Proper insulation of the walls of a country house is always a pressing issue for owners. It often arises again and again due to the fact that improved, new thermal insulation materials appear on the construction market, and this diversity makes it difficult to choose the optimal option.

As a rule, suburban areas are located relatively far from the city, so many people prefer to spend all their free time at the dacha, from early spring to late autumn. As you know, during this period the nights are still or already cold, and the thin walls of light buildings are not able to retain heat indoors, so sooner or later the problem of their high-quality thermal insulation becomes more acute. Moreover, some owners would not mind spending the Christmas and New Year weekends in the countryside, but without reliable insulation this desire will be simply unrealistic.

Insulation for walls inside a country house

You can use different types of insulation for walls inside a country house, especially since the modern wide range allows you to choose it to suit every taste and budget. In order to save on heating a country house and create a comfortable microclimate for relaxation, it is necessary to select high-quality material. It should not only help maintain the required temperature in the premises, but also be safe for the health of residents, and also last for many years without losing its thermal insulation qualities. Therefore, to begin with, it is worth highlighting the criteria by which it is necessary to choose insulation installed inside residential premises.

Floor

There are plenty of floor insulation methods today, but are they all rational?

For example, dry expanded clay screed from Knauf is widely popular. By the way, it costs a lot of money. Not breathing? Honestly, the floor is not the place where excess steam escapes; there are usually plenty of holes for this in a country house.

Well, now the advantages:

The thermal conductivity coefficient of load-bearing expanded clay with a density of 800 kg/m3 is equal to 0.18 W/ (m*K), while for foam plastic this value is 0.038 W/(m*K). In human terms, for equal indicators, the volume of foam will be needed 5 times less.

That is, if for tolerable thermal insulation of the floor you need a layer of polystyrene foam of at least 150 mm, then you will have to pour more than half a meter of expanded clay!

Of course, there is always room for savings. So, it is not necessary to drive a fifteen-centimeter ball of polystyrene foam throughout the house. It is enough to go around the perimeter of the building with this thickness to a width equal to the depth of soil freezing, and in other places use the budget 5 cm.

Even with this approach, the cold cannot penetrate.

Alternative – fibreboards

This is an excellent option for insulating yourself, since all the work is very easy to do. The main thing is that the walls must be clean and dry. The task is made easier by the fact that the slabs can be mounted directly on the old coating, on the plaster. For installation, buy special nails that are equipped with a recessed head. When the insulation is complete, you can glue wallpaper directly onto the fiberboard or perform other finishing work as desired.

Also used for insulation:

- Expanded clay;

- Penoizol;

- Polyurethane foam.

A new trend is ecowool insulation.

This is a very environmentally friendly material that is obtained from cellulose. It can be installed either dry or wet. True, the latter requires special equipment. And the dry method can be implemented independently. Plus ecowool is environmentally friendly, the walls “breathe”, the work quickly pays off.

If you are faced with the task of insulating your country house, you should not think that this will require fabulous financial investments and the involvement of specialists. You can choose an option to suit your taste and budget if you carefully study the theory, and almost everyone can do the work themselves.

Relaxing in a wooden dacha is the dream of every resident of our country. Strive for your dream and one day it will definitely come true.

https://youtube.com/watch?v=grjHO6Y4qFU

Walls

Insulation of walls is the main stage of work, since they occupy the main area of any building and have the highest heat transfer.

Surface preparation

Before insulating wooden walls, be sure to clean the entire surface of dirt. Carefully treat the inside of the walls with special solutions and aerosols that will protect the wood from insects. Then caulk all the gaps using dry tow and a thin chisel.

Insulation

Jute fabric is very suitable as a heat insulator for walls. It is quickly and easily laid with a construction stapler, does not rot, is not blown away by the wind and is not of interest to moths. Tow and jute fiber have low thermal conductivity due to their capillary structure and easily release moisture. In addition, as bactericidal materials, they successfully resist the spread of fungus.

It is not recommended to use improvised materials to insulate the walls of a country house: felt, batting, wool. They accumulate moisture abundantly. As a result, the process of rotting quickly begins, and moths are sure to appear in the wool.

Insulation with polyurethane foam

Modern thermal insulation polyurethane foam is very well suited for insulating a wooden house from the inside, however, it requires compliance with certain requirements.

First of all, it is necessary to clean the walls from dust and sawdust, protect the floor, windows and doors with protective materials.

Next, carry out a series of works step by step:

- perform sheathing in 60 cm increments with 4x4 cm or 5x5 cm timber;

- spray polyurethane foam between the sheathing boards;

- wait up to 12 hours until the layer of material dries completely;

- level the excess material in accordance with the level of the sheathing.

Next, lay the layers of the wall pie in accordance with the installation technology.

Insulation using polyurethane foam

Thus, insulation inside can be done quite effectively. If you carry out all the stages of laying cake materials using proven technology, you can achieve a good result: the walls will retain heat well in the room and thereby create a favorable indoor microclimate on cold days.

