The KNAUF line of construction insulation materials was developed in Germany and instantly gained popularity all over the world due to its consistently high quality, reliability and excellent performance characteristics. Knauf insulation shows excellent results in protecting a home from cold and noise for 50 years, according to the manufacturer’s warranty.

The insulation technology is based on the properties of mineral wool. Knauf insulation provides warmth due to the special structure of the fibers. Different types of material differ slightly in structure, so increased sound insulation properties are achieved through technological elongation and thinning of the mineral wool threads.

- Facade KNAUF Insulation

Knauf insulation

The company has developed several lines for professionals and for those who want to insulate themselves. The materials in the Knauf insulation line show the maximum insulation and sound insulation characteristics for basalt wool.

Knauf insulation technologies are based on creating the thinnest and longest fiber. This type of fiber not only provides premium insulation quality, but gives additional strength to the material, and also enhances the effect of 3D elasticity: the wool returns to its original appearance and volume after any compression.

Knauf insulation for insulating a frame house.

The high standards of the manufacturer allow us to talk about the safety and environmental friendliness of the insulation; in particular, the materials do not contain harmful phenols and other volatile compounds that could negatively affect health.

What are they made of?

The main types of insulation produced at Knauf factories are mineral wool and expanded polystyrene.

The basis of polystyrene foam materials is air bubbles enclosed in a polystyrene foam base. Next, the material is extruded to improve performance.

Fiberglass is a strand of molten inorganic glass with the addition of sand, limestone, dolomite and other components.

Rock wool consists of fibers produced from rocks. They are subjected to high-temperature treatment, after which threads are drawn from semi-liquid raw materials. They are formed into layers and additionally treated with hot steam, after which they are pressed.

Areas of application of Knauf insulation

When is it logical to use knauf insulation in the construction of frame houses? Primarily for high-quality thermal insulation and reliable sound insulation. Let's consider the areas of application of KNAUF insulation.

- Thermal insulation of walls, both external and internal.

- Thermal insulation of foundations.

- Heat and sound insulation of floors.

- Enhanced sound insulation of buildings located near highways and railway lines.

- Thermal insulation of the roof.

- Thermal insulation of individual spaces, such as balconies, loggias, basements, attics.

- Insulation of non-residential buildings, including unheated premises for keeping animals.

Teploknauf for the roof of a frame house.

That is, we have reliable insulation with increased sound insulation properties. This feature allows the use of KNAUF insulation in suburban construction of frame houses, insulation of constructed houses, organization of sound insulation between floors and parts of the house.

Minvata TechnoNIKOL

TechnoNIKOL is a domestic manufacturer of insulation materials, one of the five best European companies producing these products. TechnoNIKOL mineral wool is made of basalt fibers, which are characterized by high environmental friendliness and thermal insulation properties. This material is used for insulation of both multi-storey buildings on an industrial scale and in private housing construction. The most common types of mineral wool produced by TechnoNIKOL are presented below:

- Rocklight

is a basalt slab with a low content of phenol in resins, due to which this material has increased safety and environmental friendliness. The main area of application is insulation of private houses. It can be used to isolate horizontal, vertical and angled surfaces. The load on the structures is small, so they may not have high strength, which expands the scope of their application. - Heatroll

is a material consisting of long rolls of cotton wool that have improved sound insulation properties. They are most widely used in the insulation of roof slopes, floors between floors and attic spaces. - Technoacoustic

- designed primarily for sound insulation, in addition it has good heat-saving properties. It is presented in the form of cotton wool, made from specially arranged basalt fibers, due to which one layer of this material can prevent the penetration of sound up to 60 dB. This type of insulation is mainly used in the interior decoration of a building - partitions between walls, ceilings, attics. - Technoblock

- produced in the form of low phenolic flat slabs that are resistant to combustion, noise and heat insulation, and are also not susceptible to moisture. They are used in most cases for insulating layered warehouses and frame buildings.

The main characteristics of TechnoNIKOL mineral wool: thermal conductivity 0.035-0.039 W/mS, vapor permeability 0.3 mg/mhPa, water absorption 1.5-2%, Density 25-50%, compressibility 8-55%. Prices for TechnoNIKOL mineral wool are quite low and easily compete with foreign analogues. Thus, Rocklight slabs can be purchased for only $38 per cubic meter.

