Roof insulation with expanded clay is a time-tested method of reducing heat loss through the roof. Despite the advanced age of the technology, this method is still widely used to insulate the ceilings of bathhouses and private houses. And not only for the sake of economy: some modern heat-insulating materials are cheaper than expanded clay. The point is the environmental friendliness, strength, inertness and durability of expanded clay granules - no synthetic insulation can boast of such a combination of properties.

How to construct ceiling insulation based on expanded clay

The first question that needs to be resolved before starting work is what layer of expanded clay is needed to insulate the ceiling.

The material is inexpensive, but it’s still better to avoid unnecessary expenses. In theory, the thickness of the expanded clay layer for ceiling insulation can be calculated using the recommendations of SNiP No. P-3-79. To obtain high quality thermal insulation with a heat transfer resistance coefficient of 3.5-4 m2*C/W, it is enough to lay a layer 12-15 cm thick. To insulate the ceiling with expanded clay in a private house with an area of 80-100 m2, you will need to buy at least 4 cubic meters of sand and 10 cubes of dry backfill. Until work is completed, the material is stored in a dry, ventilated area. In addition, before insulating the ceiling with expanded clay in a private house, you will need to stock up on consumables:

- Glassine or vapor barrier membrane per 10 m2 of ceiling 15 linear meters of roll insulation;

- Scotch tape for sealing joints;

- Stapler with a set of staples;

- Polyurethane foam and tape measure.

If the work of filling expanded clay is planned to be carried out in an already built attic, then you will additionally need to prepare a rule, a lantern and several boards on which you can move without breaking the ceiling insulation.

Preparing for laying expanded clay

First of all, it is necessary to remove from the ceiling the old insulation and the remains of roofing material, which is traditionally used to underlay fiber thermal insulation. Usually it is glass wool, stone fiber.

The exposed surface of the rough ceiling is subjected to a thorough revision. In half the cases, it is possible to find places on the ceiling where thermal insulation did not exist at all. It is necessary to open the insulation so that the wood dries to its natural moisture content. All holes and cracks between the walls and ceiling boards are filled with foam, and if necessary, repair patches and bars are laid.

Installing patches is not necessary to combat leaks or water vapor penetrating through holes in the ceiling. This is not required; the insulation lining successfully blocks most of the fumes without patches. Repair of cracks and joints along the perimeter of the walls is necessary to ensure that small fractions of expanded clay do not spill out and reach the finished ceiling of the floor.

Laying vapor barrier on boards

As a vapor barrier, you can use parchment, vapor barrier, membranes, or any type of film insulation that can block the seepage of water vapor into the thickness of expanded clay insulation.

If the distance between the load-bearing beams is small, then the sheets can be cut separately for each span and the material can be laid in a boat, that is, with the side edges bent onto the walls of the beams by 2-3 cm. More is not required, since the sheet is laid to block spillage of expanded clay under isolation.

The edges are fixed with a stapler, while to fix the parchment on the boards of the rough ceiling, you need to use staples with long “legs”; any others are squeezed out of the wood due to the deflections of the sheathing.

In the event that there is more than 120 cm between the beams, the ceiling insulation is laid from two sheets with an overlap of 15-20 cm and the sheet must be taped with tape.

If it is necessary to install insulation on a concrete slab ceiling, then instead of film you can use an acrylic primer.

Filling the ceiling with expanded clay

The material is laid out on the surface of the ceiling in small portions. To simplify and make work easier, expanded clay is lifted to the ceiling in bags of 20-30 kg, no more, although in standard containers it can be more, up to 40-50 kg.

Backfilling of insulation begins from the far edges, filling all gaps and cavities with granulate. Due to the fact that the ceiling surface may differ from a perfectly flat plane, especially around the perimeter of the ceiling, it is quite difficult to accurately calculate the required amount of material. On average, it is believed that 1 m2 of insulated area will require a bag or 50 kg of bedding.

For arranging insulation, two types of expanded clay are used. The first layer, 3 cm thick, is covered with a fine fraction, up to 2-3 mm, the rest of the space is filled with dry bedding. This is a larger expanded clay, up to 2 cm in diameter. This device ensures trouble-free removal of residual moisture from the insulation layer.

At this stage, all the necessary communications, from wiring to telephone cables, can be laid in the thickness of the backfill. At the same time, the shell of baked clay serves as an excellent protection and thermal insulator.

At the final stage, the surface of the dry bedding is leveled using the rule. If a wooden floor is planned for the ceiling, then a layer of expanded clay is poured 1-1.5 cm below the upper edge of the support beams. This will avoid dust and creaking floorboards. Bulk insulation is covered with agrotextiles and sewn up with a floorboard.

