Progressive humanity never ceases to come up with new designs that are intended for one purpose - to make human existence as comfortable as possible. One of the relative novelties was a stove with a very unusual name “buleryan”. In general, its inventor had only one task. He needed to create a small-sized, mobile, efficient, but inexpensive device that could cope with all responsibilities. For example, with heating the temporary housing of lumberjacks leading a nomadic lifestyle (or rather, work). The assigned “mission” was completed with honor. And for those who do not yet know about all the new products, but want to be aware of what is appearing on the market, now all that remains is to find out how the Buleryan works, understand the principle of its operation, consider the positive characteristics of the design and, if any, its weaknesses.

How does the Buleryan stove work?

The Buleryan stove is often compared to a potbelly stove and a regular long-burning wood stove. We can say that the device took elements from both.

The operation of the oven is based on the principle of convection. Pipes for heat exchange are connected to the volumetric secondary chamber, in which the process of burning wood occurs. The principle of their operation is very simple. Cold air enters the pipe at the base of the Buleryan stove, and then comes out already heated at the top of the structure.

The furnace body can be of two shapes. For small rooms, cylindrical Buleryan stoves are most often made. For a large heating area, the stove takes on a teardrop shape. Pipes are placed on the outside of the structure. To ensure maximum heat transfer, they are soldered into the structure and protrude by only one third.

Operating principle of the Buleryan stove

The furnace firebox consists of three parts. A grate or fire-resistant mesh is placed at the bottom of the firebox. They can be made of cast iron or steel with a thickness of at least 4 millimeters. There is a special compartment at the top of the firebox. It is obtained thanks to a partition, for the manufacture of which a steel sheet is used. This compartment is also called the secondary chamber. In it, the combustion of gases occurs, which are released during the burning of wood. Combustion of fuel in the furnace itself is not complete. The released combustion products pass into the chimney. The length of the chimney is about 1 meter. Due to this part of the furnace, the combustion process becomes slower, and the combustion products cool down. The chimney is made curved and contains an economizer. Thanks to this device, secondary combustion of gases occurs. This stove structure increases heat transfer by 20% compared to other stoves.

The combustion process of wood is regulated using a damper. The damper is a damper near the exit from the firebox that regulates the intensity of the draft. It is attached to the pipe using a special metal rod. On the door, by changing the position of the gate, you can regulate the intensity of the oven.

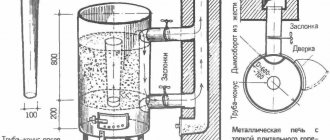

Scheme of the Buleryan furnace

The Buleryan stove is enough to heat a room of 100 m3. This will take no more than 3 hours. Large designs of the Buleryan stove are suitable even for heating large rooms, up to 400 m3. Not every oven can cope with such a task.

Keeping warm is also easy. Buleryan is an economical stove that requires adding firewood only twice a day.

Step-by-step instruction

Materials:

- Pipes;

- 4mm. 50x50 – 27 m;

- 2mm. 30x20 – 0.76m;

- 2mm. 40x25 – 2 m;

- Diameter 15mm – 0.6m;

- Diameter 95mm. (5mm.) – 1m;

- Steel – 5mm. – 3m2;

- Sheet metal – 100mm. – 0.1m2;

- Wire with a diameter of 10mm – 0.5m;

- Garage hinges – 2 pcs.

Step-by-step instructions for making Buleryan:

- We cut the pipe, which is 27 meters long, into 18 one and a half meter sections, from which we make pipes characteristic of Buleryan (two bends of 1200 each).

- 15mm nozzles are welded into 4 of them. tubes (tube length – 15 cm).

- The pipes are folded together in the shape of the future Buleryan and secured by welding. Parts with nozzles are placed two on both sides (later they will act as a blower). Everything is finally boiled down.

- To make the gas afterburning chamber we use 5 mm. steel. We cut out 2 blanks (370x700 mm with a jagged edge 50x60mm to fit the pipe size).

- The parts are welded inside the contour formed by the pipes. Pipes with nozzles should be located in front of the partitions.

