There is a strong opinion that it is better to insulate a wooden house from the outside: heat loss is minimal, the service life of the building is increased, the interior space of the rooms is saved, and the dew point moves outward. Recently, penoplex is often used for external insulation (people write and say penoplex), but some of its properties have an adverse effect on the microclimate of the house. Let's find out whether it is possible to insulate a wooden house with penoplex from the outside or not.

Installation of penoplex in frame house construction is carried out using glue and disc fasteners with self-tapping screws

When is insulation of wooden houses required?

Wood is a building material that retains heat with good thermal conductivity. If the construction technology of a log house is violated, living in it becomes less comfortable.

There are several reasons for heat loss in a wooden house:

- insufficient thickness of lumber;

- incorrect choice of method for angular connection of parts;

- insufficient sealing of windows and discrepancy between the number of cameras and the climatic conditions in the region;

- gaps between the crowns that appeared as a result of shrinkage of the log house;

- blowing due to old caulk.

Requirements for the thermal insulation circuit

To prevent the formation of cold bridges in the house, it is important to create a heat-insulating circuit between the environment and living spaces.

If the wall is not insulated, the dew point is inside the wall and creates moisture. It is necessary to use insulation to shift the dew point outward, to the surface of the insulation

A continuous circuit made of material with low thermal conductivity will prevent cold air from entering the home and prevent heat from escaping outside.

There are certain requirements for the heat-insulating circuit. He must:

- be breathable. Wood can breathe. It has high vapor permeability and regulates the natural microclimate in the house. The insulation on the outside must also allow air to pass through and at the same time be moisture resistant. Air circulation prevents the accumulation of moisture in the wood and on its surface, prevents the formation of condensation and the appearance of mold in it;

- have low thermal conductivity, keeping the house warm;

- have low flammability to prevent the wood from igniting. Flammability is the property of a material to resist the effects of fire;

- weigh little so as not to place a significant load on the structure.

Is penoplex suitable for insulating a wooden house from the outside?

To insulate the outside of a wooden house, it has long been lined with brick. But new modern materials have appeared that effectively retain heat in the house. Such materials include penoplex. It is foamed polystyrene, produced in production by exposing it to high temperature and pressure. When the pressure is released, the mass begins to expand, forming foam.

Penoplex structure

When the temperature drops, it begins to harden. It is passed through extruders. The result is a material in which most of the components are saturated with air. Closed cells measuring 0.1-0.2 mm do not allow moisture and steam to pass through. To find out whether penoplex is suitable for insulating a wooden house from the outside, let us draw your attention to its features and whether they meet the requirements for a heat-insulating circuit. To do this, we will determine the pros and cons of such thermal insulation.

Why foam

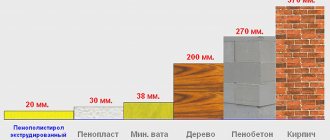

There are a considerable number of different insulation materials that have certain advantages. They are selected according to various parameters - cost, origin, level of vapor permeability, but the degree of thermal conductivity remains the most important.

- The colder the climate, the thicker the thermal insulation layer should be or the higher the thermal insulation value should be. An 8 cm thick slab of foamed polymer replaces a 10 cm thick layer of mineral wool, a 27 cm thick layer of wood, and a 76 cm thick brick wall. It is clear that foam plastics are much better in this regard. The photo shows slabs with different densities.

- The material is easy to cut and join. The technology for laying outside with your own hands is extremely simple.

- Foamed plastic is very light, insulation does not create a load on foundations and walls.

- It does not absorb moisture at all, and, accordingly, does not rot, does not become moldy and does not lose its performance qualities.

The disadvantages include low vapor permeability. However, if plastic or metal siding is used for cladding, and the house has metal-plastic windows, this no longer matters: you will still have to install exhaust ventilation, according to expert reviews.

Installation technology

Foam plastic of the PSB-S-25 brand is chosen as insulation - it is used everywhere. PSB-S-35 has a high density and is used for thermal insulation of foundations or buildings during harsh winters.

The size of the sheet is determined by needs. In regions with a temperate climate, as a rule, slabs with a thickness of 8–10 cm are used, and in cold climates the thickness can reach 15 cm.

- Do-it-yourself insulation of a house with polystyrene foam under the siding begins after installing a sheathing made of a galvanized metal profile - if the climate is humid, or wood, if the climate is dry.

