A warm garage is the dream of any motorist; it’s nice to get into a warm car on a frosty winter morning and immediately start driving without wasting time on warming up. In addition, parking in a warm garage has an extremely beneficial effect on the technical condition of the car. And minor repairs in the cold season cease to be a problem.

Warm floor in the garage

That's why more and more car enthusiasts are thinking about heating in the garage. The best option for this is a warm floor. It evenly heats the air in the room, with the lower layers receiving the maximum heat, thereby achieving energy savings. In the garage there is often a need to look under the car; if you lie down on a warm floor to do this, your back will thank you.

Features of heating in a garage

The procedure for heating a garage has its own characteristics, determined mainly by the intended purpose of the room. This is due to the fact that a garage box is a technical room in which repair work is carried out, fuels and lubricants and an expensive car are stored. For this reason, when installing a heated floor system in a garage with your own hands, it is necessary to consider not the price and economic characteristics, but the degree of reliability and safe operation.

Before making a heated floor in the garage, it is recommended to study the regulatory requirements that determine the microclimate conditions for the garage. First of all, this is effective ventilation, which ensures the removal of exhaust gases, foreign odors and fumes from the garage.

It follows that when installing a heating system, it is necessary to provide for a constant influx of cold air masses. In addition, taking into account the operation of ventilation, the temperature in the garage should not be lower than five degrees Celsius. To comply with this condition, you will have to arrange high-quality thermal insulation of the entire room, because the garage room is not heated 24/7.

Types of heated floors for garages

There are a number of restrictions that must be taken into account when installing heated floors in the garage:

- there is a possibility of chemical exposure;

- susceptibility to mechanical damage;

- the floor must be resistant to moisture and not susceptible to fire.

Today, garage floors can have the following coatings:

Installing a heated floor in a garage with your own hands makes it possible to solve several problems at once:

- create comfortable conditions for the operation of the premises, ideal for storing a vehicle;

- heat the room efficiently.

Underfloor heating systems that can be installed in a poured floor covering are divided into two types:

- water heated floor in the garage - the entire system is represented by a closed loop assembled from metal-plastic pipes immured in a screed. The heating source for a water heated floor in a garage is a boiler;

- electric heated floor in the garage - for its installation special electrical cables are used, walled up with a concrete screed.

Water heated floor in the garage

How to insulate a concrete floor

Car owners often prefer a concrete floor in their garage. This option is considered the most optimal; it is quite durable, fireproof and relatively cheap. In this case, insulation will not be difficult, but you should decide on the material before concreting.

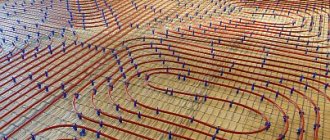

Layout of the water circuit under the floor covering.

There are many insulation options on the market; when choosing the right one, you should pay attention to several points:

cost - each method differs in price, it is better to purchase all the necessary material at once so that the process does not freeze in the middle; complexity of the work - a beginner may encounter difficulties while performing the work, so it is worth familiarizing yourself with insulation methods in advance; quality - everyone probably wants the chosen material not to have to be changed after a short time, so you should also pay attention to the service life.

Criterias of choice

Select the option for heating the garage space according to the following criteria:

- equipment for installing water heated floors in the garage;

- pros and cons specific to a water or electrical system, allowing you to better navigate the choice taking into account specific conditions;

- A water heater is easy to install, but installing a water circuit will take a lot of time and effort and require financial expenses. But in operation it is considered more profitable. True, there is a possibility of a leak, due to which the entire floor will have to be dismantled;

- if the garage is not planned to be used for a long time in winter, the water from the system will have to be drained to avoid pipe ruptures;

- An electric heated floor in a garage is easier to install. But if the garage is poorly insulated, then heating will require a lot of electrical energy;

- Having determined the option of an IR system for yourself, you will be forced to reduce the heating surface in order to prevent breakdowns from significant loads.

To do or not to do?

On the one hand, you get the opportunity to always maintain a comfortable temperature in the garage even in the coldest period. In this case, the heat will be distributed evenly over the entire area of the room, which is impossible when using autonomous convectors.

