Insulation of housing is a pressing problem of our time. Not only in new buildings, but also in old housing stock, people are trying to reduce heating costs. Continuously rising energy prices put significant pressure on the family budget, widening the gap between income and expenses.

By properly insulating your home or apartment, we will ensure comfort for ourselves and our loved ones. The amount on the virtual “counter” of savings after this work will grow every year.

The only question that needs to be answered correctly is what material to use to retain heat in your home? In answering this question, we will look at stone wool and evaluate its advantages and disadvantages.

What is stone wool made from?

This material is made from basalt, a rock of volcanic origin. In order to obtain soft fiber from hard stone, it is melted. After this, the hot mass is separated into fibers using various technologies (blowing, rolling, spunbond and centrifugal drawing).

The resulting semi-finished product has one significant drawback: the basalt fibers crumble and it is impossible to form a single mass from them. Therefore, in the next step, an adhesive is introduced into the fiber.

Most often, phenol-formaldehyde resin is used in this capacity. It connects the fibers together, allowing you to form a carpet of the desired thickness. Next, the material is given water-repellent properties by treating it with mineral oil. The last operations are cutting the insulation and packaging it.

It should be noted that in the construction market the term stone wool is not often used. The names more familiar to the mass buyer are mineral wool and basalt wool. To avoid confusion, it should be remembered that we are talking about the same material obtained from basalt rock.

One more note: basalt mineral wool should not be confused with glass wool and slag wool. The first type of insulation is obtained from molten glass. The raw material for the second is blast furnace slag. Today, mineral wool has practically supplanted its closest competitors. Glass wool is noticeably inferior to it in terms of environmental friendliness. The quality of slag wool is low, so the demand for it has fallen.

Glass wool

It is made from molten and foamed glass (usually cullet is used in production) with the addition of soda, limestone, quartz and dolomite fillers.

Disadvantages of glass wool

Phenol-formaldehyde resins are used to bind the components, which somewhat reduces the environmental friendliness of the resulting product. Glass wool mats are lightweight and can be compacted, which reduces transportation costs. They have high elasticity and flexibility, which allows them to be used for insulating non-standard structures with complex geometric shapes. Glass wool is resistant to combustion and biological destruction, while being fragile in relation to mechanical stress.

Properties, types and characteristics of stone wool

While remaining essentially a natural stone, basalt wool has acquired the best insulation qualities. From the rock it inherited resistance to fire and high temperature. This material is not afraid of aggressive acids. Oil treatment made it impervious to moisture.

The fibrous structure provided the material with excellent heat and sound insulation properties and good vapor permeability - a very important characteristic of any insulation.

Speaking about stone wool insulation, many argue about the environmental friendliness of this material. The reason for concern is the phenol-formaldehyde resin that is part of it and glues the fibers together. However, upon closer examination, doubts dissipate.

The mass fraction of glue in this insulation does not exceed 3%. Studies conducted by sanitary control authorities have confirmed the safety of mineral wool for health.

The main guideline for the consumer in the matter of environmental friendliness is the products of certified manufacturers who strictly observe raw material proportions and technology.

The main characteristic of insulation is density. Its thermal insulation ability is directly related to it. In addition, density is essential during installation.

According to this indicator, the material is divided into three categories:

- soft (roll and slab) – 10-50 kg/m3;

- semi-rigid (slab) – 60-80 kg/m3;

- hard (slab) – 90-175 kg/m3.

To classify insulation boards, alphanumeric “brand” designations are used. The letters indicate the degree of hardness (soft - PM, semi-hard - PP, hard RV). The numbers indicate density (kg/m3). The most common brands are PM-40, PM-50, PP-70, PP-80, PZh 100, PZh-120.

The main characteristics of TechnoNIKOL Rocklight basalt slabs - a popular universal material for private construction.

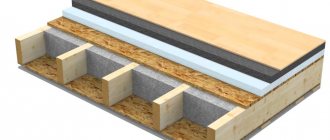

Soft rolled wool (thermal conductivity coefficient 0.033 W/m*C) is used for insulation of interfloor ceilings, frame partitions, and pipelines.