- Facade adhesive is applied to the slab.

If the surface is smooth, then the glue is applied evenly over the entire sheet; if it is uneven, then to the areas where the insulation comes into contact with the surface. You can see an example in the photo.

The sheet is glued in a horizontal position, first the lower section, and then the upper. The slabs must be joined tightly, without gaps. If they do appear, they are sealed with polyurethane foam, sealant, and, for larger sizes, with pieces of insulation. If necessary, fastening with glue is duplicated with disc screws. This operation is recommended to be carried out when insulating door and window openings.

The video explains in more detail how to insulate a house from the outside with polystyrene foam under the siding.

Advantages and disadvantages of such thermal insulation

Let's figure out what the advantages and disadvantages of external insulation with penoplex are.

- An important aspect of the popularity of extruded polystyrene foam for external insulation is its affordable price. The cost of the entire heat-insulating circuit around the house is quite acceptable for any category of citizens.

- Penoplex has a low thermal conductivity of 0.029-0.034, thanks to which heat is retained indoors.

- It is wear-resistant. Does not change its original properties over a long period of time with significant temperature changes and can withstand up to 1000 freezing and thawing cycles. At the same time, thermal insulation performance remains at the same level.

- Penoplex is impact resistant. Withstands any mechanical stress, does not deform and retains its shape from compression and stretching.

- Extruded polystyrene foam is lightweight. The insignificant mass of the material does not put pressure on the walls or foundation, so it can be used in buildings that are not strong enough.

- Easy and simple installation helps save money on calling a specialist. You can insulate the walls yourself without the help of helpers or professional craftsmen. The need for tools is minimal.

- The service life of extruded polystyrene foam, guaranteed by the manufacturer, is 50 years.

- Penoplex is characterized by low moisture absorption: up to 0.5%

- The advantage of extruded polystyrene foam is its bioresistance to various chemicals: acids, alkalis, vegetable oils.

- The range of foamed polystyrene boards is varied in type, density, thickness and thermal conductivity.

Penoplex is most preferably used when insulating frame buildings, always using a vapor barrier film inside the building or when insulating temporary buildings (houses, garages, etc.)

But at the same time, insulating penoplex from the outside has a number of disadvantages:

- it is vapor-tight. Not only water, but also steam and air do not pass through the closed pores of extruded polystyrene foam. Penoplex, enclosing the house on all sides, will prevent the passage of air inside, the tree will stop breathing. As a result, condensation forms on the inner surface of the wall;

- has a high flammability group. Being near flammable material (wood) may cause a fire. When burning, it releases toxic, caustic substances;

- cannot tolerate exposure to ultraviolet rays. From their direct influence it begins to crumble and collapse. To prevent its destruction, the insulation is covered with finishing materials;

- low frost resistance leads to the appearance of cracks in the material.

Scope of application

The extraordinary consumer properties made Penoplex an ideal solution for thermal insulation of any buildings. Using this material, thanks to its unique characteristics:

· protect the foundation and plinth from heat loss;

- equip basements with thermal insulation;

- thermally insulate floors and ceilings of buildings;

- line water supply systems and swimming pools;

- insulate loggias and balconies with slabs;

- manufacture of multi-layer sandwich panels;

- develop highways and runways;

Extruded polystyrene foam is used throughout the construction industry. It solves problems of heat conservation at facilities built in the climate zone with the lowest temperature.

Types of penoplex

To insulate a wooden house, the following types of penoplex are used:

- slabs for vertical structures. They are designed to insulate walls and partitions inside and outside the house. The insulating material has a density of 22 kg/m3. The milled surface of this type of penoplex improves adhesion to various mixtures: adhesive and plaster compositions;

- "Comfort" series. This is a universal insulation material, which, due to its positive properties: strength, low thermal conductivity and moisture resistance, is successfully used to insulate ceilings, walls, plinths, foundations, and walls. It is able to withstand high humidity, so it is widely used as a heat insulator for bathrooms, baths and saunas. The density is the same as the previous type;

- heat insulator for roofing. It has a high density: from 26 to 34 kg/m3. Successfully used for pitched roofs. The slabs have a U-shaped edge, due to which the joints between the sheets are almost invisible. The insulation forms a flat surface on which any roofing materials can be laid;

- insulation for the foundation. It has a high density of 27-35 kg/m3. Durable, withstands significant loads. Insulated structures—foundation, but also floors, basement.

