Thermal insulation material - expanded polystyrene, commonly called polystyrene foam, today is most widely used in the construction and repair of residential and commercial premises. Compared with other insulation materials, these different types of expanded polystyrene have a number of significant advantages, although they also have some disadvantages. The manufacturing technology of expanded polystyrene involves foaming the polymer - polystyrene - with gaseous pentane - a low-boiling liquid from the group of hydrocarbons.

If we consider the structure of the foam, the share of solid matter in its volume does not exceed 2.0%, and 98.0% are voids, which are miniature polystyrene chambers containing air. The closest “relative” of this classic foam is penoplex, which is produced by extruding polystyrene foam. Today, these materials are often confused. Although both of them have approximately the same physical and mechanical characteristics and equal thermal insulation properties, penoplex, despite its higher cost, is in some cases preferable to use.

Main types

- pressless (made by drying polystyrene granules, brought to a foam-like state at a temperature of 80 ° C, these two processes are repeated again, then the mold is filled with everything, there it becomes knocked down when cooling; it turns out to be more fragile, but is used in production half as much isopentane, which makes the final product cheaper)

Brands of pressless foam

- extruded (it is called an extruder, because they use similar equipment in production, we will consider it later in the article)

- extrusion (field of application is packaging in the food industry)

- pressed (becomes more durable)

- autoclave

Main characteristics

- thermal conductivity is low (the extruder has the same thermal conductivity as other types of polystyrene foam, but the extruder is more expensive)

- durability (up to 60 years does not lose properties when the temperature changes from -40 to +40 °C throughout the year)

- moisture resistance

- it does not create an environment favorable for the development of mold and similar “life” (can only occur on the joint surface of, for example, wood)

- minimal harmfulness (it is allowed to be used in the food industry (packaging));

- a light weight

- noise insulation (3 cm thickness reduces noise up to 25 dB)

- fire resistance (we can only talk about it when it comes to fire-resistant varieties; you also need to know that in the production of fire-resistant types, a larger amount of carbon dioxide is used and if the combustion process takes place directly, then the release of this gas will be greater and it will burn, although the temperature it has a high temperature of +490 °C)

- vapor permeability (similar to wood such as oak)

- tensile strength is at least 20 MPa

- resistance to alcohols and ethers, but is easily destroyed when exposed to solvents

- does not withstand ultraviolet radiation (when using slabs, they must be covered with a protective layer of primer and painted)

Expanded polystyrene is mistakenly called polystyrene foam in everyday life. Let's look at the main differences between the characteristics:

- absorbs water and vapor

- visually they can be distinguished (it has a uniform structure, and the foam has large granules)

- density higher than foam

- mechanical strength

Properties and indicators

Its popularity is due to its high performance characteristics and physical properties.

| Thermal conductivity index, W/(m•K) | from 0.028 to 0.037 |

| Vapor permeability, kg/m*h*Pa | from 0.019 to 0.05 |

| Density, kg/m3 | from 40 to 150 |

| Humidity of slabs,% | no more than 2 |

| Porosity | closed |

| Operating temperature, C° | -100 – +80 |

| Water absorption for 10 days, % by volume | 0,4 |

| Resistance to microbiological processes | high to mold, fungi |

| Resistance to atmospheric factors | to precipitation and temperature changes - high, to ultraviolet - low |

| Resistance to aggressive chemicals | high to salts, to acidic and alkaline compounds – low |

| Durability | 60-80 years |

The vapor permeability of extruded polystyrene foam is almost zero.

The whole truth about harmlessness, non-flammability and long service life

Polystyrene can serve for many years without losing its properties - tests have shown that it can be defrosted and frozen many times, and the quality of the material does not suffer. This material is not subject to combustion, since it contains special substances - fire retardants. All this seems completely correct and undeniable, but only at first glance. There are several nuances. We'll talk about them further.

Environmental issue

Unfortunately, polystyrene foam oxidizes in air. Moreover, foamed polystyrene foam, which has a looser structure, is more susceptible to this process. Extruded material oxidizes more slowly, but the same fate awaits it. Freshly laid polystyrene foam also releases styrene, since complete polymerization of the material is impossible at the production stage. Until polymerization is completed, the release of styrene will not stop.

