Features of foam insulation

The installed foam insulation is a porous polymer mass. The working solution is applied under pressure to the wall or ceiling, foams upon contact with air and hardens. Numerous gas bubbles provide thermal insulation and protect the premises from street noise and vibrations. The elastic structure of the material has sufficient strength and is able to withstand significant static and dynamic loads, increasing the overall strength of the roof.

Sprayed coatings do not have seams and joints through which heat leaks occur in other types of thermal insulation materials.

Why is thermal insulation necessary?

If you neglect thermal insulation and limit yourself only to heating the attic, then the following situation may arise:

- In winter, warm air will quickly leave the room, which will entail significant financial costs.

- When warm air comes into contact with the roof, the snow on it will melt and form ice and icicles, which can lead to damage to the roofing.

- In cold weather, condensation will form on the inner surface of the roof, leading to rotting of the elements of the rafter system.

- In the summer, the room will heat up intensely to such an extent that living in it may simply become impossible.

Insulating an attic from the inside is a more difficult task than insulating ordinary rooms:

- The need to apply insulation not only to vertical surfaces, but also to roofs that have a negative angle of inclination.

- There is a high probability of moisture from the roof getting onto the insulation and getting it wet.

- Possibility of carrying out work only in the warm season.

*

All these problems are eliminated by insulating the attic space with polyurethane foam.

Applying insulation to the roof from the inside

*

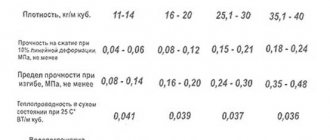

Types of material and their properties

Foam heat insulators vary in their composition and application method

Liquid penoizol

This popular material is used to insulate floors and walls. It has the following advantages:

- high-quality adhesion to most building materials;

- small amount of preparatory work;

- seamless and jointless coating;

- good vapor permeability;

- high penetrating ability;

- possibility of filling hard-to-reach volumes;

- resistance to fungus, microorganisms and mold;

- environmental friendliness.

The material also has disadvantages:

- linear shrinkage;

- strong unpleasant odor during application;

- hygroscopicity, additional water vapor barrier is required;

- fire hazard; when heated, toxic substances are released.

Roof insulation can be done using liquid penoizol.

Penoizol requires an additional fire retardant coating; it is better to use it for external insulation of the roof of a house.

Polyurethane foam (PPU)

Closed-cell polyurethane foam insulation is also deservedly popular among homeowners. Experts highlight the following advantages inherent in the material:

- applicability over a wide temperature range;

- compatibility with most popular building materials;

- ensuring the tightness of the sprayed coating even with a complex roof configuration;

- low thermal conductivity coefficient;

- resistance to biological influences: mold, microorganisms, insects, rodents;

- low density of the material and, accordingly, a small additional load on the roof;

- resistance to solvents and other active substances;

- ability to withstand compressive and tensile loads;

- low vapor permeability, no need for additional vapor barrier;

- minimal hygroscopicity;

- excellent noise insulation performance;

- long service life comparable to the service life of insulated structures.

There are PPUs and a number of disadvantages:

- high activity of the working staff, harm to exposed skin and respiratory organs;

- the need to use protective clothing, masks and respirators;

- vulnerability to sunlight, especially ultraviolet rays, necessitates protecting the coating with an additional layer of mastic or plaster;

- releases harmful substances when heated;

- highly qualified worker applying the coating is required;

- high cost of equipment for applying the material.

The last two factors make it difficult to apply polyurethane foam yourself. Even disposable installations, already charged with a certain volume of working solution, are expensive. If the home owner does not have experience in successfully using them, it is better to turn to professionals and insulate the roof with their help. You will be able to save your nerves, money and time.

Positive qualities of polyurethane foam

PPU has a number of properties that are not just positive, but unique:

Let's take a closer look at the characteristics of polyurethane foam.

Thermal conductivity

The thermal conductivity coefficient of polyurethane foam is 0.025 W/m*K. This is the lowest figure in comparison with mineral wool and polystyrene foam as the most common insulation materials. Its property, such as closed porosity , does not allow water to penetrate into the mass of the material, which means its working qualities are preserved. Therefore, insulation with polyurethane foam is profitable and effective.

Easy to apply

The thickness of the applied polyurethane foam coating is 3-7 cm. Moreover, dense application does not require additional fasteners, since one of the qualities is high adhesive strength. This means that when applied, it practically sticks to the surface, regardless of its composition, and fills all cracks and pores. This completely eliminates the possibility of condensation accumulation and cold penetration.

Lifetime

The durability of polyurethane foam is one of its fundamental characteristics. It has been in use for at least 30 years . If the material is not in contact with the environment, its service life is extended to 60 years . Premature decline in performance is often caused by low quality products or incorrect operating conditions. The latter may include temperatures above 100° or, for example, systematic contact with liquid under high pressure conditions.

Safety

The good thing about the material is that during operation it “works” without releasing toxic substances. In addition, it is not flammable, which is also its advantage.

