fasteners (and the walls themselves should not crumble under the weight of the batteries);

- Lack of resistance to high pressure - cast iron batteries are intended for use as part of autonomous heating systems (installation in low-rise buildings connected to centralized systems is allowed).

We can also highlight as a disadvantage of cast iron batteries MS-140 their high inertia - a lot of time passes from supplying coolant to warming up the system.

Despite the presence of some shortcomings, cast iron batteries continue to be in steady demand - consumers are captivated by the optimal combination of price, quality and technical characteristics.

Cast iron radiators MS-140 can be used as part of autonomous and centralized heating systems with a maximum coolant pressure of up to 9-10 atmospheres. The coolant temperature can reach +120-130 degrees - cast iron remains resistant to such temperature overloads. The main thing is not to subject it to strong impacts, otherwise it may break.

MS-140 radiators can be used in systems with natural and forced coolant circulation. The system can be open or closed - cast iron can work in any conditions. The main thing is that the heating parameters do not exceed the values specified in the passport data. The difficulty in operation is caused only by the need for regular maintenance - monitor the condition of the paint coating and prevent the formation of pockets of corrosion.

Radiators ms 90 technical specifications

INDUSTRIAL QUALITY TECHNOLOGY

- Catalog

- Contacts

- About company

- Partners

- Delivery

- Reviews

- Calculator

- Services

ROLLED METAL AND METAL PRODUCTS

FOR 14 YEARS WE HAVE SPECIALIZED IN THE SUPPLY OF ROLLED METAL IN A FULL RANGE, AS WELL AS METAL PRODUCTS FOR VARIOUS FIELD OF APPLICATION

POSITIONS IN STOCK

IN MAJOR CITIES OF RUSSIA

SHIPMENTS FROM WAREHOUSE

- Ferrous rolled metal Steel pipes Hot rolled

- Cold rolled

- Electric welded

- Profile square

- Profile rectangular

- Profile galvanized

- Galvanized

- Water and gas pipeline VGP

- Gas lift

- Boiler room

- Cast iron

- Borilnaya

- Asbestos-cement

- Magistralnaya

- Casing

- tubing

- Cracking

- Armature

- Steel sheet

- Woven mesh

- Cast iron hatch

- Steel wire rod

- Stainless steel pipes

- Aluminum Pipe

- Blanks

- Copper pipe

- Brass sheet

- Bronze sheet

- Titanium sheet

- Nickel anode

- Cast iron radiators

- Rope

| Monday | from 8:30 to 18:00 |

| Tuesday | from 8:30 to 18:00 |

| Wednesday | from 8:30 to 18:00 |

| Thursday | from 8:30 to 18:00 |

| Friday | from 8:30 to 17:00 |

| Saturday | Day off |

| Sunday | Day off |

- Calculator

- Cutting services

- Reviews

- Contacts

- Delivery

- About company

- Are you here:

- home

- Shut-off valves

- Cast iron radiators

- Cast iron radiator MS-90 primer 500 GOST 8690-94

If you still have questions or comments about your purchase, please contact our managers at the numbers below.

Telephone numbers for ordering goods in Yekaterinburg

8-(800)

770–08–06

Opening hours in Yekaterinburg

How to purchase rolled metal

Fill out the application form and the manager will contact you during business hours

within

15 minutes

you sign an agreement

and pay the bill

You get it ready

rolled metal at point B

Leave a request for a call back and we will call you back within 15 minutes

Old style radiators

Old-style cast iron batteries do not have the most attractive appearance. However, this does not mean that their installation will spoil the interior of the room. Today it is fashionable to cover radiators with decorative grilles, boxes and screens. Their level of heat transfer is reduced, but outwardly everything looks much more aesthetically pleasing.

Decorative screen for battery

Compared to radiators manufactured in Soviet times, modern batteries have a reduced distance between sections, which makes them neater.

Modern cast iron radiator

The main advantage of old-style radiators is their affordable price. The cheapest devices are manufactured in Russia. Batteries produced in other countries (for example, Belarus) are a little more expensive, but in addition to price, they differ in size.

Old-style cast iron batteries are unpretentious in operation. If the apartment owner does not dislike their appearance, he can simply paint them to match the color of the walls.

Cast iron radiators of the old type are called “MS”. After the name there are numbers separated by a dash. The first number indicates the depth of the sections, and the second - the distance between them (for example, MS-140M-500, MS-110-500).