How to comply in practice

To properly insulate a wooden house from the outside, you need to take into account several nuances.

If a frame house is to be thermally insulated, it is important that the wood is well dried in special chambers, otherwise damp wood can lead to the formation of mold.

Let's see if there is ventilation in the timber structure. Air does not pass through foamed polystyrene boards because penoplex has low vapor permeability. Water vapor tends to escape through the joints between the slabs, which are covered with polyurethane foam. Vapors pass through it, accumulating condensate in these areas. Every day the amount of accumulated moisture increases. Insulated walls become covered with fungus.

To prevent the formation of condensation in a wooden house, you need to ensure good ventilation. Fanned walls and insulation will remove excess moisture. Optimal ventilation can be ensured by creating a ventilation gap between the wooden wall and the thermal insulation. But in this case, creating a gap between the wall and extruded polystyrene foam is prohibited, because wood is a flammable material, and in the vicinity of extruded polystyrene foam the risk of fire increases.

If you eliminate the gap between the penoplex and the wall and tightly glue the insulation to it, then after a while black mold will form under the thermal insulation, a damp smell will appear, and the wooden house may begin to collapse. In addition, it is impossible to ensure a tight fit of the material to the logs due to the structural features of the crowns.

Risks when insulating with penoplex

To prevent the appearance of mold when gluing penoplex in a frame and timber structure, it is necessary to create powerful supply and exhaust ventilation, which will negatively affect the heating system in terms of costs. Only an expensive ventilation system based on heating cold air from the street with warm air from inside the house will save you. Then cheap penoplex will turn into a “golden” insulation product.

If you do not install a forced ventilation system, then there is a high probability of mold formation between the wooden wall and the penoplex, the wood will simply rot, it’s only a matter of time.

In the case of installing insulation with a gap between the outer surface of the wall and the insulation, there is a risk of immediate spread of fire in the event of a fire, since this gap will act as a tube with strong draft; in addition, such ventilation gaps are contrary to building codes.

If you decide, despite our warnings, to insulate the outside walls of your house with extruded polystyrene foam, then we’ll tell you how to do it.

Material selection criteria

It is important to understand that only high-quality material is selected for a reliable layer of thermal insulation. Therefore, when buying expanded polystyrene, do not make a choice on the first one you come across, focus on the following criteria:

- Availability of quality certificates and related documentation.

- Manufacturing standards. If the documents indicate specifications, refuse such products; GOST gives the green light to purchase.

- Marking - PSB-S is suitable for facade insulation; this material is treated with fire retardants, which means it will extinguish on its own in the absence of a fire source.

- Density not less than 40 kg/m3. Other options are not suitable for facade insulation.

- Try breaking off a corner of the slab of the option you like. The scrap should be smooth, and the visible elements (balls) should have the shape of a polyhedron. If this is not the case, the option is suitable for packing things during transportation, but it will not withstand the load that the facade is subject to.

Insulation of a wooden house using penoplex from the outside

Do-it-yourself insulation of a wooden house from the outside with penoplex is carried out in a certain sequence. Correct installation of insulation will increase the service life of your home and ensure comfortable living in it:

- before laying insulation on the external walls, they need to be leveled so that there are no holes or bulges;

- clean them from dust and dirt;

- install sheathing made of wooden or metal profiles;

- the insulation is mounted between the battens of the sheathing. For a tight fit of the foam boards to each other, the step between them should be 5 cm less than the length of the insulation. Adhesive for external insulation with penoplex is not used when insulating a log house, because it will rigidly fix the material to the wall and can lead to the appearance of pathogenic microorganisms under the insulating layer.

Some people prefer to simply glue the penoplex to the wall; in our opinion, it is advisable to do this only for frame construction

The process of mounting on disc fasteners

In order for the insulation to be securely fastened, it is screwed onto universal screws using special disc fasteners. They are dowels with large caps that look like a mushroom. They come in metal or plastic. It is better to take plastic dowels because they are warmer and cheaper.

The consumption of fasteners is 5-6 pcs/m2

The mushroom should be on the same level with the penoplex along the plane of the facade. The self-tapping screw is screwed through the mushroom. Next you need to process the joints between the insulation sheets. If the gaps are 5 mm, then they are filled with construction foam, the excess is cut off after it hardens. If the gaps are large, more than 2 cm, then small pieces of penoplex scraps are inserted inside and filled with foam. After this, the surface of the wall is sanded using sandpaper. Before finishing, the walls are primed.