- Frame . From the same metal as for the afterburning chamber, we cut plates that will close the gaps between the pipes: 18 pieces for the middle part (400mm x 50mm). 36 pieces for all lower and upper spaces (350mm x 50mm).

- We cover the ends with two 6-carbon plates from the same 5 mm. metal (side 40cm). We make a hole in one of the plates for the chimney. It should be 85 mm in diameter. and located in the afterburning chamber.

- And a hole for the door is cut in the front plate. Approximately 25x25cm. We weld both plates into place.

- The chimney will be a 95 mm pipe, 50 cm long. A valve is installed in the pipe on a wire axis (similar to a throttle valve in a carburetor), with a quarter cut out.

- A pipe frame (40 x 25mm) is made around the perimeter of the door opening.

- We cut out two squares from 10mm metal. The first is 330mm, the second is 246mm. We weld the smaller square with a profiled pipe (40x25), so that it fits into the frame onto the hole for the door (see points 8, 10).

- The blower will be similar to the chimney, only the valve in it will not have a selected quarter. Pipe for 95, 140 m long.

- A 95 mm hole is made in the finished lid, and a blower is welded there.

- Awnings . The door is fixed (by welding) and at a distance of 40 mm from its top and bottom, 2 professional pipes with a length of 380 mm are welded horizontally. Where there will be awnings, the ends of the pipes should protrude 5 cm beyond the hatch. Garage hinges are welded to them.

- Constipation . You can make the lock yourself, or you can order it from a turner. After welding it to the door, the fixing welding is removed.

- All welds are ground.

- You can weld the legs.

Don't be tempted by narrow water pipes. For efficient operation of Buleryan, pipes of 50-70 cm are better suited.

Advantages and disadvantages of the Buleryan stove

The Buleryan stove was first used by foresters in the Canadian taiga. They needed to carry a compact stove with them, into which it was necessary to rarely add firewood, and also to warm up very quickly from its heat. The Buleryan stove easily coped with this task. Advantages of the Buleryan stove:

- Compactness. A stove capable of heating 100 m3 weighs only 50 kg.

- Fast heating of the room. A small room of 30 m3 can be heated using a Buleryan stove in less than half an hour.

- Low energy consumption. The stove gradually burns wood, so there is no need to frequently add new combustible material to the firebox. It is enough to heat the room once to forget about adding firewood for 10-12 hours.

Despite the fact that the stove is a very well-thought-out design, there are still several disadvantages:

- Soot. Due to the fact that not all combustion products remain in the firebox, the soot goes into the chimney. Because of this, the length of the pipe relative to the furnace must rise at least 3 meters. This may also cause an unpleasant odor during heating.

- The need for constant adjustment. To prevent the temperature in the room from falling and the firewood to smolder slowly, it is necessary to constantly adjust the position of the damper. This requires skill and time.

- Dust combustion. Heat transfer in the Buleryan model occurs from the surface of the furnace. The metal becomes hot, causing the dust that settles on it to burn. Because of this, the air becomes musty and an unpleasant odor may also appear.

The lineup

It is worth noting that such stoves do not have a large range of models, but this will not prevent you from choosing the most suitable option.

For example, the Breneran-Aqua model.

It allows heating of significant volumes of water, so it is most often used for water heating. Its efficiency is 70%, but with just one tab it can work for almost 12 hours straight.

Another model is a gas generator. It is designed to quickly heat indoor air and can heat 4.5 cubic meters of air in one minute.

Good to know: Breneran stoves, unlike conventional potbelly stoves, can operate without even getting hot. In general, any Breneran model can quickly increase the temperature in the desired room. This allows you to start bathing procedures after just half an hour. But the most important thing is the enormous savings in firewood, with an excellent rate of injection of thermal air.

Popular models of Buleryan stoves

Furnaces based on the use of air pipes are produced under two brands: Buleryan and Breneran. The first established production of stoves was organized, oddly enough, not in Canada, but in Germany. Since 1993, stoves began to be produced in Russia. It has become possible to purchase a Breneran stove since 2005. It was this year that the official Russian stove manufacturer decided to rename the Buleryan stoves. This was due to an improvement in the design of the furnaces and an increase in the warranty period to 2.5 years. At the moment, there are many popular stoves of famous brands.