Cast iron radiator MS-140M-500

When choosing a cast iron radiator, you must take into account the depth of its section. First you need to measure the depth of the window sill. After all, if the battery is located in a niche under the window opening, then it should not stick out from under the window sill. Firstly, this can ruin the entire appearance, and secondly, the radiator will interfere with approaching the window. For example, the MS-110 model produced by the Santekhlit plant has a small depth of sections, only 11 cm. Such a battery will easily fit under any modern plastic window sill.

Cast iron radiator MS-110

Which radiators are better - domestic or imported? In Western countries, heating systems are of higher quality and cleaner, therefore cast iron batteries manufactured by Western developers, when working with domestic coolants, can quickly fail. Dirt (rust, various chemical elements) accumulates inside the batteries, narrowing the opening for the passage of hot water. As a result, their thermal efficiency decreases and they may stop heating the room.

New generation radiators

Cast iron batteries of the new generation look much more attractive in appearance than old-style devices. They have a modern look and visually resemble radiators made of aluminum or steel. They have a flat front panel and a smooth surface. Some products already have factory enamel applied, other models are sold without it, and you will have to paint them yourself.

More recently, new generation cast iron batteries were imported only from Europe (Czech Republic, Italy) and China. Now they are already produced in Russia, Belarus and Ukraine.

Cast iron radiators CONNER HIT, Modern - European design

What are the advantages of modern radiators from European manufacturers? Their advantages include:

- high quality coating, they are marketed painted, while domestic models are only primed;

- smoother shape (both outside and inside);

- sections of smaller volume;

- higher level of heat transfer;

- less weight and dimensions.

Thus, imported models have more advantages than domestic ones, but they also cost significantly more.

Basic characteristics of a classic radiator

A standard cast iron battery consists of 4-10 separate sections. Its size depends on the choice of thermal conditions in the room and the architectural features of the house.

Despite the difficulties that arise when installing a heavy cast iron heating radiator, this is not considered the main problem. The main task is to correctly install the battery. To implement it, it is not enough to know only the mass of the product; the following points must be taken into account:

- Distance between axles. Standard models can have 350 or 500 mm. Batteries with a large height are characterized by proportional dimensions between the axes.

- Depth. Standard sizes 92, 99, 110 mm.

- Section width. The sizes are in a slightly larger range - 35 - 60 mm.

- Section volume. This is the amount of coolant that is necessary to completely fill the radiator element. The volume depends on the size of the section. Average values range from 1 to 4 liters.

An important problem with installing a classic cast-iron battery is that it is only intended for wall mounting. At the same time, most modern houses are made of porous materials

such as aerated concrete, foam concrete, as well as SIP panels with foam filling. These walls require special fastening of a complex structure with multi-point fixation, which is unlikely to be to your liking.

Properties of radiators MS 140

Simplicity of installation and repair, high performance characteristics, as well as good heat dissipation - all this makes MC 140 radiators a popular product among both wholesale and retail customers. In addition, similar products were installed back in Soviet times. Therefore, they have been repeatedly tested for strength and serve their owners to this day, enjoying their trust.

The peculiarity of sectional cast iron radiators of this brand is their resistance to aggressive environments. In addition, they have a classic design that is appropriate in any interior. And such equipment can be used in heating systems not only in residential buildings, but also in public and industrial facilities.

Advantages of devices

It is worth noting the following advantages of the device:

Characteristics of Breeze 500

- Expanded cross-section of water channels, due to which the service life of the radiator is significantly increased.

- High level of thermal conductivity, as well as durability and reliability. Cast iron is a wear-resistant material that is not harmed by small stones or various debris found in the coolant. For high-quality radiators, the service life can reach up to 50 years. However, manufacturers talk about 30 years of reliable use without cleaning or repair.

- Good anti-corrosion characteristics. They are ensured due to the fact that during use the surface of the cast iron radiator is covered with “dry rust”, which does not give corrosion the slightest chance.

- Convenient ability to replace sections.

- Cast iron under no circumstances can cause electrochemical corrosion. This means that there will be no problems when using such radiators with plastic or steel pipes.

In addition, cast iron batteries are best suited for Russian consumers, given the qualitative composition of the coolant circulating through centralized heating networks. Not every aluminum or bimetallic radiator can withstand the quality of the coolant for at least 10 years, but cast iron ones do this for more than 30 years.

Flaws

Decorative pattern

Among the disadvantages are:

- solid weight of the structure;

- high heat inertia;

- possibility of damage to the system due to water hammer.

In addition, due to the large mass of the radiator, difficulties may arise during the installation process or when transporting the equipment.