Roof insulation with mineral wool cost of work

So, how to properly insulate a roof ? It is very important that all work is carried out professionally and efficiently. has enormous experience in such work.

The technology for installing a thermal insulation layer includes the dismantling of the roof covering, the selection of modern materials, heat and waterproofing of the roof, partial or complete replacement of the existing roof covering. Thermal insulation is performed using the “pie” technology. The multilayer system prevents heat loss, prevents the formation of condensation, and protects against moisture. Vapor barrier prevents water vapor from entering the thickness of the roofing pie. We use modern polymer deposited materials. Installation of vapor barrier from 30 rub/m2, installation + materials 60 rub/m2. For thermal insulation, we use slabs based on basalt rocks, insulation made from extruded polystyrene foam, and backfill insulation.

Stone wool has high thermal insulation properties (the heat retention effect of a 10 cm thick slab corresponds to a 117 cm thick brick wall) and sound insulation properties, does not burn, breathes, and is environmentally friendly. 165 rubles/m2 cost of roof insulation, price of work with materials 465 rubles/m2. The thermal conductivity of XRS slabs is lower than that of basalt mineral wool. Extruded polystyrene foam does not absorb water and is resistant to mold and mildew. Requires treatment with fire retardants. The cost of work is 130 rubles/m2, labor and materials are 630 rubles/m2. The distinctive properties of expanded clay are high thermal insulation and sound insulation. It is environmentally friendly, durable and fireproof. Expanded clay is a cheap material, but the need to create a smooth slope increases the cost of roof insulation. The cost of work with expanded clay is 1600 rubles/m3. The waterproofing coating protects the wooden elements of the roofing base from moisture coming from the street. Installation of the roof with materials 440-1040 rub/m2, 260-620 rub/m2 cost of work only.

Advantages Stroy-Alliance is a company with a narrow specialization.

- The range of services is short: Liquid roof waterproofing; Installation using bitumen built-up waterproofing and polymer membranes; Roof insulation with expanded clay, XPS slabs, slabs based on basalt rocks.

- But we have developed these technologies at an expert level.

- Along with installation, we also offer building materials: insulation, waterproofing and vapor barrier films from TechnoNikol, polymer coatings of Russian and foreign production.

- We work directly with material suppliers, so prices are 20% lower than the market average. And if you take into account free delivery, competent technical calculations, roof insulation technologies, the cost of work is reduced by another 30,000-50,000 rubles. Moreover, the reduction in the amount occurs due to the optimization of consumables, and not due to savings on quality.

- We are proficient in the technology of spraying a waterproofing layer (liquid rubber).

- The hydro- and thermal insulation project is calculated by professional design engineers.

- The team consists of professional builders with certificates from the construction academy TechnoNIKOL, Firestone, Technoprok.

Advice from the experts

It is worth paying attention to the fact that if we are talking about the construction of a frame house, then the expanded clay will have to be compacted especially carefully. But insulating a wooden structure with expanded clay will be very difficult, since it is necessary to leave cavities about 30 cm thick, and this is an additional load on the structure and foundation

In this case, it will be much more effective, simpler and cheaper to use mineral wool as insulation. And if climatic conditions and the thickness of the log house allow it, then you can do without it altogether.

Despite the positive assessment of such a thermal insulation material as expanded clay, during installation it is worth paying attention to such a disadvantage as a high level of fragility, which should be taken into account when backfilling and compacting. Thrifty owners advise using economical expanded clay to insulate not only the walls, but also the floor, ceiling, and attic space

With proper care, such thermal insulation material will last for many years.

Any building material, including expanded clay, can lose its original properties if stored improperly. For example, if bags with this insulation remain in the country for a long time, then there is a risk that the expanded clay balls will eventually turn into ordinary dust. If expanded clay is needed as insulation for walls or filler for lightweight concrete, then you should choose fractions 5–10 or 10–20.

How to insulate the roof of a house with expanded clay

In winter, up to 20% of heat is lost through the roof; in summer, it heats up and heats the upper floor.

Thermal insulation helps to protect against hypothermia or overheating, which, despite the abundance of materials, is often performed using expanded clay.

The method is old, but not outdated, because expanded clay, having passed all the tests of time with honor, has proven itself to be a universal insulation material. Inexpensive and with good characteristics, the material protects the roof with a high-quality layer of thermal insulation that does not lose its properties even during extreme weather conditions.

What types of roof insulation are there?

Mineral wool

Mineral wool is divided into two subtypes - stone and glass wool. Which is the best mineral wool to choose for roof insulation?

Glass fiber-based mineral wool is excellent for thermal insulation of curved or broken areas. The material has good soundproofing properties.

However, this type of insulation causes a lot of inconvenience during operation. Its flowability significantly complicates the task of insulating the room, so you need to wear special clothing while working.