Manufacturers are trying to dispute information about the harmfulness of polystyrene foam. They say their products are less harmful than wood. This refers to the release of harmful substances by wood when burning. Indeed, when polystyrene foam burns, it produces carbon dioxide, carbon monoxide and soot. But if polystyrene foam is heated to a temperature exceeding 80 degrees, then harmful vapors are released. They contain vapors: styrene, toluene, ethylbenzene, benzene and carbon monoxide.

Flammability issue

In fact, any polystyrene foam will burn. Manufacturers are lying when they claim that it extinguishes on its own, being less dangerous than wood - alas, this is not the case. Such a statement clearly contradicts Russian GOST 30244-94, according to which foam plastics are classified in groups G3 and G4, the most dangerous, in terms of flammability.

One way to distort the facts is to spectacularly suspend a polystyrene foam board in the air and then set it on fire. To do this, a lit burner is applied to the stove from below. The result speaks for itself - only the piece that was in contact with the burner burns out, and the fire does not proceed further. But this experience in no way corresponds to real operating conditions, and can only serve as a focus. But if you put a piece of polystyrene foam on a plane made of non-flammable material and set it on fire, it will not go out at all. After all, hot drops of polystyrene foam formed when a small piece is heated will transfer the fire to its entire surface. The result will not be long in coming - the stove will burn out completely.

If we take expanded polystyrene, which does not include fire retardants, then its smoke formation coefficient is 1048 square meters per kilogram. For polystyrene foam with a self-extinguishing effect, this figure is higher - 1219 square meters per kilogram. For rubber, for example, it is 850 square meters per kilogram, and for wood it is even less - only 23 square meters per kilogram. To make it clearer, here are the following figures: if the smoke level in a room is more than 500 square meters per kilogram, then if you stretch out your hand, you may not be able to see its fingers.

Fire retardants (most often hexabromocyclododexane) are added to polystyrene foam to increase its fire safety. In our country, it is customary to designate such expanded polystyrene with the letter “C”. This should, in theory, mean that the material has the ability to fade on its own. But in practice, it turns out that polystyrene foam with a fire retardant burns no worse than one that does not contain this additive. It only ignites worse, without doing so spontaneously at elevated temperatures. Its flammability class is G2, but after a few years it turns into G3 or G4 - the properties of the fire retardant deteriorate over time.

However, it should be noted that expanded polystyrene in building structures is never used in an open form. Facade plaster is always applied on top of this material or a screed is installed. Therefore, building structures containing expanded polystyrene are fireproof.

Service life issue

If you use polystyrene foam correctly, covering it on top with plaster or another protective and decorative layer, it will last for 30 years, no less. True, in reality, everything turns out to be not so rosy - either the craftsmen hastily put together the thermal insulation somehow, or the customer will try to save money at the expense of materials, or the inexperienced master will make mistakes when installing polystyrene foam boards.

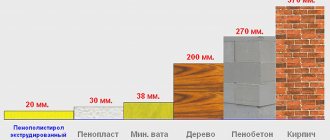

One of these mistakes is incorrect calculation of the thickness of the insulation. It seems to many that if you take a thick thirty-centimeter slab of polystyrene foam, it will last longer and the house will be warmer. But this is not so - a material of great thickness will develop cracks and waves due to temperature changes, under which cold air will penetrate. It should be noted that in Europe the accepted norm is to insulate the outside of houses with polystyrene foam no more than 3.5 centimeters. thick. This allows you to reduce the risk of poisoning during a fire.

Advantages and disadvantages

The decision to use insulation boards can be influenced by an analysis of the advantages and disadvantages of the material.

Advantages

- A low water absorption rate by volume of up to 0.5% indicates that the material practically does not absorb moisture. Therefore, it can be safely used for foundations, facades and in rooms with high humidity.

- Durability. The service life is influenced by resistance to external factors. No pathogenic microenvironment is formed in the slabs, there is no invasion of insects and rodents.

- A light weight. Due to the insignificant loads on the supporting structures, there is no need to strengthen the supporting elements of the building.

- Affordable price. Unlike other insulation materials, polystyrene foam can be purchased at a low price. This reduces the cost of creating a heat-protective layer, and subsequently heating the room.

Flaws

- The structure of the material is destroyed under the influence of UV rays. Therefore, after installation of the slabs, finishing in the form of plaster or paneling is required.

- Destruction occurs upon contact with gasoline, acetone and other solvents. Avoid direct exposure to the following: kerosene, paints, toluene, turpentine, etc.