Noise absorption

The ability to absorb noise depends on several parameters of the material: its elasticity, insulation thickness and ability to pass air. This characteristic is directly related to the rigidity of the frame and the frequency of sound vibrations. The air in the cells also affects the absorption of sound waves. It was experimentally found that elastic polyurethane foam is the best noise absorber.

Selection criteria for roof insulation

When choosing a material for thermal insulation of floors or roofs, the following factors should be taken into account:

- roof area;

- the material of the underlying surface on which the working solution will be applied;

- composition of the working solution, it is better to avoid components harmful to health;

- reputation of the manufacturer;

- price.

When choosing foam for roof insulation, you need to take into account the roof area

. In addition to the purchase price, during the analysis you will need to take into account the cost of materials and labor costs for preparatory and additional work: surface preparation, vapor barrier, fire protection, etc.

How to prepare the attic from the inside for foam insulation

The insulation process begins with preparatory activities. All foreign objects are removed from the attic. Firstly, they will get in the way. Secondly, stuck foam is difficult to remove. Expensive tools, furniture and other valuable items may be damaged.

Peeling paint and other old finishes are removed before insulating the attic elements

After freeing up the space, they begin to prepare the surface where polyurethane foam is sprayed. The peeling paint is cleaned off with a spatula. If there is old insulation or decrepit cladding, dismantle everything and get rid of dust. Wooden roof elements are inspected for integrity. Damaged beams are replaced or repaired.

The attic has windows. They are all covered with film, along with window sills and slopes. It is difficult to remove foam that gets onto an unprotected area without a trace, so you will have to try with a reliable shelter.

Methods of applying polyurethane foam

There are several ways to apply the working polyurethane solution:

- fill;

- spraying;

- installation of sheet material.

Fill

Typically used during the construction phase. In this case, a rough ceiling is mounted on the rafter system, and foam is poured over it. This method has lower requirements for the qualifications and experience of performers. A vapor barrier is installed on top of the insulation layer, and then the roof is installed.

Sputtering

The method is suitable for repair work and additional insulation of already constructed buildings.

Using special nozzles and spray nozzles, the composition is applied to all surfaces to be insulated, including hard-to-reach places.

In this case, it will be necessary to attract qualified and experienced workers who can spray the composition efficiently and meet the planned standards for material consumption.

In cold regions, spraying is carried out in two layers to increase the overall thermal insulation of the coating.

Ready-made thermal insulation panels

This method is used on flat rectangular roofs. Finished sheets from rolls or panels produced at the factory are attached to the roof from the inside using adhesives and are additionally fixed with disc dowels. The seams and gaps between the sheets are filled with polyurethane foam.

This application method does not require expensive equipment or highly qualified personnel. Due to the numerous joints, the quality of insulating the roof of a house with foam and its service life are somewhat lower than with spraying.

Scope of application

The versatility of polyurethane foam and its performance characteristics provide it with a wide range of applications. For example, in light industry it serves as the basis for the production of synthetic leather and duplicated fabrics. It is used as a filler for upholstered furniture and is used in the automotive industry.

Some of the characteristics of polyurethane foam are its low thermal conductivity, low vapor permeability and waterproofing properties. This allows this material to be used as insulation. In the construction industry, it is used as thermal insulation for construction projects .

With its help, thermal insulation with polyurethane foam is carried out in the following areas:

During the construction of the foundation, polyurethane foam also performs a waterproofing function, and for walls - acoustic insulation. Typically the material is applied by spraying .

In addition to construction projects, polyurethane foam as an insulating material is used for refrigerators, tanks and various containers, cars .

Limitations for the use of polyurethane foam

Insulation based on polyurethane foam is not recommended in the following cases:

- the house is inhabited by people who are hypersensitive to chemicals;

- near the place where chimneys pass through the roof or ceiling;

- for insulating external walls without applying a light-protective coating.

The use of polyurethane foam for roof insulation is not recommended if people with chemical sensitivities live in the house

Carrying out thermal calculations

Any and even simplified thermal calculations of enclosing structures should be based on the following regulatory documents:

- SNiP 02/23/2003 “Thermal protection of buildings” -

- SP 23-101-2004 “Design of thermal protection of buildings” -

- GOST R 54851–2011 “Heterogeneous building enclosing structures. Calculation of reduced heat transfer resistance" -

- STO 00044807-001-2006 “Thermal protection properties of building envelopes” -

As you can see, the calculations are complex and take time to learn and implement. Fortunately, in our time it is possible to translate these complex formulas and long tables into much more understandable calculation programs, into which you just need to enter the initial data and select the materials used and their thickness. So there are online calculators and separate software products installed on a personal computer.

One of the most comprehensive online thermal calculators is. When making calculations, he operates with data and conditions from all four of the above regulatory documents. At the same time, it allows you to use both the existing database of materials with their properties, and supplement it with your own materials. In addition to determining the required thickness of the thermal insulation layer, it allows you to assess whether excess moisture will accumulate in the structure during operation, as well as estimate heat losses.

A program for thermal engineering calculations is often used as a free software product for PCs. The program carries out calculations based on all necessary regulatory documents. The program management interface is very simple. The program makes it possible to carry out calculations in two modes - calculating the required thickness of the heat insulator and checking the designed “pie” of the structure.

