Thermal insulating material for a bath should be highly resistant to high temperature and humidity. Aluminum foil has these properties, and therefore is one of the most popular insulation materials in baths. It is used both in combination with other materials and without them, depending on the thickness of the walls and operating conditions.

Aluminum foil for bath insulation

Characteristics and properties of foil

One of the most important characteristics of aluminum foil is its reflective ability - up to 97% of infrared rays. Continuous covering of the steam room with this material contributes to maximum heat retention, because IR rays are not absorbed by the walls, but are reflected back into the room. And even if the surface of the foil fades over time, this will have virtually no effect on the reflective properties.

Foil on the bathhouse ceiling - photo

In addition, it can withstand temperatures up to 300 °C and higher, depending on the brand, has a low specific gravity and does not emit compounds harmful to the body.

Bath foil

This material also has other important properties:

- resistance to ultraviolet radiation and corrosion;

- vapor tightness;

- plasticity;

- durability;

- moisture resistance.

Almost all the heat remains in the steam room, and the walls and the insulating layer under the foil are reliably protected from condensation. For greater efficiency, not only the walls, but also the ceiling are sheathed with foil, because steam and hot air first rise upward. Attaching it is not difficult, the main thing is to avoid its deformation during operation and not leave gaps between the panels.

Foil is produced in rolls and sheets, the thickness is from 0.007 to 0.2 mm, the width of the tape is from 1 to 150 cm. Depending on the manufacturing method, it can be annealed (soft) and unannealed (hard), and this is indicated by the marking - the letters "M" and "T" respectively. Both types are suitable for thermal insulation of rooms. It is recommended to sheathe the steam room with foil from 30 to 300 microns thick.

Photos of the appearance of rolls of reflective insulation Megaspan FB for baths and saunas

Choosing a lining: with what lock and what length?

Good, high-quality lining helps the walls of the bathhouse to “breathe,” prevents the appearance of condensation and fungus, and uniquely regulates the humidity in the bathhouse. The main requirements for these materials are environmental safety requirements. It is worth clarifying that at one time all the lining was made “in tongue” and “in quarter”, but the slats often shifted during operation, and the density of the joints was violated. That is why today almost all lining on the market is made with tongue/groove profiles.

A little secret for those who like to save money: clapboards up to 1.5 meters long in warehouses are much cheaper than those that are more than 2 m long. And figuring out how to cover a bathhouse with clapboards of this length is not difficult. You just need to make a rail in the middle. But the benefits will be quite tangible.

Using foil in a bath

Using foil in a bath

To choose the optimal method of thermal insulation, it is necessary to take into account several factors, the main of which are the operating conditions of the bathhouse and the material from which it is built. For warm log buildings with high-quality caulked walls, foil insulation is not needed, it will only be a waste of money.

Do not use foil in a bathhouse made of timber or logs

If the bathhouse is wooden, but large enough and does not warm up well, it is enough to sheathe the walls and ceiling with ordinary thin foil, and then cover it with clapboard. You can cover only the surface behind the stove with foil, this will speed up the heating of the steam room and save some fuel.

The walls behind the stove are covered with foil

A bathhouse made of aerated concrete is also considered quite warm, but such material requires high-quality vapor barrier. The choice of foil in this case is completely justified, and for convenience you can use laminated rather than ordinary foil.

Fastening laminated foil

Brick and frame baths must be insulated. Here, foil insulation based on cotton wool or expanded polystyrene is optimal. For the ceiling, the type of foil is also selected taking into account the thickness of the ceilings and the presence (absence) of thermal insulation in the attic.

Foil on the ceiling in the bathhouse

Operating conditions also have a certain meaning. If the sauna is used periodically and people steam in it for a short time, there is no great need for thermal insulation with foil. It’s a completely different matter if the steam room is heated very often or the bath procedures drag on for several hours: thermal insulation of the room will save a lot of firewood, the bath will warm up faster and take longer to cool down.

Decorating the rest room

The bathhouse is always perceived as a place of relaxation from everyday worries. Each room in it is intended for its own purposes. The name of the relaxation room speaks for itself: this is where you relax after water treatments

Therefore, it is important to create a cozy and relaxing environment in it.

Proper finishing of a relaxation room in a bathhouse is not an easy task, the implementation of which can be entrusted to specialists: designers and artists.

A cozy environment is created through the correct choice of facing materials, furniture, accessories, organization of lighting and illumination of various zones and architectural elements of the room.

How to attach foil

Simple cladding

Another advantage of aluminum foil is that it is convenient to attach it at any time, on any surface. This does not require major repairs; the work will take very little time and effort.

Simple sheathing of walls and ceilings with foil

To protect wooden walls, you first need to make sure that the surface is smooth enough and there are no sharp protrusions that will tear the foil. If such defects are found, they should be cleaned with sandpaper. Then everything is simple: take a roll of foil, unwind a strip along the height of the wall, cut it off, and fix it in the upper part with a stapler. Straighten the canvas downwards, fix it again so that it does not move, then attach the next strip with an overlap of 5-7 cm over the first. The joints must be secured with aluminum tape. The usual one cannot be used for these purposes.

The foil strips can also be positioned horizontally, if it is more convenient for you to mount it that way. The main thing is that there are no gaps left anywhere. Around window and door openings, the foil is also attached close to the ends and secured with a stapler around the perimeter.

An example of fixing foil around a window opening

Methods for attaching panels to walls

Using nails or self-tapping screws is the traditional option for attaching panels to walls. A more modern method is the use of clamps. It does not damage the panels, but requires additional costs of both time and money when installing the lining.

Using nails or screws

This method will require a screwdriver or hammer, as well as special nails or self-tapping screws - galvanized or made of copper alloy. Such fittings are more expensive, but if you save on them and buy ordinary nails, they will begin to rust over time. This will lead to the appearance of red streaks on the lining, which will spoil the appearance of the finish and stain the skin and things when touched. The fasteners are driven or screwed into the lining tenon at an angle of 45 degrees. The fastening points will have to be sanded so that there are no burrs or other defects left. The disadvantage of this method is that holes will have to be created on the planks when fastening them with nails. And when you try to remove the lining, the fastening points will be further damaged, which precludes the reuse of the panels if necessary.