Technology and stages of external insulation of a country house

Technological features of external thermal insulation in the form of a ventilated facade include the following stages.

Preparatory work

The facade walls are treated with antiseptics in two layers to eliminate the risk of rotting. The product is applied especially carefully, including on corner surfaces and the crown. The treatment is carried out in dry weather and left to dry for 24-36 hours.

Arrangement of metal or wood sheathing

An insulating film with a vapor-permeable coating is attached to the wall, with the porous side facing the wall and the glossy side facing the street. Next, a vertical wooden sheathing is constructed. To ensure a tight fit of the mineral wool mats, the interval between the beams is maintained 4-5 cm less than the width of the insulation.

Laying thermal insulation material

Lay insulator slabs between the sheathing bars and, if necessary, temporarily attach them with slats. The final fixation of mineral wool is carried out using anchor nails. When installing mats in two layers, a technique with offset seams is used, that is, the elements of the second layer cover the tile joints of the first.

Next, a layer of wind and waterproof membrane is performed with the material overlapped using a stapler. Mounting tape is used to seal joints. The next step is to install the ventilated frame:

- the structure is constructed from the same bars that were used for lathing under the mineral wool mats;

- The ventilation frame bars are installed to the previous sheathing using self-tapping screws.

In this case, a technical gap is left between the insulation and the frame for ventilation.

Finishing activities

The following materials are recommended for cladding a country house:

- imitation timber;

- lining;

- block house;

- wood-look vinyl siding and other solutions.

Blockhouse - material for cladding a country house.

Cladding material is attached according to the manufacturer’s instructions

It is important to eliminate any gaps to prevent the risk of moisture seeping into the insulation system.

How to insulate a floor in a country house

The foil thermal insulation discussed above will work perfectly as a material for quick and budget-friendly floor insulation. When you need to quickly insulate your dacha, this is what you need for emergency help. The easiest and fastest thing would be to simply insulate the places where the floor meets the walls: there are still cracks there, even microscopic ones, but that’s the only way heat escapes into them. Cut the material into strips and use a stapler or small nails to attach it so that one edge goes to the wall and the other to the floor.

The material is attached so that the foil layer faces the room, and not the floor!

It will become warmer immediately. You can go further and insulate the entire floor area by placing insulation under the floor covering.

Or solve the problem radically by insulating the floor from the foundation side (if there is no time to open the floor, just as there is no opportunity or desire to turn the insulation of the house for the New Year into a full-fledged reconstruction). This is what our user with the nickname id57026527 did.

id57026527FORUMHOUSE Member

It was decided to resort to a simple option - pour mineral wool waste directly onto the ground in a layer of 20 cm. Leave a gap for ventilation of also 20 cm. Friends did this, they said, the floors became much warmer.

This is how the summer resident implemented his plan: he “crawled” and treated all the wood under the floor, especially the beams, with a powerful antiseptic against mold and bark beetle. I laid the membrane on the ground with the rough side down, and scattered mineral wool waste onto it in an even layer.

Here's how you can insulate the floors of residential buildings and cottages, if you have the time and energy. This is what our user with the nickname d130585 did at his small dacha:

- Load-bearing beams at a distance of about a meter from each other - timber 100x100 mm;

- A 45x45 mm block is attached to the beams; this is a support for the subfloor (OSB slabs);

- OSB boards end-to-end, without gaps;

- Layer of vapor-thermal insulation;

- A layer of mineral wool 50 mm thick;

d130585FORUMHOUSE Member

50mm is not much, but if you use a couple of heaters, it will be fine for comfortable winter gatherings with friends.

- The second layer of vapor-thermal insulation.

- The main floor is covered with 40x150 tongue and groove.

For air circulation and so that “nothing breaks,” a gap of 1 cm is left between the insulation and the main floor.

The main floor is covered with thick linoleum - this way moisture will definitely not get on the boards. For the same reasons, the holes around the perimeter of the foundation are covered with decorative panels; wind and moisture do not penetrate into the subfloor. The owner of the dacha is sure that in a few years the floor insulated in this way will be alive and well.

Features of insulation and suitable materials

Types of insulation

When choosing methods and materials for wall insulation, you should not forget about other structures through which cold air can enter the room. You should start with windows and doors. It is necessary to seal all the cracks and install high-quality seals on the sash. If finances allow, it is better to install energy-saving products.

According to the law of physics, heated air rises upward, accumulating near the ceiling. If its surface is not insulated, the air will quickly cool and fall down, cooling the rooms. The ceiling must be reliably insulated from the attic using the highest quality materials.

No less attention should be paid to floor insulation. The microclimate in the house and the comfort of living in it depend on the temperature of its surface. Cold floors can negatively affect people's health. If it is not possible to install a heating system, you need to create an effective thermal insulation layer under the final coating.

Before making a choice in favor of one or another method of arranging your home, it is recommended that you familiarize yourself with the types of insulation for walls inside a country house.