However, there is a downside to everything: due to the temperature difference, frost will appear on the gate, and condensation will invariably appear inside the room. It also makes sense to use underfloor heating in your garage if you use it frequently. Periodic switching on will not give a noticeable result in warming up, and the potentially high efficiency of the system will remain unrealized.

And one more point, no less important: all installation work must be carried out in full compliance with the requirements of SanPin. Therefore, studying them carefully is your obligatory task.

Advantages and disadvantages of heated floors in the garage

Before making the final choice of a heated floor in the garage, you need to consider all the available pros and cons for each system.

The advantages of a heated floor in a garage powered by water heating are as follows:

- energy saving;

- uniform heating of the surface.

Negative points include:

- complex installation;

- there is a possibility of a leak, to detect which the floor will have to be dismantled;

- If the garage is located separately, it is necessary to install a water supply system.

For a complete comparison, consider the option of electric heating. Such a system is easier to install, but the cost of paying for electrical energy will increase significantly.

The advantages of the system are as follows:

- there is no need to provide other communications;

- to install the system you will need an electrical cable and a thermostat;

- the system does not require maintenance.

There are also disadvantages:

- electricity costs increase. True, they can be reduced by almost half if the garage is well insulated;

- the infrared floor will have to be located locally to prevent the impact of load forces on it.

Basic technical requirements for installation

Let us briefly consider what requirements should be observed when installing a particular heating system in a garage.

Water floor

In this case, even at the construction stage of the garage, provision should be made for the installation of an insulating layer. You will have to spend additional money on supplying water and purchasing the necessary equipment.

It is necessary to plan in advance the location of the heating device, which will take up part of the space in the garage.

Electrical

Before installing this system, you should decide what functions will be assigned to it. As a rule, it represents the only source of heat. Therefore, when choosing a kit, you should focus on the area indicated in the documentation. In addition, you should take into account the ratio of the entire garage area to heated areas and the power of the heating system per 1 sq. m.

In principle, any underfloor heating system used in a garage must meet the following requirements:

- ensure uniform heating of the entire room from floor to ceiling;

- if such a need arises, heating should be interrupted automatically;

- the system should be easy to install and operate;

- equipment should not occupy useful floor space;

- The heating system must fully comply with safety requirements.

Installing electric heated floors in a garage

Difficulties encountered in installation and use

Possible difficulties that may arise during the operation and operation of a system based on heating using a boiler:

Incorrect calculations of the required amount of power of thermal appliances; Difficulties in calculating pipe pitch. The pitch in this case is the distance between the pipe arcs

You should not do it by eye, but it is important to calculate it correctly after calculating the heat loss. Neglecting to install insulation for heat and moisture. Sometimes these layers are missing from the system, which leads to poor heating performance and an increased risk of moisture ingress. No damper tape

This can lead to damage and even deformation of the pipe when the screed expands. Incorrect contour calculation. Wrong pump selected. Connection errors. Wrong screed thickness. Damage to pipes during installation work.

All these mistakes lead to prolongation of installation work and increased prices for them.

Installation technology for heated electric floors

How to make an electric heated floor in a garage? Let's consider the main working stages.

Preparing the base

First you need to learn the safety rules. After this, certain events are held. As a rule, the floor in the garage is earthen, so it must first be insulated to minimize heat loss.

Thermal insulation

If this condition is neglected, the loss of thermal energy will reach thirty percent.

To begin with, a gravel cushion is placed on the ground base, the height of which reaches twenty-five centimeters. The gravel is leveled and thoroughly compacted. After this, a seven-centimeter sand cushion is arranged using the same principle. A screed of concrete mixture is placed on top, which is poured over the reinforcement frame.

The next stage is laying thermal insulation material. It can be different, but in the case of a garage floor, experts recommend using polystyrene sheets or penoplex. The thickness of the layer can vary from four to nine centimeters, and this depends on the climatic conditions of your area.

The top of the thermal insulation layer is covered with polyethylene. The final step is pouring the sand-cement screed. Its surface should be smooth, without sudden changes in height. The installation of the thermal insulation layer is completed.

Features of installation technology for water heated floors

Now let's study the sequence of work when installing a water heating system.

Preparing the base

If there is flooring in the garage, it will have to be removed. The surface of the subfloor is leveled, for which in most cases an additional screed is poured.