Stone or basalt wool has a dense structure. Available in tile form.

It is much easier to work with than glass wool. In a pitched roof, stone wool can be conveniently laid between the rafters. It is also used for flat roofing.

Mineral wool is considered one of the best insulation materials for the roof of a private house. This is due to the positive properties of the material. Soft insulation is light in weight and does not load the roof.

High elasticity allows the insulation to be installed in smaller structures. Creates good sound insulation and has a long service life.

Among the disadvantages of the material, a high degree of hygroscopicity is noted. When exposed to moisture, mineral wool is destroyed. Due to its brittleness, glass wool is not used on surfaces subject to vibration.

Thermal insulators based on polystyrene

Foam plastic is the cheapest roof insulation.

The heat insulator, like mineral wool, is lightweight, so it does not overload the roof structure. The slab shape makes it easy to transport and install.

Important! Polystyrene foam does not allow water to pass through at all, but has a major drawback: it is flammable. The material does not burn, but melts at high temperatures, releasing a pungent odor that is deadly.

The insulation belongs to a number of unstable polymers, so it cannot be called durable.

Expanded polystyrene, unlike polystyrene foam, has higher strength and a lower thermal conductivity coefficient.

Special additives in the composition prevent fire and reduce the percentage of decay. Therefore, expanded polystyrene is considered more durable compared to polystyrene foam.

Important! Of the polystyrene-based insulation materials, penoplex has gained the most popularity.

Sprayed insulation

Polyurethane foam is considered the most effective material for insulating attic and pitched roofs. It is sprayed onto the surface, penetrating into hard-to-reach places, leaving no gaps or cracks.

A very low degree of thermal conductivity and vapor permeability allows you to avoid unnecessary costs for vapor barrier. Synthetic material is not susceptible to rodents and insects.

Ecowool has similar properties as polyurethane foam. The insulation is based on cellulose fiber. The main advantage is environmental friendliness.

But when insulating a roof with ecowool, it is important to consider that the insulation loses volume over time. Therefore, when blowing out, specialists must take this into account

Typically, a heat insulator is placed a quarter of the volume more.

One of the varieties of bulk material that serves as insulation for the roof. It consists of light stones of different sizes. It is used for pitched and flat roofs, falling asleep between the joists.

Cheap material is not afraid of moisture and rodents. It is made of clay, therefore it is considered an environmentally friendly material. Expanded clay granules have low thermal conductivity, which is a definite advantage when insulating a roof.

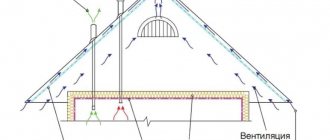

Vapor barrier

A vapor barrier is needed to prevent warm air from the room from penetrating into the insulation in winter. When this happens, condensation forms.

Polyethylene film, foil, and roofing felt are used as a vapor barrier. The material is laid over the entire surface in overlapping strips. Insulation of a pitched roof is carried out from the attic side, the insulating sheets are fastened horizontally, the work is carried out from top to bottom.

Places adjacent to all elements, overlaps of canvases, places where pipes pass through the vapor barrier are carefully taped to prevent moisture penetration.

Layer thickness calculation

The thickness of insulation such as expanded clay depends on its properties and technical characteristics of the wall materials. Of course, it is easier to turn to the services of professional builders, who will definitely take into account the peculiarities of the local climate when calculating the thickness of the insulation layer.

You can calculate the required thickness of the insulation layer yourself using the following indicators:

- thermal conductivity coefficient of expanded clay – 0.17 W/m x K;

- minimum thickness – 200 mm;

- thermal resistance, which is equal to the temperature difference along all edges of the material and the volume of heat passing through its thickness. That is, R (resistance) = wall thickness / CTC (wall thermal conductivity coefficient).

Characteristics, pros and cons of expanded clay

Expanded clay is small, mostly round, porous pellets of baked clay. Obtained by rapid heating of moistened, fusible clay or clay shale. During the process of evaporation of water, the raw material “boils”, as a result of which numerous pores are formed, which give expanded clay its thermal insulation properties.

Advantages and disadvantages

The material obtained by firing clay has both advantages and disadvantages. Among the advantages it is necessary to highlight:

- low price for 1 m3 of material. However, some clarification is needed here: insulation in small packages is quite expensive. Expanded clay can only be purchased in big bags at an affordable price;

- long service life comparable to the service life of the building as a whole;

- resistance to sudden temperature changes - in domestic conditions it is impossible to create conditions under which destructive processes begin inside the granules;

- does not apply to flammable materials;

- high frost resistance - withstands from 150 to 300 freezing/thawing cycles;

- low specific gravity;

- versatility - can be used as backfill and filler for lightweight concrete;

- environmental safety;

- simple insulation technology;

- resistance against fungus, mold and mice and rats.