Might be interesting:

- Step-by-step instructions for finishing siding on a wooden house

- What is better to choose: a house made of timber or frame

Mineral wool

It is worth noting that stone wool made from basalt rocks is quite often used (its characteristics are described in detail here). But it has a “minus” - it cannot be compressed. Therefore, very precise sizing will be required, and therefore labor costs will increase. The use of glass wool is associated with additional installation difficulties, in particular, with measures to protect the skin and respiratory tract from its dust.

Therefore, it is more advisable to use mineral wool. However, it must be taken into account that working with ecowool requires certain professional training.

For high-quality insulation, the density of mineral wool must be at least 30 kg/m3. It is better (more convenient) to use the material in the form of slabs rather than rolls. Thickness – 50 mm.

- High vapor permeability.

- Practically does not “shrink” during operation.

Technology

The total thickness of the “insulation” is usually from 10 cm. Therefore, installation is carried out in at least two layers, with offset joints between the slabs. They are placed “at odds” between structural elements (racks). The material shrinks slightly, and after laying, increasing in size, it is tightly fixed at the landing site.

Unlike foam plastic, joints are sealed with reinforcing adhesive tape. In this regard, the insulation process is simpler.

General recommendations

- Polystyrene foam is a dense material, so it will not allow the walls to “breathe.” Cotton wool absorbs moisture well. Based on this, the issue of natural ventilation is one of the paramount ones.

- A material such as glassine is excellent for waterproofing. But there must be a gap between it and the insulation (an air gap for ventilation).

- To reduce the amount of work associated with processing the material, you need to decide in advance on the size of the slabs. Based on this, mount the frame with the required distance between the posts (according to the width of the products).

- For high-quality protection of the foundation, it is better to use permanent formwork, which is mounted from slabs of the same extruded polystyrene foam. It simultaneously serves as both a mold for pouring and an insulator (hydro- and heat).

Conclusion

There are different opinions regarding the quality of insulation with this or that material. Some people may praise the same “thermal insulator” too much, but others may not like it. Here you need to understand the following.

Firstly, a lot depends on the correct choice of “product”. In this case, you must first of all focus on the conditions under which it will be used.

Secondly, the quality of thermal insulation largely depends on the conscientiousness and professionalism of the workers. After all, ill-considered actions, violation of technology and irresponsibility can ruin anything.

Before choosing the appropriate material, it is a good idea to consult with people who already live in a frame house, and most importantly, built it with their own hands. Their assessment given to the insulation used will be quite objective. You can read the material on insulating a house from the outside, where similar work is described.

There are also cheaper options - filling the gap between the walls with expanded clay, sawdust, even straw. But here everyone must decide for themselves, taking into account the following aspects:

- the walls will be thicker;

- maintainability is “zero”, since the entire structure will have to be disassembled;

- except expanded clay, all other materials quickly get wet.

We have indicated only the main aspects of insulation work. But the wall of a frame house itself is a “pie”, in which, in addition to insulation, there are other layers (waterproofing, vapor barrier). Therefore, it is necessary to study the features of their arrangement, as well as the criteria for selecting appropriate materials.

Exterior finish over insulation

The insulation of a wooden house with penoplex ends with cladding. A plaster or putty layer cannot be applied on top of the insulation, because extruded polystyrene foam has a high coefficient of thermal expansion.

Extruded polystyrene foam on a timber house, plastered using “wet facade” technology

With large temperature differences, its values will change. Therefore, the frame on which the insulation is placed must be floating, not rigidly connected to the heat insulator. Next, the facade can be sheathed with siding, imitation timber, slabs and so on, whatever the owner wants.

Preparing the sheathing step by step installation

To make the lathing, you need to decide on the material from which it will be made:

Wood is more environmentally friendly, but more complex in terms of installation. The aluminum frame is much more convenient and practical. Let's move on directly to installing the sheathing:

- The first step is to clean and prepare the surface for future lathing.

- At the second stage, you will need certain tools to attach the frame to the prepared wall.

- The third step is to mark the entire surface where the sheathing frame will be installed.

- After all the preparatory work, you can begin installing the sheathing elements according to the marked marks.