Wooden buildings have low thermal conductivity and a beautiful appearance. However, under the influence of internal and external factors, unprotected material dries out, cracks appear in it, and cold air easily penetrates inside.

Measures to insulate a house made of timber outside and inside help prevent the problem, but they need to be carried out correctly.

House made of wooden beams.

The need for thermal insulation of the room

The procedure for insulating a building is required in those climatic zones characterized by harsh winters. Without it, the temperature in the room becomes uncomfortable for living.

Insulating walls allows you to reduce the cost of heating your home. The materials used in the work process have sufficient technical characteristics to protect the structure from the influence of external and internal negative factors, high humidity, and the development of fungus and mold.

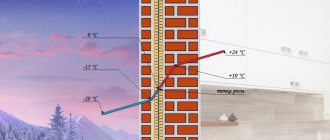

When warm and cold air come into contact inside the wall, condensation forms. When exposed to negative temperatures, it freezes and then melts. This process has a negative effect on the wood.

Thanks to external insulation, it is possible to shift the dew point to the surface of the cladding, so the wood is not damaged for many years.

Insulation methods

Methods for insulating a wooden house directly depend on the materials used for this. In modern construction, several types are used:

- Slabs made of mineral basalt wool are used most often. This material does not burn, is environmentally friendly, its use provides excellent heat and sound insulation. Low mechanical strength requires the construction of an enclosing structure, and high hygroscopicity requires covering mineral wool with special vapor barrier films.

- Expanded polystyrene boards (foam plastic). also found application in internal insulation. Their use is not recommended, as they can release substances containing styrene into the air. When burned, pressless polystyrene foam releases deadly substances: hydrogen cyanide and toluene diisocyanate. Therefore, you can only use extruded polystyrene foam, flammability class - G1. Insulation with polystyrene foam also requires a building envelope.

- Glass wool is a widely used insulation material. It has a lower price than basalt wool, but also has greater thermal conductivity. To insulate interior spaces with glass wool, only material specially designed for this purpose should be used, which should additionally be covered with films. Small particles of glass wool are very harmful to health, so installation is carried out only with skin and respiratory protection. Requires enclosing structures.

- Isoplat is a modern insulation material that consists of a layer of pressed flax fiber and fibreboard with a thickness of 12 to 25 mm. High mechanical strength makes it possible not to make powerful enclosing structures, and the environmental friendliness of this material allows it to be used indoors. The thermal conductivity indicators of Isoplat are worse, and the price is significantly higher than that of other insulation materials.

- Insulation with polyurethane foam. sprayed onto the surface - a modern excellent method that requires special equipment. Enclosing structures are needed for such insulation.

In this video you can see how a wooden house is insulated from the inside with polyurethane foam.

Features of house timber

The choice of thermal insulation for a home depends on the following characteristics of wood:

- Hygroscopicity. The material absorbs moisture from the air, both inside and outside.

- Changes in linear dimensions. Shrinkage of timber leads to a decrease in its thickness and width. When moisture is absorbed, the reverse process occurs.

You should not fix the insulation with glue: it does not have a sufficient level of elasticity to withstand changes in the size of the wood. The choice is influenced by how much the insulator costs.

What kind of insulation should this be?

Any interventional insulation - regardless of what material it is made of - must meet certain requirements. Let's get to know them.

Density and elasticity. The insulation must retain its original properties throughout its entire service life, and it must also compensate for the changing sizes of the cracks. An additional advantage will be the absence of shrinkage.

Safety

It is important that the material meets all sanitary standards and requirements.

Low thermal conductivity. Its indicator should not be higher than that for wood.

Resistance to various environmental influences

The material should not rot. It is also important that insects do not grow in it (good insulation materials have repellent properties).

The material must “breathe”, and this is important. The crowns should not be separated hermetically; the wood should “breathe”, absorbing and releasing moisture.

Interventional insulation for timber must be of high quality

Pros and cons of timber insulation

Internal thermal insulation can be carried out at any time of the year, but the procedure has disadvantages:

- due to the construction of sheathing for fastening the insulation, the usable area of the room is reduced;

- the natural beauty of the walls is hidden;

- the dew point moves inward at the base.