Among the disadvantages :

- very high level of water absorption, reaching 25% for whole granules, 40% for damaged ones;

- thermal insulation properties are manifested only when the thermal insulation layer is openly backfilled with a thickness of 200 mm and above;

- a large amount of fine dust penetrating into all cracks during backfilling.

More complete information about expanded clay, with detailed comments about the advantages and disadvantages, can be found in the work “Expanded clay as insulation.”

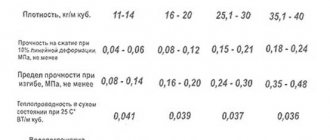

Characteristics

Expanded clay insulation has a high range of values for all indicators, which is explained by the quality of the clay. Him:

- thermal conductivity - 0.1-0.18 W/(m×°K). 0.23 W/(m×°K) is also found;

- density - 300-800 kg/m3. In St. Petersburg, for locally produced expanded clay, this figure is 1,200 kg/m3;

- compressive strength - 1.0-4.0 mPa.

Insulation with expanded clay

This option for insulating flat roofs in use has been used for a long time. It is gradually losing its popularity in private housing construction, because the expanded clay layer is inferior in thickness to both mineral wool and polystyrene foam. And here the difference is 2-2.5 times. In addition, expanded clay is heavier than its two competitors, which increases the load on the load-bearing structures of the building.

Just a few words about how thermal insulation with expanded clay is carried out:

- thermal insulation material is scattered

over the surface of the flat roof; - level

, strictly observing the thickness of the backfill;

a reinforcing frame made of steel mesh is laid on top

concrete solution is poured

Diagram of the arrangement of layers on a flat roof when insulating it with expanded claySource stroy-legion.ru

Thermal insulation with polyurethane foam

It should be noted that foamed polyurethane is a material with the best thermal insulation properties. It is applied in the form of foam to the surface being treated, which, after drying, forms a fairly strong layer; you will not find a single seam on its surface. Therefore, this method of thermal insulation is called seamless.

But polyurethane foam has two serious negative points:

- special equipment

is required to apply insulation ; - Thermal insulation material is expensive

.

And, despite this, polyurethane foam is a fairly popular option for insulating roofs of various types, shapes and sizes. As for the technology, the foam is simply applied to the surface of a flat roof of small thickness.

Materials and tools

The roof of private houses and high-rise buildings can be flat (attic or without an attic, requiring thermal insulation) and pitched. Therefore, different materials and tools are required to insulate a roof with expanded clay. Here is a universal list of everything you need, indicating where you will need it:

- expanded clay sand - necessary for insulating a flat roof;

- expanded clay granules measuring 0.5-20 mm in approximately the same proportions of grade M250-M350;

- Portland cement for cement laitance, grade M300;

- edged boards 20-25 mm thick of any width or OSB (plywood) sheets;

- softwood timber 25-35 cm wide, 50-75 mm thick;

- vapor barrier film type C or simple polyethylene film;

- windproof membrane type A (AM);

Attention: the types of films, their purpose and installation methods are described in detail in the article “Installing a vapor barrier with your own hands.”

- a board of any size for manual compaction of the backfill;

- slats for installing counter-lattice;

- wood screws;

- metal corners for attaching the timber to the flooring;

- reinforcing mesh for pouring screed on a flat roof;

- scotch;

- board or rule for leveling expanded clay;

- a screwdriver with a cross bit for self-tapping screws and a mixing attachment for preparing cement laitance;

- construction knife;

- roulette;

- solution container;

- buckets for supplying expanded clay to a pitched roof.

Calculation of the amount of expanded clay

The volume of expanded clay for insulation can be calculated using the formula: V = S x h x 1.2 , where:

- V is the volume of expanded clay;

- S - insulation area;

- h—thickness of the heat-insulating layer;

- 1.2 is the correction factor for shrinkage for a flat roof. For pitched - 1.1.

Sometimes buyers have difficulty calculating the required number of bags - they indicate the volume in liters. In this case everything is simple. There are 1000 l in 1 m3. Therefore, the figure obtained during calculations using the formula must be multiplied by 1000 and divided by the number of liters in the bag.

Video description

The video shows how to insulate a flat roof using polyurethane foam:

Foam concrete

This material is a concrete solution consisting of cement, sand and water, to which foaming agents are added. That is, the solution itself is not foamy. Air bubbles form inside it as the mixture dries and hardens.

The strength of the material depends on the volume of components added. The less foaming agent, the stronger and heavier the mass. But at the same time, the thermal insulation properties decrease. To form the covering of flat roofs, you can use a solution with low strength characteristics. Today, manufacturers recommend adding modifying additives to foam concrete, which increase the frost resistance of the mixture, its moisture resistance, and reduce the shrinkage of the applied layer.