Foreign cast iron radiators

Foreign-made cast iron batteries are made in modern or retro style. The latter have more weight due to inlay and artistic elements. As a rule, they can be installed on the floor.

Viadrus Termo (Czech Republic)

Without water

- 500/95 – 4.35;

- 500/130 – 5,35;

- 623/95 – 5,1;

- 623/130 – 6,45;

- 813/95 – 6,7;

- 813/130 – 8,8.

With water

- 500/95 – 4.95;

- 500/130 – 6,15;

- 623/95 – 5,9;

- 623/130 – 7,45;

- 813/95 – 7,7;

- 813/130 – 10,1.

Carron (England)

- The Chelsea 675/67 – 13.3;

- The Daisy – 11.3;

- The Orleans - 17.3;

- The Rococco – 16.6;

- The Verona – 14.3.

Carron Chelsea cast iron radiator.

Demrad Ridem (Türkiye)

- 2/813 – 5,15;

- 3/350 – 3,37;

- 3/500 – 4,8;

- 3/623 – 5,5;

- 3/813 – 7,05;

- 4/500 – 6,15;

- 4/623 – 7,25;

- 4/813 – 8,95.

What it is

Description

A sectional battery made of gray cast iron with cast iron or steel connecting nipples and intersectional gaskets made of paronite is sold under the name cast iron radiator MS-140M-500 (MS-140-500).

The properties of the product are quite common for cast iron heating devices:

- Significant mass and, as a consequence, high thermal inertia;

- Solid capacity per section, again increasing thermal inertia;

- Relative fragility (gray cast iron is not resistant to impact loads);

- Moderate resistance to internal pressure.

Fastening elements are not included. Depending on the choice of brackets, the device can be mounted on the wall or installed on the floor.

Let's face it: the batteries in the photo are not a masterpiece of design.

Characteristics

Technical characteristics of the MS-140-500 radiator are given on the websites of numerous manufacturers and sellers. We will publish them too.

| Parameter | Meaning |

| Number of channels for coolant in a section | 2 |

| Heat flow per section at a temperature difference between the battery and air of 70 degrees | 160 W |

| Permissible maximum coolant temperature | 130 C |

| Section material | Gray cast iron SCh10 GOST1412-85 |

| Material for making nipples | Malleable cast iron GOST1215-79 |

| Gasket material | Heat-resistant rubber (paronite) 1T-P, 1T-S according to TU38-105376-82 |

| Operating pressure | 9 kgf/cm2 |

| Test pressure | 15 kgf/cm2 |

| Section length (including gasket thickness) | 108 mm |

| Section height | 588 mm (500 along nipple axes) |

| Depth (distance from front to back surface) of section | 140 mm |

| Nipple/Manifold Thread Size | DN32 /1 1/4 inches) |

| Section capacity | 1450 cm3 (1.45 liters) |

| Section weight | 7.12 kg |

| Section price | 300 – 400 rubles |

Cast iron batteries will get along well with a solid fuel boiler. The considerable weight of cast iron batteries was reflected in Soviet cinema.

Cast iron radiator MS 140 technical characteristics: diagrams and installation techniques

People of the older generation remember very well that during the period of mass housing construction in the 60s and 70s of the last century, exclusively cast iron heating radiators were installed everywhere in new houses. And many of these batteries, having already served for half a century, or even more, still cope with their task to this day. It is interesting that when attempts were made to massively transfer the construction industry to steel plate or panel radiators, this was received by the population without much enthusiasm. The owners of new apartments, having spent the winter with such “new items,” mercilessly cut them off and looked for an opportunity to install “good old” cast iron. There were times when this even caused a rush of demand; cast iron batteries fell into the category of scarce goods, and it was not so easy to find them.

Cast iron radiator MS 140 technical specifications

How have cast iron batteries gained such high trust? The secret lies in the operational potential inherent in them. Let's take a closer look at such a battery, or, as it is correctly called, the cast iron radiator MC 140 technical characteristics, varieties, advantages and disadvantages, basic installation rules. In addition, we will try to independently calculate how many sections the battery will need so that it can fully cope with the task of heating a particular room.

The main advantages and disadvantages of cast iron radiators MS-140

If you go to a specialized hardware store, you can see with your own eyes a very wide selection of modern heating devices. The buyer is offered steel radiators of various modifications - from panel to tubular, lightweight aluminum with very high heat transfer, and the most technologically advanced and reliable bimetallic. Almost all of them have a very original design that will easily fit into the interior of a living room.