Fastening with clamps

Do-it-yourself installation using clamps is safe for lining strips because it does not damage them. A clamp is a special bracket that is attached to the lower half of the lining groove - a recess into which the tenon of the next plank is inserted. The fastenings of the bracket are covered with the next strip in the row. Fixing the staples to the sheathing beams is carried out with nails or self-tapping screws.

With this installation method, the lining is not damaged, and there are no nail heads or screws left on the outer surface of the cladding, which eliminates the risk of getting burned or getting a rusty drip on your clothes after visiting such a bathhouse.

It is also easier to partially replace the lining mounted in this way - just pull the boards out of the grooves and pull out the fasteners. If you do not work carefully, it will be the staples that are damaged, not the boards.

Features and assessment of the feasibility of use ↑

Reflectivity is the main property that makes aluminum foil a suitable insulation for a bathhouse - a room that needs to be heated quickly and strongly. The second argument in favor of choice is resistance to humidity and high temperatures. Not every material can withstand the hot conditions of a steam room.

How to use foil with maximum efficiency ↑

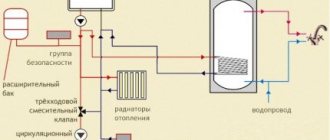

In a bathhouse, foil can be used as an independent reflective heat insulator or as one of the layers in a “pie” with other materials. If you place foil between the thermal insulation layer and the lining, you get the effect of a thermos. This thermal insulation option is ideal for baths made of brick, concrete blocks and those built using frame technology.

Aluminum foil without insulation will act solely as a reflector or vapor barrier, protecting vulnerable materials from moisture. This option is often chosen to increase the air temperature in small steam rooms, as well as to protect wall materials and for fire safety purposes near the stoves.

Advantages and compelling reasons for choosing ↑

Significant advantages of foil for bath insulation compared to other options arise from its unique properties:

- Impermeability to gases and vapors. Even a sheet 0.009 mm thick allows water vapor to pass through in an amount of only 0.01 g per 1 square meter. m of surface during the day, and starting from a thickness of 0.025 mm, gas-vapor permeability is practically zero. The metal atoms are arranged so tightly that only hydrogen penetrates through the network. If we compare any polymer material with foil, its permeability will be the smallest.

- High resistance to corrosion. When exposed to air, the foil becomes coated with oxide, which protects it from exposure to chemicals and greatly prevents corrosion.

- Excellent fire-resistant characteristics. Withstands temperatures up to 145 degrees.

- Environmental Safety. Foil is non-toxic, does not absorb odors, and is not attractive for the growth of microorganisms.

- High reflectance coefficient - from 95 to 98%. This is a screen that both retains heat inside the room and serves as a barrier to the penetration of heated or cold air from the outside.

- Not susceptible to deformation. The canvas can take any shape.

- Good ductility, maintained at high temperatures.

- Resistance to ultraviolet rays, rotting, and the proliferation of pathogenic organisms.

- No harmful fumes.

- Easy to install.

Disadvantages of foil thermal insulation ↑

The advantages of foil for baths and saunas are much greater than the disadvantages, but they cannot be ignored. The following properties can be attributed to the disadvantages:

- Tendency to gradual corrosion, as a result of which the reflective layer becomes cloudy and the quality of protection decreases. Therefore, when choosing a foil heat insulator for a steam room, pay attention to the presence of a metallized film layer.

- Limited temperature range, which is why it is necessary to install a ventilation hole to prevent overheating.

To buy high-quality bath foil, you need to choose certified products from manufacturers with a good reputation in the market.

Criteria for choosing lining for cladding

Lining for the interior decoration of a bathhouse must be selected taking into account several rules

First, you should pay attention to the type of wood. Pine is completely unsuitable for high temperatures, as it also does not cope well with high humidity.

But a rest room can be easily sheathed using lining made from this material. If you want to save money, then it is better to choose exactly this material for finishing the dressing room.

If you want to completely protect yourself and those who will visit the bathhouse, you should choose alder lining for lining the inside of a brick bathhouse. It has a pleasant aroma and attractive shade. When covering a bathhouse for yourself, you can also choose linden. It is completely unsuitable for premises that will be visited by a large number of people, since this breed is not resistant to mechanical damage.

If you want to do the work yourself, you should also pay attention to the profile. If you are looking at a soft line, you should know that products with such a comb have a wide board. The brick wall after finishing will look aesthetically pleasing and without obvious changes

If you don’t plan to cover the wall yourself with anything after finishing installation, you should ask how the slats were protected. It is best if the finishing layer is acrylic compounds with antiseptic characteristics. They are made on a wax base. Special impregnation for baths is excellent. It forms a colorless film on the surface, which is easy to care for, and does not change the natural color of the wood.

Prices for wooden lining

If you want to decorate a bathhouse with clapboards yourself, then you should also inquire about the cost of the material. For example, top-class fake products cost 130 rubles. a piece. Sometimes manufacturers also indicate the price per square meter. So, you can purchase aspen trim for 815 rubles.

Marking and technical requirements

The cheapest type of finish is the one designated by the letter “C”. This material has visible defects, but it can be used for cladding indoor bathhouses for household purposes. This allows you to save money, and not only when you want to decorate utility rooms. After all, although such material has its drawbacks, it can be used for all rooms if the bathhouse is a family one and it is not intended to invite guests.

If you want to purchase higher quality material, but at the same time save money, it is best to choose grade “B” lining. It includes dark and light knots, as well as cracks and recesses. Such material will be ready to last longer, but it can be further decorated to be installed, for example, in a dressing room or a rest room.

Grade “A” lining is made of even higher quality. You will not see any defects on the surface other than light knots. The base will be smooth and is perfect for finishing the main rooms in the bathhouse. This is what is called the golden mean. Since it is in a not so high price segment, it also looks quite presentable.