Mineral wool

The material is tightly compressed fibers with air enclosed between them. Models made from dolomite, glass and waste from the steelmaking industry (slag) are on sale. The products are produced in the form of rolls and slabs of rectangular and square shapes. The most popular is basalt wool, which has excellent performance characteristics.

The thermal insulator has the following advantages:

- low thermal conductivity;

- good acoustic qualities;

- resistance to dampness, fungus and mold;

- biological inertness - rodents and insects do not live in cotton wool;

- environmental Safety;

- long service life;

- elasticity and flexibility;

- fire resistance, the ability to block the spread of fire;

- ease of installation;

- vapor permeability.

Expanded polystyrene

Insulation of walls with foam plastic

Polystyrene foam and its modifications are produced in the form of slabs measuring 1x1 m, with a thickness of 2, 5, 10 and 20 cm. It consists of many compressed balls with a porous structure.

Advantages:

- low specific gravity;

- waterproof;

- ease of installation;

- low thermal conductivity;

- durability;

- affordable price;

- resistance to pathological microorganisms.

Expanded polystyrene also has disadvantages. The coating can harbor rodents and insects. The slabs are fragile and crumble even under weak mechanical loads. The material absorbs moisture, which leads to its destruction. Also, polystyrene foam decomposes from ultraviolet radiation; its surface must be protected from direct sunlight.

Polyurethane foam

Work with polyurethane foam is carried out in a protective suit

PPU belongs to the category of sprayed insulation. After application to the surface, the liquid increases in volume, hardens and forms a dense porous substance with open cells. To process large areas, special equipment is required. Today this material is considered the best in almost all respects.

Advantages of polyurethane foam:

- high application speed;

- the lowest thermal conductivity among analogues;

- excellent adhesion to any surface;

- filling all cavities, voids and cracks;

- creation of a continuous monolithic coating, devoid of cold bridges;

- long service life;

- resistance to temperature changes;

- waterproof;

- fire resistance on some models.

Examples of roll insulation for walls

Laying roll insulation

When arranging smooth, curved and complex surfaces indoors, roll insulation materials are in demand.

The most popular materials are:

- soundproof foil polyurethane backing.

- mats made of natural linen 5 cm thick;

- foamed polyethylene;

- foam rubber;

- compacted fiberglass;

- felt tapes.

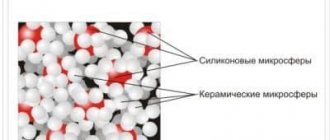

It is recommended to pay attention to liquid insulation for the dacha. These include facade plaster and ceramic paint

These materials are well suited for equipping buildings made of concrete, gas silicate blocks and bricks.

Window

After insulating the walls, we move on to the windows

They also lead to significant heat loss, so close attention should be paid to windows, especially if the design is outdated

Cleaning and waterproofing

The frames of the house should be thoroughly cleaned of dust, cracked glass should be replaced, and the gaps between the walls and frames should be sealed.

For high-quality insulation you will need silicone sealant in a special gun. It reliably protects joints from the inside from fungi and mold. Polyurethane foam will also work. However, it quickly deteriorates from the sun and is not entirely aesthetically pleasing. If you choose foam, you will have to take measures to protect it from ultraviolet rays.

D-profile tape

Then you need to glue the sealing tape. D-profile tape is best suited. It effectively closes gaps up to 7 mm. For a more secure fixation, you can secure the tape with nails or staples.

Film on glass and insulation of slopes

To maximize the insulation of windows, cover them with heat-saving film. This material is applied directly to the glass. When laying the film there should be no folds, swelling or bubbles. Carefully done work will help save more than 30% of heat.

Don't forget about insulating the slopes. For this, you can use various materials, for example, polyethylene foam or mineral wool. The insulation is fixed to the slopes using glue.

What thickness of insulation will be required?

Before work, it is necessary to carry out thermal calculations. The multilayer structure consists of a wall with external finishing. Inside – insulating layer and lining

It is important to correctly determine the thickness of the insulation

For a comfortable temperature, the layers inside and outside, regardless of the time of year, must have a total resistance to heat transfer. The sum is obtained from the resistance of each layer.

The total resistance is established by SNiP standards for each region, taking into account the climate. The value is easy to find out in any construction organization.

An online calculator will simplify the calculations, where the result is usually shown in millimeters. It is necessary to round up.

Material selection

There are a number of requirements for thermal insulation materials.

The insulation must have low thermal conductivity, good hygroscopicity, fire safety and environmental friendliness.

It is necessary that the material reliably prevents heat exchange between the external and internal parts of the walls and protects the structure well from the inside. Today, mineral wool based on basalt or fiberglass is widely used as insulation. If the ventilation of the house is properly equipped, moisture will not be a problem for this material.

New products for high-quality do-it-yourself insulation of a dacha are constantly appearing on the construction goods market. For example:

- insulation made of flax fiber - the material is produced in slabs, is easy to cut, does not change shape, is environmentally friendly, has good antiseptic properties;

- ecowool is a sprayed loose heat insulator consisting of recycled cellulose with the addition of antiseptics and fire retardants;

- soft fiberboard (fiberboard) is an environmentally friendly material that can be used to immediately strengthen walls.