Having completed this stage, the thermal insulation material is laid, the thickness of which must be at least 30 mm. The recommended insulation density is 35 kg per meter. Polystyrene or penoplex is best suited for this. You can purchase special insulating mats equipped with locking devices.

After laying the insulation, a damper tape is laid along the entire garage perimeter, designed to compensate for the thermal expansion of the screed.

Pipe installation

A layer of insulating material is covered with polyethylene, on which a frame made of reinforcing mesh is placed. The heating system pipes will be fastened along it. This is done using plastic clamps. Expansion joints are protected by corrugated pipe.

Installation of water heated floor in the garage

Installation control

A hydraulic test is mandatory. A pressure of 3–4 bar is created in the system, and the pipes remain in this state for more than one day. If problems in the form of leaks are discovered during testing, the coolant is drained, the defects are eliminated, and then a re-check is performed.

Filling the screed

After the tests, a screed is poured, the height of which should be 3–15 cm higher than the level of the pipes. To achieve maximum evenness, it is recommended to use beacons. The poured floor is left alone for a month so that the concrete gains strength. During this time, the heating system does not turn on.

As soon as the concrete dries, the heating is turned on, but the temperature is increased gradually. The floor, ready for use, can be covered on top with tiles or other material suitable for a garage.

Whether your garage needs underfloor heating is up to you to decide. If, in addition to storing equipment, various work is performed in the garage, then floor heating will not hurt. You just need to make the right choice between the water and electrical systems.

From the point of view of many, heated floors in the garage are overkill and a waste of money. However, caring owners of cars or other vehicles are well aware of how temperature changes, dampness and cold have a detrimental effect on their iron friends. Corrosion, damage to parts and sometimes even rotting of the housing are all possible consequences of non-compliance with the temperature regime.

Repairs can cost a decent amount. Taking into account that in damp conditions repairs will be required more often, as a result, the cost of restoration will significantly hit the family budget.

Which coating is better?

The above characteristics of water heating showed the presence of some disadvantages. Repairing the electrical system is much easier.

The water system is not so reliable, sometimes it is difficult to control the temperature in it, which in the second type occurs with the help of special sensors.

For profitable savings, choosing a water floor is a good idea, since using a boiler saves quite a lot.

The main thing is to get used to the operation of the system, learn to independently control the heat supply and surface temperature, then the shortcomings will not be so obvious.

Electric floor classification

When should you think about installing underfloor heating?

A warm floor for a garage is not a luxury, but a necessity. Even if you do not take into account transport, the owner himself remains: being in an unheated room in winter is fraught with colds, and if you need to carry out your own repairs, the cold garage floor will cause pain in the lower back or joints.

Carrying out such heating will be necessary if:

- The garage is attached to the house. The cold from this room can penetrate into the main part of the house.

- The car is vulnerable to the negative influences of the environment. If the machine is made of poor quality material, moisture and cold will cause corrosion.

- The owner is often in the garage. Often the garage is used as a workshop and warehouse, in which you have to spend a lot of time.

- There is sensitivity to cold or draft. Provided that a person has previously suffered from pain due to unfavorable weather conditions, then such a floor is irreplaceable.

All of the above reasons are good reasons to install a heating system.

We grout the joints

Expansion joints can be sealed with any sealant. A day after the glue dries, the final grouting of the tile joints is carried out. The mixture is applied with a rubber spatula or grater. The remaining mixture is removed immediately.

After installation is completed, it is recommended to check the gate for free movement. The floor is ready for full use in 2-3 weeks.

When installing porcelain tiles on the garage floor, some craftsmen create a slight slope. This will allow you to wash the car right in the box. For drainage, a container is provided in the middle or a storm drain at the entrance. A significant advantage of floor tiles is that there is no need for major repairs of the entire floor. If one segment is damaged, it can be easily replaced with a new one.

Using cheaper materials is only a one-time saving. Renewing a leaking floor or walls every year is not very exciting. Alterations are not cheap either. To avoid mistakes, approach all stages of work responsibly. If you are not confident in your abilities, invite a specialist. Laying porcelain tiles is a labor-intensive and technically complex process. Maybe choose a rubber coating for the garage?

What is the advantage of heated floors?