When your budget allows, you can purchase “Extra” grade lining. There will be no defects on it, the base will be smooth, and this decor can also be used to decorate the main premises. The Premium grade is based on smooth wood with an ideal surface. You will not see any defects on it. The service life of such material is so long that you will most likely want to build a new bathhouse, but not change the finish.

Brief overview of types and brands of foil insulation ↑

Aluminum foil is an excellent sealant and reflector. These qualities contribute to both rapid heating of the walls and air in the room and long-term maintenance of high temperatures. Thin film with a mirror surface is not the only option; the industry produces many types of thermal insulation based on it.

Types of materials for arranging baths and saunas ↑

Folgoizolon. It is a foil insulation made of foamed polyethylene or polypropylene with a thermal conductivity of 0.031 W/mK. The second of them is PPE with a density of 33 kg per cubic meter. m, has a thickness from 1.2 to 50 mm. The first, denoted by the abbreviation NPE, is a low-density material - up to 31.7 kg per 1 cubic meter. m. Its maximum thickness is 15.5 mm. The shape is rectangular, square sheets or rolls, covered with foil on one or both sides.

Plain foil in rolls. Affordable material manufactured in accordance with GOST 618-73. The decisive point when choosing foil for a bath is the last parameter. The optimal option is 30-300 microns, and the width can be any. If the package is marked in the form of the letter M, then this means that this is soft or annealed foil, and a roll with T is a hard, unannealed material, which is sometimes produced in sheets.

Foil with mineral wool as a base. It is a heat-resistant foil insulation for a bath with high thermal insulation ability. On sale there are rolls and rigid slabs 5-10 cm thick with a thermal insulation layer of 8 to 10 mm. The main term can hide both basalt wool, obtained from the melt of volcanic rocks, and glass wool, made from glass and quartz sand.

Kraft foil. High-strength paper-based foil for baths. This category also includes three-layer material containing cellulose, a thin layer of polyethylene and an aluminum coating. Foil on kraft paper or fabric is the best option for a bathhouse. Operates in a temperature range from 50 to 100 degrees C. If installed correctly, it reflects up to 95% of heat. Sold in the form of sheets 0.03-1 mm thick or rolls 1 m wide and 30 m long.

What is “Penofol” and its varieties ↑

Under the Penofol trademark, a thin material with a dense structure and high thermal insulation properties is produced. To achieve a good effect, a thickness of no more than 10 mm is sufficient. "Penofol", in addition to its main function, acts as a sound insulator, and also does not allow moisture to pass through from the outside, is hypoallergenic and resistant to mechanical stress. The material is produced in rolls, which is very convenient for transportation.

Execution of work

Sheathing device

A timber with a thickness slightly greater than that of the insulation used is used (mineral wool is usually used as a heat-insulating material). It is installed perpendicular to the selected direction of the lining in increments of approximately 45-55 cm. If the walls are uneven of significant size, it is necessary to use pads made of the same type of wood or some material of sufficient density. The sheathing is attached to the wall with screws and dowels made of plastic or self-tapping screws made of galvanized metal.

Laying insulation

In most cases, as mentioned above, mineral wool is used, which is available on the market in a wide variety of types and modifications. The main rule for laying insulation is that there are no gaps between the materials to avoid the formation of cold bridges.

Video instruction:

Sometimes mineral wool is not installed at all - if there is no need for additional insulation, and the lathing is done only to secure the lining.

Vapor barrier device

Glassine, roofing felt or simple plastic film can be used. The strips are fastened with a stapler for furniture work with an obligatory overlap of at least 5-7 cm. For greater reliability, the joints are additionally glued with adhesive tape or tape as wide as possible.

Ventilation device

A favorable microclimate in a bathhouse largely depends on proper ventilation. For its normal functioning, when installing insulation, it is necessary to provide ventilation holes.

Installation of lining on the walls of the steam room

Fastening must be done using a hidden method, using self-tapping screws, clamps or nails.

This is necessary in order to:

- avoid the possibility of contact with heated hardware;

- prevent it from coming into contact with steam or water, and as a result, prevent corrosion, which can ruin the surface of the lining

Coating bath walls from clapboard

Standard technology is used, during the production of which the following points must be taken into account.

- The lining is fastened with self-tapping screws made of galvanized steel into a tenon, and the holes must first be drilled to avoid chipping. It is allowed to use fastening with nails or clamps (special staples for wood).

- The coating device starts from the corner, access to which is most difficult. This is explained by the fact that the last board will need to be adjusted both in length and width, which is almost impossible to do if there is insufficient access to the place of its installation.

- The corners are finished using a wooden plinth, which is secured with stainless steel nails.

- We should not forget that all wooden structures must be treated with an antiseptic compound.

Installation of a ceiling covering for a steam room made of lining

The installation of a lining ceiling covering, as a rule, starts from the entrance. Only clamps or nails are used for fastening. This is due to a fairly serious load from the mass of the material. When installing the last boards, a hidden nail without a head is used, which is driven in using a hammer. To give a pleasant appearance, the place where this nail is driven is treated with sandpaper. It is necessary to take into account the need to leave a gap of 4-5 cm between the ends of the lining and the wall of the bathhouse for normal ventilation. In addition, it is necessary to provide the structure with the opportunity to “play”, since the temperature under the ceiling will be the highest.

Correct gap between boards

The coating looks most attractive when all joints are made of the same type.

This can be easily achieved by marking the boards when installing them, and also using a level to ensure that the boards are level or vertical. The wall covering must be closely adjacent to the ceiling covering.

Covering door and window slopes with clapboard

When finishing doors, you must first prepare boards of the required length. Doorways are trimmed with platbands.

How to choose the best insulation for different tasks ↑

The choice of insulation with foil for a bath depends on the material from which the building is constructed and the frequency of its use. In some cases, you can get by with simple aluminum foil, while in others you need cladding using a heat-insulating layer.

General recommendations for selection ↑

Regardless of what type of bath foil you choose, you must proceed from the following considerations:

- When buying cheap products of unknown origin, there is a risk of purchasing material made from poor quality raw materials. Its performance properties will be at the lowest level.