External insulation is more suitable for a wooden house. It does not lead to a reduction in the area of the rooms and helps protect the façade of the building. Installation work is carried out in dry and warm weather.

External insulation of the house.

Mineral wool

And yet, most developers use mineral slabs . Basalt insulation is not much different in its thermal insulation characteristics from the same polystyrene foam and at the same time does not exceed it in price.

Yes, mineral wool is an allergen, and it is afraid of moisture, but these shortcomings can be easily eliminated. But environmental cleanliness, vapor transparency and the ability to carry out installation independently are constant factors and they are what allowed basalt slabs to gain well-deserved popularity.

If your home really needs thermal insulation, and your budget does not allow you to invest in spray insulation, mineral wool is your chance to protect your home from frost.

Description of materials for thermal insulation

Roll and slab materials are used to insulate the structure. They must have the same vapor permeability as wood, be moisture resistant and fireproof.

Mineral wool and similar materials

Stone, slag and glass wool are used for thermal insulation of wooden structures. All varieties reliably protect the house from heat loss.

The choice of product is influenced by its density, the level of humidity in the region, and the method of cladding the building. For installation outside, slabs measuring 50*100 cm are suitable. Their density is 65-80 g/cubic. m. For a wooden house it is better to use stone wool.

It has the following advantages:

- fire resistance;

- low thermal conductivity;

- average level of hygroscopicity;

- soundproofing properties.

The material absorbs moisture over time, its technical characteristics deteriorate, so you need to place the cotton correctly.

Insulation of walls with mineral wool.

Extruded polystyrene foam (EPS)

Expanded polystyrene is made from a polymer mass passed through an extruder. The boards are resistant to negative temperatures, provide good insulation, and are environmentally friendly. They are suitable for insulating a house built from timber with a cross-section of 150x150 mm.

Extruded polystyrene foam does not allow steam to pass through, so if installed incorrectly, condensation accumulates on the surface of the wood, and it begins to rot. The material is also flammable.

Extruded polystyrene foam is resistant to negative temperatures.

Wood-based isoplat (slabs)

Isoplat plates are produced on the basis of coniferous microfiber. There are no resins, glue or chemical binders in their composition. The products fit tightly to the base, are resistant to mechanical damage, and do not shrink over a long period of use.

The material allows steam to pass through, so the development of fungus, mold, and rotting processes is excluded.

Thanks to additional paraffin impregnation, the boards are resistant to atmospheric moisture. They are not afraid of temperature changes. The material of minimal thickness provides good noise insulation. Its service life is 50 years.

Isoplat does not rot.

Foam plastic and analogues

Polystyrene foam is made from polymer. The slabs provide reliable thermal insulation (if you choose the appropriate thickness), are inexpensive, and are easy to install.

Instability to ignition and low vapor permeability are the main disadvantages of polystyrene foam. When using it, the organization of an effective ventilation system is required.

Folgisol - foil-based insulation

Folgizol is a rolled material. Its basis is fiberglass. The product contains rubber-bitumen binders and mineral filler. The canvas is treated with an antiseptic.

The foil layer reflects heat and repels moisture. The insulation is easy to install, but it requires sheathing. The material is resistant to negative temperatures, suppresses noise, and has a long service life.

Folgisol based on foil.

Polyurethane foam (sprayed)

The insulation of the facade with sprayed polyurethane foam is justified by the fact that the material has good adhesion to the base and is safe for humans.

Installation work is carried out quickly. After hardening, the polyurethane foam forms a monolithic protective layer. There are no air pockets between the wall and the insulator.

Spraying the substance requires special equipment, so installation work cannot be called cheap. In addition, you need to be careful when using material for insulating wooden houses, because the timber underneath begins to rot, reducing the service life of the structure. Before using sprayed polyurethane foam, careful treatment of wood with protective compounds is required.

Spraying polyurethane foam on the walls of a wooden house.

Foam polyethylene

Polyethylene foam has a cellular structure, does not contain toxic components, and is highly durable and flexible. It is used to insulate a log house from the outside.