When answering the question of whether a heated floor is needed in a garage, it is necessary to highlight all the advantages of this type of heating:

- Natural heating. For the human body, the most comfortable way of heating is from the bottom up.

- Moisture protection. A constantly warm floor eliminates dampness in the room.

- Uniform heating. An evenly distributed system under the floor guarantees equal heat transfer throughout the entire area.

The absence of radiators allows for more efficient use of space, and the ability to regulate the temperature allows you to select optimal conditions.

Most often, in garages there is no point in achieving values above 15 degrees. This temperature is enough to avoid the formation of ice or dampness.

Warm floors in the garage: heating system options

The features of a room such as a garage impose their own restrictions on the choice of heating system. The floor may be subject to:

- Chemical exposure. Car care products and compounds simply stored in the garage can be very aggressive.

- Mechanical impact. Heavy tools and parts often fall onto the surface.

- Constant loads. The weight of a passenger car constantly impacts the floor.

In this regard, the screed in the garage must be at least 30 millimeters. The ideal figure is 8 centimeters - it is guaranteed to withstand any load.

This thickness means that only water or cable electric heated floors in the garage are suitable. Infrared film will be useless in this situation - its power is not enough for an 8-centimeter layer of screed. For this reason, water or electric floors are used.

Safety considerations

Any construction activity increases the risk of injury. To prevent this from happening, when laying the TP you need to follow some safety rules:

- It is better to install an electric heated floor using plastic rather than metal reinforcing mesh;

- the electric floor is not checked without ensuring the quality of the contact insulation;

- installation of a water TP eliminates contact of water with the electrical network.

If all processes are carried out correctly, the garage will become a comfortable room for doing what you love.

Cable electric floors: characteristic features

Unlike their water counterparts, electric heated floors are less demanding under installation conditions. To increase efficiency, it is also necessary to use heat-insulating materials, but the system can be laid on an uneven surface.

It is important to note that the heat-insulating layer must be at least 30 mm. Otherwise, at the first frost, the efficiency of this type of heating may decrease by up to 30 percent.

For installation, a special fixing mesh is used, to which the heating cable is attached. It is important to note that if you need to prepare the floor for electricity, DIY garage flooring is not the best idea. Communications and connection of the thermostat should be entrusted to a specialist.

By adjusting the cable pitch, you can identify areas with greater heating - the frequency of turns there will be higher than in the rest of the room. This will be needed to neutralize the cooling effect from walls that have contact with the street.

Advantages of cable electric floor:

- ease of installation;

- ability to regulate temperature;

- fast warm-up.

In addition, such a cable can last a significant period - more than 50 years. Unlike water-based ones, this type of underfloor heating can be safely turned off even in severe frosts - nothing will happen to the cable.

For easier installation, heating mats are used. Essentially, these are mounting grids with a heating cable already installed. This is one of the ways to make a heated floor in a garage quickly and without unnecessary difficulties. Apart from simplified installation, this subtype of electric hearth is no different from a cable hearth.

Throughout the entire process, it is important not to step on the cable and ensure that the integrity of its sheath is maintained. In case of damage, it is strongly recommended not to cut out the damaged area or twist it. At best, this will reduce efficiency and lifespan, and at worst, it can cause trouble.

The optimal solution in this case would be to replace the entire cable.

It should be noted that after electric underfloor heating is installed, electricity consumption in the garage will increase sharply. However, this drawback is completely offset by the fact that such a heating system can warm up the garage in a very short time, so you don’t have to keep it on all the time.

What else do you need to know about installing heated floors in a garage?

Regardless of which heated floor was chosen, the garage will also need to be prepared, otherwise the heating effect will be minimal.

First of all, insulation is required. The selection of material thickness depends on the climatic characteristics of the zone. The most commonly used materials are polystyrene foam or mineral wool.

Due to thermal insulation it is possible to obtain:

- additional protection from drafts;

- milder temperature difference;

- protection of freezing of car parts.

The lack of thermal insulation will not only negate the operation of the heating system, but can also harm the car itself. Temperature differences may cause slight ice or condensation to form. Due to this, the risk of corrosion increases significantly.

Before you make a warm floor in the garage with your own hands, you need to carry out all the necessary communications. Particular attention should be paid to the wiring, since often the garage is a remote building and it will not be possible to immediately detect a starting fire or other problems.