Stove Buleryan

Breneran AOT-14

This model is one of the most bulky, but capable of heating a large room up to 400 m3. The Breneran AOT-14 model weighs 130 kg, respectively. Although it is worth noting that many stoves designed for smaller spaces weigh an order of magnitude more.

Is it possible to make a Buleryan stove yourself?

For more than 20 years, the secrets of creating Buleryan stoves have been kept secret. Manufacturers do not disclose drawings and parameters of the materials used. But stove specialists have long measured the stove to make an analogue of a well-known brand. You can purchase a Buleryan stove from other manufacturers, not only from Laotherm. True, such stoves will be much inferior in quality. You can also design a Buleryan stove yourself.

Construction of the Buleryan furnace

The furnace is made of pipes for convection heat exchangers and steel sheets. Making the Buleryan stove yourself follows several steps:

- The pipe must be divided into 8 identical parts no more than 140 centimeters long. A pipe bender is needed to give the product a curved shape. The radius of curvature should not exceed 23 centimeters. All pipes must be equally curved.

- You need to make slits in two pipes and insert a small tube 20 centimeters long into each of them. Most of the tube should be on the outside. The joint should be carefully welded. These pipes will need to be used at the oven door.

- The pipes are placed one on top of the other, with the first pipe ends to the left, the second to the right, the third to the left, etc. A partition is made of steel and installed at the bottom of the structure, leaving the lower part of the pipes outside. The distance between the pipes is sealed using sheets of metal. The front and rear walls with holes for the chimney and door, respectively, are also made from this material.

- The chimney must be made taking into account a device for removing condensate. You should make a gate with a small hole and a metal handle. And also a blower that will be attached to the door. All these parts can be made independently from sheet metal.

When making a stove yourself, make sure that all parts of the design fit perfectly together. It is necessary to first calculate the dimensions of the stove and be sure to connect it to the chimney before checking the operation.

Buleryan is a time-tested stove. At low costs, the efficiency level of such a furnace is one of the highest in the world - it reaches up to 80%.

Speaking about Buleryan stoves, one cannot help but recall the story with which it all began. Lumberjacks worked in the Canadian forests. The work took place in winter, and they were very cold, and the stove that they had, unfortunately, could not provide enough heat. This is where it all started. It was the lumberjacks of Canada who invented the Burelyan stove, which has become very popular today. They made it from what they had at hand: a barrel, bent pipes and imagination.

In the photo there is a Buleryan stove

Manufacturer of stoves Buleryan

Canadian Buleryan stoves appeared in our country almost 20 years ago. For several years they were called Buleryan, and today the name has been changed to Breneran. However, both then and now, these stoves are widely used for heating:

- Residential premises;

- Work premises;

- Ban;

- Sauna;

- Garages;

- Teplitz;

- Workshops, etc.

They are capable of heating from 100 to 1000 square meters. The manufacturer of these furnaces presents 5 models of this type of units, the power of which can be from 6 to 35 kW. It is worth noting the fact that today some of them have a special viewing window and are produced for air and water heating.

Installation "Buleryan"

When installing, you must maintain the distances to the walls that are recommended by the fire department. Examples of wall protection and distance to the stove depending on the material:

- wooden unplastered - at least 1000 mm;

- layer of heat insulator 7 mm, and metal on top 1 mm - distance 500 mm;

- non-combustible plaster with a layer of 25 mm and ceramic tiles - 700 mm;

- single brickwork (55 mm) - 500 mm;

- double brickwork (110 mm) - 300 mm;

- a shield made of two sheets of metal 1 mm thick, assembled using non-flammable inserts, the distance between the sheets is 30 mm; The structure is mounted on a wall protected by a layer of thermal insulation - the distance to the walls is 300 mm.

The Bulerjan stove must be installed on a non-combustible base. This could be four rows of bricks laid flat. A clay mixture is used as a solution. The dimensions of the base are 30 cm larger than the parameters of the stove in any direction. To save bricks, you can leave voids in the two bottom rows. Another type of non-flammable base is a metal stand for “Buleryan” made of pipes. Its height is 150-300 mm. For any installation method, a metal sheet must be placed on the combustible floor in front of the stove; its dimensions are: width 500 mm, length 700 mm.