Most often, foam concrete is used for thermal insulation of flat roofs of industrial buildings and facilities. It is rarely used in private housing construction. But if you need to form roofs of the type in use, then this option is one of the best.

Pouring foam concrete onto a flat roof Source vl-fasad.ru

It should be added that foam concrete is not a cheap material, plus equipment is required to pour it on roofs. And its transportation is not an easy process; it requires special vehicles or a cart on which a container with foam material is placed.

Technologies

Wall insulation with expanded clay is most common in brick houses, although it is sometimes used in frame versions. The technology is the same - it is laying in bulk. Although in most cases, in frame buildings, builders resort to insulation with lightweight materials. They use mineral wool, polystyrene foam, liquid polyurethane foam and penoizol. But owners choose expanded clay primarily because of its low cost.

One of the common ways to insulate a house with expanded clay is to organize a three-layer frame.

The inner part is usually about 40 cm thick and is made of expanded clay concrete - this layer acts as thermal insulation.

- The second layer is expanded clay mixed with cement in a ratio of 10: 1. This mixture is called capsic cement. Such a solid mixture gives the frame additional strength and rigidity, and its small mass carries almost no additional load on the foundation of the building.

- The third outer layer plays the role of protecting the insulation and simply decorating the building. Various finishing materials are used for it, depending on the preferences and financial capabilities of the owner, as well as the overall architectural solution. It can be wood, clinker bricks, lining, granite, stone, fiber cement boards or aluminum panels.

With three-layer wall insulation, experts use three finishing options, depending on the type of structure.

- Masonry with diaphragms. In this option, walls are erected: one as thick as a brick, and the other half as thin, and the distance between them should be 20 cm. After every fifth row, insulation is poured into the gap between the walls, tamped down and filled with cement laitance. Then 3 rows of brick are laid out, and the corners are made without cavities.

- Masonry with embedded parts is done using a similar technology with expanded clay filling between the walls, as with masonry with diaphragms. In this case, the walls are fixed together with brackets made of reinforcement.

- Well masonry involves building walls at a distance of 20–30 cm from each other. The walls are tied across a row using jumpers of 80–100 cm. The cavities are filled first with expanded clay and then with cement laitance.

Roof preparation

When insulating with expanded clay, the type of roof must be taken into account. It is easier to insulate flat structures; on sloped ones, you will have to make special pockets from slats that prevent bulk material from rolling down.

The work is carried out according to a single scheme:

- The surface is cleared of debris, especially sharp elements that can damage the vapor barrier layer;

- Vapor barrier is installed;

- Insulation is poured;

- Waterproofing spreads;

- Finishing material is installed.

Features of roof insulation with expanded clay

Expanded clay is a porous insulating material of dark brown color, obtained by firing clay for 30-45 minutes at a temperature of +1200 degrees. The raw materials are crushed and loaded into a special oven, which is capable of rotating at a given speed. As the clay moves through it, it sticks together into lumps, and the rotation of the kiln gives them a rounded shape. The size of the granules and their quality are regulated by the speed of rotation of the apparatus and the temperature of the hot air in it.

The result of the production process is an environmentally friendly, fireproof, frost-resistant bulk insulation with excellent thermal insulation and soundproofing properties. It comes in three types:

- Expanded clay gravel

. Its particles have a smooth oval shape and size from 5 to 40 mm. The material is used to insulate foundations and enclosing structures with a required thickness of insulating backfill of more than 50 mm. - Expanded clay crushed stone

. It has a rectangular shape with sharp corners, obtained by crushing pieces of sintered clay, and is used as insulation. - Expanded clay sand

. The size of its grains is in the range of 14-50 mm. This allows for insulating backfill with a thickness of less than 50-60 mm. Expanded clay sand can be used as a filler for mortars.

Due to the fact that sand weighs a lot, and crushed stone has inconvenient torn edges, expanded clay gravel is more suitable for thermal insulation of the roof. They can fill any cavity, creating a reliable insulating layer. To insulate roofs, you can use expanded clay of several fractions at the same time, and also add foam chips to it for greater effect. In terms of thermal insulation properties, a layer of expanded clay 10 cm thick is comparable to 250 mm of wooden beams or a meter of brickwork. The maximum insulation effect can be achieved with a layer of expanded clay thickness of 15 cm. In addition, this method of heat conservation is three times more economical compared to using wood, and 10 times more economical when using brick. It does not require special skills from the performer; expanded clay can be used to insulate the roof inexpensively, quickly and efficiently.

Expanded clay insulation for roofing is used only in the form of a dry bulk layer of a given thickness. Adding granules to concrete or cement mortar does not bring much effect. Due to the fact that expanded clay is free-flowing, its use is most optimal on flat roofs or those with a slope of up to 5%.