Having examined the main types of mineral wool offered for sale, you can make a choice in favor of one manufacturer or another. Depending on the scope of use, the conditions, price and other nuances, you should buy a certain brand of mineral wool. Not only the comfort and warmth of your home, but also the safety of the whole family will depend on how responsibly you take this matter.

The topic of modern thermal insulation materials, both imported and domestically produced, continues to interest readers, because thanks to these materials it is possible not only to reduce home heating costs, but also to significantly reduce the cost of building construction. A leading specialist advises.

Advantages of KNAUF insulation

- Low thermal conductivity coefficient.

- High sound absorption coefficient.

- High fire resistance. The entire line of insulation materials is marked as non-combustible materials NG.

- Maximum biostability: mold does not grow in insulation materials.

- Insulation based on mineral wool is not damaged by rodents.

- No odors from the material.

- The completely natural composition based on basalt ensures hypoallergenicity.

- Convenient packaging and release form. Knauf roll insulation allows you to quickly cover large areas.

- Convenient installation and dismantling of insulation.

- Low weight of insulation: an extremely important characteristic when logistics of the material and working with it.

- Elasticity: the material can be compressed, it will straighten itself to its original state.

- Very long service life - up to 50 years.

- The versatility of the material: suitable for insulation and sound insulation of all house structures.

Knauf heat insulation rolls.

Today the Knauf company produces two lines of insulation materials, differing in their main areas of application.

- KNAUF insulation – for industrial and multi-storey construction,

- TEPLOKNAUF - for country construction and insulation of a summer house, cottage, private house.

Peculiarities

The Knauf company was founded by the Knauf brothers in Germany in 1932. Initially, the main activity was the production of gypsum plaster mixtures. Over time, the range became more and more diverse. In 1947, a plant for the production of construction gypsum mixtures was opened in Bavaria, and in 1958 the production of plasterboard sheets began.

Since the 70s, the company has significantly expanded the scope of its activities. First, cement-based building mixtures appear, then construction chemicals, then structural parts and thermal insulation materials based on polystyrene and mineral wool.

The products appeared on the domestic market in 1993, and 10 years later the first Knauf factories appeared in Russia. Today they can be found in St. Petersburg, Kungur, Chelyabinsk and other cities.

Technical characteristics of Knauf insulation

KNAUF mineral wool is produced on the basis of basalt fiber and does not contain any acrylic or phenol-formaldehyde compounds. It is safe for people. Additionally, the material is treated with a water-repellent composition, which provides additional moisture resistance and preservation of heat-shielding characteristics when used in conditions of high humidity.

On a note

When installing insulation, do not neglect wind and vapor barrier films. Even with the high moisture-repellent characteristics of KNAUF insulation, the use of a film or membrane will increase the service life of the material and also increase its thermal protective properties.

It is worth noting the technical characteristics of Knauf insulation, which are very important during installation:

- Light weight allows installation alone, without assistants.

- Convenient packaging in rolls or blocks contains sheets 50 or 100 mm thick.

- The material is not scratchy and does not cause pain when working with it.

- Knauf mineral wool does not require mandatory respiratory protection.

- The material can be easily cut with a regular stationery knife; no special tools are required for the job.

- The material straightens itself in the space provided and fits tightly to the base: no additional work with seams and joints is required.

Fire at the enterprise

Enterprises in most cases are equipped with alarms or automatic fire protection systems.

There are notices in a visible place that will tell you what to do in case of a fire. The procedure in this case will be as follows:

- Call the fire department or press the fire safety button;

- notify all employees about the fire;

- try to extinguish the fire using available means.

Enterprise employees must act in accordance with the developed fire prevention plan and assist people in evacuating a burning building.

Insulation materials TeploKnauf

The TeploKnauf line is focused on construction, insulation and sound insulation of private houses, as well as insulation of parts of apartments. To work with it, professional construction skills are not required. It is available in two types of convenient packaging: rolls and sheets assembled into blocks. Knauf slab insulation is usually used to insulate walls using frame technology; it is very convenient to lay it between vertical posts.

Teploknauf insulation for walls and roofs.

The entire TeploKnauf line includes three products: TeploKnauf Dacha, TeploKnauf Cottage and TeploKnauf House. Let's look at the features of each product.