A semi-rigid slab (0.039 W/m*C) is placed in multilayer sandwich panels and mounted on ceilings, ventilated facades and roofs.

Rigid insulation (0.046 W/m*C) is used where the surface experiences mechanical loads (floors, flat roofs in use, foundations, underground pipelines).

Basalt wool has good sound-absorbing qualities. Its fibrous structure actively dampens acoustic air vibrations, reducing the noise level in the room. It is used as sound insulation in internal frame partitions. For external cladding of facades, it performs the functions of heat and sound insulation.

The sound absorption coefficient of the material ranges from 0.87 to 0.95. When purchasing, pay attention to it. The higher its value, the better the material dampens sound.

Mineral wool does not have a single classification based on geometric dimensions. Each manufacturer offers its own “line” of insulation. Different brands only have the same thickness of material - 50, 100, 150 and 200 mm.

Three types of stone wool are produced: rolled, in slabs and shaped (in the form of a round shell for insulating pipelines). To increase heat-reflecting qualities and protect against external influences, rolled mineral wool is used, onto the surface of which a layer of metal foil is glued.

The length of the rolled material can be from 3 to 50 meters, with a width from 0.6 to 1.5 m. Slabs (semi-rigid and rigid) are produced in widths from 60 to 120 cm and lengths from 120 to 150 cm.

There is also no strict gradation in terms of vapor permeability level. This indicator is indicated in the certificate and can take a value from 0.3 to 0.55 mg/m hPa. The higher it is, the better the material allows water vapor to pass through.

In terms of fire safety, basalt wool belongs to the category of non-combustible materials (NG), withstanding direct heating up to a temperature of +1100 C.

Advantages and disadvantages of stone wool

Having considered the main characteristics of this material, we can draw conclusions about its advantages and disadvantages.

The positive qualities of mineral wool include:

- High thermal insulation ability;

- Good vapor transmission;

- Fire safety;

- Biostability;

- Environmental friendliness;

- Durability;

- Easy to install.

The main disadvantage of basalt wool appears at the installation stage. When working with it, dust is formed, consisting of small particles of stone fibers. They enter the respiratory system, causing coughing and irritation. Eliminating the damage caused by dust is not difficult. To do this, you should use standard personal protective equipment (masks or respirators). Also, negative factors include the considerable cost of the material.

Crafts. MAAM Workshop

- Crafts from waste material

- Crafts made from natural materials

- Crafts for March 8th. Gifts for moms

- Origami

- Crafts for February 23. Gifts for dad

- Winter crafts

- Crafts made from fabric and threads

- Stained glass. Stained glass painting, crafts

- Spring crafts

- Master classes. Making DIY crafts with step-by-step photographs

- Teamwork. Collaborative work, collective creativity

- Summer crafts

- Pencil holder. DIY pencil holders

- DIY photo frames and frames

- Sun, sunshine. Crafts and drawings on a “sunny” theme

- Easter. Easter crafts.

- Space. Crafts for Cosmonautics Day

- Crafts for May 9

- Beading. Bead crafts

- Flowers. Flower themed crafts

- Topiary, tree of happiness. Master classes, works, photos

- Cardboard crafts

- Clay crafts

- DIY bracelets

- DIY headbands

- Plasticine, we sculpt from plasticine. Crafts

- Crafts and bouquets of sweets. Candy gifts, suite design, flowers

- New Year's crafts

- Wreath. DIY wreaths for the holidays, seasonal, New Year's

- Wire. Crafts made from chenille and ordinary wire

- DIY brooches

- Bell. Crafts and master classes

- Senior group

- Preparatory group

- Middle group

- Junior group

Showing publications 1-10 of 77789.All sections | Crafts, master classes. Making crafts with children

New

Master class “Postcard for Mother’s Day” Master class “Postcard for Mother’s Day”

Educator: Konyukhova S.R. Goal: to make a greeting card for Mother's Day. Objectives: -introduce children to the technology of making postcards in an unusual way; -develop attentiveness and consistency of correct...