The quality of roof insulation made with expanded clay depends on the choice of good materials, including waterproofing, roof slope and calculation of its structure under load.

Let's sum it up

Expanded clay is a durable material, resistant to fungus and mold, that does not burn and does not support combustion. This is one of the most environmentally friendly types of insulation, since it is made by firing pure clay granules in special drums.

Which expanded clay is best suited for insulation? To do this, use a mixture of expanded clay gravel - rounded pellets - of two fractions: 5-10 mm and 10-20 mm. On flat surfaces, the underlying layer is made of expanded clay sand.

The minimum thickness of the expanded clay layer for insulation is 20 mm. Standard - 30-40 mm for flat roofs and ceilings. It is not recommended to pour expanded clay on pitched roofs in a layer thicker than 30 mm, since the rafter system may not be able to withstand the heavy weight.

Expanded clay, like other bulk insulation materials, is best suited for laying on flat surfaces. It is also possible to insulate pitched roofs with its help, but it is more difficult to do, and the insulation itself is always distributed unevenly, which leads to the appearance of cold bridges near the frame

Characteristics of backfilling with sawdust

Until modern insulation materials appeared, people used simple folk materials. Such insulation materials include:

- clay;

- moss;

- seaweed;

- sawdust.

Due to their low thermal conductivity, these technologies are still used today. True, progress has made its own adjustments, improving some indicators.

Let's consider insulating the floor with sawdust. There is no need to spend a lot on such thermal insulation material. This type of insulation is common, so you shouldn’t overpay for delivery. Often, sawdust is considered garbage at woodworking plants. Therefore, you can pick them up for practically nothing.

Due to its weight, sawdust does not put pressure on the floors. Insulation with sawdust is the same:

- hypoallergenic;

- does not emit an unpleasant odor;

- do not emit harmful substances into the air that can harm residents.

With the help of such material it is easy to insulate the attic floor even in the most inaccessible places. It is convenient to level the layer and, if necessary, increase it. For the insulation process, it is best to take small sawdust.

We would like to suggest a technology for insulating floors with sawdust. Its pros and cons will become clear upon review:

- Sawdust requires at least two years of aging. The ceiling from the attic side is covered with parchment paper. Wooden beams and crossbars must be treated with a fire-resistant agent. It is best to work with this element in mid-spring or summer. It will be warm outside, and the sawdust could dry out if necessary. The material must not be moldy. The material should not have a musty odor. Then the sawdust is mixed with cement and water is added, the mixture should come out a little damp. The mixture is placed between the beams, filling the entire space. Then let it dry. Ideally, the insulation should crunch when touched;

- In most cases, cement is replaced with clay. This is due to the fact that insulation in this way will be cheaper than using cement. In addition, clay is the same environmentally friendly material as sawdust. The ceiling covering must be covered with a vapor-proof film. Clay is mixed with water and sawdust is added. This mixture is applied to the attic floor to a thickness of 10 centimeters. Then they smooth it out with a board, compact it and wait until everything dries. If after drying there are cracks, they are sealed with clay;

- In this method, only sawdust is used for insulation. Before this, they are treated with an antiseptic and mixed with tobacco or glass fragments. This will prevent the appearance of rodents and harmful insects.

Calculator for calculating floor insulation on the ground

Explanations for using the calculator.

Special explanations are probably not required - everything should be intuitive. But nonetheless…

- We start by determining the normalized value of thermal resistance for our region (for floors) using the diagram map and indicating it in the input field.

- Next, you have to immediately decide whether the insulation will be carried out exclusively with expanded clay, or whether another thermal insulation material will be used, again, independently or in combination with expanded clay. Further actions and the final result depend on the choice of calculation path.

A. If the path “only with expanded clay” is chosen, then all that remains is to indicate (if necessary) the thickness and material of the floor covering - and immediately go to the “CALCULATE …” button

The result will be shown in millimeters, and this is the thickness of the layer of expanded clay backfill required.

B. If the calculation path using other insulation materials is selected, several additional windows will open.

— First, you will be asked to indicate the thickness of the additional expanded clay backfill, if it is planned. In the case when it is not there, the default thickness value is simply left, equal to zero.

— There are no changes to the finishing floor covering.

— But the next step will be to select the main thermal insulation material from the proposed list. The values of thermal conductivity coefficients of insulation materials have already been entered into the calculator database.

After pressing the calculation button, the result in millimeters will be shown. This is the thickness of the selected insulation.