TeploKnauf Cottage

Knauf Cottage insulation has two release options: TeploKnauf Cottage and TeploKnauf Cottage+. Of the entire line for private housing construction, this product has the highest heat and sound insulation characteristics.

The thickness of the TeploKnauf Cottage mineral wool layer is 50 mm, the dimensions of the slab are 1230x610 mm, the dimensions of the sheet in rolls are 6148x1220 mm. Knauf insulation 50 mm in one layer allows you to reliably insulate houses in the southern and central regions of Russia; for Siberia and the Northern territories you will need either insulation 100 mm thick or a double layer of 50 mm.

On a note

The material is universal, suitable for comprehensive insulation of any structure of a private house, as well as for sound insulation in interior partitions.

TeploKnauf Cottage+ has an increased slab thickness - up to 100 mm. Knauf 100 mm insulation allows for faster installation. The release form is exclusively slabs; TeploKnauf Cottage+ is not sold in rolls.

Parameters of basalt wool TeploKnauf Cottage:

- Thermal conductivity: low – 0.037

- Noise insulation: good – index 45

- Fire resistance: non-combustible material, NG

- Dimensions: in rolls 6148*1220*50 mm, in slabs 610*1220*50 mm

- Packaging volume: in rolls and in packaging 0.75 m³

- Material area: 15 m²

- Quantity per package: slabs – 20 pcs., rolls – 2 pcs.

- Packaging: marked in red.

TeploKnauf Dacha

TeploKnauf Dacha is focused on insulating buildings in which it is not planned to spend the winter, so it has the least thermal insulation properties of the entire line. The material is used for insulating summer houses, sheds, cabins, and guest houses. The release form is exclusively in rolls.

Installation of mineral wool.

Parameters of TeploKnauf Dacha basalt wool:

- Thermal conductivity: high – 0.044

- Noise insulation: good – index 45

- Fire resistance: non-combustible material, NG

- Dimensions: in rolls 7380*1220*50 mm

- Packaging volume: in rolls and in packaging 0.9 m³

- Material area: 18 m²

- Quantity per package: rolls – 2 pcs.

- Packaging: marked yellow.

TeploKnauf House

Knauf Dom insulation is also produced in two versions: TeploKnauf Dom and TeploKnauf Dom+. Scope of application: for insulating private houses located in moderately cold climates, as well as non-residential premises to protect them from freezing - balconies, loggias, basements, buildings for farm animals.

The material has three main advantages: heat, sound and waterproofing, and also has increased elasticity. TeploKnauf Dom+ differs from TeploKnauf Dom only by doubling its thickness: 100 mm versus 50 mm.

Parameters of basalt wool TeploKnauf Dom:

- Thermal conductivity: average – 0.040

- Noise insulation: good – index 45

- Fire resistance: non-combustible material, NG

- Dimensions: in rolls 6148*1220*50 mm, in slabs 610*1220*50 mm

- Packaging volume: in rolls and in packaging 0.6 m³

- Material area: 12 m²

- Quantity per package: slabs – 16 pcs.

- Packaging: marked in orange.

AcoustiKNAUF

AcoustiKNAUF is the main component of an acoustic solution from KNAUF, designed for sound insulation of partitions, walls, ceilings and floors in apartments and residential buildings. A comprehensive solution from KNAUF can significantly reduce or completely eliminate major household noise.

AcoustiKNAUF is a safe sound insulation, which is produced using the new generation ECOSE technology, without the use of phenol-formaldehyde resins. Thanks to this, it is recommended by the Research Institute of the Russian Academy of Medical Sciences for use in residential premises, kindergartens and schools.

- A safe solution for any living space

- Excellent sound insulation performance

- Ready-made and simple acoustic solution from KNAUF for partitions, walls, ceilings and floors

- Fills the structure optimally, does not slip and is easy to install

- Non-flammable material

Characteristics

| Thickness | mm | 50 |

| Width | mm | 610 |

| Length | mm | 1230 |

| Slabs in a pack | PC | 16 |

| Area per pack | m2 | 12 |

| Volume per pack | m3 | 0,6 |

| Packages on a pallet | PC | 28 |

| Flammability group | Not flammable |

Knauf Insulation - insulation for professionals

If the TeploKnauf line of insulation products was developed for self-insulation of a house, and working with them did not require any special professional skills, abilities, knowledge, or tools, then the professional line of Knauf Insulation insulation products are professional-quality materials for multi-story construction and are aimed at industrial and social construction.

A feature of the line is the division of insulation according to purpose:

- For façade insulation.

- For roof insulation.

- For soundproofing.

The scope of application is determined by the specific technical characteristics and installation features. The KNAUF Insulation size range is wider: 50 mm, 70 mm and 100 mm in thickness.

Do-it-yourself insulation of the frame.

Facade KNAUF Insulation

The material was developed for insulating external walls made of any material and built using any technology. Knauf Insulation insulation is perfect for insulating buildings made of brick, blocks, concrete slabs, and houses built using frame technology.

Today, knauf insulation insulation for facade systems is produced in two slightly different variations: Thermoplate 034A and Thermoplate 032A. They differ primarily in density, and as a result, in the quantity and volume in the package.

Insulation for walls Knauf facade is mounted between two layers of the wall - internal and external; it is often used to create ventilated facades, as well as when sheathing a house with siding systems. Special impregnation with water-repellent compounds ensures that the insulation does not lose its properties upon contact with atmospheric moisture.

KNAUF Facade allows you to reduce the cost of heating buildings by 2 or more times.

On a note

The Knauf Insulation façade is optimally suited for industrial construction, as well as for insulating the walls of social infrastructure facilities. It is often used as the main insulation for agricultural buildings where animals are planned to be kept year-round.

Knauf Ecoroll

Special mention should be made about the material for horizontal surfaces. Knauf Ecoroll insulation is designed specifically for insulation and sound insulation of floors and ceilings on joists. A special feature of the insulation is its high vapor permeability, which ensures proper steam and air exchange in the room and guarantees not only comfort for residents, but also protection from moisture and mold.

KNAUF ECOROLL is very popular when constructing houses using frame technology.

Pitched roofing KNAUF Insulation

A special development by KNAUF will allow you to easily insulate a pitched roof. Features of the material are a convenient form of release, which allows you to quickly install insulation on inclined surfaces, as well as high-quality impregnation with Aquastatic water-repellent compounds.

Insulating the roof with KNAUF Insulation pitched roofing material will not only protect the house from freezing in winter, but will also provide a comfortable indoor temperature in the summer heat, and will also soundproof the rooms on the roof side.

Knauf for roof insulation.

KNAUF Insulation pitched roofing is a solution for those buildings where the top floor is an attic, and iron or metal tiles were chosen as the roofing material. The material will absorb unwanted sounds that inevitably occur during rain.

In addition to Knauf roofing systems, roofing insulation is popular for insulating floors on joists on the first floors and in attics.

KNAUF Insulation pitched roofing is available in two thicknesses of 100 and 50 mm and two types of slab and roll, which allows you to select the material so that a minimum amount of scraps remains during installation.

Installation features

Preparing the frame for external wall insulation

When installing Knauf Cottage brand mineral wool, you must follow the manufacturer’s recommendations and basic rules so that the result is as ideal as possible. The installation process consists of several stages and includes installation of the frame, the insulation itself, and the application of a vapor barrier film. You can handle this process yourself if you have skills in the field of construction and finishing work, or you can entrust the installation to professionals.

Frame

A primary wooden frame is necessary for direct installation of insulation on the walls. Without it, the material will not hold up. Before installation, the walls are cleaned of unnecessary elements and wooden blocks are prepared, which are treated with a fire-resistant compound. They are fixed horizontally and vertically to the walls from one corner to the other; in the presence of unevenness, special substrates are made from various materials.

The beams are secured using 75 mm self-tapping screws, each fastening is installed at a distance of at least 40 cm from each other. After installing the first beam, you need to measure 58 cm from it, since the width of the slab is 61 cm, then fix the second and subsequent beams while maintaining this distance. The windows are framed with bars horizontally and vertically, taking into account the plane of the wall.

Installation of insulation

Installation of insulation

The slabs are installed starting from the corner, they are slightly compressed and placed between the beams, then fixed to the wall using special mushrooms. For one slab you will need at least 3-5 mushrooms, taking into account the material in one package, each of them is mounted in a through hole with a diameter of at least 6 mm, made with a hammer drill or drill. The insulation can be cut to fit the spacers using a paint knife. After filling all the cells between the bars, they proceed to installing the film.

Installation of vapor barrier film

Vapor barrier of attic roof

The film is necessary to prevent the formation of condensation inside the insulation; if it is present, the steam particles simply come out to meet the cold air. It must be installed with the smooth side up, taking into account the instructions, each strip is placed from bottom to top, taking into account an overlap of 10 cm or vertically from the corner. For the most reliable fastening, the film is sewn to the wood blocks using a construction stapler. The seams must also be taped with double-sided tape to prevent them from coming apart. After the walls are covered, you can begin installing the siding.

Siding

For siding, bars measuring 25x50 or 25x100 mm, special screws with a length of 35 to 55 mm and a screwdriver are used. The frame boards are impregnated with a bioprotective solution and cut to the required length, which must correspond to the length of the boards for the first frame. Next, you will need to form the corners and screw them to the horizontal bars on the first frame vertically, the next boards are attached at a distance of at least 25 cm from each other. Following these rules helps make the structure more durable in addition to the standard insulation procedure.

Purpose of thermal insulation materials

There are a range of insulation products on sale, among which you can find options for installing roofs, floors, facades and ceilings.

For walls

For external walls, Thermo Plates 037 from the Insulation line are most often used, which have ideal insulating properties. They are used to maintain heat in rooms, as well as additional sound insulation. Another good option is Acoustic partitions, mainly used in frame construction. They easily fit inside sandwich panels. Experts often use TeploKnauf mineral wool of the standard type or intended for cottages. It is easy to use and does not cause any difficulties during installation.

For floor

You can choose floor insulation from Knauf among materials from the Insulation line. Experts recommend using Thermo Plates 037; they help insulate floors and maintain an optimal level of heat in the room. Semi-rigid mats Thermo Roll 040 and slabs from the “Pitched Roof” series intended for attic floors are also suitable for flooring.

For roofing

Mats and slabs from the “Pitched Roof” series are designed specifically for pitched roofs made of wood. Builders use Thermo Roll 037 and Thermo Plate 034 of the required length, width and thickness. For cottages and country houses, it is better to choose mineral wool slabs from the “Dacha” series, which are produced in the form of rolls.

Basalt wool

It is often called stone wool, hinting at the origin of this material. It is obtained as a result of melts and extrusion of mountain dumps, slags and slag mixtures.

- Knauf basalt insulation is available in the form of rolls, slabs, pipes and even lamellas glued to metal foil.

- The density of the proposed types of insulation is different. Thus, the Knauf Insulation LMF AluR product, which is designed for insulation and insulation of air ducts, external walls and facades, has a density of 35 to 90 kg/mK. Roll insulation has density parameters from 80 to 100 kg per cubic meter. And the materials intended for insulation of roofs and facades of buildings, Knauf Insulation DDP slabs, have a density of 150 to 200 kg per cubic meter. In terms of density, only some types of rigid polyurethane foam approach basalt insulation with an indicator of 100 kg/mK.

- The thermal conductivity coefficient of this type of insulation ranges from 0.04 to 0.045. This indicator is not the minimum; for example, it is somewhat less for fiberglass, and even more so for liquid insulation. Approximately in the same group with basalt wool is polyurethane foam with an index of 0.04 to 0.05. However, this low degree of thermal conductivity makes stone wool one of the most effective thermal insulation materials.

- Knauf basalt insulation has such valuable qualities as excellent sound insulation, fire resistance, and a wide range of uses.

- In the manufacture of Knauf basalt insulation, artificial resins are used as a binder, which reduces the environmental friendliness of the final product. But this material is produced using hydrophobization technology, which increases its water resistance.

- Basalt wool, like fiberglass insulation, has biological and chemical neutrality, which increases the safety of its use for insulating residential premises.

Application:

- Knauf stone wool slabs are used for insulation of flat roofs, facades, and external walls. Knauf Insulation HTB boards, reinforced with canvas or foil, are successfully used for pipelines.

- Rolled basalt-based insulation is used for insulating pipes and other engineering structures and equipment.

- Mineral wool cylinders are used for thermal insulation of pipes. Additional reinforcement with foil enhances the waterproofing of structures.

- Another type of roll material - LMF AluR - consists of lamellas glued to a foil base. This product does an excellent job of insulating air conditioning and heating systems. It is great for baths, saunas, and any wooden structures.

Price:

For professional use

The use of Knauf Insulation insulation gives excellent thermal insulation results regardless of who installs it: a professional builder or the owner of the house.

The line of manufactured products allows you to select the material needed for a specific case.

Due to its environmental friendliness, Knauf Insulation insulation is recommended for use in residential buildings, preschools, schools, medical and medical institutions.

ECOSE technology improves ease of use and ease of use:

- more rigidity

- better elasticity;

- less dust;

- worse moisture absorption.

Thermal insulation is produced under the following brands:

- Knauf Insulation Thermoplate for insulation of vertical structures and sloped roofs.

- Knauf Insulation Thermo Roll (TeploKnauf Ecoroll) for thermal insulation of horizontal surfaces. It is best to use Knauf for unloaded floors.

- Knauf Insulation Pitched roofing for thermal insulation of buildings for any purpose.

- Knauf Insulation Facade to prevent heat loss through walls as a middle layer with cladding.

New development

Monolithic materials are used for thermal protection of houses, cottages, walls, facades, roofs, floors, foundations.

The newly developed Knauf Therm Floor is a durable material for insulating plinths, foundations, and blind areas with a load of up to 12 tons per m2. Flor foam has moisture absorption of up to 0.8% of the volume of insulation. Used in the installation of “warm floor” systems.

If you need an effective, convenient, innovative material to protect your home from heat loss and noise penetration, choose Knauf products. It meets all the stated characteristics and will help you forget about the cold and noise in the house for a long time.

https://youtube.com/watch?v=Vaq424J-G5Y

Layer insulation

TeploKnauf Premium is the first material developed for use in private households. Does not contain fiberglass. During operation, it does not change its dimensions and does not shrink, which avoids ruptures in the insulation layer.

It has increased heat-retaining capacity and good sound insulation. Resistant to getting wet. It is used for insulation of enclosing structures, including layered masonry walls. The mini-slab has dimensions of 1230x610 mm.

Main settings

It is logical to evaluate Knauf insulation materials according to the main criteria for all thermal insulation materials:

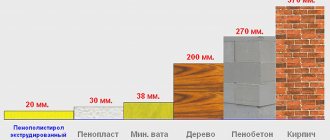

- Thermal conductivity. Depending on how much heat a material conducts, its thermal efficiency is determined. In other words, the insulation must have the lowest possible thermal conductivity. The products of the brand in question have a thermal conductivity in the range of 0.31÷0.42 W/m×C, which allows them to be considered effective insulation materials. Thus, a 12 mm thick polystyrene foam board in its thermal insulation qualities can be compared with the thermal efficiency of 450 mm thick brickwork or a 2100 mm thick concrete wall.

- Vapor permeability. The ability of a material to conduct moisture vapor, preventing its transformation into water droplets and wetting of walls or finishing materials. Indicators are within 0.02÷0.03 mg/ (m×h×Pa). Expanded polystyrene boards have the lowest rating, that is, they are essentially impermeable to vapor. In contrast, mineral wool is characterized by very good vapor permeability. This makes it the optimal (and practically the only) insulation for wooden surfaces.

- Wet strength. Expanded polystyrene boards have the best indicators of wet strength. They do not absorb moisture. Mineral wool insulation is afraid of water, so when installing it, be sure to consider the presence of a waterproofing layer. The manufacturer uses a special technology - it treats mineral wool with hydrophobic compounds, which somewhat increases its moisture resistance. If we compare glass wool and basalt insulation, the first is less resistant to moisture.

- Compressive strength, resistance to deformation. Both types of material are suitable for loaded surfaces and are resistant to deformation. Mineral wool can be produced in rolls and placed in compact boxes, but after removal from them it takes on its original shape and no creases form on its surface.

- Biostability. Expanded polystyrene in this regard loses to mineral wool - it attracts rodents.

- Fire resistance. Mineral wool is a non-flammable material, which cannot be said about polystyrene foam.

Other characteristics include durability (the service life of mineral wool is up to 50 years, polystyrene foam boards are half as long), soundproofing qualities (mineral wool is also suitable for sound insulation), cost (stone wool has a higher cost).

The material has different release forms (plates, mats, rolls for mineral wool, slabs for expanded polystyrene), as well as different dimensions. Standard sizes: slab width – 1000 mm, length – 1000-1200 mm, width – from 20 to 150 mm. The most popular products are those with a thickness of 50 mm and 100 mm.