Variety of modern heating radiators

In order not to get confused when choosing heating radiators for your apartment or house, we recommend that readers familiarize themselves with the information contained in a special publication on our portal.

So why are there many consumers who reject all new developments and still opt for cast iron radiators?

- The undoubted advantage of cast iron batteries is their highest durability and reliability. Manufacturers estimate their service life at approximately 50 years. This is not an exaggeration at all, since practice shows that such heating devices, with proper care, last much longer.

A striking example of this is the record-breaking battery installed in one of the palace complexes of Tsarskoe Selo. It has been serving regularly for more than 110 years, and so far does not give any reason to doubt its reliability and make any replacement. But this is an officially confirmed fact, but in fact, it seems that in houses of old housing stock you can find radiators with more extensive experience.

By the way, not everyone knows that the history of cast iron batteries, in approximately the same form that has come down to us, dates back to the middle of the 19th century, and specifically in Russia. They were first cast in St. Petersburg back in 1855. The “father” of the cast iron radiator is considered to be the Russian entrepreneur Franz San Galli, the owner of the plant and at the same time a talented inventor in the field of water supply and heating. The first batteries had an interesting name - “hot box” (heizkörper). And the technology for casting them, in principle, has not changed to this day - gray cast iron and special clay molds are used for this.

“Father” of the cast iron radiator Franz San Galli and a monument in honor of the 150th anniversary of this device

To end with a historical digression, one more eloquent fact can be mentioned. How many objects of human life have monuments erected? But the cast iron radiator deserves such an honor! To commemorate the sesquicentennial anniversary, in 2005, a monument - a bas-relief - was erected at the Samara State District Power Plant. Isn't this evidence of the highest reliability of the cast iron radiator and its undeniable popularity?

- The unpretentiousness of a cast iron radiator to any heating system is one of its most important advantages. And it consists of several parameters:

— Firstly, it is capable of withstanding very serious pressure loads - for them, a pressure of 10 ÷ 12 atmospheres is considered quite acceptable.

— Secondly, the operating temperature range is up to 130 degrees, allowing them to be used in central systems with high pressure and temperature of the coolant.

— Thirdly, the cast iron sections of the batteries have wide internal cavities and channels. This means a minimal risk of blockages and high resistance to water hammer, which is not uncommon in central heating systems.

— Fourthly, cast iron is practically impervious to corrosion. This means that radiators are absolutely “not capricious” regarding the quality of the coolant. It is no secret that the water circulating through the pipes of central heating systems is very far from pure, and its aggressive environment is simply contraindicated for many other batteries. But not for cast iron ones.

Summary - cast iron batteries are suitable for any central and autonomous heating systems without restrictions.

- The high heat capacity of cast iron allows you to retain heat longer and effectively heat the room. Moreover, it is precisely these batteries that, to the maximum extent, have the ability, in addition to convective heating of the air, to also release heat through infrared radiation, and this is a very significant help to the entire heating system. Remember the “blazing heat” cast iron radiators – you can feel the heat even at a distance from them. No other radiator can compare with them in this regard.

- Cast iron batteries MS-140 are a collapsible design. This allows you to set the number of sections required for a specific room, change it as necessary, and replace the emergency unit.

The cast iron radiator can be disassembled to replace a section or for maintenance work

- The price of such cast iron radiators is quite affordable. Often, for reasons of economy, owners even purchase used batteries, which, after washing and proper refurbishment, will serve for a very long time.

Some of the advantages are a kind of “double-edged sword”. So, for example, wide channels are, on the one hand, a good thing, but filling them will require much more coolant. And the high heat capacity of cast iron also determines the very significant thermal inertia of radiators. To bring them to operating condition, much more energy consumption will be required, that is, the boiler at the start-up stage will work with a higher load, with virtually no pauses. True, this is compensated during operation - cast iron batteries will remain hot longer even after the heating is turned off.

After the above, you may get the impression that cast iron radiators are practically devoid of serious drawbacks. However, this is not so - they also have very significant “disadvantages”:

- Despite all the positive qualities of cast iron, it is a non-ductile, hard and brittle alloy. It does not like accentuated mechanical loads - it can simply crack. Lack of plasticity also means a high risk of damage due to sudden temperature changes; the crystal lattice “does not keep up” with linear thermal expansion. For example, if cold water suddenly enters a battery heated to high temperatures, the walls of the section may crack. Likewise, at subzero temperatures: if the battery is frozen, then with a very high degree of probability it will fail.