By the way, the calculation along the second path also allows us to compare various insulation materials according to their effectiveness. In addition, one more side problem can be solved. For example, it happens that it seems financially profitable to purchase insulation boards 50 mm thick. By varying the thickness of the additional expanded clay backfill, you can quickly and easily determine which layer of it will be required for the main insulation to “fit” into the planned thickness of the slabs.

* * * * * * *

One more important note. Beginning builders often ask the question: is it possible to reduce the thickness of the thermal insulation if the insulation is planned to be “strengthened” with a floor heating system? There is already a semantic error in the question itself! Floor insulation and the “warm floor” system are completely different concepts! And the planned installation of a floor heating system not only does not reduce the requirements for its thermal insulation, but even makes them more stringent

There is already a semantic error in the question itself! Floor insulation and the “warm floor” system are completely different concepts! And the planned installation of a floor heating system not only does not reduce the requirements for its thermal insulation, but even makes them more stringent.

The fact is that heating a floor that does not have full thermal insulation is literally throwing money away. The funds spent on energy resources will be spent on unnecessary “heating” of the soil under the floor or the air on the street.

Disadvantages of such insulation

The main disadvantage of expanded clay is its flowability, which makes it difficult to use on pitched roofs, as well as its tendency to generate dust, which is why you often have to work in a respirator.

You can also add to the list of shortcomings:

- The ability to absorb moisture, which increases the weight of the material and reduces the insulating properties;

- The fragility of granules, which, after damage, lose some of their properties;

- High weight compared to modern insulating materials;

- For high-quality insulation, expanded clay must be laid in a thick layer.

The listed disadvantages are eliminated if all installation conditions are met.

Applications of expanded clay in a summer cottage

As was said earlier, expanded clay can be involved both in construction work and in landscape design, let’s consider everything in order.

Expanded clay is most actively used as an inexpensive insulation material for floors, basements, ceilings and walls. By insulating the roof and floor, you will not only create high-quality thermal insulation, but also provide the room with good sound insulation. Expanded clay pillow retains heat well, etc. It is light in weight and will not create large loads on the structure of the building.

Applications of expanded clay for floor insulation

Applications of expanded clay for wall insulation

As for public utilities, expanded clay has recently played an important role here too. As a result of a pipeline break, it is necessary to dig up soil at the accident site for further repairs, which is very difficult. The most common cause of an accident is water freezing in a pipe, causing the pipe to rupture. As mentioned earlier, expanded clay has good thermal insulation properties, so if you use it to fill a water supply channel running underground, the chance of pipes freezing is significantly reduced.

It is also advisable to use expanded clay to create various types of foundations. Unlike gravel, expanded clay is light in weight and has fairly good strength, which means that the foundation will be able to withstand the same loads, while transporting the building material will be simpler and less expensive. It should be noted that due to its thermal insulation properties, a foundation with the addition of expanded clay can be laid at a shallower depth.

In addition to creating concrete mortar, expanded clay is used in construction to create expanded clay blocks that are lightweight and have good strength and thermal insulation. Using expanded clay blocks, you can build both internal and external walls of a building.

Expanded clay block

Another area of application for expanded clay is road construction. When a road is being built in a wetland or on soil that has a high-lying aquifer, expanded clay bedding is often used, which quickly removes excess water and prevents flooding of the road.

Expanded clay cushion for roads

A drainage cushion made of expanded clay drains water well, so such a cushion is often made under the foundation, as well as borders.

Expanded clay also has an important purpose in the landscape design of home gardens. Due to its decorative appearance, expanded clay gravel is often used to decorate garden terraces and luxurious alpine slides built on hilly areas

Expanded clay in landscape design

In gardening, expanded clay is used as a good insulation material, as well as drainage for plant roots. Very often, expanded clay is added to the container with plants grown hydroponically, which, unlike soil, reduces the risk of plant diseases, as well as the appearance of various pests.

If you add expanded clay to fertile soil, the yield will increase, and by an order of magnitude. You can add expanded clay in 2 ways:

- When planting trees and shrubs, a hole is created, a cushion of expanded clay is poured into its bottom, and soil is poured on top of it. We place the root system of the plant on the ground, sprinkle it with a little soil and fill the remaining space, again, with expanded clay. The resulting “soil-expanded clay cake” will well saturate the root system with nutrients and water.

- An easier way is to mix a fine fraction of expanded clay with soil to further pour the mixture into the hole with the plant placed.

Both the first and second methods increase plant fertility with minimal costs for soil improvement.

The advantage of expanded clay, which is added to the soil with plants, is that it increases the water saturation of plants, improves air exchange, and also protects the roots from drying out in hot weather and mold formation in rainy weather.

Expanded clay can also be used to increase the fertility of indoor plants. To do this, fine expanded clay is added to the plant grown in a hydroponic pot.