It provides good thermal insulation, does not lose its qualities under the influence of negative temperatures, and is resistant to aggressive substances. The material is characterized by low mass, but has a low level of vapor permeability.

Polyethylene foam provides good thermal insulation.

Warm plaster

Warm plaster contains cement, glass, plasticizers and hydrophobic components. The layer protects the building from the cold, does not burn, does not collapse under the influence of direct sunlight, and has a good decorative effect.

The finish is easy to repair.

Before applying it, you need to wait for the house to shrink, otherwise the plaster will quickly crack.

SIP (Structural Insulating Panel)

Structural panels are used for cladding facades. The material consists of several layers connected to each other using polyurethane adhesive under pressure. It is based on wood chips and resins.

The slabs are durable, resistant to moisture and rotting processes, provide a decorative appearance to the facade, and a good level of thermal insulation. They can be used in the temperature range -60…+60 ºC.

The panels are fire resistant, environmentally friendly and durable.

Finished with structural insulation panel.

How to insulate a house using the ventilated facade method: step-by-step instructions

Ventilated facade technology, which was tested on brick buildings, has recently begun to be used for thermal insulation of wooden buildings. The technology ensures proper steam exchange. In general, the design of a ventilated facade looks like this:

- supporting structure

- insulating layer

- steam and windproof membrane

- forced ventilation

- external finishing

The frame is a lattice structure - purlins. For wooden houses it should be made of wood so as not to interfere with breathability. Step-by-step instructions will help you consider in detail the sequence of actions in the location of the ventilated facade: Insulate the walls of the house in this order:

- Installation of a vapor barrier.

- Purlin frame installation.

- Installation of insulation.

- Install another layer of vapor barrier.

- Finishing work

All steps must be completed in order.

Vapor barrier

If the thermal insulation material is a material without a film, then the vapor barrier can be laid after the preparatory work. The main purpose of a vapor barrier is to prevent moisture condensation on walls during large temperature fluctuations. The most common vapor barrier material is vapor barrier film. It provides the desired effect at a low price. If you install a high-quality vapor barrier, it will eliminate excess moisture. Mold and mildew will not spread. The life of the entire wall structure will be increased many times, and a normal microclimate will be established in the house.

By the way! It will be interesting to know: How not to spoil a wooden house by insulating walls under siding

Installation of the sheathing frame

Before laying the battens, it is necessary to get rid of all protruding corners. This is necessary for uniform distribution of thermal insulation. Next, you need to make racks in the shape of the letter “L”. They are made as follows:

Laying insulation

The selected thermal insulation material is placed on the sheathing. The tools that will be required during work depend on the material chosen. For example, pollock is fixed with special anchors, polystyrene is fixed with good water-repellent glue. The material must be placed tightly. In case of voids and gaps, they should be covered with small cut-outs of the same material. If the holes are very small, it is better to use polystyrene foam.

Installing a second layer of vapor barrier

A second layer of vapor barrier is used to enhance the effect and strength of the structure. By installing a second layer, you can reduce moisture condensation and increase the life of the insulation.

Finishing work

After installing the second layer of vapor barrier, finishing work is necessary for the aesthetic appearance of the walls of the room. The material for finishing work is selected in accordance with personal taste and the desired design of the room. The most economical option is to use GFB (gypsum board) as a finishing material. After using plaster and regular wallpaper.

What happens to the timber after laying it on top of the heat insulator?

When using vapor-tight heat insulators, the timber absorbs moisture from inside the rooms. The partial pressure inside the wood increases and steam molecules escape to the periphery.

From the open side they again enter the room, and from the outside they accumulate. This exchange process can last for years, but leads to the formation of a water film on the timber and insulation.

Over time, rotting processes begin and fungus begins to multiply, so it is better to use vapor-permeable materials.

New and old thermal insulation technologies

In the past, moss was used to insulate walls. At that time, there were no special requirements for the decorativeness of the facade of the house. After laying in the crack, the moss grew and filled the entire space. Since the houses were built from massive logs, no additional internal insulation was required.

Today, timber is used for construction, the cross-section of which does not always provide good thermal insulation properties. To maintain a cozy atmosphere in the premises, it is necessary to insulate the structure with modern materials.

Work progress

To ensure complete thermal insulation, one caulk is not enough. It is necessary to insulate the walls of the entire structure. The modern market offers a wide selection of various thermal insulation materials, the most affordable of which are mineral and stone wools; it is quite possible to install them yourself.

Lathing

To attach soft or lightweight hard insulation with your own hands, you must first equip the frame. To do this, a vertical or horizontal sheathing is placed on the wall surface, in which the guides are placed at a distance of 40 - 50 cm.

Depending on the thickness of the insulation layer, the geometry of the bar or board for the frame ribs is also selected. So, to lay a layer of 50 mm, it is best to make a frame that protrudes from the wall by 70 mm, which ensures the formation of a ventilation gap.

First, the corner elements of the sheathing are created. A 50x50 mm timber strip is attached to the rib at an angle of 90°. Such elements are placed in all corners of the room and, after checking the location according to the level, they are attached to the walls. The remaining space is marked for the selected number of sheathing ribs. It is advisable to treat all frame elements with antiseptics to prevent rotting.

Moisture protection

Before installation, the entire frame is covered with waterproofing film, which is attached with the smooth side to the wall. The film is laid horizontally and the seams between the cuts are insulated with special adhesive tape.

Then insulation is placed in the frame and a vapor barrier is applied on top of it to protect against internal moisture. Before installing any type of waterproofing, you must carefully study the instructions, since an error in the location can lead to the insulation getting wet and losing its properties.

The gap left will facilitate natural ventilation and evaporation of condensate. Next, the entire frame is covered with any finishing material.

Laying insulation

After creating the frame, the heat-insulating material is cut into strips or sections 2–3 cm wide greater than the distance between the guides and placed between the frame elements. Sometimes additional fastening of the insulation with special polymer anchors is used. This technique ensures a tight fit of the material to the frame and reduces its subsidence.

What is the best way to insulate: outside or inside?

Before applying insulation on the outside of the house, it is determined whether it is necessary to insulate the house from timber inside. Fastening the material indoors is required if the area is characterized by severe winters.

Still, it is better to use external insulation. This method increases the speed of installation, expands the choice of materials, and does not require changes to the interior decoration.

The only advantage of installing insulation indoors is the ability to carry out work at any time of the year. However, there remains a risk of condensation appearing on the wood, under the influence of which it is destroyed.

It is recommended to insulate the walls from the outside.

Why do you need inter-central insulation?

What benefits does using such insulation provide? Let's look at some key points.

- Linear changes in timber dimensions that occur annually are compensated. This insulation is plastic; it expands when the gap increases, and therefore heat loss is eliminated.

- Protecting the premises from street noise. This characteristic is directly related to the thermal conductivity of the material.

- Increasing the service life of the building. Moist, cold air can penetrate through the cracks, causing moisture to condense on the timber. It takes a long time to dry, and therefore the wood will deteriorate faster. It will begin to rot, mold will appear, and as a result, the strength of the wood will deteriorate (this can even lead to critical deformations of the house). Repairs in this case will be difficult and expensive, and also – it is possible – ineffective.

- Heat saving increases. This point is especially important in view of the permanently rising fuel prices. Sometimes the use of inter-crown insulation makes it possible to do without external wall insulation, and this, again, saves money.

Installation of interventional insulation

Interventional insulation comes in various types

Preparation of material

Experienced builders know how to properly insulate a house made of timber, and strongly recommend fastening the material only after the natural processes of shrinkage of the house have occurred. This takes 1-2 years. The structure is inspected for cracks and other defects.

Treatment of timber with impregnations and antiseptics

To prevent rotting processes, protect the base from fungus, mold, and damage by insects, it is treated with an antiseptic. The product is applied 2-3 times.

To increase the resistance of the timber to fire, it is impregnated with fire retardants. The work is carried out with a roller or wide brush. Each previous layer must be absorbed before applying the next. This work should not be performed in hot weather or in direct sunlight.