Freezing most often becomes fatal for a cast iron radiator.

- The second important drawback is excessive massiveness. Even one section (with an interaxial distance of 500 mm), not filled with coolant, depending on the specific model, can weigh 6 ÷ 7.5 kilograms. Plus there are a lot of connecting nipples and plugs. As a result, an average battery, say, with only seven sections, can produce a load of about 50 kilograms. And if you add the mass of the coolant (and in each section this is another 1.45 kg), then the total weight already jumps over 60 kg. And we are talking about a relatively small battery! What then can we say about assembly in 10 or more sections.

Brackets or stops for installing heavy cast iron radiators

This feature significantly complicates installation work - sometimes it becomes an impossible task to do it alone, without an assistant. In addition, powerful brackets or hooks are needed. And one more thing - not every wall structure is able to withstand such a load.

Several options for hanging cast iron radiators MS-140

We have to come up with quite complex designs, with emphasis on the floor surface or even with reinforcement on the back side of the wall.

True, some models of cast iron radiators can be equipped with legs-stands, or be directly designed for installation on the floor - the legs in this case become part of the structure (for example, on the outer sections of the battery).

Cast iron radiator equipped with feet

- Most radiators coming from factories have only a primer layer. This means that in order to give the batteries maximum aesthetics, you will have to paint them yourself, and this is not as easy as it might seem.

Typically, MS-140 radiators come from factories only in primed form.

In addition, such repainting will have to be carried out regularly, at least once every 3 to 5 years.

Some manufacturers supply batteries with external decorative painting

To be fair, it must be said that some manufacturers still meet consumers halfway, and their products go on sale after a cycle of multi-layer painting with durable polymer paints or even with decorative powder coating. It is clear that such radiators are already significantly more expensive.

- A disadvantage similar to the one mentioned above is that cast iron radiators are often criticized for their unaesthetic, as they say, “barracks-like” appearance.

Honestly, this is a very subjective question, that is, it lies in the plane of personal preference. Steel panel radiators may also not shine with beauty, and some people don’t like the overly modern look of bimetallic batteries, which can be difficult to fit into some interior styles.

In the end, no one bothers to cover the radiators with a decorative screen (of course, so as not to impair the efficiency of the heating system).

How to properly cover a radiator with a grille

Installing a decorative screen, box, or grille will help cope with the problem of the unaesthetic appearance of the heating radiator. How to choose the right decorative grille for a radiator so as not to reduce the efficiency of the home heating system - read in a separate publication on our portal.

And some manufacturers also practice casting sections with a decorative design - original “antique” relief designs are obtained on the walls of the radiator.

Very nice model with a relief pattern

Prices for cast iron radiators MS 140

Cast iron radiator MS 140

Main technical characteristics of cast iron radiators MS-140

Now - about the specific technical characteristics of various models of cast iron radiators of the MS-140 series

By the way, there is no consensus on what the abbreviation “MS” itself means. There are versions “modified standard”, “Moscow standard”, “metal sectional”, “assembly sectional” and other options.

But “140” is a very specific value, specifically indicating the depth (distance from the back to the front side) of each section - 140 mm. Usually this name is accompanied by a second numerical value.

- For example, the abbreviation MS-140-500 indicates that this is a cast iron radiator with a section depth of 140 mm and an interaxial distance of 500 mm.

This is the most common series, which was used for installation in high-rise apartments during their mass construction. The average heat transfer power of such a section is about 160 W.

MS-140 radiators can have different center distances - 500 or 300 mm

- But this series also includes radiators MS-140-300. As is clear from the classification name, they differ in the center distance - only 300 mm. These batteries were not so popular, but in a number of cases (for example, low window sills), they were used. Of course, their heat exchange area is significantly smaller, which is also reflected in the heat transfer power characteristics - only about 120 W from one section.

- MS-140-500 and one more variety are produced. In them, both vertical channels of the section are connected externally by diagonally located ribs. Such fins sharply increase the area of active heat transfer, and the power of the section increases to 190 W.

Radiator MS-140 with internal fins

True, such radiators are difficult to paint and also require frequent cleaning. The area of dust settling on the flat surfaces of the fins is large, and if they are very dusty, it is no longer possible to talk about 190 W per section - losses can be on the order of 30 ÷ 40 W.

The initial raw material for casting the sections themselves, and also very often blind or through plugs, is gray cast iron (according to the classification - SCh-10). Coupling nipples are made either from malleable cast iron (KCh - 30-6-F) or from steel (08KP or 08PS). Threads on sections, nipples and external threads on plugs - G1 ¼ ʺ Pass-through plugs also have a threaded hole G ¾ or ½ inch.