- The insulation must be covered with real aluminum foil. Some manufacturers practice spraying, but there is very little benefit from it.

- The fire threshold is of great importance. Foil in the bath is exposed to high temperatures, so fire safety is the main selection criterion.

- It is important to choose the right thickness of insulation with foil on the walls for the bathhouse; the effectiveness of the work you do will depend on this.

What foil insulation is needed for a wooden bath ↑

A log bathhouse with well-caulked walls does not require any additional insulation. Wood does not conduct heat well, so it is well retained inside.

In a small building, only the ceiling is sheathed with foil or kraft foil. If the bathhouse is spacious and you need to update the interior, then you can line its walls and ceiling with plain foil, and then line it with wooden clapboard.

In order to protect the wood from fire, they use wall cladding behind the stove. This measure further increases the temperature in the steam room, as heat is reflected from the foil.

When choosing regular foil for a bath, do not ignore such a parameter as the thickness of the aluminum layer. It ranges from 0.007 to 0.2 mm, and the vapor permeability of the material is directly proportional to this value.

Wall cladding made of other materials ↑

Buildings made from aerated concrete blocks are considered very warm, but a vapor barrier is required here. You can use regular foil for such a bath, but it is better if it is glued to waterproof craft paper. Such insulation will become a reliable barrier to the occurrence of dampness, will retain heat inside, and steam will not harm your health.

Baths with frame and brick walls are subject to mandatory insulation for the reason that they do not retain temperature well. Here you need foil insulation, the basis of which is mineral wool or expanded polystyrene. You can also make a “thermos” from a quencher and aluminum foil.

Basic finishing methods

The construction of a bathhouse frame is permissible from wood, aerated concrete and foam blocks, and brick. If building standards are observed, the building will be functional. The choice of material depends on the personal considerations of the developer. In central Russia, preference is given to wood in 50% of cases. A log or beam. Another 25% falls on frame structures, the basis of which is also wood. The last quarter remains for other materials.

The interior decoration of a bathhouse built from logs, using frame technology or bricks and blocks, does not depend on the material of the box

It is important that it meets the specific requirements imposed by the functionality of the building. The most stressful conditions are in the steam room, where the humidity reaches 70% and the temperature reaches 90°C.

For the washing room and dressing room, a humidity of 40% at a temperature of 30 - 35°C and low humidity at 20 - 25°C are recommended, respectively. The given numerical values are indicative and justified from a medical point of view. In life, differences happen. When it comes to steam rooms, the rule of thumb is: higher the temperature, lower the humidity.

Reflective insulation installation technology ↑

When insulating a bathhouse with foil with your own hands, work begins with thermal insulation of the ceiling, then moves on to the walls. These two stages have their differences, although they are basically similar to each other.

General installation recommendations ↑

- It is important that the reflective layer of aluminum foil is oriented towards the interior of the room.

- Fixation is carried out directly to wooden planks using staples or nails. If the width of the canvas is large, it is secured both at the edges and in the middle.

- There should be an air gap between the foil and the covering material, which will reduce the thermal conductivity properties, and the maximum number of rays that fall on it will return again to the bath or sauna room.

- Particular attention should be paid to the joints to eliminate cold bridges.

Sequence of work on ceiling insulation ↑

The temperature is maximum under the ceiling, therefore, heat loss through it is large. When mineral wool plays the role of insulation, the installation of foil on the ceiling should be performed in the following sequence:

- Cover the ceiling with rolled paper.

- Make a sheathing from wooden slats. The thickness depends on the choice of insulation.

- Place rolled or slab insulation between the sheathing elements, securing it with temporary strips.

- Proceed to install the foil. It must be laid with an overlap of 20 to 25 cm and an overlap on the walls.

- Apply metallic tape at the joints to create the most airtight coating.

- Place 50mm thick battens on top.

- Treat the nails you are going to use to attach the trim with a special compound that protects them from corrosion. Cover the wood on all sides with waterproof varnish - this will extend its service life.

- Install the finishing material. An air corridor will remain between the foil and the finish, equal in height to the thickness of the slats, which will ensure good air convection.

- Cover the area around the chimney with asbestos. Do not install insulation close to the pipe.

Installing foil insulation on the ceiling greatly simplifies the process. It is simply cut into pieces of the required length and mounted end-to-end on the ceiling. Heat-resistant tape is used to seal the joints.

Technology for insulating steam room walls ↑

Having completed the work on the ceiling, proceed to covering the walls:

- Mount the frame on the walls using wooden slats. If there are ventilation holes, also make a frame of bars around them, and then attach insulation and foil to it. Glue the edges around the perimeter with tape.

By choosing foil for arranging a bath or sauna, you will save from 25 to 30% of the fuel used for heating, protect the building from the development of mold and harmful microorganisms, thereby extending its service life. But all this is possible only with the correct choice of insulating material and its proper installation. Only professionals can help in these matters.

Step by step guide

To do the work correctly, it is important to observe some nuances. Before proceeding directly to the sheathing, wooden planks are fixed along the vertical surface

Subsequently, they will play the role of a frame for attaching the material. A layer of insulation is placed between them. Thermal insulation is laid, aluminum tape must be glued at the joints

Before proceeding directly to the sheathing, wooden planks are fixed along the vertical surface. Subsequently, they will play the role of a frame for attaching the material. A layer of insulation is placed between them. Thermal insulation is laid; aluminum tape must be placed at the joints.

You can attach the lining to the foil with a fifteen-centimeter air gap. This step is necessary for efficient heat transfer.

Thanks to the air gap, the thermal conductivity of aluminum decreases; infrared rays hitting the foil sheet will reflect heat into the steam room.

You can also consider more detailed instructions for covering.

Log steam room

If the walls are built from logs, covering with foil is pointless. In this case, the quality of caulking is much more important. The thermal insulation layer on the log house will not play a role. In a log steam room, foil may only be used to cover the ceiling surface. In addition, aluminum foil is used to decorate the walls around the heating device. This way the heat will be reflected into the room rather than heating up the back wall.