Treating wood with an antiseptic.

Working with wall surfaces

Before insulating a house made of timber from the inside or outside, the walls are carefully inspected for irregularities. You can get rid of the latter using a plane. The surface is cleaned of dust. If there are cracks in the walls, they need to be caulked.

Insulation of a wooden house with isolon. Material selection

What is the best way to insulate floors in a wooden house? Insulation materials can be divided according to the method of working with them:

- Bulk (these are sawdust, slag, expanded clay, foam glass).

- Bulk (polymer mixtures).

- Rolled (penofol, flax, mineral wool, glass wool, isolon, cork).

- Tile (foam plastic, penoplex, gypsum fiber, linen in mats, basalt wool, mineral wool in blocks, foam glass).

- Sprayed (ecowool, penoizol, polyurethane foam).

Ecowool floor insulation

How to choose

Humidity. Glass wool, gypsum fiber board and flax are not recommended for use if there are problems with high humidity in the room, or they need to be carefully waterproofed.

Thickness. If the ceiling is low and you need to make the insulation layer as thin as possible, you should choose: self-leveling option, penofol, isolon, cork, or sprayed materials.

Price. With limited funds, you can opt for polystyrene foam, mineral wool or sawdust.

Some disadvantages of materials that you need to know about in advance:

- All mineral wools cake over time and begin to conduct heat better; in addition, you need to work with them while protecting your nose, eyes and throat, since their particles injure the mucous membranes.

- Rodents often settle in layers of glass wool, polystyrene foam and other popular insulation materials, nullifying their effect. Only ecowool, foam glass, foam concrete and expanded clay are resistant to rodents. Polyurethane foam (PPU) is also classified as a material that is unattractive to rodents.

- Sawdust is a wonderful place for life not only for rodents, but also for insects. Over time, they dry out greatly and can be susceptible to mold and rot. To prevent these troubles, cement, lime, boric acid, etc. are added to sawdust.

- Sprayed materials are good for everyone, except for the high cost and difficult application technologies.

- Expanded clay protects against cold almost twice as bad as, for example, mineral wool. Accordingly, its layer should be twice as thick. The weight of the structure will be impressive, so it is recommended to use expanded clay only on the ground floor.

Subtleties and rules

The choice of insulating material is influenced by its technical characteristics and service life. It is better to use natural-based insulation.

Installation of lathing and frame

To form the frame, wooden slats and bars are used. The lathing should not interfere with the free circulation of air between the insulation, the base and the finishing.

Before installing the frame, remove protruding corners and measure the walls. The length of the vertical elements must correspond to the height of the base.

Self-tapping screws are used to secure the frame. The vertical elements have a cross-section of 50*10 mm, and the horizontal ones - 50*50 mm. All bars are treated with protective agents.

Lathing the house for subsequent upholstery.

Ventilation of timber

Ventilation allows you to eliminate condensation and get rid of excess moisture both inside the room and between the finishing and the heat insulator.

The best place to install the system is the attic. By installing a fan, air circulation is activated. As for the exterior finishing, when laying insulation and cladding, gaps of 1-2 cm are left.

Steam and waterproofing

The main function of a vapor barrier is to protect the base and surface of the insulation from the accumulation of condensate. The film is distributed around the entire perimeter of the house.

The canvases are fixed with an overlap of 10 cm on each other. This layer is installed after screwing the spacer rails.

Construction staples are used for fastening. When using ecowool or penofol as insulation, vapor barrier can be abandoned.

After installing the material, a waterproofing film is fixed on top of it. You need to attach it to the sheathing using a construction stapler.

Features of floor insulation

To lay insulation on the floor, you need wooden logs with a cross section of 15*15 cm. Thanks to the procedure, you can achieve a reduction in heat loss by 20%. Mineral wool and expanded polystyrene are often used for work.

The old floor covering is dismantled. If it was attached to joists, then they are inspected and the shortcomings are eliminated.

After preparing the base, a moisture-proof film is laid on the wooden elements, and the selected material is placed between them.

