Thermal insulation of a house or any structure is a very important stage. Laying specialized materials will allow you to achieve the desired temperature level in the room, save thermal energy and ensure comfortable living. Moreover, the easier the material used is to work with and the more reliable and durable it is, the better from the point of view of construction and operation of the premises. Penoplex Comfort, technical characteristics, features and a description of the installation process of which can be found in this material, is one of the most popular newest thermal insulation coatings on the construction market.

This is a fairly new material, which is made using the extrusion method from polystyrene and helps to solve a number of problems at once:

- allows you to achieve a high level of thermal insulation;

- protects all building structures from exposure to cold;

- helps reduce heating costs;

- provides a healthy and suitable indoor microclimate for humans.

The material has many advantages over conventional insulation materials, which is why it has earned popularity. First of all, it is worth noting its homogeneous porous structure, as well as its low weight, which makes it easy to work with the material and not burden the structure. Thanks to its homogeneity, the material does not crumble.

is a large Russian manufacturer of construction and decorative finishing materials based on polymers. The company began its activities in 1998 with the launch of the first production line in Russia for the production of thermal insulation materials from extruded polystyrene foam under the PENOPLEX® brand.

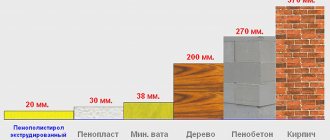

produces extruded polystyrene foam (EPS or XPS). This material is used as insulation. It differs from its cheaper analogue - foamed polystyrene (foam plastic, EPS or PPS) in its greater density, due to which it better withstands mechanical loads. Another distinctive feature is lower vapor permeability. Or rather, it produces almost no steam. And the main trump card is the best thermal characteristics. Penoplex 20 mm thick in terms of heat retention is equivalent to almost double the thickness of mineral wool and 37 cm of brickwork.

Penoplex is a modern, effective thermal insulation material.

These characteristics determine the area of use of Penoplex. It is recommended for insulating areas where resistance to stress is important, and low vapor permeability is one of the requirements. More specifically, it is recommended to use Penoplex:

- For floor insulation: under the screed, on it, as an intermediate layer;

- when installing a floor on joists (with some reservations);

- thermal insulation layer under a heated floor (water or electric).

Another area of use is thermal insulation of facades or interior walls. But here you need to understand that due to the fact that Penoplex practically does not conduct moisture, additional measures will be needed to ensure that vapors do not get inside the wall. In addition, a well-thought-out ventilation system is needed to normalize the humidity in the house. And, in addition, you need to select the thickness of the insulation so that the dew point is inside the insulation, but not in the wall.

Optimally - insulation of a recessed base

If you prefer “breathable” walls and natural humidity regulation, Penoplex is not suitable for wall insulation in this case. It does not fit under ventilated facades either. The exact task there is to remove moisture from the insulation due to the movement of air in the ventilation gap. This material is not able to provide this, since moisture simply does not get inside Penoplex.

One of the best insulation

Penoplex is the most popular thermal insulation material.

Despite the presence of disadvantages, penoplex is the most popular thermal insulation material. It is stronger than polystyrene foam and is absolutely safe for installation. The abundance of extruded polystyrene foam boards on the market allows you to select the required size and thickness, depending on the purpose of use.

Appearance, description

Insulation made of polystyrene, pressed into plates - EPS. The PENOPLEX company was one of the first in Russia to start producing this heat-insulating material. In appearance, extruded polystyrene foam is similar to regular foam, but its structure is denser, the cells are smaller, and the color is orange.

Production technology

To understand what penoplex is, consideration of the method of manufacturing insulation will help, since it is the special technology that gives it the necessary performance qualities.

Unlike the production of pressless polystyrene foam (PSB), penoplex is subjected to pressure and molding. The manufacturing technology is as follows:

- Polystyrene granules are mixed and exposed to high temperature.

- A foaming agent (consisting of freon and carbon dioxide) is added to the fused mixture under pressure, which is responsible for creating small cells.

- The resulting mixture is passed through an extruder for molding.

- The resulting sheets are cooled.

- Cutting into slabs of the required size is carried out.

The finished slabs are wrapped in a special shrink film, which minimizes the negative impact of external factors without blocking visibility for consumers. Through it it is easy to determine what it is and how much the integrity of the material has been preserved.

Types, sizes and weights of thermal insulation boards

The characteristics of insulation depend on its parameters. The slabs are available in various thicknesses and lengths.