When working with the ceiling, the foil is attached with the reflective layer down, overlapping, extending up to 5 centimeters onto the walls

It is important to seal the joints with special tape. The work should be done efficiently, without creating loopholes for steam

If desired, cover the top of the foil with clapboard, but you can leave it like that.

Brick steam room

When using frame technology or brick, it is important to follow a step-by-step guide, which includes covering the entire area of the ceiling and walls with material. Creates a thermos effect

- The master marks the wall onto which the sheathing bars are attached, the thickness of which must correspond to the thickness of the insulating layer, since it will be laid between the beams. If the lining is subsequently attached in a vertical position, the planks are secured in the same way.

- The width between the beams should be equal to the width of the insulation product. If there is ventilation or windows on the surface, bars are attached around them, onto which the foil will subsequently be attached.

- The insulation material is placed.

- It is covered with foil and secured to the sheathing with a construction stapler. Material with a small thickness should be laid with an overlap, but if it is thick, the material is attached end-to-end. Around windows and ventilation, the work is done more carefully.

- The joints are covered with metallized tape. They must be hermetically sealed.

- Slats with a thickness of about 25 mm and a width of 4 cm are attached to the sheathing. They will act as a retainer for the foil with insulation, create a gap and become a support for further installation of the lining.

- At the final stage, the lining is attached to the sheathing. When attaching the planks horizontally, you need to start from the bottom; they are placed with the grooves down. For vertical fastening, installation is performed from the corner, leveling the first element.

Work with the ceiling is done in the same way. You need to fill the baseboard around the perimeter.

The principle of a thermos for thermal insulation of a bath

During operation of the furnace, up to 80% of the heat is transferred by infrared radiation; up to 20% - due to the thermal conductivity of air, surfaces and objects located in the steam room; up to 7% - due to convection (mixing layers of air). That is why the role of the infrared screen is becoming in demand. This is what foil for the bath does, which is produced by industry in the form of a single-layer material, or as part of a two- or three-layer sandwich.

What does heat reflection do?

The use of flexible cladding with a glossy aluminum layer allows you to heat the steam room faster and retain heat longer. Foil for bath insulation acts as a mirror, reflecting the intense infrared radiation of the stove arches back into the room. Skeptics believe that this is only possible in one case: if you do not cover the foil with casing. They are wrong. The lining reduces the percentage of reflected heat rays, but when heated from the back side of the foil, the lining becomes a much less thermally conductive material. The design of the thermos thus changes, but the overall energy effect remains the same.

Illustration of the principle of heat reflection from foil material using the example of Alucraft products

What ensures that the cooling of the bath slows down? After all, the foil does not affect the thermal conductivity of walls located outside of it. In this case, other physical laws apply. The heat reflector promotes more uniform heating of air, surfaces and objects in the room. Heat transfer works from more heated bodies to less heated ones. By reducing the temperature difference, we thereby reduce heat transfer.

Why is foil glued to the insulation layer?

If the heat-reflecting material is placed without direct contact with the thermal insulator, then an air layer is formed behind the infrared mirror, heated by heat transfer through the foil. This layer will transfer heat towards the street. Therefore, no matter what kind of bathhouse you are going to equip - chopped, brick or with concrete walls - there is no point in using foil without insulation.

Insulation of a log bath

Another question is whether an additional layer of insulating material is needed? In log houses, it is enough to use thin bath insulation with aluminum foil. foil sandwich. Log baths do not require any other insulation, except for inter-crown gaskets and caulking of seams. Infrared mirror technology is economically feasible in any steam room, but stone walls require thorough thermal insulation using wool or slab materials, the effect of which cannot be replaced by foil-based coatings.

Treatment of lining with protective agents

Sheathed walls are subjected to protective treatment.

Solutions that are water-based or contain wax are considered the safest to use. They are environmentally friendly and harmless to health. A waterproof film is formed on the surface of the lining, which prevents moisture from penetrating into the wood, extending its service life.

Before application, it is important to read the manufacturer's instructions. Often, even one layer of product is enough.

Using wooden paneling to cover the bathhouse, the owners create a special microclimate inside the room, which has a positive effect on the health of vacationers. Plus, wood is a natural material that fits perfectly into the interior decoration of the bathhouse, looks beautiful and smells nice.

Types of insulators based on aluminum foil

In addition to considerations related to the physics of heat transfer and infrared reflection, the choice of substrate type is related to the ease of installation and mechanical strength of the two-layer material. The foil is easily torn during installation, which requires additional time to seal the gaps with special tape. When paired with a backing, the material becomes much more reliable, which makes it easier to attach it with a stapler to the wooden battens of the sheathing.

Foil insulation for baths

As a strengthening and/or thermal insulation layer, the following is industrially glued onto the foil:

- Mineral wool. The material is produced in rolls with a thickness of 5 - 100 mm. However, not every foiled cotton wool is suitable for arranging baths. In order to increase hydrophobic properties, mineral fibers are impregnated with special compounds that are unsafe for human health when the material is heated. Only insulation without these impregnations should be used with a direct indication of its purpose in the name. For example, "ISOVER Sauna" or "ROCKWOOL Sauna Butts".

- Kraft paper. The main commercial names of the material are “Kraft foil”, “Foil paper”, “Alucraft” and “Isolar”. In Izolar, a third element is added to the aluminum layer and paper - a polyethylene film, which increases strength and serves as a waterproofing layer for the paper layer. The thickness of kraft paper is in the range of 0.3 - 1.0 mm.

- Foamed polyethylene (FPE). The most popular material in the group of foil insulation. Produced under the names "Folgoizol", "Folgoizolon" in rolls with a thickness of 2 - 10 mm and plates (20 - 110 mm). Rolled foil insulation is usually used to equip baths and saunas in log houses without additional thermal insulation. It is produced in large quantities and has good installation and performance qualities combined with a reasonable price.

- Fiberglass mesh. As an infrared screen, a three-layer material “Folar” is sometimes used, containing a reinforcing layer of mesh with a cell of 4x4 mm. The original purpose of the folar is vapor barrier.

We insulate the joints with special tape

A separate group of materials includes PIR slabs, which are formed from high-strength polyurethane foam (PPU) and lined on both sides with aluminum foil. This thermal insulator is available in thicknesses from 30 to 250 mm. It makes sense to use PIR slabs with a thickness of 80 - 120 mm for insulating saunas, baths and hammams in buildings with walls made of brick or concrete. In this case, the slabs play the role of both the main insulation and a layer intended for infrared reflection and vapor barrier. Despite the high price, this material justifies itself on objects intended for long-term use.

Step-by-step instruction

Before lining the inside of the bathhouse with clapboard, you should decide whether the ceiling or just the walls will be covered.

We cover the bathhouse with clapboard with our own hands, starting from the ceiling. However, before you start covering, you should take care of thorough thermal and waterproofing.

We start with insulation

Before covering the steam room with clapboard with your own hands, the room needs careful thermal insulation.

Every bathhouse needs an insulating layer, especially in the steam room. An exception is a small summer bathhouse made from a log house, since in this case only the steam room is insulated.

Fire-resistant and environmentally friendly basalt wool is chosen as the insulation material. You should not choose insulation materials like polystyrene foam, as this is completely unsafe for your health.

Before laying the insulation, a sheathing is installed under the lining in the bathhouse, relaxation room and other rooms that need finishing. A vapor barrier is attached under the sheathing, then insulation, on top of which a waterproofing film is attached. For better reliability, you can cover the entire pie with foil. It is attached between the sheathing using buttons or a special construction stapler.

Preparing panels

The fact is that after drying, the finished material is immediately placed in a sealed package. That is why, immediately after opening, the lining absorbs moisture from the air, which can cause it to swell.

You should also take care of the impregnation of the panels. We recommend choosing special impregnations for baths, which contain antiseptics and fire retardants that prevent fire and the appearance of various microorganisms.

How to nail it correctly

As mentioned earlier, decorating a bathhouse with clapboards with your own hands starts from the ceiling. Before attaching the lining to the ceiling in the bathhouse, you should measure the length of the ceiling and cut the lining to the required size.

The first panel is attached opposite the door in one of the following ways:

- Using small nails at a forty-five degree angle. In this case, the nails will not be visible, and the ceiling lining will look like a single whole;

- To the sheathing, right through the wood panels. This method is most often used for eurolining; at the end of the work, the nail heads are closed with wooden plugs.

Just as the lining in a bathhouse is attached to the ceiling, it is placed on the walls. You should start from the most visible corner of the room, moving further along the perimeter.

Before lining the inside of the bathhouse with clapboard (as in the case of the ceiling), you need to measure the height of the room, then adjust the panels to the required dimensions.

More about the mount

How to nail lining in a bathhouse is a question that interests many developers.

The first thing to remember is that covering a bathhouse with clapboard is done with your own hands using hidden fasteners.

There are a number of reasons for this:

- If the fastenings are made through, then when the room heats up it will also heat up, and this can lead to burns;

- The metal fastening on the surface of the lining may succumb to corrosion, which will subsequently damage the panels;

- The aesthetic aspect, because the fastenings that are open to view look quite sloppy.

What is the best way to mount the lining in a bathhouse:

- Nails;

- Kleimers;

- Self-tapping screws.

Features of installation of foil insulation

If work is carried out in a log house, then, as a rule, foil insulation is used. The material can be attached directly to logs (beams) using a stapler with the aluminum side facing the inside of the room. Depending on the thickness of the cladding, butt or overlap joints are used. The joints are taped with metallized tape.

Air gap between foil and lining

To drain condensate, it is planned to release foil material from the ceiling to the wall, and from the wall to the floor. Slats with a thickness of at least 3 cm are attached on top of the foil insulation. They perform two functions: they serve as a lathing for the finishing cladding and form an air gap between the foil and the lining. The gap is important in order to exclude direct heat transfer from the lining through the aluminum layer.

The arrangement of baths in rooms with brick or concrete walls has a single, but very significant difference from work in log houses: contact of foil material with the load-bearing wall is strictly unacceptable. First, the main insulation is carried out with heat insulators of sufficient thickness. Then the foil material is installed. The gap between the foil plane and the finishing lining must be observed.

Another important note for all types of baths and saunas equipped on the principle of a thermos using foil: such rooms must have high-quality ventilation.

Final recommendations

Now you know how to insulate a bathhouse from the inside under the lining and how to do it correctly. Let's summarize some small but important results:

- It is not worthwhile to insulate wooden buildings from the inside, including bathhouses; if possible, do only external insulation

- It is simply necessary to insulate the steam room, the main thing is to follow these rules: To insulate the walls, we use stone wool with a vapor barrier made of foil.

- For the ceiling we use expanded clay or stone wool with a vapor barrier in the steam room area made of foil and in other areas from a high-quality vapor barrier roofing membrane. It is better to insulate the ceiling on both sides, from the attic and from the inside.

- For the floor we use insulation: for wooden subfloors we use stone wool with the organization of waterproofing in the steam room and sink. For floors on the ground in the steam room, it is better to insulate them with expanded clay; in other rooms we use EPS.

Where is it used?

It should be noted that the heat-insulating effect of foil is not based on the same property as that of other heat-insulating materials. Aluminum foil for a bath, on the contrary, conducts heat very well, but its effectiveness is based on the reflection of heat rays.

Any household infrared heater, electric fireplace, air heater uses an aluminum heat reflector. To eliminate the disadvantage of aluminum’s high thermal conductivity and low strength of foil, manufacturers produce composite materials.

They have a layer of foil (reflective layer) and a layer of thermal insulation, such as polyethylene foam. There are also many options where the foam layer is replaced with plastic film and (or) kraft paper.

Suitable wood species

Wood for lining should not contain a lot of resinous substances. When choosing the type of wood for lining a bathhouse with lining, take into account the purpose of the room. Coniferous boards are not recommended for cladding a steam room. Due to the high temperature, they release resin, which causes burns upon tactile contact, and aromatic components, which in high concentrations provoke an allergic reaction. Steam room decoration uses hardwood:

- Linden - the low heat capacity of lumber, the pleasant aroma and golden hue of the boards ensured the popularity of lining when finishing saunas. The wood is durable, easy to process, and lasts a long time in extreme conditions.