If the master does not have experience, then you can look online at how to make a heated floor in a garage with your own hands: videos of this kind are distributed on thematic channels and forums.

A competent approach to the installation of heated floors is not only the key to the integrity and safety of your iron friend, but also significant savings on car repairs and medications for colds and back pain. Regardless of the type of heated floors chosen, comfort while staying in the garage is guaranteed.

If there is heating in the garage, the best conditions for storing the car are provided, it is easier to start the engine in winter, and the warm-up time is reduced.

The heating will especially please those car enthusiasts who spend a long time repairing or manufacturing something here.

Today, the most effective way to heat a room is considered to be underfloor heating. Let's see what a heated floor in a garage is and how you can make it yourself.

Types of heated floors for garages

Underfloor heating has a number of undeniable advantages:

- The room is heated evenly, while the warm air, rising, follows through the heated zone, and does not flow along the wall, as is the case with a radiator or potbelly stove.

- The “warm floor” system is characterized by minimal heat loss, since, firstly, it is operated in a low-temperature mode, and secondly, it ensures minimal contact of warm air with the outer walls, through which the heat mainly evaporates.

- Since the heat source is built into the floor, the usable area of the garage is not reduced by a single square meter. cm.

Some tips

- When performing work on laying porcelain stoneware, it is necessary to take breaks.

- It should be taken into account that the tiles laid earlier will be located lower than those that are being installed now.

- As a rule, the adhesive for porcelain tiles hardens within 24 hours, after which you can begin grouting. At the same time, the floor cannot be used yet, otherwise it will become unusable.

- It is advisable to let the glue sit for two weeks.

Laying porcelain tiles is a complex and troublesome type of work and can only be carried out if the recommendations and advice of specialists are followed.

Warm water floors in the garage

The heating element is a long, winding pipe through which a heated coolant fluid—water or antifreeze—circulates. The heat source is a gas or solid fuel boiler, but electricity is also required: the coolant cannot move through such a pipeline by gravity (natural circulation) due to high hydraulic resistance, so the system must be equipped with a circulation pump.

The main advantage of this solution is the relative cheapness of the energy resources on which the heat generator operates.

Installation of heated floors in the garage

But it also has significant disadvantages:

- you will need space to install the boiler and other equipment;

- there is a possibility of leakage of the working medium due to depressurization of the circuit;

- installing a boiler, be it gas or solid fuel, is a rather complicated process (at a minimum, you will need to install a chimney), and it is not advisable to leave such equipment unattended for a long time.

It would be irrational to install such a system in a separate building.

Electric heated floor in garage

In this version of the heated floor, the heat source is the so-called resistive element - a conductor with high electrical resistance, which heats up when an electric current is passed through it. The heater can have one of two designs: cable and infrared film.

Cable

There are two types of heating cable:

- Unregulated. The simplest and cheapest option. It is, roughly speaking, just a long wire. If heat transfer is hampered in some part of it, for example, a piece of furniture or a car wheel is placed above the cable, the element will overheat and burn out.

- Self-regulating. This cable is more expensive, but it is not afraid of overheating. The role of a resistive element is a polymer matrix with semiconductor properties, on both sides of which there are conductive busbars. The electrical resistance of the matrix depends on temperature. If any part of it overheats, the matrix in this place simply stops passing electric current, thus turning off this segment. The main part of the cable remains operational.

Double reinforcement of insulated garage floor

The easiest way to install a heating cable is supplied in the form of so-called cable mats. Each such mat is a rolled mesh of fiberglass or similar material.

Infrared film

A very thin product consisting of two layers of polymer film, between which there are tracks of carbon paste.

The peculiarity of this substance is that even with relatively little heating, it gives off a significant part of the thermal energy in the form of infrared radiation. IR film is much thinner than a heating cable and provides more uniform heating.

Do-it-yourself warm floor in the garage

The sequence of operations when installing a “warm floor” system looks like this:

- The existing floor covering is dismantled.

- Having reached the subfloor, it is repaired so that the surface is level. If the base is severely damaged, a cement-sand screed should be laid on top of it. To reduce heat loss into the ground, you can add insulating components, for example, expanded clay, to the screed solution, or use a special ready-made mixture for a “warm” screed, for example, expanded polystyrene concrete.