When ordering, you can specify your sizes. The manufacturer is able to implement even non-standardized parameters. The main indicators vary within the following limits:

- thickness: 2-10 cm;

- length: 1.2-2.4 m;

- width – 60 cm.

Since the cost of penoplex is considerable, it is better to choose the right thickness and determine in advance the required amount of insulation in order to eliminate excessive costs for thermal insulation of the house.

Calculation of material quantity

The packaging of penoplex usually indicates the area and volume of insulation, which means that the required amount can be calculated in two ways:

- Calculate the area of the insulated surface. Find out the area of insulation in the package. For example, to insulate 20 m² with extruded polystyrene foam 40 mm thick, 3.2 packages will be required (since the insulation area in the package is 6.24 m², the calculation is as follows: 20/6.24 = 3.2).

- According to the volume of required insulation. To determine the volume of the surface to be thermally insulated, you will need to multiply its area by the thickness of the penoplex. In the case of 20 m², the volume of the insulated surface is 0.8 m³ (20 m * 0.04 m). The volume of one package of penoplex with a thickness of 40 mm is 0.2493 m³. Therefore, for thermal insulation you will need 3.2 packages (0.8/0.2493=3.2).

If during calculations it turns out that a non-integer number of packages is required, then it is better to find a supplier from whom you can purchase the material in separate sheets. This will save money, but you will have to correctly calculate the missing number of slabs.

When purchasing extruded polystyrene foam, it is better to take a small supply of 12 sheets, since unforeseen situations and improper trimming can lead to damage to the material.

Types and what are their differences

Penoplex is a universal material that is used for thermal insulation of various structures. Manufacturers produce several product lines to make it easier for consumers to choose the right material.

Wall

Penoplex Wall is designed for thermal insulation of internal and external structures. Insulating exterior walls is more effective and helps reduce heating costs. This type is also suitable for thermal insulation of partitions and facade systems. A distinctive feature of the slabs is the presence of stripes on the surface, applied with a milling cutter. The rough surface improves the adhesive properties of the insulation, resulting in strong adhesion to the base.

Foundation

Foundations, floors, house paths, and plinths are insulated with Penoplex Foundation material. Its distinctive feature is its high strength, which allows the use of insulation for floors and other structures where there are requirements to withstand significant loads. The slabs have a low moisture absorption coefficient, which is useful because this quality allows you to reliably protect the basement and foundation of the house.

Roof

Extruded polystyrene foam for thermal insulation of flat and pitched roofs has high heat-saving qualities. Recently, the manufacturer has been producing a universal version of Penoplex Roofing and a specialized Penoplex Pitched Roofing, characterized by a longer length and a special tongue-and-groove fastening system.

Slope

Special elements for creating slope and counter-slope structures on roofs, parapets and other protruding structures are presented in the Penoplex Slope line. These extruded polystyrene foam elements have different widths on two sides and provide the required angle.

Block

Penoplex Block consists of several glued polystyrene foam boards.

The increased thickness allows the material to withstand high loads, which is why it is used in road construction.

Comfort

Penoplex Comfort is in demand among consumers. For mansions (balconies, loggias, extensions) and city apartments, this is the most common option, which has important heat-saving characteristics, high reliability, strength and durability. At the same time, the cost of this line is in the average price range. Has an L-shaped edge to prevent the formation of cold bridges.

GEO

Penoplex GEO is an alternative to extruded polystyrene foam for foundations, floors, blind areas and other structures that are subject to heavy loads. Unlike the Foundation line, GEO has greater compressive strength and is more often used in professional construction.

The basis

Penoplex Base has sufficient compressive strength and is considered a universal heat insulator, as it can be used for walls, floors, roofs, provided there are no heavy loads. In all respects, this line is close to Penoplex Comfort, but the Base is more often used in professional construction, and Comfort in domestic construction.

Facade

An improved option for walls, which can be used for insulation outside, inside, and also be part of facade systems. Penoplex Facade has characteristics similar to the Wall line. It has an L-shaped edge, which guarantees the absence of through seams.

Methods for insulating the external wall of a panel house

The external walls of panel houses can be insulated using two installation methods: dry or ventilated and wet. Each technology has its own characteristics and advantages that are worth considering separately.

Dry

Insulation in high-rise buildings is laid using the wet method under plaster.