Rules for installing Buleryanov on a flammable floor

When installing the Buleryan stove with your own hands, it is important to make the chimney correctly. They are subject to general requirements (except that it must all be insulated, but this is not a requirement of firefighters, but technological nuances). The chimney pipe can be:

- Brick. Wall thickness 120 mm.

- Concrete with a wall of 60 mm.

- Metal (including sandwich).

The chimney parameters depend on the model. For Buleryan stoves of types 00 and 01, the minimum height is 4 m, cross-section is 120 mm; for models type 02, 03 and 04 - above 5 m, with a cross-section of 150 mm. The chimney must be made airtight, and the joints must be sealed with heat-resistant sealant.

Both types of chimney outlet are allowed: through the roof or into the wall

Both methods of exhausting the chimney are allowed - through the wall and the ceiling. Output to the wall is easier to implement, especially if there are several floors. When exiting through the ceiling, it is necessary to equip a passage unit through the ceiling and roof in compliance with all fire safety measures. The height of the chimney above the ridge is at least 0.5 m.

As you can see, there are no excessive requirements for the installation: you have prepared the place, built a sealed insulated chimney, and you can carry out the first fire. So installing a Buleryan stove with your own hands is possible.

Design and mechanism of operation

The Buleryan stove consists of a barrel-shaped body, the internal space of which is divided into two sections. The process of kindling and burning wood occurs in the lower part, this is where the temperature begins to rise and heat accumulates. At the same time, as the wood burns out, hot gases accumulate in the upper part of the body.

Radius pipes pass through the center of both parts of the furnace, in which convection occurs. Cold air, entering the furnace through the pipes, encounters a hot circuit, which creates a fast flow that rushes out and carries away the heat of the furnace. The basic principle of operation of the device is the correct combination of several heating options, including: convection, heat transfer and heat exchange. Due to the lack of a ventilation system, heating thus occurs quite quickly.

Scope of application of stoves

Initially, Buleryan stoves were created to organize heating in the houses where Canadian lumberjacks lived. Subsequently, they began to be used for heating ordinary houses and country houses. Having spread throughout the world, they delight users with the coveted warmth and ease of operation. In Russia they are used for heating dachas, country houses, industrial premises and outbuildings. If necessary, Buleryan stoves can be used to heat multi-room buildings - for this they are retrofitted with air jackets and air ducts.

Water circuit

To increase the efficiency of the furnace, many choose to add an aqua circulation system to it, through which the coolant moves. As a result, new devices appeared for organizing a water heating system - “Breneran-Aquaten”, “Aqua-Buleryan”.

Buleryan with a water circuit for heating also uses the convection principle of operation, however, instead of air, a liquid coolant is used, so it is easier for heat to penetrate through the partitions.

The peculiarities of this device are that inside the casing there is a combustion compartment, which is tightly fitted with pipes with liquid, due to this heat is transferred faster. The pressure in the system is provided by a special pressure manifold, capable of raising the coolant by 8 m. Due to its heating, natural circulation occurs, and due to the gas generation process, the Breneran-Aquaten furnace is more productive and consumes less fuel.

Scheme for using the oven

In other words, the furnace operates due to the fact that the coolant rises to the maximum height and is distributed through the pipes, then it returns again through the return line. On it, other circular equipment and a drain valve are installed. This entire design makes the system operate as efficiently as possible.

In the furnace structure itself, 70% of the entire combustion section is allocated to the water circuit; accordingly, the water is heated quickly and evenly without noticeable heat loss. There are no temperature or pressure differences.

Installation features

General connection diagram with description

Fire safety

For any room where the stove will be located, it is necessary to comply with fire safety standards:

- The structure can only be placed on a non-combustible base; steel sheets or a concrete floor are perfect for this.

- A sheet of steel must be laid on the floor near the firebox, the length of which must be at least 1.25 m.

