Home / Heating

Back

Published: 12/18/2020

Reading time: 3 min

0

1453

The question of what is the difference between a hydraulic accumulator and an expansion tank remains unclear to some consumers, although such equipment has been used in boiler houses for quite a long time.

Water supply and heating systems cannot be imagined without such successful additions; most people are accustomed to distinguishing these devices by their shade.

One of the units is available in blue, and the other in red, but their structure has its own nuances. I want to analyze in detail the differences between the devices and describe the purpose of installing each type of device.

- 1 Design and purpose of the expansion tank

- 2 Design and purpose of the hydraulic accumulator

- 3 What are the differences 3.1 How does the expansion tank work

- 3.2 How a hydraulic accumulator works

Purpose of the equipment

Design of the expansion tank

The expansion tank is used in the heating system of private houses. Its functional responsibilities are to compensate for the expansion of water or other coolant. The liquid pumped into the heating of the house, when heated, begins to expand in volume, creating increased pressure. In order not to break the network elements, an expansion tank is installed, where excess heated water is collected.

A hydraulic accumulator is an element of the water supply system of a private house. Its functional purpose is to create pressure inside the network when the pumping unit is not working.

The tanks are painted in different colors: the expansion tank is red, the hydraulic accumulator is blue.

Design and purpose of the expansion tank

This device consists of elements that I want to list, which will help in the future to understand the function of the unit for the heating system. The design includes:

- Connection pipe.

- Membrane.

- Working cavity.

- Gas tank.

- Air nipple.

The principle of operation of the device is quite simple; it is aimed at compensating for the expansion of the coolant due to the free space, which is separated by a special device made of soft rubber.

Without this tank, the hot water supply system going to the radiators could be subject to various breakdowns; the maximum permissible pressure value when heating any liquid in the wiring increases according to the laws of physics.

I always give an example for better clarification, in order to highlight important points as accurately as possible, it looks like this: if water is heated to 100 degrees, its volume will become 4.3% larger.

An increase of 1 degree without taking into account the deformation of the pipeline can increase the pressure by 3 bar, which, with significant changes, will be detrimental not only to the boiler, but also to the radiators.

All connections will inevitably depressurize over time, and the liquid will form a flood; this will be a rather unpleasant phenomenon in any home, which will lead to forced repair of the floor covering.

Design features

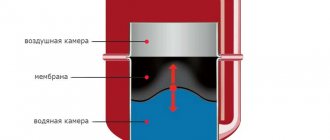

In terms of appearance, both tanks differ from each other only in color. They are available on the market in horizontal and vertical versions. As for the internal filling, the devices consist of a steel tank with a membrane inserted inside.

Since the expansion tank is used in a hot water system, the membrane in it is made of polymers that do not change their technical characteristics when in contact with hot liquids. Manufacturers use EPDM, SBR, butyl rubber and nitrile rubber for this.

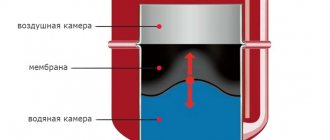

Membranes are also used in hydraulic accumulators. But they differ in the form of their execution. In these containers, the demarcation material is presented in the form of a pear. In expansion tanks, this is simply a partition dividing the container into two parts.

The water in the hydraulic accumulators enters the bulb without coming into contact with the walls of the steel tank. Here, the starting material for the membrane is food grade rubber.

We suggest looking at water supply tanks “under a microscope”

Let's move on to the second point, namely hydraulic accumulators, in other words, drinking water tanks. Quite often, experts call them hydraulic accumulators for water supply. What is the scope of their application and its nuances?

1. Firstly, to ensure adequate supplies of water and appropriate pressure at the proper level. It is the hydraulic accumulator that should say “Thank you” for turning on the pump, not in situations where someone simply wants to fill a glass of water, but only when the pressure level drops below normal. Without any doubt, this is what allows you to significantly increase the service life of the pump. Plus, when purchasing a hydraulic accumulator of different volumes (for example, 100, 200, 300 liters, and so on), you can achieve a water supply, which is never superfluous.

2. Secondly, it is the hydraulic accumulator that is designed to provide a decent level of protection of the system from water hammer. The latter can appear if you turn the pump or tap on/off quickly enough. As a result, water hammer is a real risk of pipeline breakthrough, which reduces the service life of the valves.

Source

Principle of operation

How the expansion tank works

The expansion tank works simply. The coolant, expanding, enters the lower part of the container, filling it. If the volume of water increases, it puts pressure on the membrane, pushing the latter towards the walls of the second upper part of the container. Therefore, it is very important to accurately select the tank in the ratio of its volume to the volume of coolant located inside the heating system of a private house.

Everything happens exactly the same way during water hammer, only many times faster. It is the expansion tank that makes it possible for other elements of the heating system not to fail when the coolant heats up quickly.

The hydraulic accumulator works almost the same way, but air is pumped into it, or more precisely, into the space between the rubber bulb and the walls of the container at a certain pressure. It creates pressure inside the water supply network. It all happens like this:

- The water pumped by the pump enters the pear.

- The latter expands, squeezing the air pumped in at the factory.

- The latter presses on the bulb, pushing out water.

The hydraulic accumulator has two main functions:

- Having a certain volume, it allows the pump not to turn on when a consumer is opened. As long as the water in the pear is under pressure from the pumped air, there will always be pressure inside the water supply. As soon as the water and air pressure are equalized, the pumping unit will immediately turn on.

- The hydraulic accumulator creates constant and stable pressure inside the pipes of the water supply system. Accordingly, all household appliances, especially washing machines and dishwashers, work without failures.

Large volume hydraulic accumulators, ranging from 50-100 liters, mean an additional volume of water that is under pressure all the time. This is convenient in cases where the power supply is turned off and the pump simply cannot pump water. In suburban villages this phenomenon is not uncommon.

The hydraulic accumulator, like the expansion tank, well holds back hydraulic shocks of the plumbing system, protecting it from breakdowns.

What is a hydraulic accumulator?

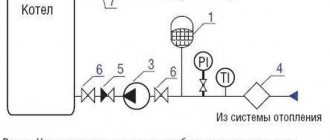

For a better understanding, I will immediately show you a picture showing a pumping station:

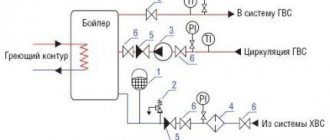

From the picture you can see that a hydraulic accumulator (abbreviated as HA) is a container to which a pump with a pressure switch is attached. Inside, this container is designed in the same way as a membrane expansion tank. Moreover, they often have exactly the same EPDM membranes. The air pressure in the HA is also 1.5 bar and, if desired, it can be increased or decreased. Many installers use hydraulic accumulators instead of expansion tanks in closed systems. It’s not uncommon to see photos like these on the Internet:

In addition to horizontal GA models, stores have their vertical counterparts. They are most often used to assemble a pumping station based on a deep-well pump. A separate article has been written about the need for this.

Why do you need a hydraulic accumulator?

This “device” has two main functions:

- It is necessary for the correct operation of the pumping station automation. This applies not only to the pressure switch, but also to some pump control units. For this function, the tank volume is not particularly important. For example, miniature pumping stations with a vortex pump have a tank volume of 1 liter.

- Reducing the number of pump starts - this helps reduce the negative impact of starting currents and save energy. For this function, volume is most important. If you need a full-fledged buffer container with water, then you need to choose a capacity of 80, 100 or more liters.

Based on what was written above, we can say that the choice of a hydraulic accumulator is not strictly tied to the parameters of the water supply system. But this does not mean that you need to buy the first one you come across. For example, if your pumping station will operate in conditions of high humidity, then it is better to purchase a hydraulic pump made of stainless steel. This will significantly increase its service life.

That's probably all. I look forward to your questions in the comments and likes on social networks. See you again on the pages of this blog!

znayteplo.ru

Other Features

Hydraulic accumulator design

The differences between the two devices must also be approached from the perspective of the possibility of replacing them with each other. Here we must take into account the fact that the accumulator is used in a drinking water system. Therefore, its pear-shaped membrane is made of food-grade rubber, which does not spoil the characteristics of the water itself, does not change its color or smell. It is not worth installing an expansion tank in the water supply, because its membrane will first of all transmit the pungent odor of rubber to the water.

The main function of the accumulator is to create pressure inside the water supply. This cannot be done using an expansion tank.

Using a hydraulic accumulator as an expansion tank is possible. But there is one point that concerns the pressure of the pumped air. In a heating system, the coolant moves at a low speed created by a circulation pump. This pressure is not enough to overcome the pressure of the pumped air. This is where a problem may arise. It’s not difficult to solve: the air needs to be vented (bleeded). At the top of the tank there is a nipple through which air can be pumped into the chamber with a conventional air pump. Air can be vented through it.

The volume of the expansion tank is selected based on the volume of coolant in the heating system of a private home. The ratio is 10% of the water inside the heating.

As for the hydraulic accumulator, there are no such strict parameters when choosing it. More often, its functionality is taken into account, because, in essence, it is a container for storing water. Therefore, the larger the device, the better.

Design and purpose of a hydraulic accumulator

Such equipment has its own structural features, which I can also list, the device includes:

- Air nipple.

- Membrane.

- Metal body.

- Gas cavity.

- Working tank.

- Hole for connecting fluid inflow.

According to most owners, the blue color of the body implies the function of storing water, but this unit performs not only this operation.

I would like to note the frequent occurrence of pressure fluctuations in the water supply system; during the operation of a powerful pump, water hammer may occur; all these excesses are successfully damped by the device, meanwhile protecting the pipeline, fittings and taps from rupture.

I have always assured users that with such a device it is possible to significantly extend the life of the pump, because it will turn on less often. The hydraulic accumulator has a simple structure, but thanks to its operation, a lot of problems can be avoided.

Since the volume of the tank is filled with drinking water, its contact with the metal body will cause unpleasant deposits of rust and other substances harmful to human health, so a special membrane was invented inside the device.

Such an element is more susceptible to deformation, which is different from an expansion heating installation, which is created from the most durable material.

Installation rules

This is the only position that does not differ between the two tanks. Typically, both containers are connected to the pipework using American connectors, making the connections detachable. This makes it easy to disconnect the device if it needs to be repaired or replaced with a new one.

As for the installation location, there is no difference here either, if the heating system has a circulation pump in its circuit. If the heating network is gravity-flow, the coolant in it moves under the influence of physical laws (heated up, cold down), therefore the installation location of the expansion tank is the highest point of the heating circuit.

The first thing you need to pay attention to when choosing a hydraulic accumulator and expansion tank is the color of the tank. This is the factor that will prevent you from making a mistake. The remaining characteristics are selected for each network separately, taking into account their complexity and performance.

Prevention

We recommend conducting diagnostics for the presence of bleed air and the integrity of the hydraulic tank membrane annually. In the second case, the hydraulic accumulator ceases to act as protection against water hammer. The membranes are sold separately and can be replaced in a couple of minutes.

Let's summarize. The hydraulic tank easily provides water to a cottage or country house, while protecting the water supply system from water hammer, leading to breakdowns, and premature wear of equipment. This will make it possible to use water without thinking that it may run out or something will happen to the equipment.

Different functions - different devices

The fundamental difference between a hydraulic accumulator and a compensation tank is determined by functionality. The hydraulic accumulator is designed to protect water supply systems, the expansion tank is designed to compensate for the thermal expansion of water. Different tasks place different demands on the design of units, so do not be deceived by external similarities.

The main task of the expansion tank is to maintain stable pressure in the heating circuit, adjusted for the thermal expansion of water. Liquids, like gases, increase in volume when heated, but are not able to compress. When the water becomes crowded, it strives for freedom, regardless of obstacles. The ending is predictable: a leak at the joint or a pipeline rupture. To prevent accidents, it is necessary to install a compensating tank in which excess water is collected.

The hydraulic accumulator performs protective functions in the water supply system , compensating for pressure drops in the network when the pump is turned on and off. This way it is possible to avoid water hammer, which shortens the life of the system. In addition, pumping equipment cannot operate continuously, so it is important to have a supply of water in case of a sudden power outage or pump breakdown.

At the same time, the hydraulic tank maintains sufficient pressure in the system during downtime of the pumping equipment. Until the pressure in the network drops to a critical level, the pumps rest - there is no need to start them every time someone opens the tap. The less on and off, the longer the pump will last. Of course, not all hydraulic accumulators are equally effective in their jobs - it is important to choose the right unit and accessories for the tank, taking into account the characteristics of the pumping equipment, the number of water points and the estimated water flow in the system.

On the Internet you can find formulas for determining the optimal volume of a water storage tank, but sometimes adjustments need to be made to the calculation methodology for operating conditions. For example, in case of frequent power outages, the volume of the vessel is selected with a reserve - but just enough to prevent stagnation of water. If you do not have enough knowledge and experience to take into account all the nuances and install the hydraulic tank yourself, contact specialists for help.

It's all about the membrane: design differences between hydraulic accumulators and expansion tanks

At first, the compensation tanks were made open, but later it turned out that such an engineering solution created new problems. Firstly, water constantly evaporates, and its losses need to be replenished. Secondly, no one has canceled the corrosive effect of oxygen. Thirdly, in open circuits it is more difficult to control the pressure. Finally, installing the tank costs a pretty penny, since the structure has to be insulated.

The emergence of durable and elastic membrane materials suggested a way out of the engineering impasse, making it possible to manufacture closed expansion tanks that do not allow oxygen to pass through. The problems of maintaining a constant water level and regulating pressure were solved in a similar way. In addition, the closed design has simplified the installation and maintenance of expansion tanks - from now on the unit can be installed not only at the top point of the system, but where it is more convenient for you.

The diaphragm membrane divides the capacity of the compensation tank into two parts. The upper compartment is filled with coolant, and air is pumped into the lower compartment, tightly pressing the diaphragm to the walls of the tank. An increase in the volume of coolant when heated compresses the air, allowing water to flow into the upper compartment of the tank.

Hydraulic accumulators are also equipped with membranes, but their shape and location are completely different. A balloon membrane, similar to a pear, is placed inside the vessel, which is attached between the flanges, eliminating contact of water with the inner surface of the tank. This is why the use of expansion tanks in water supply systems is unacceptable: if drinking water comes into contact with the walls of the tank, its quality will be unacceptable - for example, rusty water may flow from the tap.

Until the pressure of incoming water balances the air pressure between the walls of the vessel, the membrane expands, trying to fill the entire capacity of the accumulator. Air pressure is regulated by a nipple. At the top of the vessel there is a pipe to which an air vent and a safety valve are connected.

Since the membranes of expansion tanks and hydraulic accumulators operate under different conditions, the requirements for materials will be different. Thus, heat resistance is important for a diaphragm membrane, since the water temperature in heating systems reaches 90°C.

For balloon membranes, the priority is dynamic elasticity and resistance to frequent repetition of stretching and compression - from 5 to 15 cycles per hour in normal mode. Since the membranes of hydraulic tanks come into contact with drinking water, they are made of food-grade rubber with minimal diffusion. Resistance to thermal influences is not particularly important - the water temperature in cold water supply networks does not exceed 30°C.

Which membrane is better?

Based on the properties of the membranes, we can draw a conclusion about the permissible areas of application of the units. If you install a membrane accumulator in a heating system, the balloon membrane will quickly fail. But expansion tanks are successfully used in automatic fire-fighting installations as vessels for fire-extinguishing liquids or powder fire extinguishing modules.

Different materials are used to make membranes:

Now that you know what dictates the design differences between the elements of heating and water supply systems, not a single seller will confuse you. You yourself will figure out which unit you need - an expansion tank or a hydraulic accumulator. Carefully study the technical data sheets of the proposed models and make the right choice!

Source

How to determine that the membrane has become unusable

In general, manufacturers claim a service life of 5 years for these products. However, in practice, this rarely happens. After all, they really don’t like membranes:

- temperature rise above the set value;

- frequent pressure changes;

- intense compression.

In practice, it is rarely possible to avoid operating the hydraulic tank in hard mode, so the service life of the bulb is reduced to 3 years.

How to determine when it’s time to change the membrane in a hydraulic accumulator:

- the pump started to turn on too often;

- The water pressure does not maintain constant pressure.

These are clear signs of damage to the membrane, however, it may also indicate damage to the accumulator housing. Therefore, before disassembling the container, it is advisable to check the condition of the tank itself.