With the dry method, mixtures with added water cannot be used. To create a layer of thermal insulation using this method, a layer of insulation is made, closed using panel materials. Finished facades are called ventilated, since an air gap must be left between the insulation and the panel material for the purpose of complete ventilation. You can insulate a house in this way with minimal financial costs, especially if you choose the most economical materials, for example, polystyrene foam.

Wet

The wet method allows you to insulate the surface of the facade using special water-based mixtures, the composition of which can be different. Most often, a special foam insulation containing cellulose is used. The main advantage of this method is the ability to fill all holes and cracks. Thanks to the wet method, cold bridges do not appear in the walls, causing heat to leak out of the room.

Details about the characteristics

Extruded polystyrene foam has gained popularity due to its excellent performance and quality characteristics.

Extruded polystyrene foam has gained popularity due to its excellent performance and quality characteristics. In many respects, the insulation is superior to all known thermal insulation materials.

Coefficient of thermal conductivity

Low thermal conductivity allows for effective insulation. The coefficient is almost 10 times lower than that of high-quality mineral wool. Penoplex has a thermal conductivity coefficient at 25±5°C of 0.032 W/(m•°K).

Low vapor permeability

The vapor permeability of the material is almost zero.

This allows for better thermal insulation, but can lead to condensation, so it is not recommended to use penoplex when insulating baths and saunas.

Moisture resistance

The material has a high moisture resistance, which allows such insulation to be carried out without additional waterproofing. Moisture absorption is practically zero.

Features of foamed heat insulators

The thermal conductivity of a particular insulation largely depends on the amount of atmospheric or other gas (for example, carbon dioxide) that is in the pores of the material. Typically, air is contained in sealed cells of a porous thermal insulator (foam) or between individual strands of fibrous material (basalt wool).

There are many types of foam insulation.

Foamed insulation is a separate category of insulation materials, which, as the name suggests, are obtained by foaming raw materials (mineral or polymer) with the participation of third-party chemicals (foaming agents) or using other technology (for example, using steam).

Due to the specifics of production, foam materials acquire not only a low thermal conductivity coefficient, but also a whole set of additional advantages, which I want to talk about below.

Long service life

The manufacturer claims a minimum service life of 50 years. However, there is no exact data available, since extruded polystyrene foam has been produced for insulation only since 1998.

Compressive strength

The compressive strength of extruded polystyrene foam is high. The indicator varies depending on the line of material. On average, the compressive strength of penoplex is 0.25-0.5 MPa. The higher the number, the greater the load the insulation will withstand.

Environmental friendliness

Despite the fact that the insulation is made from polymers, it does not harm the environment because it does not react with aggressive substances. Only when burning can harmful smoke be released, which can harm a person. Otherwise, penoplex does not harm a person. use during insulation does not require the use of personal protective equipment.

Fireproof properties

According to the flammability class, the material belongs to highly and moderately flammable (G3-G4). In this case, penoplex burns only when exposed to direct fire. In other situations, it smolders and is not able to sustain combustion on its own. Manufacturers strive to reduce the flammability of insulation by adding fire retardants.

Scope of application

Performance characteristics allow the use of polystyrene foam in various situations, both in domestic and industrial construction.

Insulation of façade walls from the outside

External wall insulation is considered the most effective. To do this, use the material of the Base or Wall ruler. Thermal insulation of external walls allows you to significantly save on heating costs in winter.

Insulation of the walls of a balcony or loggia

High heat-saving characteristics make it possible not only to insulate a balcony or loggia using penoplex, but also to make it an extension of the apartment, increasing the usable area of the room.

Roof thermal insulation

The roof is insulated using extruded polystyrene foam both from the inside and outside. At the same time, it is possible to combine various materials for external and internal thermal insulation to achieve a better result. Penoplex is ideal for both flat and pitched roofs.

Thermal insulation of concrete floor

Strength indicators allow the material to be used for floor insulation on concrete screed. This is also facilitated by low moisture and vapor permeability.

Reflective type thermal insulation

Insulation materials, called reflective or reflective, work on the principle of slowing down the movement of heat. After all, every building material is capable of absorbing this heat and then radiating it. As is known, heat loss occurs mainly due to the exit of infrared rays from the building. They easily penetrate even materials with low thermal conductivity.

But there are other substances - their surface is capable of reflecting from 97 to 99 percent of the heat reaching it. These are, for example, silver, gold and polished aluminum without impurities. By taking one of these materials and constructing a thermal barrier using polyethylene film, you can get an excellent thermal insulator. Moreover, it will simultaneously serve as a vapor barrier. Therefore, it is ideal for insulating a bathhouse or sauna.