A software product for specialists, which is designed to calculate temperature fields and thermal resistance of buildings and structures, requires special attention. In addition to the functions included in the above programs, “Temper-3D” allows you to conduct a three-dimensional thermal analysis for each individual node or section and display a graphical 3D picture of the temperature distribution, as well as draw up documentation with calculation results and conclusions, and calculate the power of heating devices.

Further in the article, we will consider simplified calculations that will allow you to make a preliminary assessment of the required thickness of polyurethane foam, and also give examples of calculations using polyurethane foam.

Stages of roof insulation with polyurethane foam

When applying the coating, you must follow the technology and sequence of work

Necessary tools and protective measures

To work you will need:

- reusable and or disposable spraying installation;

- mounting knife for cutting rolled and sheet materials and removing frozen excess foam;

- measuring tool for marking surfaces;

- painter's protective overalls with a hood and elasticated arms;

- tight shoes;

- safety glasses or face shield;

- respirator;

- gloves.

Preparatory work

During preparation, it is necessary to clean the surface to be treated from debris, dirt and remnants of old coatings.

Next, install the sheathing and metal profiles or wooden slats. Their thickness should match the planned thickness of the applied foam layer. In the future, the finishing trim will be attached to this frame.

The working solution is thoroughly mixed to the consistency required in the instructions.

Spraying material onto the base

The first layer of foam is applied to the prepared base. It is necessary to achieve a continuous application, closing gaps and filling uneven areas.

Spraying is done from top to bottom. If necessary, after the first layer has hardened, apply the second and subsequent layers. Each time you need to let the previous layer dry and set.

Excess insulation is cut off with a mounting knife flush with the installed sheathing.

If you plan to cover the insulation with a layer of plaster, a polymer or metal reinforcing mesh is mounted on the sheathing.

Application of fire retardant composition

Polyurethane foam is highly flammable and releases toxic substances when heated and burned. Therefore, the insulation layer is coated with a fire retardant compound. The composition must be selected specifically recommended for use together with polyurethane foam. It would be wise to choose it from the same manufacturer as the main material. The layer is applied with a sprayer or roller so that the coating is continuous and the entire insulation is protected.

Preparatory work

Before installation, it is necessary to prepare the surface and check the functionality of the equipment.

It is necessary to thoroughly clean the surface from dirt, debris, and mold. The roof must be dry, otherwise the polyurethane foam will not adhere well to the surface, and as a result, defects will remain.

If there are cracks or holes larger than 6 mm, they must be sealed.

Preparatory work also consists of arranging a wooden sheathing, and its height must correspond to the height of the layer of heat-insulating material.

It is important to carry out a test spraying to ensure that the thermal insulation material has a normal structure. If necessary, adjustments are made and re-spraying is performed.

Materials and tools for spraying

A device for spraying polyurethane foam can be rented or purchased. However, the second option will be expensive. The equipment consists of the following components:

- Cylinders with contents (polyol and isocyanate)

- Spray gun

- Hoses

- Nozzles

- Lubrication

The contents in the cylinders are mixed with each other directly during the spraying process.

The roof must be well and efficiently insulated, otherwise there is a high probability that it will begin to leak, and as a result, dampness will appear in the house and high humidity will be felt in the rooms. It is important to choose quality material.

What is penoizol?

This is what applied penoizol looks like.

The method for producing this substance differs from the production of foam in that its production is based on a urea polymer, which is exposed to chemicals, as a result of which it, like PU foam, swells many times. In appearance, this material is very similar to foam plastic that is familiar to humans.

Properties of penoizol:

- Has a low level of density in the hardened state.

- It has a good thermal conductivity, which allows you to retain heat in a living room. But polyurethane foam has a much higher rate of preserving and maintaining room temperatures.

Since this substance in the solid state does not have a very high density, it is not often used to insulate those surfaces that may be subject to various mechanical effects or varying degrees of load. Also, you should not use it for insulating basements or any other rooms in which the humidity level is higher. Penoizol is not strong enough to withstand moisture.

The most common material is penoizol when it comes to insulating the walls of a frame house, roof, internal roof area, or for placement between material presented in the form of bricks.

The transition from a liquefied to a solid state occurs quite quickly, taking no more than half an hour. But further work should be postponed for about 2-3 days to achieve a better effect.

This material is advantageous in that after acquiring hardness it can be compared with monolithic materials. Many who used penoizol to create the outer thermal insulation layer of their home were satisfied. This substance completely provides the wall material with protection from freezing, exposure to air flows and liquids. If the substance was sprayed correctly, then various defects in the form of microcracks will not form on its surface.

Insulation work must be carried out in favorable weather conditions. In order for the workers to carry out the necessary manipulations, you will have to pay them approximately 150-200 rubles per square meter insulated with foam insulation. Also, this is not the final amount, since everything will depend on what thickness of the layer the customer prefers and what the working surface will be.

To save a little on labor costs, you should prepare the surface that will be insulated yourself. Namely, to clean it from debris and dirt, to ensure a state of dryness and absence of dust particles.