Photo report on collective work in the pre-school speech therapy group of the Frosty Day kindergarten On the eve of the New Year holidays, kindergartens are being transformed. Teachers and parents decorate group cells with tinsel, toys, and lanterns. This task is mainly carried out by adults, since the work is labor-intensive and everything must be done perfectly. But children also want...

Installation rules

Most often, mineral wool is used for external insulation of walls, attic floors and roofs. For thermal insulation of the foundation, foam plastic is better suited - an inexpensive and fairly rigid material that does not allow water to pass through.

Failure to comply with technology is costly!

Stone wool for the facade of a wooden house is installed after treating the walls with an antiseptic, which protects them from rotting. Before insulation, the surface of foam concrete and brick is cleaned of old paint and peeling plaster. The work of installing insulation is best done during the warm season on dry walls.

All window sills and door trims must be removed before installation. Since the thickness of the walls will increase after covering with mineral wool, you will have to buy new elements of window and door cladding.

Dry installation of insulation into the frame

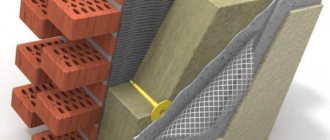

There are two ways to insulate with stone wool: dry and “wet”. The first involves the use of a wooden or steel frame (lathing), in the cells of which insulation is placed. In the second method, the slabs are attached to walls without a frame using glue and disc dowels.

"Wet" installation option

It should be noted that installation in a frame is most often used when constructing a ventilated facade. The lathing allows you to create a gap between the insulation and the outer cladding (4-6 cm), through which water vapor is released into the atmosphere.

The disc dowel is used for both dry and “wet” installation

Mineral wool is placed on glue and dowels in cases where a finishing layer (plaster, putty) will be applied to its surface.

How to determine the required thickness of insulation?

To determine the required thickness of the insulation layer, imagine the wall as a “sandwich”, in which there is a load-bearing part (inner), a heat insulator and an outer layer covering it. The formula for calculating the thermal resistance of a three-layer structure looks like this:

Rtotal = Rinternal + Rinsulation + Rexternal

where Rtotal=3.2 m² °C/W

(according to amendments No. 3 SNiP II-3-79 “Building heating engineering”).

The thermal resistance of each layer is determined by the formula

R=δ/λ

,

where λ

— thermal conductivity coefficient, W/(m °C);

δ

— thickness of the material layer, m.

Knowing the material of the wall (brick, cellular concrete blocks, beams, etc.) and its thickness, as well as the material and thickness of the finishing layer, having found out λ of both materials, you can calculate the thermal resistance of the internal ( Rinternal

) and outer (

Rexternal

) layers.

Next, you need to select insulation and find out its thermal conductivity coefficient λ

.

By substituting the previously obtained results and λ

of the insulation into the formula for calculating

Rtotal

, it is easy to find out how thick the layer of the selected insulation should be.

Rinsulation = Rtotal – Rexternal – Rinternal

whence δinsulation = (3.2 – Rexternal – Rinternal)/ λinsulation

But for accuracy, it is necessary to take into account not only the heat transfer resistance of the wall itself, but also heat loss through windows, doors, ceilings, etc., and therefore detailed calculations are much more complicated. The formula we have given may be more useful for preliminary calculations, so that you can determine the approximate volume of purchased materials.

Dry installation technology (ventilated facade)

When mounting the frame, its slats are placed so that the distance between them is 1-2 cm less than the width of the slab or roll of basalt wool. In this way, a tight installation is achieved. Work on installing the sheathing begins from the corners of the building, using a level and a cord to install the guides in the same plane.

The roll is rolled out from top to bottom. The slabs, on the contrary, are placed from bottom to top. Having filled all the rows of the sheathing with insulation, a vapor barrier film is fixed to it, which performs the function of wind protection. The joints of the film sheets are glued with construction tape. After this, holes are drilled in the wall and plastic dowels are hammered into them, securing the mineral wool and the wind barrier.

The next operation is to attach counter-battens (second sheathing) to the frame, creating a ventilated gap between the insulation and the outer cladding of the facade.