- On the leveled subfloor you need to lay a durable thermal insulator that can withstand the weight of the car. Extruded polystyrene foam, which is produced under various brands, for example, Penoplex, is best suited for this purpose. Due to its strength, this type of foam is even used under the road surface. The thickness of the slabs must be at least 30 mm, density - from 35 kg / cubic meter. m. The seams between the plates should be taped with reinforced tape. It is best to lay the insulation in two layers, so that the seams of one overlap the slabs of the other (bandaging the seams).

For water heated floors, special heat insulators with fasteners are produced, with which it is convenient to fix the pipes.

In order for the screed with which the heating element of the heated floor will be filled to be able to expand freely when heated, a damper tape must be secured in the area where it adjoins the walls.

- A dense polyethylene film is laid on top of the insulation, which will serve as waterproofing.

- If you plan to use a water heated floor, the next layer should be laid with aluminum foil or a thin foil insulator. When installing an electric heated floor, the use of foil is not allowed.

- Next, a mesh of thin reinforcement with cell dimensions of 150x150 mm is laid on special plastic bosses. The height of the bosses should be such that the mesh is in the bottom layer of the screed. The thickness of the screed will depend on the type of heated floor - we will talk about this below.

- Let's start laying the heating element. If the floor is water, then the contour is made of a metal-plastic pipe, which is laid in a “snake” or in the form of a double spiral. The pipe is attached to the reinforcing mesh using plastic clamps.

If the floor is electric, then first you need to attach a special mounting tape to the reinforcing mesh, and then a resistive cable to it, using the clamps on the tape.

DIY water floor snake

Now you need to make all the connections and test the heated floor. The water circuit is subjected to pressure testing with a pressure of 3 - 4 atm, which is maintained for several hours. It is enough to simply turn on the electrical system to check the integrity of the contacts. If the system turns out to be operational, you can move on to the next step.

- if the floor is water, then its surface should rise above the pipes by 30 - 150 mm. The optimal screed thickness for this type of heated floor is 100 mm;

- for the electrical system, a screed 50 mm thick is arranged.

Special additives should be added to the solution - plasticizers, which help avoid the appearance of cracks when the temperature changes.

The screed must be given time to dry and harden, which usually takes about 28 days. Only after this period can the “warm floor” be turned on, and its temperature must be raised as smoothly as possible.

The final layer of the “pie” is the finishing floor covering. In addition to sufficient strength, it must have good thermal conductivity. Ceramic tiles and self-leveling floors best meet these requirements. Porcelain tiles are not recommended, as they conduct heat worse.

Underfloor heating is an ideal solution for a private home. Do-it-yourself water-heated floor – instructions for installation work.

The screed for a water floor must be done correctly, special attention must be paid to the drying of the concrete and its thickness. You can familiarize yourself with all the intricacies of making a concrete screed in this article.

The optimal thickness of the self-leveling coating is from 3 to 5 mm. In order to improve its aesthetic qualities, it can be painted with water-based paint.

If ceramic tiles were used as a finishing coating, then the floor can be subjected to maximum load only a week after its installation.

Electrical installation

Work on installing the floor begins after the subfloor is completed. To do this, the soil is cleaned to a depth of up to half a meter, a layer of sand and crushed stone is poured in and concrete is poured. Electric floor heating does not require a high screed, but its optimal height is 10 centimeters.

Attention! It is recommended to lay a regular floor in places where wheels pass. And the cable can be covered with plasterboard, laminate or other covering.

Do-it-yourself work is performed in the following order:

- Laying waterproofing. Groundwater should not get onto the cable. To do this, use roofing felt or thick film.

- Creating a thermal insulation layer to prevent heat from escaping into the ground. It is not recommended to use foil as an insulator.

- Laying reinforced mesh and fixing it.

- Laying the cable and tying it to the sheathing. Calculate the required cable length in advance. Choose a solid wire, without solders. Heating mats can replace the wire.

- Installation of temperature sensors, especially in the area near the machine, where it is necessary to maintain a certain temperature.

- Connecting the cable to a separate panel and test switching on.

- If everything works properly, a layer of screed is poured over the grate, allowed to dry, and the finished floor is installed.

The system does not require special maintenance.