Opinions are divided about the danger of mineral wool as insulation for walls, roofs or floors. Manufacturers, for their part, claim that the materials are completely environmentally friendly and offer to confirm their words with certificates; experts and doctors consider the impact on the health of insulation to be questionable, to say the least, negative.

What remains for users? The main thing is to analyze the opinions of both and draw conclusions about what mineral wool to buy, how to use it correctly so as not to harm your health, and what you need to know about the choice and composition of insulation materials.

“Toxic dust” or a few words about the dangers of mineral wool insulation

Is mineral wool really an environmentally friendly building material? Can its use as insulation harm our health?

The construction season is in full swing and now is the time to purchase building materials, especially since self-isolation is coming to an end and more and more shops are returning to work.

Today I want to talk about the environmental friendliness of building materials, and specifically about such an important thing as thermal insulation. Mineral wool is most often used as insulation. This material is considered environmentally friendly because it is made from natural raw materials. But is this really so? Let's figure it out.

You've probably used mineral wool as insulation. And if you have had experience working with it, you have seen how lint and dust fall off it, and in considerable quantities.

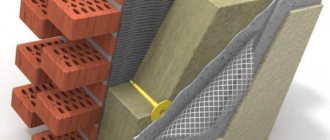

That is why, when working with mineral wool, experienced builders always use gloves, respirators and safety glasses. Actually, these rules are dictated by work standards: GOST 4640 and GOST 9573. Although even without them, anyone who has dealt with mineral wool will quickly understand that protective equipment is necessary. Fiber particles penetrate the skin, enter the respiratory tract and eyes, causing itching and irritation.

Mineral wool particles of 2.5 and 10 microns in size that appear in the air of the working area during facade insulation work were studied by specialists from the St. Petersburg State University of Transport and Communications (PGUPS). The scientists described the results of this research work in the article “Assessing the risk of damage to health from exposure to fine mineral wool dust,” published in the Kazan Medical Journal, Volume 95, No. 4, 2014.

Thus, it was found that during the work the content of these particles was four times higher than the MPC standards.

And although manufacturers of mineral wool present it as a natural building material, since it is made from molten rocks such as basalt, limestone and others, it is worth knowing that these rocks contain oxides of aluminum, iron, potassium, calcium, etc. Penetrating into the body in the form of dust, they have a fibrogenic effect, in other words, they lead to the occurrence of pneumofibrosis - replacing healthy lung tissue with scar tissue. At the same time, a severe form of pulmonary fibrosis is more dangerous than cancer, since it is incurable.

In addition, during the production of mineral wool, various types of waste from metallurgical production are used such as charge, slag and others. Thus, mineral wool contains heavy metals. According to PGUPS employees, the entry of heavy metals into the human body can cause problems with the cardiovascular system.

As the above-mentioned study showed, the risk of serious illness is associated with the length of work of construction workers who regularly interact with mineral wool. So, after four years of work, the risk of loss of health is high, and after fourteen years it is extremely high. Workers who regularly interact with mineral wool are at risk of developing heart and vascular disease long before retirement.

Now let's think: is life easier for the consumer of mineral wool? After all, he does not participate in repair and construction work, but receives the finished result, and the mineral wool is hidden behind a layer of finishing materials. However, even in this case, negative health consequences cannot be avoided. The smallest particles of mineral wool, ranging in size from two to ten microns, will always find their way into living spaces. Gradually accumulating in the air, they penetrate the body of people living in a house insulated with mineral wool. And although there is no such serious risk as in the case of construction work, nevertheless, significant harm to health can still be caused. Moreover, in addition to microparticles containing heavy metals, phenol vapor and gaseous formaldehyde are gradually released from mineral wool.

Myth No. 1. Harmful from contact with moisture

Let's start with a justified myth that has a lot of truth in it. This applies to heat insulators that are produced using outdated technologies (use of glass wool). A negative reaction of mineral wool to contact with moisture leads to the accumulation of liquid with the further formation of mold. At the same time, it is not the cotton wool itself that is harmful to health, but the mold, which weakens the immune system and causes allergic reactions and inflammatory processes in the respiratory system. Also, contact with mold can cause skin, cardiovascular and central nervous system diseases.

To prevent the risk of exposure to mold on the body, it is recommended to simply choose high-quality building materials. When choosing, pay attention to heat insulators with a minimum water absorption coefficient. Even at high levels of humidity, such material does not absorb it, which eliminates the risk of mold.

Myth No. 2. Harm from burning

There are many rumors about the dangers of various insulating building materials from exposure to fire, and they have been spreading for quite a long time. For some time, users seriously believed that even burning laminated veneer lumber could have a negative impact on health, since chemical compounds are used in its production. Let’s not talk about the fact that by nature, when burning, any materials can emit harmful gases. One has only to note that when burned, mineral wool is absolutely harmless. Everything is very simple. Mineral wool does not burn. Modern building materials are produced on a basalt basis. As we know, basalt is a stone, which is why the material is also called stone wool. The stone does not support combustion processes, as well as its derivatives.

Research confirms this. Even under a gas burner aimed at the roll, the insulation may slightly change color and become charred, and even then only with direct and prolonged contact with the flame. If we talk about fires and destruction, they will not happen. Therefore, the myth that mineral wool releases harmful substances when burned is untrue.

Basalt wool - how do they do it?