- The distance from the wall to the stove should not exceed 1 meter for plastered surfaces and 80 cm for surfaces with an insulation layer.

- The stove can be installed in a room with excellent ventilation and an area of 12 sq.m. machines for heating elements are installed only in adjacent rooms.

Correctly installed Buleryan stove according to PPB rules

Installation of a smoke removal system

When installing a chimney, the following requirements must be met:

- materials that are resistant to corrosion, high temperatures, and acids are used;

- the chimney pipe inside must be perfectly smooth;

- The layer of the pipe facing the street is insulated with basalt wool, the thickness of which will be at least 50 cm.

All chimneys are installed vertically; the length of the pipe outlet from the stove to the common chimney cannot be more than 1 meter.

Gravity system

When connecting Buleryan with a water jacket to a natural heating circuit, the following recommendations must be observed:

- The wood-burning stove is placed 50 cm lower than the radiators are installed;

- pipes are mounted at an angle;

- an expansion tank is placed at the highest point (usually in the attic);

- for unheated attics, the installation site of the expansion tank should be insulated;

- supply pipes require a special safety circuit.

Forced circulation

A Buleryan stove with a water circuit is installed together with an additional pump. The scheme includes:

- a circulation pump is installed on the return line;

- Thermal sensors are used for adjustment;

- the circuit requires a closed expansion tank;

- To operate the pump, you must install a UPS with a voltage stabilizer.

Pipes for piping

Various pipes are used for Buleryan, but their choice should be taken responsibly, since they have a great influence on performance. Three types of pipes are recommended for piping Buleryan:

- metal-plastic, corrosion-resistant and easy to install (can be used with forced-air heating systems only for industrial enterprises);

- polypropylene pipes can be easily installed with your own hands, they are inexpensive, lightweight, and easy to install (allowed for installation in residential buildings);

- steel pipes can withstand high temperatures for a long time (can be used for any Buleryan, but require a system of greater power than a circuit with plastic pipes).

Advantages

- Even the largest areas are heated quickly and evenly.

- Heat is easily transported throughout all floors of the building.

- The stove, despite its extensive properties and power, has quite compact dimensions.

- The stove is simple and convenient to use, and with careful and correct approach it can last for a very long time.

- Installs quickly.

- Breneran with a water circuit is fuel efficient. Firewood can be loaded once every 12 hours.

- Thanks to autonomous wood burning, no gas or electricity is consumed to heat the room.

- After burning, there is practically no ash left, so servicing the device itself does not take much time.

- The user controls the heating process independently.

Flaws

- When loading wet firewood, resins will form as it burns, so you should only use completely dry fuel.

- When selecting wood for fuel, you need to choose species that do not emit resins.

- In the second furnace in Buleryan, only 70% of the generator gases are burned.

- If the chimney was not insulated before the Breneran sauna stove was installed, then condensation may be released, which will reduce the performance of the device.

- Due to the metal body of the device, in addition to the additional protective coating and sheathing of the surrounding walls with basalt insulation, a distance from the walls of at least half a meter will also be required, which is not always convenient in small spaces.

- Due to dust getting into the pipe opening, an unpleasant odor may occur when the oven heats up.

- The rooms in which the stove is located require daily cleaning and ventilation, since during its operation charged ions are formed that can have a negative effect on the human body.

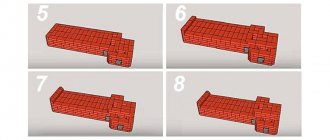

Brick lining

To increase heat distribution in the steam room, as well as to increase the service life of the stove, a specialist is recommended to create a “protective casing”.

It is not difficult to understand how Brenaren is covered with bricks.

Laying must be done in a checkerboard pattern. To do this, the brick must be soaked in advance. After this, it is shaken, freeing it from excess water, and placed on the cement solution, leveling it with a wooden hammer.

When the installation is completed, the brick walls will need to be dried, leaving the mortar to set for several days. After this, the surface can be finished. At the same time, the first fire must be carried out extremely carefully so as not to overheat the furnace and thereby allow the solution to finally thicken.

Watch the video in which a specialist reveals the secrets of installing a stove and a chimney for it: