What is Ursa made from?

Insulation structure

In short, insulation of this type is created from a mixture that includes dolomite, sand, soda, and a number of other components. The composition is melted, passed through centrifuges, and the result is a fine-fiber material that is quite dense and has important qualities.

The most famous manufacturer of this material is URSA Eurasia from the URALITA concern. It creates a range of products used for insulation in different conditions and within different designs. At the factories of this manufacturer, materials are created from the best raw materials, in professional conditions, always under the careful supervision of specialists. (See also the article How to insulate walls with your own hands.)

Special material properties

It can be used everywhere

Practice shows that this insulation has a number of properties that make it so in demand and purchased.

And in particular, it not only has low thermal conductivity, but also:

- Not prone to deformation.

- Soundproof. It can be used as sound insulation.

- Fireproof. Its composition makes it not prone to fire.

- Unattractive to all kinds of living organisms. You don’t have to worry about rodents or insects settling in.

- Not susceptible to any processes associated with biological effects in general.

All similar products from this manufacturer have these properties. In addition, it is worth noting that this insulation feels great at temperatures from -60 degrees to + 180.

Important! With its help, it is possible to insulate any inclined structures.

With all these advantages, the price of this material remains relatively low. If you are interested in how much Ursa costs, then the average price can be determined at approximately 1800-1900 rubles per cubic meter. (See also the article Features of ceiling insulation.)

However, this figure is relevant for the most common type - Glasswall. Other products from this manufacturer may be sold at completely different prices.

Can I use it myself?

All abundance - for the master and the amateur

Despite the fact that the certificate of conformity defines this material as intended for professional construction, it is quite possible to use it yourself for current small construction or repair needs.

At the same time, the instructions warn about the need to wear a certain work uniform - thick clothing, a mask or goggles, a respirator, and gloves. But, nevertheless, this material is environmentally friendly, which is undoubtedly another advantage.

What are URSA insulation materials and their varieties?

This thermal insulator is based on treated staple fiberglass. So this material is the closest relative of glass wool. When making it, sand, soda, dolomite and other additives are taken in certain proportions. The mixture is heated to the melting point and passed through a special apparatus. The result is a fibrous substance, the thin threads of which are glued with a special composition.

There are several products manufactured by URSA. The most common are the URSA GEO series insulation, made of fiberglass. In addition, the company produces polystyrene foam heat insulator URSA XPS, made by extrusion. A new product from the manufacturer, manufactured using the latest technologies, is PureOne insulation. Let's take a closer look at all these materials.

1. URSA GEO fiberglass mineral insulation is distinguished by the fact that only environmentally friendly components are used in its production. This is strictly controlled at all stages of the production process. So you can be sure that neither the raw materials nor the finished material contain harmful additives.

Line of materials based on XPS

The materials have a low thermal conductivity (0.028-0.035 W/mK), have increased strength and low specific weight (45 kg/m³), which reduces the weight of the structure. Extruded polystyrene foam is characterized by closed cells in the structure, the diameter of which does not exceed 0.2 mm. This structure ensures moisture resistance in damp conditions.

URSA XPS

The insulation is resistant to stress and chemicals

In the EPS product category, only one type of product is produced. The material has universal application, but is more often used for insulation work during the construction of railway embankments, runways, lower and underground floors of buildings.

Assortment of the URSA XPS line:

- high strength material NV, sold in slabs 60 x 125 cm;

- N-III sheets are available with straight and stepped side edges;

- N-III-G4 slabs are produced in thicknesses of 3-10 cm, size 60 x 125 cm.

The products do not react to the action of acids, fats, alkalis, lime, bitumen and other caustic substances, but decompose upon contact with tar, hydrocarbons, gasoline and formic acid.

"Pure One"

The product is based on acrylic. In addition to high-quality insulation, it also provides good sound insulation. The peculiarity is that when working with it, no protective equipment is required. Recommended for use without restrictions.

Peculiarities

- The product is characterized by increased sound absorption. Excellent for insulating surfaces when the thickness of the protective layer is important (interior decoration, partitions, etc.).

- Inert to almost all substances.

- Increased elasticity, which in some cases eliminates the need for additional fixation of products.

- In terms of basic characteristics (thermal conductivity, vapor permeability) it surpasses GEO products.

Price – from 120 rubles/m².

Dimensions

- For XPS slabs, the main linear parameters (L x W and T) are 1.25 x 0.6 m and from 3 to 10 cm.

- Samples based on glass wool are characterized by roll length from 9 to 18 m, width - 1.2 m, thickness - from 5 to 20 cm.

There are other options on sale, including ready-made “cutting” for standard and non-standard sizes. For example, 1 x (0.5 or 0.61) m.

For a more complete understanding of the specifics of use, it is necessary to clarify that all varieties of “Urs” are also divided into a number of “modifications”, each of which has certain, individual properties. Therefore, when choosing a material for specific conditions of use and further operation, it is advisable to become familiar with all the characteristics in more detail.

Main advantages

Ursa is an excellent solution for sound and heat insulation of floors, roofs and facades of premises. The company's products have many advantages and are a universal option when performing construction work. The main advantages include:

- excellent thermal insulation;

- high environmental friendliness and noise insulation;

- resistance to temperature changes;

- wide scope of application;

- non-flammability, increased flexibility, resilience and elasticity;

- light weight and easy installation;

- low price;

- excellent vapor permeability;

- good resistance to various loads.

However, despite such a large list of positive characteristics, there are also several disadvantages. These include susceptibility to an alkaline environment, the need to use protective equipment when working with Ursa insulation.

You can buy it in many construction stores or using online services. The price of insulation in rolls and sheets is presented on many websites, including the official website in the product catalog . The price differs depending on the type of product and its size. For example, the cost of URSA GEO will be from 1100 to 2400 rubles, and URSA Pure One 1200 rubles. The price of URSA TERRA is low; you can buy it from about 400 rubles per package, depending on the size and brand.

Technical characteristics of URSA mineral wool

Technical characteristics of URSA mineral wool The mineral wool is based on glass fiber, in the manufacture of which dolomite, sand and other additives are used.

All components are melted and drawn into thin threads. Next, the fibers are glued together with a special adhesive with anti-feathers. Due to its structure, URSA mineral wool is suitable for heat and sound insulation of house facades, interior partitions, etc. But in the line of insulation from this manufacturer there is not only glass wool, but also extruded polystyrene foam URSA XPS, a direct competitor of Penoplex. Let us further consider the thermal insulation brands URSA GEO, URSA TERRA, URSA PureOne and extrusion URSA XPS that are common today. Let's take a closer look at the technical characteristics of the materials and their possible applications.

Characteristics of URSA XPS and its purpose

Extruded polystyrene foam retains heat well when wet, unlike basalt wool, since it practically does not absorb water. The fact is that extrusion in its structure consists of closed polystyrene foam cells filled with air. Thanks to this, URSA XPS boards are highly resistant to deformation and can withstand high compressive and bending loads.

Summarize. URSA XPS insulation is extruded polystyrene foam with low thermal conductivity and vapor permeability. Due to its high strength and moisture resistance characteristics, URSA XPS extrusion should be used for thermal insulation of foundations and basements, as well as for insulation of facades, flats and roofs of houses.

Characteristics of URSA GEO, purpose

URSA GEO thermal insulation does not contain harmful components, since it is made from natural materials. The characteristics are no different from glass wool, since it is fiberglass. The material is produced in mats and slabs. The slabs are denser and are intended for vertical structures, while mats are used for horizontal structures.

Summarize. According to the manufacturer, URSA GEO insulation will serve you for about 50 years. All materials from this line are fiberglass, which has its pros and cons. The thermal conductivity coefficient of this fiberglass is up to 0.045 watts per meter per Kelvin. In terms of noise absorption, URSA GEO mineral wool belongs to class “A” or “B”.

Characteristics of URSA TERRA, purpose

URSA TERRA thermal insulation is available in the form of slabs 125 by 60 cm, 50 or 100 millimeters thick, as well as in mats 61 cm wide, 10 meters long and 50 millimeters thick. Mineral wool belongs to the NG class - non-combustible materials, the temperature range of use is from -60 to +220 degrees, but, like any mineral wool, protection from moisture and wetting is required during installation.

Summarize. Mineral insulation URSA TERRA will protect your home from the cold and will reduce the noise level in the room. Moreover, the material is environmentally friendly and non-flammable, and therefore has no restrictions on use in residential premises. It easily fits on horizontal and vertical structures, creating a continuous layer.

Characteristics of URSA PureOne, purpose

According to laboratory tests, URSA PureOne thermal insulation in slabs has a sound absorption class of “A”. Plates and mats of this brand are tightly fixed between the guides, and the original dimensions and shape of the slabs do not change over time. Technical characteristics distinguish it from analogues; the material is pleasant to the touch and resembles natural cotton or wool.

Summarize. URSA PureOne mineral wool is excellent for thermal insulation and sound insulation of residential premises. In terms of environmental friendliness, sound absorption and thermal conductivity, this material is today a world leader. It is very easy to work with, the material does not prick and does not cause irritation on the skin, which can be confirmed by the video below.

Thermal insulation Ursa

The URSA brand is a very well-known manufacturer of building materials, including thermal insulation. Its products are in demand throughout Europe. The thermal insulation material of this company is used mainly in the construction of private houses, as well as for technical insulation.

A wide range of products makes it easy to choose the required insulation option. Thanks to the variety of materials, buyers can choose it for insulation outside and inside the room, including for rooms with high humidity.

Products are manufactured based on extruded polystyrene foam, polystyrene foam and fiberglass. URSA also produces basalt insulation based on ;

- stone wool;

- mineral wool;

- glass wool.

The most common are fiberglass insulation . These product lines allow you to provide effective heat and sound insulation of the room. Most of the insulation range is available in rolls or mats. They have their own markings, which make it easy to navigate in choosing the right material for certain work.

The material is high-quality, easy to work and transport, and most importantly, has excellent thermal insulation characteristics. More detailed information about URSA products can be found on the company's official website.

Features of home insulation

When insulating different parts of the house, you should use a specific size and type of material. First of all, the façade will be insulated. To do this, it is better to use URSA GEO mineral wool, after which you can use external finishing with siding, natural and artificial stone, and brick.

Roof insulation

For the roof, you should select an insulation option based on the type of roof covering and the characteristics of the attic space. For pitched roofs, thermal insulation is laid under the rafters and between them, a super-diffusion membrane must be laid on the outside, and a waterproofing film on the room side.

To insulate a flat roof, materials with high strength should be used, so mineral wool is not used in this case. The optimal solution would be to use Ursa XPS, which is characterized by high strength and moisture resistance.

Installation of Ursa to a frame wall

For internal thermal insulation work, it is recommended to use various options of mineral wool. It not only protects from the cold, but also largely absorbs sound.

Installation of insulation

The use of high-quality insulation guarantees an optimal indoor microclimate and savings on heating. Installation of Ursa is quite simple, so even inexperienced builders can use it.

Where are Ursa materials used?

"Ursa" is an insulation material used not only in the construction of buildings, but also in the assembly of water supply systems, heating systems, other communications, as well as in the construction of roads, bridges, airfield runways and in many other areas. In each specific case, varieties of this insulation are used, the technical characteristics of which most accurately correspond to this specific purpose. Next, we will consider what types of this material are currently produced by the company.

Dimension

Types of packaging

Many buyers of this material are primarily interested in the dimensions of a roll of Ursa insulation - after all, only knowledge of the dimensions allows one to accurately calculate how many rolls are required to perform certain jobs. (See also the article Insulation of building facades: types.)

And the dimensions of Ursa insulation are quoted as follows:

- length 10000 mm, width 1200 mm, thickness 100 mm for GLASSWOOL on pitched roofs;

- length 9000 mm, width 1200 mm, thickness can be either 50 mm or 100 mm - GLASSWOOL for various purposes,

- length 18000 mm, width 1200 mm, thickness 50 mm - with one or two canvases in the package. Used as a material for various purposes.

Important! At the same time, the cost of Ursa insulation varies depending on whether the material belongs to one of these types.

Price issue

The cost of insulation will vary depending on what type you prefer, what product you purchase, in what volume and from which distributor. Approximately the following prices can be mentioned:

- Ursa Geo mineral insulation will cost from 900 rubles per cubic meter (Ursa Geo light product) to 4,600 rubles per cubic meter. This is the cost of Ursa P-60 insulation. A cubic meter of Ursa light insulation contains about 20 square meters, and P-60 contains about 40 square meters.

- PureOne can be purchased at a price of 1500-1600 rubles per cubic meter of material, about the same price as TERRA insulation.

- As for URSA XPS slabs, their cost starts from 3,500 rubles per cubic meter of insulation and reaches 5,500 rubles per cubic meter. At the same time, depending on the thickness of the slab, a cube of this insulation contains from 10 to 30 square meters of material.

The cost of the material will be slightly lower if you make a wholesale purchase and pick up the purchase from the warehouse, pick-up.

Ursa insulation materials are attractive not only for their properties, but also for their high environmental friendliness of materials. Today this is an additional significant argument in favor of this product.

Areas of application

Ursa slab insulation can be used as a substrate for asphalt.