- Expanded polystyrene itself does not attract rodents, but they can easily damage the insulation when making their way in search of food. This requires the creation of additional protection on the outside of the building.

- Toxicity. When the material is heated above 60 degrees, phenol begins to be released from it.

- In brands with low density, condensation may form. The presence of moisture increases the thermal conductivity rate by up to 10%.

- Fire hazard. To reduce flammability, you should choose slabs containing a fire retardant.

Application of foamed polystyrenes

An important reason why the material has become so widespread is its low cost. The main use of expanded polystyrene is its use as insulation during construction and repair work. In addition, it is used as a heat insulator in some types of household and industrial equipment (refrigerators, thermal vans, containers), and is also used in packaging. For insulation of external and internal surfaces of walls in individual and low-rise housing construction, the most widely used polystyrene foam of the PSB-S brand of various densities. Due to its greater breathability, compared to extruded foams “Penoplex”, “Stirex”, “TechnoNIKOL”, its use allows you to create a more comfortable microclimate inside residential premises.

For external insulation of wall structures, the use of PSB-S boards is preferable for the following reasons: This type of expanded polystyrene does not require additional vapor and moisture insulation, which makes it possible to attach insulating sheets directly to the wall surface. When externally insulating walls, plastering can be carried out directly on sheets of dense foam grades (“PSB-S-35”), having previously secured a reinforcing mesh to them. Due to the ability of polystyrene foam boards "PSB-S" to withstand short-term temperatures up to +100.0°C, it is ideal for insulating the base, where the material is fixed using heated bitumen mastic.

To insulate attic and floor ceilings, you can use any type of material, and: Due to the greater density and strength of Penoplex or Technonikol, when insulating attic spaces, it is possible to lay the coating directly on the surface of the insulation. To avoid the formation of condensation when insulating floors with PSB-S sheets (slabs), the use of vapor and moisture insulation is not provided. Skirting boards, platbands and other decorative elements made of polystyrene foam are widely used for interior decoration. They can have different colors and a relief surface, which significantly increases the decorative effect of the overall cladding.

For finishing ceilings, polystyrene foam boards with dimensions of 500.0×500.0 millimeters are widely used. They have a wide range of colors that correspond to the color standards “RAL” (Germany), “NCS” (Sweden) and “MoniColor” (Finland), and the surface of some types of this finish is made in the form of bas-relief. If we summarize all the properties of various materials based on foam polystyrene, then their use during repair and construction work allows us to: Significantly reduce the cost and time required for insulating building structures for residential and domestic purposes. Increase the usable area of residential premises by reducing the thickness of external walls. Increase the environmental safety of residential buildings. The operational advantages of this material include: Reduced heating costs. Reducing financial costs for the purchase of heating equipment and heating system elements. Increasing the thermal comfort of residential premises.

Useful videos

Look at the commentary from a specialist who will tell you what extruded polystyrene foam is suitable for, and where it will only be detrimental: A brief process for the production of expanded polystyrene foam, see: Next in the video below - insulation using extruded polystyrene foam, how to prepare the base, what materials to choose, what should be used be a pie, let's look: The advantages and disadvantages of penoplex, in which cases it can be used for insulation, and in which it is not worth it: Expanded polystyrene is a modern material with many advantages. If SNiP is observed, its use is completely safe for health. By correctly using it in thermal insulation, you can significantly reduce the cost of heating a room in winter and cooling in summer.

Foiled polystyrene foam

It is a mixed thermal insulation material, which is covered on both or one side with polished foil with an aluminum layer or metallized polypropylene film. Due to the metallic properties of the coating, the reflection effect can reach 97%. The choice of FPS as a solution for heated floors is considered ideal insulation. The foil layer reflects heat rays, thereby improving the insulating properties of the material. FPS is also used for insulating pipes in heating networks; thermal insulation of ventilation ducts, air ducts in ventilation and air conditioning systems; thermal insulation of walls; sound insulation between floors; used as technical insulation of process equipment.

Air-filled insulation cells perfectly combat acoustic pollution. It is insensitive to pressure, horizontal loads, liquid media, thermal instability (the upper limit of the operating range is 180 °C heat, the lower limit is 180 °C cold), it retains its original qualities for a long time: it is not inclined to dry out, swell, or deform. Its synthetic nature makes it resistant to decay, inert to the influence of chemical factors (solutions of salts, alkalis, acids), and the destructive activity of pathogenic microorganisms.