The tightness of the connecting units between sections is ensured by ring gaskets. For their manufacture, special heat-resistant rubber (PI or TTC), or paronite, is used.

A number of enterprises in the Russian Federation and neighboring countries are engaged in the production of cast iron radiators. They all adhere, in principle, to the same technical standards, although battery performance may vary slightly.

Among the MS-140 cast iron batteries on sale, the most common are products from the Novosibirsk, Nizhne-Tagil Boiler and Radiator Plant, from the Bryansk region. Radiators from the Minsk Heating Equipment Plant and the Lugansk Foundry and Mechanical Plant are in good demand.

Let's take a closer look at them.

Radiators of OJSC "Santekhlit" (Bryansk region, Lyubokhna village)

Corporate logo

Please note that the table shows cast iron radiators of two more series: MS-110 and MS-85. Perhaps, for reasons of compactness, they are more suitable for someone.

- The maximum coolant temperature for all series is + 130 °C.

- Allowable operating pressure:

— for the MS-140 series – 9 atmospheres;

— for the MS-110 and MS-85 series – up to 12 atmospheres.

| Radiator model name | Center distance (mm) | section width | depth | height | Heat transfer power, average (W) | Coolant volume (l) | Section weight (kg) |

| MS-140M-500-0.9 | 500 | 93 | 140 | 588 | 160 | 1.45 | 7.1 |

| MS-140-300-0.9 | 300 | 93 | 140 | 388 | 120 | 1.11 | 6.1 |

| MS-110-500-1.2 | 500 | 82 | 110 | 588 | 125 | 0.85 | 5.6 |

| MS-110-300-1.2 | 300 | 82 | 100 | 381 | 79 | 0.63 | 4.45 |

| MS-85-500 | 500 | 76 | 85 | 581 | 115 | 1 | 4.45 |

Cast iron radiators Novosibirsk

Logo of Descartes LLC

The specialists of this company are engaged in both the production of new radiators and the restoration of old ones. Moreover, after restoration, cast iron batteries are not much inferior in quality to freshly made ones, and the price is significantly lower, so they are often in even greater demand.

All products of Dekart LLC are designed for operating conditions:

- Coolant temperature – up to + 130 °C.

- The operating pressure limit is 9 atmospheres.

| Radiator model name | Center distance (mm) | Linear dimensions of the radiator (mm) | Heat transfer power, average (W) | Coolant volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140/500 | 500 | 93 | 140 | 588 | 160 | 1.45 | 7.1 |

| MS-140/300 | 300 | 93 | 140 | 388 | 120 | 1.11 | 6.1 |

| MS-90/500 | 500 | 71 | 90 | 581 | 130 | 1.45 | 6.5 |

Products of OJSC Boiler and Radiator Plant, Nizhny Tagil

If you come across such a brand name, then these radiators are from Lower Tanil.

The products of this plant are widely in demand far beyond the Ural region. Cast iron radiators meet all the requirements of Russian and international standards.

Terms of Use:

- Coolant temperature – maximum – 125 ÷130 °C.

- The excess pressure limit in the system is 12 atmospheres.

| Radiator model name | Center distance (mm) | Linear dimensions of the radiator (mm) | Heat transfer power, average (W) | Coolant volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140-M2-500 | 500 | 94 | 140 | 580 | 160 | 1.45 | 6.65 |

| MS-140M-300 | 300 | 104 | 140 | 388 | 117 | 1.11 | 5.4 |

| MS-90-500 | 500 | 90 | 90 | 580 | 130 | 1.15 | 5.48 |

Radiators of the Lugansk Foundry and Mechanical Plant

Radiators from the Lugansk Foundry and Mechanical Plant are in demand.

This manufacturer offers consumers cast iron radiators not only in a primed form, but also with a high-quality enamel multilayer coating. In addition, the company's assortment includes models that are improved in terms of decorativeness and are quite suitable for modern interiors (RD series).