Expanded clay for indoor plants

Well, the last, important area of application of expanded clay at a summer cottage is that the expanded clay pillow serves as a good filter, so if a layer of expanded clay is poured at the bottom of the treatment plant, the liquid will quickly separate from solid waste.

Expanded clay pillow serves as a good filter

As you can see, expanded clay has a lot of advantages and a wide range of applications, both in construction and in gardening and even in landscape design, so it makes sense to purchase

Subscription

Category: Insulation Date: 2014-12-10 09:26:57 Roofs were first insulated using expanded clay about half a century ago. Naturally, the modern market offers a huge range of insulation materials, but many continue to consider expanded clay insulation to be the best way to properly equip a pitched or flat roof.

Attention! It is expanded clay that can ensure an almost complete absence of problems that may appear during the formation of condensation, and will also reduce such a phenomenon as the “dew point” to “zero”. The roof is an important element of any home

For the space inside the home, this is the primary protection. Both cozy conditions and comfort of living in the house will completely depend on its reliability. Expanded clay is an insulation material that helps provide all these qualities over a long period of time.

The roof is an important element of any home. For the space inside the home, this is the primary protection. Both cozy conditions and comfort of living in the house will completely depend on its reliability. Expanded clay is an insulation material that helps provide all these qualities over a long period of time.

Characteristics of expanded clay

Having a natural origin, expanded clay has good strength and lasts quite a long time, unlike synthetic materials. With roof insulation with expanded clay, you don’t have to worry about processes such as rotting, for example, in wooden structures, the structure does not change under the influence of low or elevated temperatures. Moisture that gets into the insulation will not affect it in any way. Thus, expanded clay is a universal material for thermal insulation.

Attention! Based on its properties and characteristics, expanded clay is considered the best way to insulate a roof. This way you can achieve better indoor comfort in your home.

It must also be said that in pitched roofs there is very little space for thermal insulation. In this case, flat roofs are much more convenient.

Roof insulation technology using expanded clay

The first stage of work is similar to that for insulation with any other material. The ceiling must be protected from condensation. To do this, you can use a vapor barrier film, aluminum foil or foil-coated isolon.

It is forbidden to apply expanded clay onto a vapor barrier. First, the insulator layer must be fixed and then covered with a layer of soft clay. Clay itself is a fairly good material for sound insulation and has excellent thermal insulation qualities. That is, it should act as the first layer of thermal insulation, and the expanded clay backfill should act as an intermediate insulation material.

When insulating a pitched or flat roof, expanded clay gravel is most often poured. It is very convenient for filling all kinds of cavities and recesses. Often, to improve thermal insulation, it is supplemented with foam chips. Using this insulation, the roof installation process is very simple. First, expanded clay is poured onto the surface of the attic, which is then evenly leveled to make the surface as smooth as possible. A layer thickness of 15 cm will not place a large load on the load-bearing beams.

Then the roofing felt carpet is installed. It is advisable to choose better material that is sold in rolls. He presses down the expanded clay layer, thereby securing it. If the attic space will be used for its intended purpose, then you can fill it with a cement screed. This helps to insulate the ceiling and serve as a solid foundation. You can also add any waterproofing on top of the thermal insulation layer, which will also increase the service life of the roof.

How to work with expanded clay

Expanded clay is an insulation material that has many universal properties. Naturally, there are a number of disadvantages that the material has. For example, fragility - this obliges you to handle the insulation as carefully as possible.

Attention! Laying thermal insulation using fill must be done carefully so that individual parts are not damaged. When parts break, they lose their qualities and effective thermal insulation is not achieved.

By carefully pouring expanded clay, you can achieve effective insulation with small material investments and minimal costs.

Expanded clay is based on ordinary clay. Expanded clay is brought into its final state by firing - granules in the form of ovals. Sometimes manufacturers use the same technology as for sand production. Having absorbed moisture, the granules do not give it back, while absorbing even microscopic particles of water.

Purpose of vapor and waterproofing

One of the most important stages of roof arrangement is the hydro- and vapor barrier of expanded clay. This stage cannot be neglected, since expanded clay is capable of absorbing water. Its thermal insulation properties become worse and its weight increases.

If expanded clay gets wet, the service life of the roof can be significantly reduced and repair work will need to be carried out much earlier than expected.

Hydro- and vapor barrier provide protection for the thermal insulation layer. Without them, not a single type of insulation is able to protect the building from the cold.

Installation of vapor barrier material is usually carried out from the inside of the room. It protects thermal insulation from vapors rising from the premises of the building. The waterproofing layer is laid on the outside, since it protects the thermal insulation layer from moisture from the street.

Membranes and films are most often used as waterproofing materials. Polyethylene film, glassine, styrofoam and foil are also often used. Styrofoam is a type of foam plastic. It has high vapor barrier characteristics.