How and with what to insulate is a matter of taste and good choice. The main thing is that the country house is reliably protected from the winter cold.

How to choose inexpensive wall insulation

When choosing the optimal material, you need to pay attention to many nuances. It makes sense to consider the most common materials in order to understand their features, advantages and disadvantages in table form

Table. Comparative characteristics of popular materials

| Insulation | Advantages | Flaws |

| Basalt wool | low thermal conductivity; easy to cut to required sizes; excellent vapor permeability; does not burn; light weight; thickness from 50 mm to 200 mm; optimal density indicators. | may lose shape over time; absorbs water well; during work it is required to use personal protective equipment; high price. |

| Expanded polystyrene | good compressive strength; thermal conductivity is low; poor water absorption; retains its shape for a long time; thickness from 20 mm to 50 mm. | requires cutting quite accurately; cannot be used for roofing; highly flammable materials; high price; susceptible to damage by rodents. |

| Styrofoam | low price; not afraid of water; retains its shape perfectly; environmentally friendly material; not interested in rodents; thickness from 20 mm to 50 mm; light weight. | flammable material; it is necessary to cut accurately; may crumble during operation; thermal conductivity is low; low density. |

| Glass wool | low price; compacts well; does not burn; environmentally friendly material; thickness from 50 mm to 200 mm; light weight. | personal protective equipment is required when working; hygroscopicity; loses its shape over time; relatively low chemical resistance. |

| Polyester fiber insulation | retains its shape and does not absorb water; low thermal conductivity; phenol is not used in the production; hypoallergenic material; light weight. | flammability; high price. |

When choosing a material, you should also consider the following parameters:

- thermal conductivity - the lower the indicator, the less heat loss will be;

- vapor permeability or the ability to allow moisture to pass through;

- shrinkage – over time, materials lose their shape, so this parameter is critical;

- mass and density;

- water absorption or hygroscopicity;

- Operating temperature range;

- flammability;

- thickness;

- material form - roll or in the form of a sheet or plate;

- environmental friendliness;

- chemical resistance.

Calculator for calculating the thickness of ceiling insulation in a house with a cold attic

It is highly recommended to ask for a certificate from the fire department before purchasing. This will allow you to check whether the material meets safety requirements. If this certificate is missing, then you should refuse to purchase.

Choice of insulation

Before starting work, you need to decide on the type of thermal insulation. If you have basic construction skills, the correct selection of insulation and knowledge of technology, most activities can be done with your own hands.

The modern market provides customers with a wide range of materials that will help to efficiently insulate a country house. Each of them has its own advantages and disadvantages.

Several groups of thermal insulation materials can be distinguished:

- mineral wool;

- cellulose;

- polystyrene.

Each of the above groups deserves detailed consideration.

Mineral wool

Mineral wool insulation, often referred to simply as mineral wool, is an inorganic fiber, usually made from porphyrite. There is an air gap between the fibers, occupying about 95% of the total volume.

The advantages of mineral wool are its high heat and sound insulation qualities, durability, environmental friendliness, and fire safety. The main disadvantage is low resistance to moisture.

Cellulose insulation

Cellulose insulation is made from recycled cellulose. The main advantages of the material are its low thermal conductivity coefficient and the ability to fill hard-to-reach places for insulation; it fits well into any small cavities and gaps. Installation is carried out by spraying, manual or mechanized laying, backfilling. Typically, such materials contain antiseptic and fire-retardant impurities, which makes them reliable in case of fire and resistant to rodents and insects.

Among the disadvantages of cellulose insulation are:

- severe shrinkage over time;

- when applied wet, all metal structural elements must be coated with paint or varnish, since due to the long drying time of the material, corrosion may begin;

- high final cost of the thermal insulation system, since high-quality insulation requires a large amount of insulation.

Polystyrene thermal insulators

Polystyrene insulation, the main representative of which is polystyrene foam, are granules filled with air. Due to this, the materials retain heat well. The granules have a cellular structure and therefore practically do not allow moisture to pass through. Expanded polystyrene is produced in the form of slabs, which are very light and easy to install.

A significant disadvantage of this group of insulation materials is their instability to high temperatures, and, as a result, a fire hazard.

What's better?

The most competent solution to the question of which material to choose is the combined use of several types of insulation in different parts of the building structure.

Mineral wool should be used for thermal insulation of structures that are not subject to constant loads. Cellulose ones are better suited for insulating facades, roofs, and floors, while polystyrene ones are better suited for foundations and basements.

Insulation materials for thermal insulation of a cottage from the inside

To insulate a dacha, you can use various types of thermal insulation materials, differing in the composition of the raw materials used for their manufacture, technical characteristics, sizes and shapes.

Based on the type of raw materials used for production, thermal insulation materials are divided into products from:

- mineral wool;

- glass wool;

- ecowool, the raw material for which is cellulose;

- expanded polystyrene;

- polyurethane and penoizol.

At the same time, materials based on mineral wool, glass wool can be made in the form of slabs or rolls, ecowool is represented by slabs, as well as a scattering of compressed fibers, although this option is used less often for walls, as it requires special technology.

Expanded polystyrene insulation is presented in the form of foam boards and extruded polystyrene foam, and polyurethane-based insulation is a sprayed material, for the application of which special equipment is used.

How to attach penoplex to the wall? Video:

Walls

We've finally come to the topical issue. Wall insulation is probably the most discussed topic before winter.

There are exactly two main materials. These are polystyrene foam and mineral wool. The first option is cheaper, but the second one “breathes”. In fact, all this is nonsense and fables of PR people.

Cotton wool wrapped in a steam membrane allows steam to pass through no better than polystyrene foam, which means you still have to organize good ventilation in the room. But this is for general development, and you still have to buy Izover.

And those who have heard about the fire in the “Lame Horse” completely bypass the foam material, especially since the thermal conductivity of the products in question is almost the same.

And now a few words about the insulation itself.

In order to determine the required layer of insulation you need to know two things.

Let's say you have a two-brick wall and you live in Moscow. Keep track of the arithmetic

Two bricks equal 51 centimeters of wall. Thermal conductivity of brickwork is 0.814 W/ (m*K).

To find out the actual heat transfer resistance, divide the wall thickness by its thermal conductivity.

0.51/0.814= 0.62 mK/W

If you look at the tables, you can see that the norm is 3.28 mK/W

Let's subtract the actual from the necessary and find out that we still need to get 2.66 mK/W. Cool, yeah? This is four times more than we actually have.

Now, to determine how much mineral wool we need, we carry out the reverse manipulations. We multiply the missing value by the thermal conductivity of the insulation.

2.66*0.056=0.146 m

It turns out that fifteen centimeters will be just right.

https://youtube.com/watch?v=TMLhlO86hf0

Just buy basalt insulation. The one that comes in rolls tends to bunch up and sag over time, it is not for vertical planes.

Energy saving when insulating walls outside

- Brick and concrete tend to accumulate temperature and return it gradually. When the walls of a house are insulated from the outside, the cold does not reach them, but they warm up from the inside. After 10 minutes of airing the rooms, the temperature in them hardly drops a couple of degrees.

- Porous thermal insulation material only impedes air movement. But it is not able to accumulate heat. When the insulation is located in a house whose walls are frozen through, an open window cools the room in 5 minutes. It will take a long time to restore a stable temperature regime.

- In addition, the internal placement of insulation does not cover the cold bridges formed by the floor slabs. Enormous heat losses are inevitable. External insulation of walls removes them from the zone of influence of external factors, which significantly extends their service life.

Carpentry

And it’s a no-brainer that if you still have old Soviet windows in your house, then you heat not only the room, but also your yard. The thermal conductivity of glass is 0.81 W/ (m*K), exactly the same as that of brickwork, although the thickness is only 3-4 mm.

The glass unit is another matter. Properly manufactured, it significantly increases the heat transfer resistance of a window unit, and therefore people, without hesitation, take two, three, and if they sell even five chamber glass products.

The trap is that the optimal chamber width is 16 mm, and the width of the produced window profile is 32 mm.

It would seem that a two-chamber product can still be “fitted” tightly, but let’s add the thickness of the glass, and there will be as many as 3 of them and we’ll get an extra 1.2 cm.

It is important not to chase the chambers, but to understand that it is not the glass that retains heat, but the air sandwiched between them, and if the amount of this air is reduced by the same volume, heat loss will only increase. Conclusion: not everything is good because it’s expensive!

Conclusion: not everything is good because it’s expensive!

Wall insulation process

When installing thermal insulation on your own, you need to know the sequence of work:

- First, prepare the walls - level them, eliminate problem areas.

- Install waterproofing. The simplest is polyethylene. It is secured with tape.

- Select materials according to the design of the house.

- The insulation boards are attached - to enhance adhesion, the surface is coated with glue.

- The slabs are laid in a checkerboard pattern, filling the joints with glue or foam.

- Additionally secured with plastic dowels.

- Apply a top layer of glue around the perimeter of the insulation.

- Mount the reinforcing mesh on the glue, pressing it with a roller.

- After complete drying, the surface is plastered and the final finishing is carried out.

Stages of work

The best insulation for country walls is penoplex. A novice technician without experience can install it. To live in the house all winter, it is better to prefer mineral wool. It is more difficult to insulate it.

When planning to insulate a home, you need to understand the difference between the main materials. If the product is vapor-tight, it is enough to secure it in the chosen place. Otherwise, a vapor barrier film is required. Without it, condensation will appear between the thermal insulation and the wall, destroying the thermal insulation layer.

No less important information on the topic: Insulation for bath walls

Seal cracks in walls and insulate

In wooden beams dried using the appropriate technology, cracks form that need to be sealed.

Means for sealing cracks are:

- sealants and other synthetic products : resins, mastics, mounting foams. Synthetic sealants should not have an acrylic substance. Silicone seals must have a high level of frost resistance. The mixtures are placed deeply into the gap, and after drying the area is leveled. Polyurethane foam is used in places where facing work will subsequently be carried out;

- wood shavings mixed with wood glue . Used at any stage of finishing, as well as during additional inspection. The prepared mixture is poured into the previously cleaned crack of dust, then, after complete drying, the area is processed by grinding. The method is advisable to use for small cracks;

- decorative mixtures for sealing;

- fibrous materials - caulk (moss, wool, tow). Pre-cleaned cracks, impregnated with antiseptics and solutions that prevent the formation of mold, mildew, and dampness, are clogged with caulk.

NOTE!

Insulation at the joints of timber is done with sealants, mixtures or adhesive shavings . If the wall is made of logs, then the joints should be sealed only with fibrous materials.

Wood requires constant care and timely sealing of cracks that may appear over time. Regular inspection of the wood will help prevent gaps from growing, which can reduce the insulation properties of the walls.

Sealing tow

Sealing with sealant

Advantages and disadvantages of internal insulation

This type of insulation has a number of disadvantages:

- Due to the size of the insulation, the useful area of the room is reduced - for small rooms this is especially critical.

- Due to a shift in the dew point (condensation), if the technology is not followed, condensation and mold may appear on the walls.

- The premises cannot be used for living while work is being carried out.

- Cheap wall insulation can negatively affect human health.

But many people prefer this method, which is explained by the positive aspects of internal insulation:

- Work can be carried out regardless of weather conditions, which allows you to insulate the room several times faster.

- Internal insulation technology is cheaper than external insulation.

- It becomes possible to align the walls and change the interior of the room.

A shift in the dew point during internal wall insulation leads to the accumulation of condensation. Source sovet-ingenera.com

The formation of condensation on the walls is the main problem of internal insulation. There are several methods to solve this:

- use a high-quality vapor barrier membrane;

- choose thermal insulation material with minimal thermal conductivity;

- It is better to use moisture-resistant drywall as a finishing material;

- organize additional ventilation in the room.

If you follow the insulation techniques and these recommendations, thanks to competently carried out work, the insulation of a country house from the inside will perform its function without negative consequences.

How to choose?

In order to choose the appropriate insulation for a country house, which will be located from the inside, it is important to know what you have to work with. If you need to insulate the second floor or turn the room into a living area instead of an old cold attic, it is important to choose the right type of insulation

It is important to analyze what material the house is built from. Wooden huts must have a breathable heat insulator, and brick or foam concrete structures can do without it.

When choosing a material for working with walls, you need to evaluate its moisture resistance, which will be one of the main criteria. Heating is also worth considering. If the stove is running inside, the difference between the temperature outside and in the house will become very large. This process will lead to the formation of condensation, which will affect the insulation and contribute to its soaking. In such conditions, the material will not last long and will soon begin to deteriorate. To avoid this outcome, it is necessary to use a vapor barrier film, which will protect the insulating sheet from moisture.

To choose the right insulation, you should pay attention to the following indicators:

thermal conductivity, which must be low in order to be able to maintain optimal conditions in the living room; resistance to frost - this is important for those dachas that are not heated in winter and the temperature in the house can be zero, which negatively affects some types of thermal insulation; ease of installation work, which is important in the case of a country house, the work on which is often carried out by the owner himself, therefore the simplicity of all actions is extremely important in this case; pricing policy, which is especially important in the case of furnishing a country house, where cheaper materials are taken.

If, in addition to the walls, it is also necessary to insulate the ceiling, then you should take care of the availability of materials for this procedure. If the attic spaces in a house are being converted into living spaces, then finishing and using insulation are indispensable

To cover the ceiling, it is important to choose materials that are resistant to precipitation and significant temperature changes. The density of the slabs must be high so that they can retain heat in the room without letting in external cold from under the roof

When reconstructing an attic, you may also need to insulate the floor, especially if it is on a reinforced concrete slab. To do this, you need to make a sheathing, lay insulation, on top of which place a covering material such as plywood, fiberboard, etc.

In this case, almost all surfaces should be supplemented with a layer of thermal insulation material in order to create conditions suitable for living inside the living space. Having the necessary materials for this process, you need to know how to use them correctly.

Penoplex - a bestseller

The most popular insulation for walls inside a dacha house in recent years is expanded polystyrene (penoplex). The material is compacted white granules, the composition is foamed polystyrene and air. People often confuse penoplex with polystyrene foam, but these are completely different materials, since the first differs favorably from the second in a number of characteristics, including compressive strength (achieved due to the fact that the molecules are very tenaciously connected to each other).