Terms of Use:

- Maximum coolant temperature – up to +130 °C;

- Pressure limit – 12 atmospheres.

| Radiator model name | Center distance (mm) | Linear dimensions of the radiator (mm) | Heat transfer power, average (W) | Coolant volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140M4-500-0.9 | 500 | 102 | 140 | 588 | 184 | 1.33 | 6.74 |

| MS-140 M1-300-0.9 | 300 | 102 | 140 | 388 | 120 | 1 | 5.5 |

| MS-100 M1 3KP 500 | 500 | 63 | 100 | 570 | 135 | 0.7 | 5.4 |

| MS-1003KP 300-1.2 | 300 | 63 | 100 | 372 | 95 | 0.55 | 3.23 |

| RD- 100 500 -1.2 | 500 | 60 | 100 | 585 | 120 | 0.8 | 4.6 |

Cast iron radiators, Heating Equipment Plant, Minsk

The products of the Minsk plant are always distinguished by the highest quality.

The products of our Belarusian neighbors are extremely popular. Radiators from the Minsk plant are always of high quality and interesting engineering solutions.

In addition to the usual forms, the product range includes radiators with legs for floor placement - this allows you to get rid of the complex and time-consuming hanging procedure

Enterprise designers are also trying to get away from boring forms. Thus, the production of cast iron radiators has been mastered, which structurally remain the same as MS-140, but have a smooth enamel-coated front surface. In addition, options are offered with artistic relief casting in a retro style.

| Radiator model name | Center distance (mm) | Linear dimensions of the radiator (mm) | Heat transfer power, average (W) | Coolant volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140M | 500 | 108 | 140 | 588 | 160 | 1.45 | 6.7 |

| BZ-140-300 | 300 | 98 | 140 | 376 | 120 | 1.27 | 5.4 |

In a word, despite the apparent similarity of all cast iron radiators, the buyer still has a choice.

Basic technological methods for installing cast iron batteries MS-140

During initial installation, the battery is assembled from the required number of sections. However, sometimes circumstances force owners to either increase the radiator if its total power is clearly not enough, or, conversely, make it smaller. In addition, during operation there are situations when it is necessary to disassemble the battery, for example, to replace a section that has become unusable or to carry out maintenance work, cleaning or flushing.

Heating radiators require maintenance

Poor quality coolant can lead to gradual overgrowing of the channels inside the radiators. flush the heating system yourself - read in a special publication on our portal.

To fully understand how cast iron batteries are disassembled and assembled, it is necessary to understand the principle of connecting the sections to each other. Attention to the diagram:

Schematic diagram of the connecting unit for the MS-140 radiator

Any section (item 1) has two G1¼-inch threaded sockets on each side, top (item 2) and bottom. The distance between their centers is the center distance, which is indicated in the product classification. The threads on the horizontally opposite sides of the sections are oppositely directed (left and right), while the upper and lower sockets on the same side necessarily have equally directed threads.

Plugs are installed at the end sides of the assembled battery (item 3). They can be straight-through, with a threaded hole, or blind. Depending on the installation side of the plugs, they can also have a right-handed or left-handed thread. The diameter of the internal thread is G ½ or ¾ inch, always only the right one - pipes, pipes or fittings are connected (packed) here for further insertion into the heating circuit, or taps for air release.

The sections are connected to each other using nipples (item 4). This part is a cylindrical coupling with two counter-threaded sections that meet at the center of the pin. A gasket must be installed between the sections (item 5).

On the inner surface of the cylindrical nipple there are special bulges (protrusions) (pos. 6), which are necessary for engagement with the splines (position of the mounting key (pos. 7). The key itself may have a welded T-shaped handle for applying force, a loop for insertion lever, or the faceted surface of the rod for gripping it with a gas wrench.

mounting key (pos. 7). The key itself may have a welded T-shaped handle for applying force, a loop for insertion lever, or the faceted surface of the rod for gripping it with a gas wrench.

Main spare parts for assembling cast iron radiator MS-140

1 – nipple (protrusions for the key are clearly visible).

2 – ring-shaped gaskets, paronite (as in the picture) or rubber. Installed between sections and under radiator plugs.

3 and 4 – blind and through plugs. There are left and right.

Installation of a heating battery from individual sections is shown in the diagram below:

For installation work, it is best to prepare a convenient site for yourself, for example, on a spacious workbench or on the floor. It is recommended to cover the surface with a sheet of plywood so as not to be scratched by the ribbed edges of the sections.

How the sections are assembled into a single battery - schematically:

1 – Place gaskets on the nipples so that they stand in the center, in the place where the two threaded sections meet. The sections are arranged coaxially; the correctness of their relative placement must be checked - at the junction, the threads in the sockets must be in the opposite direction. Usually the manufacturer puts brand marks on the sections - this will help to avoid mistakes, since these marks should take a uniform position.