The technology for making fiber from stone is “borrowed” from Mother Nature. One day, on the Hawaiian Islands, researchers found strange fibers, which later became known as “Pele’s Hair.” In honor of the beautiful girl Pele, the goddess of fire among the ancient settlers. Fibrous materials were produced as a result of volcanic eruptions. The formations resembled cotton wool made from thin threads of volcanic rocks. It was they who became the “progenitors” of modern heat-insulating material.

For the first time, such a substance was prepared artificially from rocks in 1897. in the United States of America. The production of basalt wool is not far removed from the natural work of the volcano, and to this day is based on the same principle. The rock is heated in furnaces to 1500 °C. As a result, a fiery liquid molten substance is formed, from which the threads that serve as the basis of fibrous wool are drawn.

Okay, we figured it out, all materials are mineral, although they are obtained artificially. What is the difference between glass wool and stone wool? Does using these materials mean we are at risk? Or are there differences? And the most incomprehensible thing is, if the material is mineral, then why is basalt wool harmful to health? What is this, speculation or rumors?

We found out that igneous rocks serve as raw materials. By the way, both dormant and active volcanoes can boast large deposits of basalt. Foreign - Etna and Vesuvius. In Russia - the Kamchatka and Kuril Mountains. These minerals and their derivatives, cotton wool, are truly harmless. But formaldehyde resin is used to bind the fibers together. It is this that contains phenols.

Basalt wool characteristics

A few words about the characteristics of the volcanic rock basalt. In the future, this will help to get a better picture of the remarkable properties of mineral wool produced from its raw materials:

- Hardness on the Mohs scale from 5 to 7

- rock density 2.60 - 3.10 g/cm3

- specific gravity 2.6-3.11 g/cm3

- specific heat capacity 0.84 J/kg•K at 0°C

- abrasion 1-20 kg/m²

- rock melting from 1100-1250°C

- The compressive strength of rock stone reaches 400 MPa

Production of crushed stone, production of basalt wool, stone casting, paving slabs, paving stones, decorative facing elements, concrete mix filler, this is not a complete list of magma uses. Building materials made from basalt have become widespread and have gained immense popularity.

The best basalt wool

Now that we have identified the main “enemy,” everything falls into place. It turns out that the matter is not in the material, but in the absolutely precise ratio of components and following the established technological process. And the question of what is the best basalt wool can be answered with confidence - the one that was produced in compliance with the technological chain and complies with quality certificates.

In this case, the main rule for purchasing material is to carefully check the origin of the product. Any product has maximum permissible standards for the content of harmful substances, so do not be afraid to use basalt wool where they are not exceeded. The main well-known manufacturers today:

- Rockwool (Rockwool Scandic thickness 50mm, Rockwool Light Butts thickness 50mm), light butts 1000x600x50 mm

- TechnoNIKOL Rocklight thickness 50mm, Technolight extra 1200x600x100 mm

- Paroc thickness 50mm

- Isover thickness 50mm

- Knauf thickness 50mm

- Ursa thickness 50mm

- IZOVOL thickness 50mm

- Beltep thickness 50mm

- BASWOOL thickness 50mm

Myth No. 6. Environmental friendliness

The quality of modern building materials plays an important role. In view of the increase in diseases of the respiratory system, this is not surprising. However, upon careful study of the composition of the material, as well as after research, scientists found that phenol-formaldehyde, which is contained in mineral wool, does not pose the danger that they say. According to experts, there are more harmful substances in urban air than in the insulation, which is hidden behind the skin and additionally treated with special impregnations.

Ursa Pure One

Ursa Pureone mineral wool has the best thermal insulation properties. At the same time, it is environmentally friendly and does not contain any harmful substances. The use of phenol and formaldehyde in production is completely excluded. This is the latest generation material, differing from simple mineral wool even in appearance: it is white, reminiscent of cotton or sheep's wool.

Harmful. If it is stuffed inside the body in large quantities, it can cause indigestion (((You can try brick crumbs, in terms of the chemical composition they are the same)))

If you are not satisfied with the answer or there is none, then try using the search on the site and find other answers in the Family category

Myth No. 4. Harmful emissions

This myth is the most popular about building materials in general. For this reason, mineral wool simply cannot be ignored. No matter what kind of insulation is used in a particular case, you will hear about the harm it can cause to the environment. In fact, some thermal insulators are actually harmful. If the manufacturer uses low-quality materials with chemical additives, then such heat insulators can be harmful. But mineral wool is a material with which things are different. It is produced using unique technology; even despite the use of various additives, the products are environmentally friendly. The percentage of phenol resins used in production is so small that, despite all their harm, they are not capable of causing harm to health. The content of these substances in mineral wool is 1-2%. Well-known manufacturers go even further and do not use phenol resins. In such building materials, bitumen binders or derivatives are used.

Evaporation

In addition to the above-described problems associated with basalt fiber, ecowool contains resins. These resins are composed of various chemical compounds, including phenol and formaldehyde derivatives. It is due to these components that the fibers are bonded to each other.

Each such compound poses a great threat to human health.

Of course, these compounds are completely harmless if the highest quality raw materials were used during manufacturing and all requirements for the production of basalt insulation were followed.

In properly manufactured insulation, all components are bonded with phenol-formaldehyde resins. Only in this state are they absolutely harmless.

Materials manufactured in violation of the prescribed order may contain additional impurities. These impurities can cause various lung diseases (due to vapors) and skin irritations.