Today's reflective insulation is polished aluminum (one or two layers) plus polyethylene foam (one layer). This material is thin, but gives a tangible result. So, with a thickness of such insulation from 1 to 2.5 centimeters, the effect will be the same as when using a fibrous heat insulator from 10 to 27 centimeters thick. As an example, let's name Armofol, Ecofol, Porilex, Penofol.

One type of reflective thermal insulation

Installation technology

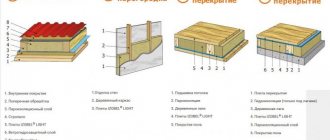

There are several options for installing penoplex. Which one is better depends on the type and location of the insulated surface.

On glue

Special glue is applied to the surface of the base, after which the foam board is pressed tightly against it.

Fungus on dowels

The dowels securely fix the slabs if the installation rules are followed. It is important to correctly determine the required quantity. Dowel mushrooms (umbrellas) are used to fasten all the joints of the sheets, and two fasteners are also fixed in the middle of the slab.

On the foam

There is a special foam on the construction market that ensures reliable fastening of the penoplex to the base.

When insulating, it is better to combine options and use an adhesive base together with fastening dowels, especially for vertical bases.

Construction stages

Insulated masonry of walls in one brick with facing fragment finishing is the best way to improve the characteristics of the main material and keep the house warm. The algorithm of actions depends on the chosen construction technology. Layered masonry using effective insulation involves performing several stages of work:

- The three-layer construction begins with laying out the corners.

- After this, the anchors are attached.

- Insulation is being installed.

- A vapor barrier is installed.

- Facing bricks are laid.

If it is intended to complete the insulation work after the construction of brick walls, the facing material is not laid out. Typically, this tactic is chosen over the less expensive method using polystyrene foam. Then the finishing work is completed after fixing the material. By sequentially performing the steps and having high-quality material, you can not only retain heat, but also improve the strength characteristics of the structure.

Domestic analogues of the material

Domestic manufacturers produce extruded polystyrene foam, whose characteristics are not inferior to penoplex. At the same time, the cost of insulation differs, and you will be able to save money if you purchase an analogue.

Technoplex

Manufacturer TechnoNIKOL supplies Technoplex extruded polystyrene foam to the construction market. This insulation has greater heat-saving ability, since the manufacturer included graphite particles in the composition. But penoplex can withstand heavy loads.

Polyspen

According to the stated characteristics, Polyspen and Penoplex are similar. The first also presents several lines of material with different densities. At the same time, users note that the structure of materials with the same density parameter is significantly different and Polyspen is inferior to Penpolex.

Useful tips

Insulation using extruded polystyrene foam is effective and simple.

In order for the result to meet expectations, the main advice of professionals is to purchase high-quality thermal insulation materials from trusted suppliers and carry out insulation taking into account the rules and requirements.

By choosing the right adhesive mixture and calculating the required thickness of the insulation, using penoplex you can create a comfortable atmosphere in the house and additional protection outside. Moreover, such insulation will last more than half a century without loss of performance characteristics.

Disadvantages of masonry without insulation

More recently, the issue of thermal insulation of brick buildings was solved in a simple way - by increasing the thickness of the wall. Thus, for the middle zone, the usual wall thickness was 3 - 3.5 bricks, and in the northern regions it could reach 1 - 1.5 m. This is due to the high thermal conductivity coefficient of the brick, which causes large heat losses.

Comparative analysis of materials

Laying walls of such thickness was a necessary measure in the absence of effective and inexpensive thermal insulation materials. Another factor promoting the use of “thick wall” technology in Soviet times was the relative cheapness of bricks. This made it possible to simplify masonry technology by eliminating the use of thermal insulation materials.

However, recently this approach has become too wasteful from a financial point of view: in addition to the cost of bricks, the costs of arranging reinforced foundations are increasing.

Another problem that you may encounter when installing brickwork without thermal insulation is a shift in the dew point indoors.

The most preferable option is to locate the dew point outside the building, in which case the condensing moisture will simply evaporate under the influence of wind and sun. It is much worse if the dew point is shifted indoors. Dampness that forms on the inner surfaces of walls negatively affects the microclimate in the house, becoming a source of increased humidity and the cause of the appearance of fungus and mold.

During winter frosts, walls that are not insulated are cooled to their entire thickness, as a result of which steam condensation occurs on their internal surfaces.