Characteristics of penoplex:

- This wall insulation inside a country house has excellent thermal insulation and sound insulation properties;

- Repels water;

- Durable, resistant to compression;

- Mold and fungi do not appear on it, the material does not rot;

- Absolutely safe: it is even used in the food industry, it is so environmentally friendly;

- Resistant to combustion and temperature changes;

- It weighs little, is easy to process, and is relatively inexpensive.

Thanks to this set of almost ideal properties, penoplex is most in demand as wall insulation inside a country house and in other rooms.

Methods

So, insulating the walls of a private house from the outside has many more advantages than disadvantages

But it is important to understand the features of individual materials and structures

Houses made of expanded clay concrete blocks are insulated from the outside most often using:

- mineral wool;

- polystyrene foam;

- its more modern analogue is penoplex.

The first option is preferable due to zero fire hazard and low cost. But the problem is that the affordable price is largely negated by the need to organize a protective screen. Polystyrene foam is lightweight, also belongs to the budget group of materials, and it can be installed quickly.

Quite often people are faced with the problem of insulating the external facades of old panel houses. The main condition for high-quality thermal protection is its design in which the permeability to vapor increases from the living space to the street. There is no need to remove the outer cladding of the home; a number of technologies have been developed that make it possible to install thermal insulation on top of it.

When choosing a suitable option, you should give preference to solutions that do not overload the foundation and absorb the least amount of water. It is the significant heaviness and the presence of the dew point inside the hygroscopic thermal protection that cause the most problems for the owners of panel buildings.

Insulating dacha houses for winter living is very important.

It is imperative to provide thermal protection:

- internal floors on the ground;

- floors of the first tier (if the foundation is not insulated);

- external walls;

- cold attic floor or attic roof.

It makes no sense to single out any one of these elements, even something as important as walls. If at least one area is not insulated, all other work can be considered wasted, as well as the money spent on it. The walls must be equipped with waterproofing and vapor barrier; when choosing mineral or environmental wool for insulation, it is necessary to leave a ventilated gap of 50-100 mm. The insulation of a panel house from the outside has its own specifics. The slightest irregularities should be removed, and ideally, leveling should be done using a primer.

If paint is splitting or other finishing is falling off, all these layers are removed, even if the technology does not require such manipulation. In most cases, polystyrene foam is used for external thermal protection of concrete walls, and the most reliable way to attach it is to combine glue and dowels. The work is carried out from the bottom up; a special bar is installed at the lowest point, designed to prevent the material from slipping. Please note: it is possible to replace dowels with plastic nails. Regardless of fastening methods, it is necessary to carefully monitor any gaps that appear.

The insulation of the junction of the wall and the roof deserves a separate discussion. This work is done traditionally using stone wool, but for lovers of modern technologies it is better to focus on Macroflex foam. In many cases, a steel bonding apron is formed. Whether it is needed in a particular house, on a particular wall, only trained specialists can find out. The insulation of junctions is too complicated to be done properly by the owners of the house themselves or by randomly found freelance craftsmen.

We insulate the house from the outside

Entire separate books can be devoted to the topic of insulating a dacha from the outside. This is the most extensive of all means of insulating a dacha, and the most expensive method. Insulating a house from the outside cannot be done using improvised means. Yes, and you should choose a technology based on the recommendations of the master, since many nuances should be taken into account: what is the material of the house - timber, logs, what is the thickness of the walls, etc.

Mineral wool and polystyrene foam are used as insulation.

These materials have long been known and are the most affordable. However, today there are other, more modern and expensive ones on the market. Choose according to your taste, but do not forget that even the old-fashioned materials for thermal insulation of a dacha give excellent results.

Where does the heat go?

A warm house is a house that retains heat inside. Heating the street means not respecting your Galaxy. In recent years, people have been trying to make any buildings energy efficient so as not to pay extra money to suppliers of gas, electricity or other fuel, and the effectiveness of these insulation measures is visible to the naked eye.

qazwer1973FORUMHOUSE Member

I have a log house 150x150, everything is caulked, but without insulation - the house cools down in winter in 4 hours. A 150x150 timber extension with an insulated ceiling and floor takes much longer to cool down. Now I’ve insulated the walls of the extension with 50mm mineral wool, I’ll see how it goes in winter.

How does heat escape into uninsulated house structures?

But these numbers in the diagram are conditional; it all depends on the material of the structures and compliance with construction standards.

Cat-EdgeFORUMHOUSE user

This is very conditional and individual. Heat loss through the walls can be 5%, or even 80%.

Dimastik25FORUMHOUSE user

What's the point of insulating the walls if you plan to install windows with a 50-gauge profile and a single-chamber double-glazed window?

There is a simple and old-fashioned method that allows you to detect heat leaks in wooden walls without a thermal imager. You need to wet your hand with water and move it along the walls, at a distance of 15-20 centimeters from them. You can’t help but feel a stream of cold air from a wall or window; you need to mark with chalk the place where it comes from.