2 — The mounting key is inserted through the section window so that its working head with slots fits into the nipple. It is best if you have two keys at your disposal - it will be easier to work this way, alternately moving from one to the other. The sections being assembled are brought together and pressed against one another. By rotating the key, the nipple is turned - in this case, you must make sure that it is “baited” on both sections at the same time. A similar operation is performed on the opposite side. Then, alternately, avoiding distortions and wedging, the nipples are screwed in, simultaneously pressing the sections one against the other. Twisting is carried out until the tightest contact is possible in the connecting knots. Experienced plumbers can “by eye” determine the required force during assembly. The manufacturer indicates in the technical documentation that the torque applied when tightening should not exceed 15 kgf×m, so as not to deform the threads and protrusions on the inner surface of the nipple.

3 – after installing the first two sections, you can connect the third in the same way, and so on, until the required battery is completely assembled.

4 – it is quite possible to connect the battery in “fragments” - several sections pre-assembled into blocks. The only requirement is that the length of the mounting wrench rod be sufficient. By the way, this is the method usually used to dismantle and replace a failed section if it is located somewhere in the center of the battery. There is no need to sequentially disassemble the entire radiator - dismantling is carried out only at the required point.

The battery after removing the faulty section is ready for assembly

It is clear that dismantling is carried out in reverse order. However, there are situations when corrosion has “eaten” the protrusions on the inner surface of the nipple, and it is not possible to unscrew it. In this case, there is only one way out - carefully use a grinder to cut at the location of the gasket between the sections, and then heat the remaining nipple fragments and unscrew them from their sockets.

When reinstalling after disassembling the radiator, it is certainly worth carefully assessing the integrity and “survivability” of the nipples - they are inexpensive, and it would be reasonable to replace “doubtful” parts with new ones.

Video: example of disassembling and reassembling a cast iron radiator MS-140

How many sections of the MS-140 radiator are required to heat the room?

There remains one more unclear question - how many sections are needed to ensure full heating of a particular room?

There is a simple rule that heating requires 100 W of thermal energy for every square meter of room area. This means that calculating the quantity will not be difficult - the area is multiplied by 100 and divided by the thermal power of one section of the selected radiator model.

For example, a room of 18 m² requires, respectively, 1800 kW of thermal energy. This means that if a standard MS-140 with a power density per section of 160 W is selected, the required quantity will be 11.25. The value is rounded up to the nearest whole number. Total – 12 sections.

The calculation is indeed simple, but very inaccurate. The fact is that 100 W/m² is a very average value, and in different climatic conditions, of course, does not fully reflect the need for thermal energy - somewhere this may be lacking, but in the southern regions such power will simply be excessive. In addition, the features of the building, the location of the room on the cardinal points, the size and number of windows and their design, the degree of insulation of the walls and ceiling are of considerable importance. Even the way the batteries are inserted into the heating circuit can affect the heat emitted by the radiators.

Therefore, we invite the reader to use a special calculator, which already contains most of the criteria that influence the required heating power. Enter the requested values and immediately get the result, depending on the selected type of cast iron radiator:

Calculator for calculating the required number of sections of a cast iron radiator

Go to calculations

So, the MS-140 cast iron radiator was examined in detail. Despite the more than respectable age of the model and, as some may think, its unsightly appearance, there is no doubt that such heating devices will not soon disappear from apartments and houses and will serve more than one generation.

Qualities and characteristics

The described heating devices are designed to transfer thermal energy from the heating system to the premises of public, residential, industrial and other buildings. They are designed for coolant temperatures up to +130 degrees and operating (excess) pressure of the medium up to 0.9 MPa. Products are manufactured in accordance with GOST No. 31311/2005, as well as TU No. 4935/005/00288372/05.

Advantages of cast iron batteries

- High degree of corrosion resistance. This quality of cast iron is explained by the fact that during operation “dry rust” grows on its surface. It protects the material from corrosion.

- Cast iron has good wear resistance. Dirt and debris inside the system do not harm it.

- Excellent level of thermal inertia. Cast iron batteries, 60 minutes after turning off the heating, retain about 30 percent of the heat. For steel analogues, this parameter is only 15 percent.

- Very long service life. A high-quality device can last about 100 years. Manufacturers guarantee 15/25 years of trouble-free service.

The thermal photo shows that part of the battery is clogged with debris, which means it needs to be cleaned.

- Large cross-section of the internal space of the sections. Thanks to this, the batteries only need to be cleaned once every few years.

- The price of such heating devices is relatively low.