If work is carried out on the ground, then the base is first filled with a cement screed. After a month, waterproofing is laid on it and insulation is attached.

Floor insulation.

Ceiling insulation

Thermal insulation of the ceiling is necessary if the house is located in an area with difficult climatic conditions. For work, polyethylene foam, mineral wool, expanded clay, and sawdust are used. Before installing the insulation, a frame is made on the base.

Corners of the house

Corners are the weak points of a wooden house, because they are most exposed to the wind. You need to take care of their insulation even at the construction stage. To do this, the timber is connected using a tongue-and-groove system. After this, the insulation process is no different from the wall treatment technology.

Nuances for internal insulation

Since you need to properly insulate a house made of timber from the inside, you should choose the appropriate material. You should not use polystyrene foam as it is not vapor permeable.

Fiberglass materials and stone wool are more suitable for work. They do not interfere with air exchange, but provide reliable thermal insulation.

It is better to attach natural materials to wood. They do not harm human health, do not worsen the indoor microclimate, and ensure long-term operation of the house.

Internal wall insulation with environmentally friendly materials.

Timber as a building material for cottages

Options for timber are divided depending on the shape of the logs and types of joints. Most often, the following types of timber are used in the construction of log structures:

- Planed. The cross-section of the log has a rectangular or square shape. Such timber can be purchased at a low price. But it is unreliable: the logs can become deformed and cracks appear in them. In addition, such timber is susceptible to rotting over time.

- Profiled. The cross-section of the timber does not differ from the previous version. But the surface compatibility of profiled logs is better. With such material it is possible to assemble a structure using the “tenon and groove” technology. Such log houses have no cracks.

- Glued. The timber is assembled using glue. It helps to tightly hold the logs together and protects the wood from microorganisms. These materials are expensive.

Required Tools

To work you will need the following devices:

- plumb line, building level;

- square, metal ruler, measuring tape;

- hacksaw, knife;

- hammer;

- screwdriver;

- construction tape;

- sprayer for applying protective compounds to the base (to carry out the procedure manually, use a wide brush).

Markings on the tree are made with chalk. Dowels for the facade, dry slats, and facing materials are also required.

Methods of external insulation with a description of the work

To insulate the facade, different methods of attaching the material are used. The most popular technologies are curtain and wet façade and “well” thermal insulation.

Wet facade technology

The installation of a “wet” facade involves installing insulation boards on the base surface using self-tapping screws. After this, an adhesive composition is applied to the layer and the reinforcing mesh is fixed.

First, strengthen the corners, and after a day - the remaining surfaces. Decorative plaster is applied over the reinforcing layer. If paint is used to finish the facade, then its surface is leveled with putty. To fix the insulation, special metal plumbs are used.

Wet facade on a frame house.

Ventilated curtain façade

A curtain wall is used to simultaneously insulate and decorate a home. The design has a long service life, is quickly installed, and is characterized by a wide range of colors. When installing panels, the dew point moves outward.

Installation of products involves the following steps:

- Treatment of the base with antiseptics and fire retardants.

- Attaching the sheathing. A windproof membrane and waterproofing are fixed on it. This will allow for efficient condensate drainage. When screwing wooden planks, you need to monitor the horizontal and vertical levels of the structure.

- Installation of slats. The step between them is equal to the width of the insulation and is at least 70 cm.

- Laying the heat insulator. If mineral wool is used, dowels with round heads are required to fix it.

- Screwing the bars for laying the facing layer. A gap is left between it and the insulation.

Siding and lining are used for finishing.

With a ventilated curtain wall, there remains a gap between the insulation and the cladding.

Insulation with a “well”

The “well” insulation method involves finishing the house with brick. Insulation is laid between the facing and outer surfaces of the wall.

During installation, follow the following procedure:

- Prepare the base and materials.

- Roofing material is laid on the foundation, which extends 15 cm onto the load-bearing wall.

- Install the first row of insulating boards. They are secured using hangers or dowels. At the same stage the brick is laid.

- Mount metal rods along the upper edge of the insulation. The material is pre-treated with an anti-corrosion compound and launched onto the brickwork with the free end. The installation step is 40-60 cm. The rods will prevent the cladding from collapsing, moving outward or inward.