Types of edge profile (molding)

In addition to the laminate, the most important element of the staircase trim is the edge profile or molding. This is the name given to the overlay convex strip that is used to decorate the edge corner of the step. What is the function of molding? Everything is very simple. When finishing the stairs, two laminate strips laid on the tread and riser are joined together. An unaesthetic corner is formed, exposing the cross-section of two lamellas. To cover this joint and at the same time strengthen the strength of the laminate, edge profiles are used. They are placed on top of the joint and secured with glue or self-tapping screws.

Ordinary metal L-shaped metal thresholds are often used as an edge profile. They are also called staircases. These thresholds can be made of aluminum, steel, brass. Paintings like gold, bronze, steel or wood are popular.

Metal moldings have more than just a decorative effect. They protect the edges of the steps from wear. In addition, the surface of such a profile is often corrugated and this gives the surface of the steps an additional anti-slip effect.

Plastic thresholds - have the form of corners of different shades. You can easily match the color to your existing laminate flooring. Plastic thresholds ideally protect the edges of steps, form an even angle, and hide unevenness. They differ from other staircase thresholds at a low price

They are attached mainly with glue, so when installing plastic thresholds, special attention should be paid to choosing high-quality durable glue

Wooden sills are another option. Such thresholds go well with laminate flooring and have a long shelf life (in addition, they can be easily repaired - sanded, puttyed, painted). The disadvantage of wooden moldings is their high price. Fastening is done either with glue or with self-tapping screws (bolts).

In addition to the usual corner thresholds, there are also special laminated profiles attached to the steps using metal guides. For example, similar Incizo profiles from Quick Step (Belgium) are widely known. To install such a profile, a special L-shaped aluminum strip is used, available in several standard sizes (the height of the strip from Quick Step is 7, 8 and 9.5 cm).

To install this type of edge profile, a metal guide strip is attached to the surface of the step using screws. And then, a laminated profile is inserted into its grooves (with glue). In this way, the fixation of the profile is as strong as possible, while it is possible to do without metal fastening elements visible on the surface.

Assembling the remaining parts

Now you know how to make a long sofa. After installing it, proceed to installing a short sofa. It is produced in the same way, with the exception of the size of the furniture product - its length is 40 cm shorter. Everything else remains unchanged.

When making a corner for the kitchen with your own hands, the important part that unites the long and short sofas is the connecting element. It can be made in the form of a corner from pallets

According to the measurements taken, cut out all the necessary parts for the seat and back from the chipboard. Connect them together using screws or dowels. Next, cut out the bar for the stop and fasten it to the seat.

Please note that when making a kitchen corner from wood with your own hands, the side parts should be attached after the seat and back have been given the proper appearance. The first step is to secure the parts of the back and sides, and then switch to the seat and frame

It is important to note that all fastenings are made using metal corners. The next step is to secure the foam rubber and cover the product with fabric, which must be fixed using a stapler

This is how you assemble kitchen corners with your own hands. Due to the fact that the corner you make will be collapsible, all 3 elements can be moved and rearranged if necessary. If you want, you can connect all the main parts and make the structure whole. How to do it? Metal corners will come to your aid!

The next step is to secure the foam rubber and cover the product with fabric, which must be fixed with a stapler. This is how you assemble kitchen corners with your own hands. Due to the fact that the corner you make will be collapsible, all 3 elements can be moved and rearranged if necessary. If you want, you can connect all the main parts and make the structure whole. How to do it? Metal corners will come to your aid!

You also have the opportunity to improve your soft corner for the kitchen, because this softest corner for the kitchen can be equipped with a sleeping place, like in a simple folding sofa. To make a corner with a sleeping place with your own hands, there is no need to disassemble the entire structure or remake its components. You just need to slightly change the long sofa by adding 1 more sheet of chipboard, permanent hinges and lots and lots of foam rubber, and you will get a wonderful kitchen corner with a sleeping place.

Let's summarize the comparison

When thermal insulation is carried out using mineral wool, the creation of a frame is a prerequisite. On the wall, vertically installed slats will act as fastening elements. In terms of installation costs, the use of polystyrene foam is beneficial. In terms of cost, this particular material is also beneficial. Its price is three times lower than mineral wool. However, when deciding to opt for polystyrene foam, you must keep the following in mind. If rodents appear in your home, they will use foam sheets to build their house. They can destroy insulation sheets, which will lead to increased heat loss.

When thinking about which thermal insulation material to choose, you should first consult with a specialist who, taking into account the room, will recommend you a suitable insulation.

Roof

If installed incorrectly, a roof can “steal” more than 10% of the heat spent on heating the house.

When choosing thermal insulation for a roof, pay attention to its service life, which depends on many external factors: temperature fluctuations, amount of precipitation (especially snow), wind strength and direction. Pay special attention to the water resistance of the material. Isolation must also be safe for health. The first sign of safe insulation is the absence of a sharp, pungent odor.

Insulating the roof with polymer materials is not the best solution. They ignite very easily and quickly, so increased fire safety measures will have to be taken.

The best insulation for roofing can be considered stone wool, which is intended for thermal protection of structures that do not bear heavy loads.