Design for dry wall insulation (ventilated façade)

The general rule for installing mineral wool slabs is to prevent the joints of the insulation from matching the corners of door and window openings.

Basalt slabs can be installed in one or two layers. It all depends on the selected thickness of insulation.

Some manuals suggest two-layer installation as a way to protect joints from blowing. In this case, the slabs are mounted so that the upper ones cover the joints between the lower ones. With this option, the sheathing has to be placed in two rows, perpendicular to one another.

With two-layer installation, maximum tightness of insulation is achieved

Requirements for the rough foundation

In order for the flooring material to serve the owners for the stated period, it is necessary to comply with the requirements for flooring under cork. More details:

1. The rough base must be perfectly level. A difference is allowed for each square. m no more than 2 mm. 2

It is important to waterproof the cork floor underneath with a special material with perforations to drain condensate. 3. Do not lay the plug on an unpolished concrete base.

Due to the pressure from above, the screed will rub the cork from below like sandpaper. A substrate is required.

Leveling the floor is not difficult - it is similar for laying all types of flooring.

Wet installation method

With this option, the main role is played by the glue that fixes the mineral wool slabs to the wall. It must have good vapor transmission so that condensation does not accumulate in the insulation. Be sure to take this point into account when purchasing. The market offers special adhesive compositions designed to work with stone wool.

The sequence of work using the wet method is visible in the figure.

Design for insulating walls with basalt wool and adhesive mortar

The installation of the slabs begins after installing the starting profile, which covers the slabs from below and prevents them from sliding until the adhesive composition sets.

A layer of glue is evenly distributed over the slab with a notched trowel and then pressed against the wall. Having installed a horizontal row, the insulation is additionally fixed with plastic disc-shaped dowels.

Having finished covering the wall, a layer of glue is also applied to the surface of the material and a fiberglass reinforcing mesh is embedded in it. Having leveled the surface with the rule, the solution is allowed to dry. The final operation is plastering.

Hardness index

The insulation is produced in three levels of rigidity:

- Soft stone wool is made from the finest fibers. It has a huge number of cavities that hold air. Soft stone wool is used to insulate building facades, frame walls, and roofs. That is, in places where there will not be much mechanical impact

- Medium hardness wool is made from medium fibers, they are stiffer. This type of insulation is used to insulate ventilation ducts, that is, where there is a strong air flow

- Thick and durable fibers of rigid stone wool. This insulation is used for heavy loads. It can be used to insulate walls at an intermediate stage of construction, before reinforcement, concrete screed, etc.

Manufacturers and prices

In recent years, a whole “cage” of manufacturers of high-quality stone wool has formed on the market. These are foreign brands Isover (Izover), Rockwool (Rockwool), Paroc (Parok). TechnoNIKOL competes with them on equal terms . Izovol have also earned a good reputation .

The range of products they produce covers all areas of insulation, from the basement to the roof.

For a correct comparison, consider the price for 1 m2 of insulation with a thickness of 10 cm for universal use, offered by different companies:

- Rockwool LIGHT BUTTS SCANDIC (37 kg/m3) 170-190 RUR/m2;

- Isover MASTER OF WARM WALLS (38-48 kg/m3) 160-200 RUR/m2;

- Paroc EXTRA (30-34 kg/m3) from 200/m2;

- TechnoNIKOL ROCKLITE (30-40 kg/m3) from 160/m2;

- Izovol L-35 (35 kg/m3) from 160/m2.

Comparison

In fact, mineral wool is a common name for a whole group of thermal insulation materials, which differ from each other in the basis for production:

- Slag;

- Fiberglass;

- Stone basalt wool.

Stone wool is a group of insulation materials, and basalt wool is a subtype. Quite often, stone basalt wool is used. If ordinary stone wool contains diabase, gabbro, waste slag, and mineral components that can make up about 35% of the volume of the product, then basalt mineral wool is produced practically without the use of additives or binding elements.

Therefore, the comparison suggests that basalt wool is preferable to stone wool, and mineral wool is a fair, general name for all such inorganic insulation materials. Therefore, any mineral stone wool can be called that.