All manipulations are repeated with the second row of heat insulator.

Insulation using brickwork.

Recommendations for carrying out warming measures

To provide a building with a high-quality insulating coating, it is important to follow certain recommendations from experts:

- Purchased insulation for finishing external walls should be stored in a dry place, in packaging, so that moisture suddenly penetrating into it does not affect the performance characteristics of the material.

- The slabs can be secured not only with fasteners, but also in another way. To do this, the sheathing slats are located closer to each other: their width should be 15-20 mm less than the size of the materials used.

And remember that when working with insulating materials, you need to take care of your own safety by wearing goggles, gloves and a respirator.

Stages of insulating a timber house from the inside

To properly insulate a house made of profiled timber, it is necessary to follow the sequence of work.

Clogging cracks

Before caulking the cracks, the walls are cleaned of dirt and old spoiled insulation. Carefully inspect the joints of the timber and the corners of the building.

The cracks are clogged after treating the surface with protective compounds.

The procedure is carried out a year after the structure shrinks, and then every time the heat insulator is replaced. Jute fiber is used for work. Clog the gap with a chisel until the material no longer fits.

Caulk the cracks with tow.

Laying vapor barrier

The vapor barrier will prevent the insulation from getting wet, but the humidity level inside the room will increase, so installation of a ventilation system is required. The film is placed with the smooth side facing the base. Metal brackets are used for fastening.

Installation of sheathing

For a wooden house it is better to use sheathing made of the same material. First, install vertical slats in the corners and around the perimeter of the room.

The distance between them should be 1-2 cm less than the width of the selected insulation. The lathing will not only allow you to attach the insulation, but also form a ventilation gap. The cross section of the slats is 5*2 cm.

After this, a vapor barrier is attached to the base, and horizontal strips are placed on top of it.

Preparing the sheathing for insulation.

Laying thermal insulation

If mineral wool is selected, its sheets or slabs are placed between the sheathing elements. For fastening, anchors with large round caps are used.

After filling the entire sheathing, another layer of vapor barrier is fixed on top of the insulation. This time the smooth side of the material is directed indoors. The joints between the panels are sealed with construction tape.

Fastening mineral wool to the sheathing.

Ventilation system

For normal air circulation in the rooms, it is necessary to leave a gap between the wall and the insulation layer. It is 3 cm. In addition, a single air duct system with outlet to the attic should be organized. To improve circulation, use a low-power fan.

Finishing the walls

To clad the walls on top of the insulation, another frame is mounted. It is made from bars with a cross-section of 3*4 cm. Wooden lining or plasterboard is used as finishing. If the second option is chosen, then the base will have to be additionally puttied and painted (covered with wallpaper).

Whether it is necessary to insulate a house made of 200x200 mm timber determines the purpose of the building and what type of building material is chosen. When using glued elements, the thermal insulation procedure is optional. Houses made of profiled timber need additional protection.

Preparatory stage

You need to start by assessing the condition of the walls and the quality of the previously completed work on insulating the log house. It is necessary to carefully examine all the joints, corners and joints of the beams, and evaluate the compaction of the entire surface of the log house walls. If any defects are detected (for example, thinning of the caulk layer), they must be eliminated in advance.

Caulking walls

Any timber structure is distinguished by a large number of seams. After the building shrinks and the moisture content of the wood equalizes, voids may form in the grooves and seams, which reduce the ability of the entire structure to retain heat. That is why caulking is so important, allowing you to completely isolate the inter-crown joints.

Carrying out such work requires compliance with several rules:

- the caulking must be carried out from below and processed one crown from all sides at the same time, otherwise the building may warp;

- It is important to choose the right tool, because the chisel should not damage the wood;

- Taking into account the formation of a narrow groove between the timber, it must be processed “stretched”.

This type of caulking is carried out by stretching fibers of tow, moss, jute or their analogues along the seam. Part of the material is left out and after processing the groove, it is rolled into a roller and pushed in, completely covering the space between the rims.