The article will discuss what isover insulation is, how it is produced, what technical characteristics it has, what disadvantages the products of the French concern “Saint-Gobain” have, what types of presented material are most popular in our domestic market. Photos and videos will reveal the nuances of installing slabs and rolls.

Packed isover slabs Source emupauto.ru

What is isover

Isover is a material that is used to insulate flat surfaces. It is produced by French. The name of the insulation comes from two French words “isolation” - insulation and “verre” - glass. It explains what it is made of. There are two forms of French insulation on the domestic market. There are slabs and rolls. They are formed using fiberglass and basalt wool. Each variety has its own technical characteristics. They determine the scope of use.

The basis of the material is fiberglass and basalt wool. When making slabs or rolls, recycled soda, limestone and sand are added. The use of recycled materials allows us to reduce the cost of the finished product, so French insulation has a very affordable price.

Insulation in the form of plates Source obustroeno.com

The manufacturing technology of isover is extremely simple:

- The listed components of recyclable materials are mixed together, other minerals are added , the mixture is heated to 1300C and converted into a plastic mass similar to liquid glass .

- It is poured into the reservoir . microscopic holes in its walls .

- The container spins like a drum and rotates at high speed . Centrifugal force forces the loaded substance through microscopic holes. In this way, the finest threads are formed .

- The threads are mixed with a special adhesive composition . A viscous mass is formed.

- She goes into the drying oven .

- There the workpiece passes through the rollers . With their help, a layer is formed .

- At the final stage, it is cut into the required sizes . The maximum possible dimensions are 610x1170 mm, the thickness of the slab can vary from 5 to 10 cm.

Buy thermal insulation Izover Standard

Click image to view

Izover Standard, Izover, ISOVER, Thermal Insulation

Material Dimensions

Mineral wool slabs made of basalt fiber are easy to work with, transport and cut thanks to the universal dimensions of the material: Length –1200 mm Width –600 mm Thickness –50; 100 mm Amount of material in packaging – 5.76; 2.88 m2 Quantity of material per package – 0.288 m3 Quantity per package – 8;4 pcs. Slabs of other sizes are made to order.

Material Density

The density of 38 kg/m³ means that the insulation does not settle and does not deform during operation.

Compressive strength

If a force of 2000 Pa is applied to the insulation, the insulation is deformed by 8%. GOST 17177-94

Compressive strength after wetting

The compressive strength indicator at 10% deformation after sorption moistening occurs will be 12 kPa.

Flammability group according to GOST 30244-94.

ISOVER Standard has the characteristics and peculiarity of fibers to melt at temperatures above 1000 °C, which contribute to the inclusion of the material in the group of non-combustible insulation materials (NG).

Water absorption coefficient

If ISOVER Standard is not completely immersed in water for 24 hours, then the coefficient will be equal to no more than 1 kg/m² of area (GOST R EN 1609). Water absorption by volume is 1.5%. Water absorption by mass is no more than 15%.

Coefficient of thermal conductivity

Application of ISOVER Standard in walls made of layered masonry, in ventilated facades as a lower inner layer is effective due to heat conductivity indicators: λ10 = from 0.035 W/(m•K), λA = from 0.038 W/(m•K), λB = from 0.038 W/(m•K).

Organic content

The material contains no more than 3.5% by weight of organic substances.

Moisture by weight

The ratio of the mass of moisture to the mass of the material in a dry state is 0.5%

Vapor permeability coefficient

μ = 0.3 (m•h•Pa). This characteristic of ISOVER Standard means that water vapor easily passes through the insulation without staying for long (GOST R EN 25898).

Certification

Izover insulation has received all compliance documents that confirm the high quality of the material, which complies with the international standard ISO 14001-2004. It has a sanitary-epidemiological certificate, a fire safety certificate and a technical assessment.

| Thermal insulation | |

| Length, mm | 1200 |

| Width, mm | 600 |

| Thickness, mm | 50 |

| Quantity per package, m2 | 5,76 |

| Quantity per package, m3 | 0,288 |

| Density, kg/m3 | 50 |

| Vapor permeability no less, GOST R EN 25898, mg/m*h*Pa | 0,3 |

| Thermal conductivity coefficient at 10 C, W/m*C: | 0,035 |

| Flammability group, GOST 30244-94 | NG |

- Manufacturer: ISOVER

- Product code: isover

- Availability: In stock

- RUB 4,200.00

Tags:

Izover Standard, Izover, ISOVER, Thermal Insulation

Specifications

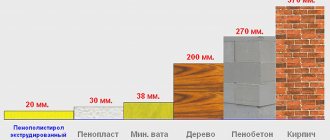

The material obtained by the method described above has unique properties. The layers have high elasticity, low thermal conductivity (0.041), and low weight. For insulation materials, these characteristics are very important. If installed correctly, the technical characteristics do not change over time, which ensures maximum heat savings throughout the entire operation of a residential or industrial building.

Isover packed in rolls Source sovet-ingenera.com

Air bubbles remain between the fibers. They prevent sound penetration. Therefore, using isover for insulation, you can significantly improve the sound insulation of a building. The manufacturer recommends using this material where it is necessary to increase sound insulation without increasing the load on existing surfaces.

The slabs can additionally be treated with water repellents. They make the insulation surface waterproof. When burning, isover does not contribute to the spread of fire; the material has low smoke-generating ability.

On a note! Isover is ideal for insulating log structures, frame or panel houses.