- Alder - the lamellas have a reddish tint, and when heated, they release healing tannins. The wood dries quickly and is resistant to moisture. It has a soft structure with a small number of knots. One of the advantages is the affordable cost.

- Aspen is a light-colored species that does not deform from moisture or temperature fluctuations. The lining heats up slightly and is safe for use in a steam room.

After cladding, the wood is coated with moisture-repellent compounds. For other rooms, lining the inside of the bathhouse with clapboard can be done with any type of wood:

- Larch is the wood that is most resistant to moisture, has a solid structure and a beautiful pattern. Due to its strength it is difficult to process.

- Pine – has a pleasant aroma and is not subject to rotting. The material is strong and durable, suitable for cladding dressing rooms and rest rooms.

- Spruce board is distinguished by a small number of knots and resin, the light shade does not darken over time. Advantage – low cost.

- Cedar is an expensive reddish-brown material that emits a pleasant aroma with medicinal properties. Wood is not afraid of moisture and has high thermal insulation characteristics.

РћР±С€РеРІРєР° парилки S„ольгой

Р' наше время обшвва парной алюминиевой фольгой очень RїRѕRїSѓR»СЏСЂРЅР°. Р' С‡С'Рј же РїСЂРµРемущества этого матерРеала, почему лучшРµ всего выбирать Rеменно фольгу? Давайте RїРѕРїСЂРѕР±СѓРµРј SЂР°Р·РѕР±СЂР°С‚СЊСЃСЏ.

R'Рѕ-первых, парРелка – это RїРѕРјРµС‰РµРЅРёРµ, RєРѕС‚РѕСЂРѕРµ РєРїРїРѕ»СЊР· СѓСЋС‚ для лечения очень RјРЅРѕРіРіРёС… Р·Р° болеваний, РІ том числе Рё заболеваний дыхательной систе РјС‹.

RџРѕСЌС‚РѕРјСѓ для RѕР±С€РІРІРєРё RїР°СЂРЅРѕР№ можно РѕЃРїРѕР»СЊР·РѕРІР°С‚СЊ S‚ольРєРѕ такие материалы, РєРѕС‚ орые РЅРµ выделяют РїРѕРґ воздействием RїР°СЂР° токсины Рё Рґ SЂСѓРіРёРµ вредные вещества.

Rменно S‚аким RјР°С‚ериалом Рё SЏРІР»СЏРµС‚СЃСЏ S„ольга.

R'Рѕ-вторых, РїСЂРё таком SЃРїРѕСЃРѕР±Рµ RѕР±С€РёРІРєРё RєРѕРЅРґРµРЅСЃР°С‚Р° РЅР° СЃС ‚енах парРелки – то РµСЃС ‚СЊ РЅР° деревянной обшивке – РЅРµ бывает, Рё дерево РЅРµ РїРѕСЂС ‚ится.

Р'-третькх, фольга сохраняет СЃРІРѕСЋ структуру Рё форм Сѓ даже РїСЂРё самом большом РЅР° греве, тогда как РґСЂСѓРіРіРµ материалы РјРѕРіСѓС‚ деформиро ваться РїСЂРё нагревании.

Р'-четвС'ртых, такое RїРѕРјРµС‰РµРЅРёРµ RSR°РіСЂРµРІР°РµС‚СЃСЏ намног Рѕ быстрее любого РґСЂСѓРіРѕРіРѕ, РІ РїР °СЂРёР»РєРµ, которую RѕР±С€РёР»Рё S„ольгой, С‚С'плый пар SѓРґРµСЂР¶РёРІР°РµС ‚СЃСЏ максимально РґРѕР »РіРѕ, поэтому банные процедуры RјРѕР¶РЅРѕ продолжать СЃ S‚олько, сколько RїРѕРЅР°РґРѕР±РёС‚СЃСЏ RїСЂРё RјРѕРЅРёРјР°Р» SЊРЅРѕРј SЂР°СЃС…РѕРґРµ S‚оплива. Фольга обладает отражающРеРј SЌС„фектом, именно РёР·-Р·Р° РЅР µРіРѕ тепло СЃРѕС …раняется так долго.

наконец, РІ-пятых, фольга РЅРµ пропускает влагу. RџРѕСЌС‚РѕРјСѓ SѓS‚еплоод ооторый находится RїРѕРґ ней РЅРµ R їРѕСЃС‚радает РѕС‚ горячего пара, Р° значит, ваша парилка будет SЃР»СѓР¶РёС‚СЊ вам очень долго.

RљР°РєР°СЏ бывает фольга?

Если РІС‹ решРели РѕР±С€Реть S„ольгой RїР°СЂРёР»РєСѓ, необходимо SѓР·РЅР°С ‚СЊ ввидах С„ ольги РѕР± особенностях такого RїРѕРєСЂС‹С‚РёСЏ.

Чаще всего бани из бруса обшввают алюминиевой фольгой.

Р•С' впределяется РїРѕ наличию добавок.

Фольга бывает простая, тканевая Рё бумага-фольга. Лучшая фольга для парилки менно простая, которая РІС ‹РґРµСЂР¶Ревает очень Р±РѕР» SЊС€РёРµ температуры. Лмст такой фольги имеет толщину 0.03 РґРѕ 0.3 РјРј.

RS‚РѕРіРѕ вполне S…ватает для S‚РѕРіРѕ, чтобы такая РѕР±С€РеРІРєР° РІ S‹РЅРµСЃР»Р° РІСЃРµ необходимые нагрузки. RљРѕРЅРµС‡РЅРѕ, R»СѓС‡С€Рµ RїСЂРёРѕР±СЂРµС‚ать R±РѕР»РµРµ S‚олстую фольгу.

R' SЃРѕСЃС‚аве S„оЂьги должно быть РЅРµ RјРµРЅРµРµ 99 СЃ половиной Рї SЂРѕС†РµРЅС‚РѕРІ алюминия. R”есять RєРІР°РґСЂР°С‚ных RјРµС‚СЂРѕРІ S‚акого RјР°С‚ериала стоят менее 500 рублей, чт Рѕ является очень выгодным.

Каждый рулон фольги ммеет маркировку «Т» Тли «М». Р'СѓРєРІР° «Т» означает «твС'рдая», Р° Р±СѓРєРІР° «М» «мягкая».

RўРєР°РЅРµРІР°СЏ фольга стоит несколько дороже. Такая форма фольги Тмеет несколько разновидностеР№ – РЅР° РѕСЃРЅРѕРІРµ стеклоткани Рели фольгоиз ола.

Самая плотная разновидность S‚каневой фольги назыв ается холст-С„ ольга.

R”R”SЏ RїR°SЂRyoR”RєRyo RµS’ RїSЂRyoRјRµРЅСЏСЋS‚ RSRµ S‚ак S‡Р°СЃС‚Рѕ, RєР°Рє RїSЂРѕSЃS‚СѓСЋ S„Р ѕР»СЊРіСѓ, потому S‡С‚Рѕ РѕРЅР° пропускает пар, хотя Рё очень S…орошо SѓРґРµСЂР¶РёРІР°РµС‚ теп R»Rs.

Р'умага-фольга делается РЅР° РѕСЃРЅРѕРІРµ S†РµР»Р»СЋР»РѕР·С‹, котору SЋ RїRѕRєSЂS‹РІР°СЋС‚ S‚РѕРЅРєРёРј SЃР» оем алюминия.

Такой матерРеал РЅРµ выдерживает температуру SЃРІС‹С€Рµ +1 20 СЏ парилки РµС' лучше РЅРµ применять.

RќРѕ зато такой фольгой можно RѕР±С€Рѕ‚СЊ RїСЂРµРґР±Р°РЅРЅРёРє РёСЂСѓРіР ёРµ прилегающРеРµ помещения.

RўР°РєР°СЏ S„ольга отлкоо РїРѕРґРѕР№РґСѓС‚ для закоулков между S ‚рубами, так как РѕРЅР° очень пластична. Стоит такой материал очень РґС'шево — 10 метров можно Rї риобрести Р·Р° СЃСѓРјРјСѓ RјРµРЅРµРµ 300 СЂСѓР±Р» ей.

RљР°Рє обшить RїР°СЂРёР»РєСѓ S„ольгой?

Обшивка парРелки фольгой должна начинаться SѓР¶Рµ RїРѕСЃР»Рµ S ‚РѕРіРѕ, как помещение Р± ани дало естественную SѓСЃР°РґРєСѓ, стены были РїСЂРѕРєРѕРЅРѕРї ачены Рё утеплены.

1. озмеряется площадь помещения определяется, СЃР єРѕР»СЊРєРѕ рулонов фольги необходимо RїСЂРёРѕР±СЂРµСЃС‚Рё.

Обычно простая фольга РїСЂРѕРґР°С'тся рулонами RїРѕ 10 РјРµС‚С ЂРѕРІ.

Следует помнить, что каждый лист нужно RєСЂРµРїРѕ‚СЊ РЅРµ встык, Р° внахлС'СЃС‚ R їРѕРєСѓРїР°С‚СЊ нужно СЃ запасом.

2. R›РёСЃС‚С‹ фольги РїСЂРёР±Реваются Rє стенам оцинкованным Ryo RіРІРѕР·РґСЏРјРё. Отражающая поверхность S„ольги направляется РІРЅСѓS ‚СЂСЊ помещения.

3.

Еслво время монтажа некоторые листы RїРѕР»СѓС‡РёР»Рё небольшРеРµ повреждения, РёС… Р·Р° клеРевают СЃ помощью металлизированного скотча. Если повреждения слишком R·РЅР°С‡РёС‚ельные, этот лист Р»С ѓС‡С€Рµ заменить. RЎРєРѕС‚С‡ РїСЂРеклеРевается RІРґРѕР»СЊ стыков лкоЃС‚РѕРІ.

4. Делается обрешетка РёР· реечек СЃ сечением RїСЂРёРјРµСЂРЅРѕ R їСЏС‚СЊ квадратных сантиметров.

Сверху устанавливается отделочный материал, напри RјРµСЂ, RІР°РіРѕРЅРєР°.

Отделочный материал РЅРµ должен устанавливаться РїСЂС ЏРјРѕ РЅР° фольгу, РѕР±СЏР· ательно должен быть небольшой промежуток.

RњРёС„ Rѕ S„ольге Рё его SЂР°СЃРєСЂС‹С‚РеРµ

Существует устойчивый РјРёС„ Рѕ том, что фольга РІ бан Рµ вредна Рё пропускает тепло наружу, мешая SЌS„фективно прогреть баню. RS‚РѕС‚ РјРёС„ легко развенчать.

Р'Рѕ-первых, перед фольгой находится RјР°С‚ериал-РїРѕРєСЂС‹S ‚РёРµ, который берС'С‚ РЅР° себя большую часть S‚епловой энергии.

Р'Рѕ-вторых, Р·Р° фольгой находится SѓS‚еплитель.

Так что добавляемая фольга РЅРµ может увеличить S‚епловые потери, Р° РјРѕР¶ ет лишь РёС… уменьшить.

Также некоторые люди РіРѕРІРѕСЂСЏS‚, что излишняя влажноS ЃС‚СЊ Рё недостаток РїСЂРѕРїСѓСЃРєР° РІРѕР·РґСѓС …Р° фольгой приведут Рє порче дерева. RS‚Рѕ неправда.

Р'Рѕ-первых, для конденсацРеРё пара РЅР° фольге (РЅРµ РЅР° обшивк Рµ) оставлено место, R ° РІРѕ-вторых, РІ бане всегда должна быть РїСЂРёРЅСѓРґРёС‚РµР»СЊРЅР°С Џ вытяжная вентиляция, включаемая РїРѕ необходимостпользователя.

Source: https://mydatcha.ru/obshivka-parilki-folgojj.html