Ursa universal thermal insulation is used in any construction process. Universal characteristics allow the protection to be used for complex curved surfaces.

Areas of use:

- pitched and flat roofs;

- foundations in damp places;

- walls outside, inside and as an intermediate layer;

- partitions;

- heating lines;

- highways and railway elevations;

- airfield strips;

- extensions, balconies;

- saunas and baths.

Reliable thermal insulation is set to a minimum thickness, which is comparable to thicker layers of other materials. Internal insulation made from Ursa material does not reduce the horizontal and height dimensions of the room.

Application area

Mineral wool insulation is produced on the basis of fiberglass using new and innovative technologies.

This made it possible to minimize the characteristic disadvantages of glass wool. The company also produces special membrane coatings to create effective thermal insulation systems. This insulation is widely used in the construction industry because it is universal. Most often it is used for the device:

- flat and pitched roofs;

- internal and external walls;

- interfloor ceilings;

- foundations;

- partitions;

- floor structures;

- highways;

- heating pipes;

- railway embankments;

- baths and saunas;:

- loggias and balconies;

- runways.

Installation of insulation can be performed not only by experienced builders. This can be done by people without experience in construction. During the work process, it is important to follow the basic rules and then the installation will be done efficiently and effectively.

Sizes at your discretion

Standard forms of release are slabs and rolls. Standardized dimensions are 1250 mm in length, 600 mm in width and 50 mm. To expand the range and for the convenience of consumers, the manufacturer offers options for length - from 1000 mm to 6.2 m and thickness - 100 mm. The material cuts well and does not cause difficulties when calculating the required quantity.

Due to their chemical composition, insulation from URSA® has a temperature range of use from minus 60 to plus 220 degrees Celsius. The average density of the material is 20 kg per cubic meter.

Insulation sheets and mats are not susceptible to moisture. So, when the material is partially immersed in water, its water absorption will be about one liter per square meter of surface.

Today, the world of insulating substances is quite crowded.

More frequent crises in construction and, as a consequence, a drop in consumer demand have provoked an intensified struggle for clients. Against this background, URSA demonstrates enviable calm. The reason here is obvious - excellent quality, excellent characteristics and a fair price - this is what the consumer was waiting for and his hopes were not deceived!

URSA insulation in house construction. Insulation of a frame house with mineral wool ARSENAL.BY

Fiberglass insulation "Ursa": reviews

The opinions of those who have already used this type of insulation are mostly more than positive about it. In particular, owners of country houses like the fact that when installing slabs and sheets, virtually no glass dust harmful to health is generated. Private developers also like the fact that the Ursa material, unlike ordinary glass wool, does not wrinkle or lose its shape. It is also noted that when working with slabs and mats, pieces do not come off the canvas.

Those homeowners who have small children highly praise the PureOn variety, since it is completely free of phenol and other poisons. Ursa insulation, reviews of which are only positive, is, among other things, very easy to cut.

Safe and environmentally friendly PureOne material

Ursa PureOne insulation - the product is manufactured according to high environmental standards, without the use of formaldehyde, phenol and recyclable materials. Thin and soft fibers are joined with acrylic. The material is white, elastic and resilient, does not emit dust during operation, and does not deform over time. It is used for thermal insulation of children's and medical institutions.

Insulation can be installed inside a child’s room on the walls and floor; it will protect the room not only from cold, but also from noise. The series includes:

- 34PN - slabs with high sound absorption class A, product dimensions 1250x600x50/100 mm;

- 37RN - mats for indoor and outdoor placement, roll size 10000x1200x50/100 mm;

- 35QN - mats for children's institutions, thickness 50-100 mm.

The material has the following technical characteristics:

- high vapor permeability - 0.51;

- low thermal conductivity - 0.034-0.037 W/m*K;

- operating temperature - from −60º to +220ºC;

- flammability class - NG.

The insulation is safe for patients with asthma and those prone to allergies.

GEO insulation - types and purpose

Ursa GEO heat insulator is made from natural raw materials; the presence of volatile compounds is 10 times lower than the norm, which indicates the complete safety of the product. Long fibers and air layers provide high sound absorption and heat retention. The material can be used in buildings with strict fire safety requirements.

The GEO line includes 9 products:

- M-11 is a universal roll material with a length of 7 and 10 meters. Used for thermal insulation of attic floors, balconies, baths, partitions and pipelines. Serves as a sound insulator under a suspended ceiling.

- M-11F - heat insulator made of fiberglass with aluminum coating. Recommended for rooms with high humidity (baths, kitchens), balconies, pitched roofs. The foil layer makes the material vapor-tight, so installation of a special film is not required.

- Mini – rolls of small size 7000×600×50 mm. Used on balconies, for insulating pipes and air ducts.

- Universal slabs are produced in a standard size, designed for installation in the sheathing with a pitch of 600 mm. The insulation is highly durable, and the convenient format facilitates installation on the wall and roof.

- Light is a lightweight roll material for horizontal covering without load. Thermal conductivity is 0.044 W/m*K.

- Pitched roof - insulation is made using technology that increases its elasticity. This quality allows the material to retain its shape for the entire period of operation. The product can be cut lengthwise and crosswise; it is optimally suited for installation with non-standard rafter spacing.

- P-15 - vapor-permeable and elastic slabs measuring 1250x610x50 mm. Designed for frame walls, partitions, external insulation under siding.

- The façade consists of semi-rigid insulation boards laminated with fiberglass on one side. The material has a low thermal conductivity of 0.032 W/m*K and does not require the installation of wind protection. The size of the slabs is 1250×600×50 mm. Scope of application: ventilated facades.

- Quiet floor - the material is used when installing a floating floor and serves as an effective noise insulator. Available in the form of semi-rigid slabs measuring 1250×600×20 mm.

The manufacturer promises effective thermal insulation for 50 years. Glass mineral wool does not attract insects and mice, and is not afraid of mold.

URSA Product Classification

For various purposes, there are different types of products under the Ursa brand, which have a certain composition, thickness and their own characteristics in terms of water absorption, thermal conductivity, temperature of use and other indicators. Today, the company’s product range includes five groups of insulation materials:

- Geo glass wool;

- boards based on extruded polystyrene XPS;

- staple glass wool insulation Pure One;

- TERRA mineral wool;

- films for steam, hydro and wind protection SECO.

URSA brand insulation has good strength indicators:

- do not burn;

- resistant to mechanical and other types of damage;

- do not rot;

- are not susceptible to mold.

But remember that some of them, in particular those made on the basis of mineral fibers, need additional equipment with vapor barrier films, since moisture negatively affects their structure and over time they will lose their integrity. And with proper equipment, insulation can last more than 20 years.

Description and technical characteristics of URSA Geo glass wool

Compared to basalt wool, glass wool has a lower thermal conductivity coefficient due to its large fiber and soft structure. Insulators are able to fit more tightly to the surface, regardless of its shape, without a single gap.

The Geo series is produced according to a patented technology in which the connecting link is acrylate resin, and not bitumen or polymer.

URSA glass wool is used mainly for the purpose of sound and thermal insulation in private and industrial construction. The series is divided into products of the following types:

- universal;

- for light building structures;

- for pitched roofs;

- insulation to provide sound protection;

- for insulation of frame buildings;

- foil insulation for rooms with high humidity;

- for pipe insulation;

- for facade insulation;

- products with additional properties;

- raised floors and floating insulation.

URSA glass wool insulation has the following technical characteristics:

- thickness from 50 to 200 mm;

- thermal conductivity at 10 degrees from 0.030 to 0.041 W/mK;

- non-flammable material;

- permissible humidity level from 0.035 to 0.046 W/mK;

- The permissible temperature of the environment is from -60 to +2200 degrees.

You should also pay attention to wall insulation and mats marked with the letter “F” (foil). They are suitable for frame buildings and provide complete protection from cold and extraneous sounds. The price of the products presented in this series starts from 94 rubles per square meter. Users also note the ease and efficiency of glass wool.

URSA XPS slabs and their description

These plates are mats based on extruded polystyrene foam, equipped with a tongue-and-groove locking joint of a stepped structure. This connection provides maximum compression without cold bridges. Such slabs are perfect for insulating large areas, in particular:

- flat roofs;

- walls;

- partitions;

- floors and ceilings;

- foundation;

- special areas.

Insulation should be laid preferentially in one layer.

Expanded polystyrene boards can withstand sudden temperature changes, do not rot or develop fungi and mold, and are almost incapable of absorbing water. It can be installed in places of contact with open ground or vegetation and does not equip the insulation with additional protective elements.

URSA insulation boards have special series designed for the following types of work:

- external and internal;

- for insulating walls in basements;

- equipping foundations;

- heated floors;

- flat roofs;

- for insulation work in industrial buildings with roofs with high loads;

- for car repair and road works.

The plate parameters are as follows:

- length is 1.25 m;

- thickness from 30 to 100 mm;

- width 60 cm.

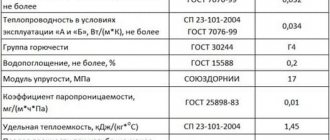

The technical characteristics of this insulation are as follows:

- thermal conductivity at 10-degree temperature ranges from 0.032 to 0.033 W/mK;

- flammability degree G3 and G4;

- temperature limits from minus 50 to 75 degrees:

- water absorption maximum 0.3 percent with partial immersion during the day;

- vapor permeability 0.004 mg/mchPa.

But remember that polystyrene foam boards cannot be used on damp surfaces; they will remain damp and moldy, regardless of whether there is insulation there or not. To prevent this from happening, the surface should either be dried before insulation or treated with a water repellent along with a biocide additive, for example, Tiprom.

XPS boards have a price of about 150 rubles per square meter and more.

Glass wool staple URSA PureOne

This position of the URSA brand is suitable for premises that have special requirements in terms of safety, noise-absorbing characteristics and environmental friendliness:

- children's rooms;

- educational establishments;

- sterile rooms;

- acoustic installations.

According to the European standardization system, this insulation received the highest category as the most environmentally friendly.

In this series “Ursa” the following positions are presented:

- slabs with sound-absorbing characteristics of class A;

- mats for insulation of facades and roofs;

- mats for construction and repair work in children's institutions.

Mats can also be used as roofing insulation, because they have increased elasticity and are easy to cut. This insulation is installed quickly and does not require additional fixation.

Technical characteristics of spatula glass wool "Ursa" are as follows:

- thickness from 50 to 150 mm;

- thermal conductivity at 10 degrees ranges from 0.034 to 0.037 W/mK;

- permissible humidity level from 0.038 to 0.043 W/mK;

- flammability - NG;

- temperature limits - from 60 degrees minus to 220 degrees Celsius.

Another feature of this insulation is that it can be used where allergy sufferers and those with lung diseases live. The average price of such URSA glass wool is about 90 rubles per square meter.

Mineral wool URSA TERRA and its description

This position is intended for the construction and renovation of private houses. Thus, these insulation materials are used for insulation and sound insulation of external and unloaded walls, as well as partitions and cladding. The insulation boards have a high degree of rigidity and are equipped with moisture-repellent impregnation. Also, this position is not hot and is bioresistant. Key technical characteristics are as follows:

- thickness 50 mm;

- length from a meter to one and a half;

- width 60 cm;

- thermal conductivity (10 degrees) – 0.034 W/mK;

- permissible temperature of use from minus 60 degrees to plus 220;

- vapor permeability 0.51 mg/mchPa.

This mineral wool can be used to insulate uneven walls, since its structure allows it to adhere very tightly to the surface, creating a continuous coating.

The price for this product in retail outlets across the country fluctuates around 200 rubles per square meter.

Advantages and disadvantages of fiberglass materials

This is the most popular variety, especially among owners of suburban areas who build houses on them. Their main advantages include:

- Very low thermal conductivity coefficient - 0.032-0.046 W. For comparison, for the same foam plastic this figure varies from 0.037 to 0.005 W.

- Convenient sizes. Ursa fiberglass insulation is available in both mats and slabs. In the first case, the most popular type is Ursa roll insulation, the dimensions of which are 1200 * 4200 mm and a thickness of 150 mm. The standard size between roof rafters and house frame posts is 60 cm. In this case, the canvas is simply cut in half lengthwise. If the pitch between the elements is different, it is cut across, measuring the required distance along the length.

- Environmental Safety. In the production of some varieties, formaldehyde-containing materials are not used.

- Easy to install. Unlike many other, cheaper types of glass wool, Ursa has a very strong structure, and therefore it is very difficult to tear.

- Fire resistance. Ursa glass wool does not burn at all.

- Durability. This insulation can withstand temperature changes from -60 to +220 degrees. It serves for about 50 years.

"Ursa" is an insulation material, the disadvantages of which include only its relatively high cost.

DIY installation of URSA mineral wool

Photo.

Application of URSA for thermal insulation of residential buildings Like any other inorganic thermal insulation made of fiberglass or basalt, URSA is afraid of contact with water. Therefore, when installing this material, you should use a vapor-waterproofing barrier to protect the mineral wool from getting wet. The air cells between the fibers of the material retain heat perfectly, but as soon as the fibers get wet, the thermal conductivity of URSA increases significantly.

Contact with water is not dangerous for extruded polystyrene foam URSA XPS, which is a clear plus when insulating the blind area and foundation of a house. The slabs can last over 50 years, while the slabs do not change in size, however, polystyrene foam emits harmful substances at high temperatures. Therefore, this thermal insulation is not recommended for use in residential premises.

On the roof

Thermal insulator from the “Pitched Roof” series of the “Ursa” product line is used. It is produced in the form of mats (slabs) with dimensions of 1200 mm x 4200 mm, which makes it possible to cut the material, eliminating a large amount of waste, and use it for roofing with absolutely any rafter pitch.

Stage one. Arrangement of waterproofing

The waterproofing film is applied directly to the upper plane of the rafters. It can be secured using staples from a construction stapler or galvanized nails with a flat head. Then it should be finally secured with a counter-lattice.

The film panels are applied exclusively across the slope, taking into account an overlap of no less than 100 mm. In this case, adjacent panels are secured using adhesive tape, and the resulting sag in the middle of the panel should not exceed 20 mm.

Waterproofing rafters

But in no case should the sheets be laid without mounting slack, that is, under tension. If this condition is not observed, then during the cold period, during the natural thermal shrinkage of the material, it may rupture.

Stage two. Installation of heat insulator

Professional builders recommend waiting ten to fifteen minutes after opening the original packaging. During this time, the insulation will restore its original dimensions.

The material should be placed between the rafters in a compressed-elastic state, that is, “by surprise”, and it will be securely fixed due to the friction that occurs between the side surfaces.

In any case, the width of the heat insulator must exceed the distance between the rafters by at least 3 cm; this is the only way to ensure its reliable installation and eliminate the presence of unwanted cracks and voids, which will significantly increase the efficiency of insulation.

Insulation is carried out with mandatory control of the size of the installation gap between the insulation itself and the waterproofing layer. Control markers can be bars of a given height.

Stage three. Vapor barrier

Produced indoors. The film is fixed with a stapler or galvanized nails on the lower plane of the rafter legs. The amount of overlap is also maintained (10 cm) in both longitudinal and transverse directions.

Vapor barrier of walls

Self-adhesive tape is used to tightly connect the canvases to each other. After this, the finishing covering of the ceiling surface is performed.

On the walls

It is more advisable to insulate walls from the outside, that is, from the facade. To do this, it is recommended to use the Ursa line, made from staple fiber, for example, P15 grade boards.

- Preparation. Removal of protruding segments (shimmers, lighting fixtures, trims, decorative elements, etc.). Next, a thorough cleaning of dust and dirt is carried out, as well as an inspection of the wall surface for possible defects. Cracks must be repaired and large irregularities removed.

- Waterproofing the wall with appropriate material.

- Marking. It is carried out on the wall surface to ensure parallelism and accuracy of further installation of the frame. Can be applied using a plumb line or laser level.

- Frame. It can be made of wooden blocks or metal profiles, the choice depends on the type of façade finishing. The components of the frame are fixed to the wall using dowels or self-tapping screws in increments of 58 cm. In this case, the frame must tightly fit around window and door openings, corners, top and the lower boundary of the insulated zone.

- The first layer of thermal insulation. The standard width of Ursa slabs is 600 mm, so they are easily placed in the space between the beams, ensuring a tight, airtight fit. For a tighter fit, the mats can be additionally fixed with construction dowels at the rate of five to eight pieces per insulation board.

The main thing is that the dowels do not compress the material at the place of fastening, otherwise this will lead to the appearance of “cold bridges”, consequently, to a deterioration in the level of thermal insulation efficiency. - Horizontal frame elements are installed on top of the first layer of insulation, similar to the technology for installing vertical posts. Just like in the previous paragraph, insulation is installed.

- Ventilated gap. Necessary for releasing steam and moisture from the material. As a rule, wooden blocks are used for its arrangement, attached to the frame in the vertical direction. As a result, a hollow space is formed; its width should be at least 50-60 mm.

- Finishing the walls.

On the floor

Experts recommend using Terra insulation from Ursa as a heat insulator for cold floors. An interesting fact is that the name of the heat-insulating material itself means “earth”, indirectly making it clear that it is preferable to choose it for insulating surfaces close to the soil.

There is a fairly large assortment of this line, so it will not be difficult for the average person to choose the heat insulator that is most suitable for the floor of his home.

These glass wool slabs have high rigidity, and therefore during installation the appearance of so-called “cold bridges” is eliminated, which only has a positive effect on the quality of insulation. Laying insulation on the floor is very similar in its technology to insulating the walls of a building.

The following is a short tutorial:

- Cleaning the surface from dust, debris and dirt. If necessary, eliminate significant defects (cracks, chips, potholes) and level the rough surface.

- Laying vapor barrier. For this purpose, it is most effective to use a SECO membrane from the same manufacturer, since it is most compatible in terms of performance characteristics with the selected insulation. The vapor barrier film is overlapped (not forgetting the lower part of the walls) and fixed with anchors.

- Next, wooden logs are arranged and laid out on the floor surface with a certain calculated step.

- A mineral insulation is laid between them, the width of which should be slightly larger than the distance between the wooden beams, this will ensure better sealing.

- Then a waterproofing layer (film) is laid out and everything is completed with the final finishing of the floor surface.

Extruded polystyrene foam boards

This type of Ursa insulation also enjoys well-deserved popularity among private developers and large construction companies. Most often, expanded polystyrene slabs of this brand are used to insulate the foundations of buildings and structures. The fact is that they are not at all afraid of moisture and the effects of various types of aggressive chemical elements present in any soil. Ursa slabs can be installed completely without any additional protective material.

Types of Urs

As mentioned above, Ursa can be provided in the form of GLASSWOOL material, which is often used in roofing, walls and ventilated facades. This is, as a rule, rolled material, which is in maximum demand.

Also sold is Ursa Pureone, a relatively new material using acrylic components. This material is characterized by increased resistance to negative environmental factors and a long service life. Its dimensions can also be different - all for the convenience of the user.

Such insulation is also produced with mats - they are presented in the form of products M 15 and M 11, which differ in size. You can see this insulation in most of its types in the video in this article.

Varieties of fiberglass "Ursa"

Thermal insulators of this brand are divided according to density, degree of thermal conductivity and area of application into several main classes:

- URSA Geo. Used for thermal insulation of pipelines and sewer pipes. However, most often it is used in private and industrial housing construction to insulate walls, floors, ceilings and roofs from the cold. The most popular among owners of suburban areas is the Ursa M 11 insulation, which, among other things, can be used on the floor and in interfloor ceilings. These are mini-slabs for universal use. The “Light” type is intended mainly for covering unloaded structures - roofs and walls. The URSA Geo line also includes soundproofing varieties designed for rooms with high humidity, for pipes, raised floors, etc.

- PureOn. This variety consists of 95% natural ingredients. At the same time, in terms of softness and fineness of the fiber, it is not inferior to cotton wool.

- TERRA. These are high-density boards of small sizes, very convenient for use in private housing construction.

Price

The most pressing question that can dot the i's. How much does insulation with URSA cost? As you probably already guessed, Pure One will be the most expensive. You have to pay for health. For example, a roll of Pur Van 37 RN 6.2 m long, 1.2 m wide, and 50 mm thick will cost 1,212 rubles. A, Terra, density characteristics - 18 kg/m3, dimensions 1000 by 600 and 50 mm, will cost 420 rubles for 10 slabs. Ursa Geo M 25 cotton wool, 9 meters long, 1.2 meters wide and 50 mm thick, will cost 900 rubles. The number of slabs in each package is different.

We have tried to focus here on technical details in order to provide as complete information as possible. When insulating your home or office, pay attention to the properties of this brand.

Types of insulation

All Ursa developments are based on the use of two materials, which, due to the optimal combination of advantages and disadvantages, are recognized as the best thermal insulators. We are talking about fiberglass and extruded polystyrene foam.

The use of these insulation materials in combination with the latest technologies has allowed the company's engineers to create several series in which any buyer can find a suitable option. Let's tell you more about them.

Ursa G insulation

Ursa G thermal insulation differs from ordinary glass wool, first of all, in the absence of phenol-containing additives, which makes this insulation absolutely impeccable from the point of view of environmental safety. Thanks to this approach, the release of volatile components was reduced to minimal volumes, amounting to less than one tenth of the permissible standard values.

Ursa G series insulation can have different densities and are available in the form of flexible mats (supplied in rolls) or rigid slabs.

The material is non-flammable (zero fire hazard class) and is characterized by absolute chemical and biological resistance. In addition, fiberglass perfectly absorbs sound waves.

The service life declared by the manufacturer is 50 years. But for fiberglass products this is not the limit; they can last longer. At the same time, age does not in any way affect the condition and technical characteristics of these heat insulators.

Flaws:

- Actively absorbs moisture, which is why it requires the installation of a waterproofing shell

- Fiberglass is thorny, so all work must be carried out with gloves

- The material is characterized by the formation of some dust

PureOn series insulation

This insulation is the latest development by Ursa engineers and is an advanced fiberglass material.

By using acrylic as one of the binders, it was possible to eliminate the main disadvantages inherent in glass wool: causticity, irritating effects on the skin, dust formation. The resulting material is soft, reminiscent of cotton or wool, has more pronounced soundproofing properties and is practically dust-free. You can work with this material without gloves; due to its absolute safety, it is recommended for use in kindergartens, schools, and medical institutions.

Another important advantage of PureOn insulation is elasticity. Thanks to this property, it completely fills the space in which it is installed, being firmly held in it due to the spacer force.

Ursa XPS insulation

The basis of all insulation in this series is extruded polystyrene foam, manufactured using advanced technology.

One of the main advantages of insulation in this series, besides, of course, excellent thermal insulation properties, is almost complete waterproofness.

A sample completely immersed in water adds no more than 0.3% in volume per day. In addition, XPS series polystyrene foam insulation is characterized by high compressive strength: various brands can withstand loads of 25 - 50 tons per square meter. m.

When using Ursa XPS insulation for external thermal insulation of buildings, almost zero vapor permeability should be taken into account. If you use this type of insulation for walls inside an apartment or house, then the room must have effective ventilation.

To insulate the facades of buildings with high humidity in rooms such as saunas, baths or swimming pools, Ursa XPS series insulation should not be used.

A significant disadvantage of polystyrene foam is that it is a fire hazardous material. Various additives, such as fire retardants, can prevent ignition, but when exposed to fire and high temperatures, thermal decomposition begins in polystyrene foam, accompanied by the release of large amounts of very toxic smoke.

There are cheaper insulation options; for example, sawdust “functions” well as insulation. Study the detailed pros and cons of this material and make your choice.

Among the inexpensive insulation materials is foam plastic as insulation, about which you can read more in this article. All options are good if they are used as intended.

Insulation materials

0 votes

+

Vote for!

—

Vote against!

Manufacturers of traditional and modern building materials are still not able to guarantee their high thermal insulation properties. Often, in order to achieve acceptable performance in this direction, it is necessary to increase the thickness of the floors. This leads to the fact that the mass of the structure becomes prohibitively large, which means that the requirements for the soil, foundation, frame and other elements will be more stringent. The use of heat-insulating products will help to avoid such problems. Insulation materials are designed to reduce heat loss and effectively maintain a microclimate in the premises that is comfortable for others. They have a relatively small specific gravity, which makes it possible to reduce the consumption of building materials, reduce energy consumption for heating the building, and also increase the level of soundproofing of the walls. The article will focus on Ursa insulation.

- Line of materials based on XPS

Of course, all this is true only if the choice was made in favor of proven insulation materials with maximum quality and reliability.

It is worth noting that thermal insulation properties are not the only characteristics that should be paid attention to. It is also very important that indicators such as strength, durability, wear resistance, fire safety and resistance to weather conditions are as high as possible.

Ursa photo

The production of insulation is a leading activity for many companies, but only a few can boast of truly high-quality products that would satisfy all the requirements of even the most demanding consumers. can rightfully consider himself a representative of just such organizations. What are the main differences between this manufacturer and others?

Company-

Despite the fact that it officially began its history only in 2002, it has many years of experience in the field of creating reliable and effective thermal insulation materials.

- The history of the company should begin with the Uralita concern (Spain), which was founded in 1907 and was engaged in the production of fiber cement. It is noteworthy that the raw materials for the products were exported from the Urals, which is reflected in the name of the brand (the name can be translated as “Ural stones”).

- In 2002, Uralita merged with (Germany), which at that time had more than a century of history and was a leader in the production of insulation products in Germany, Europe and Russia. Around the same time, there was a merger with another brand - “Poliglas”, which produces extruded polystyrene. Perhaps this determined the future direction of the concern’s activities.

- Today the Uralita production group has four main directions. The activity of the Ursa subsidiary is the production of building insulation products. Industrial enterprises and retail chains are located in Europe, Russia, the Middle East and Africa. For example, products based on extruded polystyrene foam are produced in factories in France, Italy, Germany, Spain and Russia. Mineral thermal insulation is more popular; enterprises in eight countries (Poland, Belgium, Slovenia, Spain, Germany, Turkey, France, Russia) manufacture it.

- tries to annually expand the range of its products and enter new markets. The brand's logo (polar bear and bear cub), symbolizing warmth and comfort, is recognizable in many countries around the world. The products produced are used both in primary construction and for the reconstruction of existing buildings. These are safe materials that are highly environmentally friendly. It is thanks to this indicator that the scope of their use has been significantly expanded.

- This brand is represented in Russia and the CIS countries, the production centers of which are located in the cities of Chudovo and Serpukhov. The factories are equipped with modern equipment produced in Slovenia, Denmark, Germany and the Czech Republic. All products undergo mandatory quality control and have all the necessary certificates.

Features of the Ursa material

Two types of products are produced under the Ursa brand:

- based on extruded polystyrene foam (EPS);

- based on fiberglass.

XPS insulation

- It is a synthetic product produced by extrusion. That is, under the influence of elevated temperature and pressure, polystyrene granules are mixed with special foaming agents. Then, the molten mass is extruded through the extrusion head of a high-tech machine.

- The result is a material with excellent strength, low thermal conductivity and low specific gravity. At the same time, it has a closed porous structure (that is, cells with a diameter of about 0.2 mm on the surface are evenly spaced and have a closed appearance), which makes it excellent at resisting moisture.

Fiberglass based insulation

- They are a canvas created from a mixture of quartz sand, dolomite and soda. After the components have been melted at high temperature, special substances are added to the composition that can glue the ingredients into a single mass. Next, the molten solution is forced through the dies of an extrusion apparatus. The resulting glass fibers have increased strength, do not break or break even when stretched and bent.

- labels its products depending on the material of manufacture. Thus, fiberglass products received the prefix “Geo”, as they are environmentally friendly and safe products. Also, based on glass fibers, a technologically new product called “PureOne” was created. This insulation uses acrylic components and is recommended for use in medical and children's institutions. And finally, thermal insulation based on extruded polystyrene foam is labeled “XPS” - it is a reliable, durable material that guarantees excellent heat and sound insulation.

- Today it offers consumers three types of mineral insulation and one type of insulation based on EPS.

Technical characteristics of Ursa mineral insulation

Mineral insulation includes all materials created on the basis of natural components, that is, from fiberglass. Such products are produced in rolls or slabs (one package can contain 5-24 sheets).

The composition does not contain phenolic binders, which means that the products are environmentally friendly. In addition, thanks to the non-flammable substances that are used to create insulation (sand, soda, etc.), Ursa mineral thermal insulation has an increased degree of fire safety. The warranty period is 40-50 years, but, of course, is not the limit.

- Insulation density. This indicator varies from 15 kg/m3 to 85 kg/m3. Depending on the scope of application, certain products should be selected. Thus, for private housing construction, materials with a density of up to 30 kg/m3 are sufficient; if you plan to use thermal insulation in harsh conditions, for example, in water transport, then it is recommended to use denser types.

- Specific thermal conductivity. The products have a low thermal conductivity coefficient, this indicator is in the range of 0.030-0.046 W/mK. That is, this is exactly the amount of heat that the material transmits through itself during operation, which indicates the high characteristics of thermal insulation from, which can provide effective heat conservation for almost any building.

- Temperature conditions for use. This characteristic shows at what temperatures the insulation is able to perfectly retain its properties. The manufacturer guarantees that the material can be used at sub-zero ambient temperatures from -60 degrees, as well as at positive temperatures up to +310 degrees. We are talking specifically about air temperature, since the recommended temperature on the surface of the product should not exceed +100 degrees (some types up to +180 degrees). In general, we can say that the insulation is universal for use in any climate zone.

- Dimensions of Ursa insulation. Mineral insulation is produced in various variations, in the form of rolls or slabs. The thickness of the products can vary from 5 to 20 cm, the width is 60 and 120 cm, the length of the mats is from 3 to 18 m, and the length of the sheets is 1.25 m.

A line of materials based on mineral components

Ursa GEO insulation

- Thermal insulator based on mineral glass fiber is highly environmentally friendly, and due to the absence of volatile compounds, it is completely safe for human health and the environment. When heated, harmful substances do not evaporate or be released, which means they can be used even in rooms with an increased risk of fire. The manufacturing company carefully monitors the quality of raw materials and also places high demands on the finished product. During production, specially developed eco-technologies are used, which involve the use of only natural ingredients in the composition.

- Due to the special structure (a combination of long fibers with air layers), Ursa GEO insulation materials have excellent thermal insulation and noise-absorbing characteristics, despite their low specific weight. The advantages of the products include such properties as fire safety (does not burn and does not support combustion) and biostability (does not rot or decompose, and also does not have conditions for the reproduction of insects and rodents).

- Installation is quite easy even for unprepared people. The material can be laid on any surface, regardless of the degree of curvature. In this case, the slabs take the shape of the base and fit very tightly to it. Since the product is quite elastic and elastic, precision when cutting and subsequent adjustment is not required, just as there is no need for additional fixation when installing on the frame. You can buy Ursa Geo insulation at any large hardware store.

URSA GEO product range:

- "Framework P";

- "Light";

- "Mini";

- "Pitched roof";

- "Universal plates";

- "Facade";

- "A private house";

- "Noise protection"

- Mats: “M-11” and “M-11F” (one side is covered with foil); "M-15"; “M-25” and “M-25F” (one side is covered with foil);

- Plates: “P-15”; "P-20"; "P-30"; "P-35"; "P-45"; "P-60".

The price of ursa insulation depends on the density of the product and can vary from 400 rubles. up to 1500 rub. per package.

Ursa PureOne insulation

- This is a new generation of thermal insulation material; its main feature is that 95% of its composition is completely natural ingredients that have passed quality control. The product complies with international sanitary standards and belongs to the eco-material category. According to the recipe, the use of formaldehyde or phenol, as well as any secondary raw materials and plant substances, is not allowed.

- The product has amazing softness due to the presence of the finest fibers (the texture is comparable to wool or cotton wool). Since acrylic is used as connecting components, the products are considered as safe as possible for humans, and are recommended for use in medical, school and preschool institutions. When working with insulation, there is no dust and no odor. In addition, the color of the material is also surprising - it is bright white, despite the absence of any dyes or bleaches. This can be achieved due to the fact that quartz sand has a white tint when melted, and transparent acrylic substances do not in any way affect the shade of the finished product.

- An important advantage of PureOne is that this material has increased elasticity, flexibility and resilience. This allows not only to more effectively absorb sound waves, but also to reliably install the insulation in any structure without the need for additional fixation.

PureOne product range:

- "34PN" (slabs: 125 cm x 60 cm);

- "37RN" (roll: 120 cm x 10 m);

- "35QN" (roll: 120 cm x 390 cm).

Ursa TERRA insulation

- This type of product was developed specifically for use at home, but at the same time, the material fully complies with the quality standards of professional construction. The peculiarity of the slabs is that they have a small size and increased rigidity (while maintaining flexibility and elasticity at the proper level), this allows installation without any problems by independent forces.

- The insulation has maximum thermal conductivity and sound insulation, and also has excellent moisture resistance. To increase the water-repellent properties, the product is treated with special water-repellent compounds during production, so that when water drops hit the surface, they simply roll off it and do not penetrate inside.

- TERRA thermal insulation is a non-flammable material that is ideal for insulating wooden buildings. In addition, due to the use of only natural ingredients in production, the product is absolutely not harmful to humans and the environment, that is, it is environmentally friendly and is capable of maintaining the amazing microclimate of houses built from wood.

URSA TERRA product range:

- "34 PN" (slabs);

- "34 RN" (technical mat for insulation of pipelines and air ducts).

Technical characteristics of “Ursa” EPS insulation

Thermal insulation based on extruded polystyrene foam is highly durable and wear-resistant. These products excellently resist moisture and do not absorb it from the air, due to which they are recommended for use in all parts of the house (roof, foundation, basement, facade, floors, etc.), as well as during the construction of objects in contact with groundwater, for example, highways.

- Specific thermal conductivity. This indicator is in the range of 0.032-0.048 W/mK; the material perfectly maintains the required temperature regime in almost any room, and, in addition, does not reduce the thermal insulation characteristics even in conditions of high humidity and in direct contact with water.

- Temperature conditions for use. It is recommended to use insulation at temperatures from -50 to +75 degrees. At the same time, the products are quite resistant to freezing; more than 500 freezing/defrosting cycles are allowed. It is also possible to use thermal insulation in buildings where changes in temperature conditions are quite common.

- Strength qualities. The slabs and mats are capable of withstanding loads of up to 175 kPa, as well as short-term pressures of up to 500 kPa, throughout their entire service life (that is, more than 50 years). Excellent bending strength allows installation even on unprepared bases, for example, on a sand bed.

- Safety. Products based on EPS are completely harmless to humans, since freons and other harmful elements are not used in production. In addition, thanks to the addition of fire retardants to the composition, the insulation is a non-combustible material, that is, when exposed to fire, these substances create a barrier on the surface that prevents the access of oxygen, thereby stopping the spread of flame. It is also worth noting the fact that thermal insulation can be used in structures located close to open ground or vegetation and at the same time fully retain its physical properties.

Line of materials based on XPS

URSA XPS

- In this category of products, only products labeled “Ursa XPS” are produced; the material is universal in application, but is most often used in structures such as runways, railway embankments, underground parts of buildings, plastered facades, primed floors and so on. That is, it is an ideal heat insulator for use in extreme operating conditions; it is not afraid of high humidity or heavy loads.

- Materials such as concrete (including aerated concrete), metal, brick and plastic can act as insulated surfaces. The products are resistant to a number of chemicals: alkalis, acids, lime, alcohol, oils, fats, phenol, bitumen and others. However, it is worth keeping in mind that it is not recommended to use preparations containing gasoline, tar, formic acid or hydrocarbons as boundary materials.

URSA XPS product range:

- “NV” (the most durable material, can withstand loads of up to 50 t/m2, produced in the form of slabs 60x125 cm).

- “N-III” (has two varieties: “N-III-L” and “N-III-I”, the differences lie in the shape of the edge, which can be stepped or straight);

- “N-III-G4” (thickness varies from 3 to 10 cm, parameters 60 x 125 cm);

The main advantages of Ursa thermal insulation

The insulation produced can be called a unique option, because it has a huge number of advantages that allow us to say that the product is a universal option for any construction. So, what are the advantages of the material?

- Excellent thermal insulation ability.

- Highly environmentally friendly.

- Increased noise protection.

- Long service life (more than 50 years).

- Resistant to temperature fluctuations, as well as low and high temperatures.

- Practicality and versatility (wide scope of application).

- Non-flammable material.

- High flexibility, elasticity and resilience.

- Resistance to high loads.

- Easy installation.

- Affordable price.

- Low specific gravity.

- Excellent vapor permeability.

- Biostable (that is, it does not harbor rodents and insects).

- Does not rot or mold.

Of course, it is important to identify the negative properties, because although they are not in large quantities, they are present. For example, mineral insulation is susceptible to an alkaline environment; in addition, fiberglass can cause minor troubles when cutting insulation, so it is recommended to work with products in protective clothing and gloves, which is not always comfortable. But in any case, customer reviews about Ursa insulation are mostly positive.

Scope of application of Ursa insulation

Ursa products are universal products that have a fairly wide range of applications due to the rich product range.

The most often insulation is used for the device:

- roofs (flat and pitched);

- walls (both from the outside and from the inside, and also as a spacer for the middle layer);

- interfloor ceilings (including basements and attics);

- partitions;

- floor structures;

- foundation;

- heating pipes;

- railway embankments;

- highways;

- runways;

- loggias and balconies;

- baths or saunas.

Installation of Ursa thermal insulation

Even a person without special construction training can install heat-insulating slabs or mats. Since it is enough to follow a few simple rules, and the work will be done efficiently and effectively.

- First of all, it is important to properly transport the material and store it. Thus, products should be protected from precipitation and mechanical damage. That is, when laying insulation for transportation, try not to pinch it or place it too tightly, since additional compression often leads to the fact that in the future the sheet simply will not unfold as it should, which means it may lose its main functions. During long-term storage, it is important to leave the original packaging, and also ensure that the slabs are laid horizontally, and the rolls are left standing vertically (up to three rows can be stacked on top of each other).

- Products begin to be unpacked immediately before use. Before proceeding with installation, the rolls should be allowed to rest unrolled (roll out the mats to their full length) for 10 minutes. The slabs can be used immediately after unpacking. Often the manufacturer lays the material in two layers; if there is no need for such a thickness of the product, then you can simply divide the heat insulator into a nominal thickness.

- When starting work, you need to prepare, that is, it is recommended to wear protective clothing, gloves and construction glasses; these measures will prevent dust from getting into exposed areas of the body. You need to cut the material on a hard object with a sharp knife or a special saw.

- Mineral-based slabs and rolls are laid tightly together and pressed against the base. Also, in cases where the material is placed in two or more layers, the joints of the previous rows should be overlapped, this will make the thermal insulation as productive as possible. When installing frames, the products should be several centimeters larger than the structure, then they will be held tightly without the need for additional fixation. When installing EPS insulation, it is better to use special adhesive compounds (polyurethane or cement based).

In principle, installation is quite simple, the main thing is to properly prepare the base, since this product is installed only on the surface (for example, boards or plywood). At the final stage, the room is cleaned. To do this, it is often recommended to spray the space with water to reduce dust levels. After which you should clean it with a construction vacuum cleaner.