When packaging, the mats are pressed. As a result, their volume is reduced by 60%. This greatly facilitates the transportation of insulation. After removing the packaging, the mats easily restore their shape. They can be used for external and internal decoration. During operation, no hazardous chemical elements are released from the surface of the isover. No formaldehyde or resins are used in its production. Therefore, the material described belongs to the class of environmentally friendly.

Unpacked slabs quickly restore their shape Source ar.decorexpro.com

The insulation, which is produced in the form of rolls, comes in two varieties. Single-layer and double-layer rolls are available for sale. They are used to insulate floors or ceilings. The maximum possible roll length is 14 m, standard width is 120 cm.

See also: Catalog of companies that specialize in insulating country houses.

Insulation dimensions

Such properties and technical characteristics allow the boards to be used in various industries. They are easy to install and transport. The insulation sheet has the following parameters:

- Width – 60 cm.

- Length – 120 cm.

- Thickness – 5/10 cm.

If required, the manufacturer will produce slabs of other sizes according to the client’s order. The high ductility of the product means that it does not deform or sag during operation , according to GOST 17177-94. This standard will help specialists evaluate the properties of a material when choosing it.

Typically, a package contains from 4 to 8 slabs, depending on the thickness of m2. One package is enough to cover an area of 4 to 12 square meters. The insulation is packed in polyethylene. Delivered on pallets. There is also additional protection from the effects of negative natural factors during transportation.

Today, insulation can be selected using the Internet. It is worth giving preference to trusted companies that have been working in this area for a long time and have proven themselves well. Reviews about such companies can be read online on specialized forums.

Existing varieties and scope of application

The French concern Saint-Gobain produces various types of insulation materials. Nine types of isover are most popular on the Russian market:

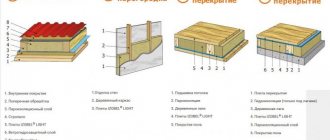

- Thermal insulation isover KL 34 - unpressed slabs that have a very wide range of applications, used for insulation of any vertical and horizontal surfaces . A wooden sheathing is constructed for installation . The plates are inserted inside it without additional fastening.

- Isover KL 37 – pressed boards packed in packaging . They are used for insulating floors between two adjacent floors , internal walls and roof slopes .

Important! When installing the plates, they must be pressed tightly against each other.

Scope of use of different types of isover Source www.tproekt.com

- Isover KT 37 – roll thermal insulation. Used for insulating horizontal surfaces. Izover of this form can also be installed on walls, but only if it is necessary to insulate internal partitions .

- Isover KT 40 – two-layer rolls used for ceiling and floor .

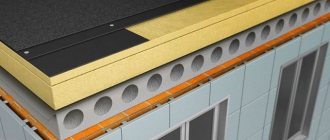

- Isover "STYROFOAM" 300 A expanded polystyrene has been added to its structure . These are plates of increased rigidity . They are attached to the surface using plastic dowels or special adhesives based on bitumen mastics.

- Isover “VENTITERM” – slabs additionally treated with a water repellent . This is a new product, it is just conquering the market. Its scope of application is insulation of facades , carried out by installing single-layer or two-layer systems.

- Isover insulation “pitched roof” is a material designed for roof insulation to improve the sound insulation of a room. Produced in the form of slabs with dimensions 610x11700 mm, thickness 10 cm. The material has high elasticity and elasticity, therefore

Insulation plus sound insulation Source e-teplo.kz

Characteristics

Isover is designed and made using special technology, and therefore has a wide range of applications. The main characteristics of the material will ensure long-term and reliable thermal insulation in various insulation systems.

They are made using steel and reinforcement. The material is also used with fiberglass. It reduces the possibility of cold penetration from outside . The main areas of application are:

- Walls.

- Attics.

- Roofs.

- Layered masonry.

The basalt slab has a density of 50 kilograms per cubic meter. When used, cotton wool shrinks by only 8%, and then regains its original volume. The product practically does not absorb water , and therefore is used in rooms with high humidity. The material does not burn . The board contains only 0.3% organic matter .

The thermal conductivity coefficient at 10 C makes it possible to use the substance for insulating foundations, wells, ventilated facades and other systems.

If Isover is placed in water for a day, it will absorb only a small amount of moisture, which is equal to one kilogram per square meter. This is about 1.5% , which is considered a high figure.

A special feature of cotton wool is that it does not burn, but melts at temperatures above 100 degrees. Therefore, it is often used in places where, in addition to thermal insulation, it is necessary to create a non-flammable layer.

Video description

The video shows the technology of insulating the walls of a frame house with isover:

Technology for installing isover on the side of the building facade

The sheathing is constructed in increments of a centimeter narrower than the width of the insulation. The slabs are laid inside, and a counter-lattice is attached on top. It should provide an air gap. A waterproof and windproof membrane is attached to it. And the finishing decorative trim (siding or lining) is already attached to it.

Soundproofing technique using isover

To soundproof the lower surfaces, floating floor technology is used. It helps reduce indoor noise levels by 50%. It is called so because the materials used for finishing do not come into close contact with the side walls. Therefore, noise waves are not transmitted to them.

Technology for laying floating floors Source sk.decorexpro.com

To build such a structure, a layer of vapor barrier is first spread on a reinforced concrete base, then an isover is laid on it. Waterproofing material is spread on top. The top of such a cake can be filled with concrete screed or covered with gypsum sheets. Even before starting work, damper tape must be glued to the walls along the entire perimeter of the floor. It will ensure the formation of a technological gap that will not allow noise to move across the floors. The width of the tape should exceed the thickness of the screed by 2-3 cm.