Polystyrene foil mats

Foiled polystyrene foam with markings

FPS is able to increase the overall energy efficiency of the facility, retain heat, and significantly reduce the cooling properties of the cement foundation on which the floor covering is installed due to its high sealing characteristics.

The solution to the problem of creating a warm floor today is FPS profile slabs. They have high mechanical strength. On top they are covered with a rigid vapor barrier film. Their surface has a special molding, which allows for reliable and convenient fastening of heating pipes of different diameters. They are laid hermetically, thanks to the side locks, reliable adhesion of the structure is ensured, which eliminates the divergence of the seams. An additional ruler is applied to the sides of the slabs for convenient adjustment of the elements; the embossed lower surface smoothes out unevenness of the flooring and helps absorb noise.

Popular manufacturers of thermal insulation boards

There are many manufacturers that produce extruded polystyrene foam of various types and purposes. The most popular of them:

- Europlex. They produce materials for the construction industry. Their thermal insulation boards have a smooth or textured surface and are distinguished by a variety of physical properties;

- Styrex. They produce materials for civil and industrial construction, for the manufacture of railway, aircraft and automobile fabrics, and sandwich panels. They offer customers slabs with different thermal insulation and strength properties;

- Penoplex. Presents materials for insulation of residential and industrial buildings, utilities. To achieve better performance characteristics, slabs with different types of edges were created, which also facilitates the process of their installation;

- URSA XPS. Offers customers materials with good performance properties, which helps create an effective thermal insulation shell of a building at minimal cost.

All manufacturers of extruded polystyrene foam guarantee its high quality. This is achieved through careful control over all stages of material production.

Extruded polystyrene

Extruded polystyrene (hereinafter referred to as EPS), let's consider this issue in more detail. It was invented back in 1941 in the United States of America. The range of applications is very wide: thermal insulation of floors, roofs, plinths and foundations, layered masonry and plaster facades. It is used in the construction of railways and highways, reducing the risk of freezing of subgrade soils and subsequent freezing and swelling. The material successfully solves the problems of thermal insulation of sports grounds, refrigeration units and ice arenas.

There is no ideal insulation, so the area of application is determined by the strengths and weaknesses of its characteristics. One of the main advantages is almost zero water absorption. Thanks to the closed-pore system, moisture does not pass inside; only the side cells at the cut of the insulation collect water. In a humid environment, it does not collapse and does not lose, like mineral wool, its thermal insulation capabilities. They allow the use of EPS for insulation of: basements, underground parts of buildings and structures, foundations from the ground side.

We can say with confidence that when properly combined with waterproofing, extruded polystyrene enhances its properties. The high density of the insulation gives it rigidity, compressive strength, and the ability to withstand high mechanical loads, and therefore it is practically indispensable when constructing floors, including on the ground, when installing floating screeds. The use of EPS is limited by its high degree of flammability, for example, most EPS belongs to the increased flammability group IV. They support combustion, do not die out, form melt drops, which also burn successfully and, when burned, emit flue gases with a temperature of 450°C.

For comparison, traditional foam plastic marked PMB-S belongs to the G1 flammability group, this is a low flammability group, the burning time is no more than 4 seconds, when the fire source is removed, it stops burning and goes out, because contains fire retardants. Its use should be avoided when insulating roofs, especially with a wooden rafter system.

Due to its high flammability and low vapor permeability, it is practically unsuitable for wooden structures and indoor walls. An exception is the use of EPS in SIP panels, because In the manufacture of SIP panels, artificially dried wood is used, which increases its moisture resistance. And in houses built from this kind of materials, forced ventilation should be used, only in this case mold will not appear there.

EPS cannot be used for insulating facades using the bonded thermal insulation method for the following reasons:

- zero vapor permeability, in winter it will act as a barrier to moisture that penetrates the wall from the warm air of the room. This can lead to the formation of condensation in the wall and the appearance of fungus and mold on the inner surface. For comparison, the vapor permeability coefficient of white foam is five times higher.

- the second reason for not using it on a wet facade is that, due to the structure of its surface, even the highest quality adhesive and reinforcing mixtures do not stick to it with the required strength. Over time, the plaster and reinforcing layer on such facades may begin to lag behind.

- The third reason why it should not be used on the facade is the tendency to photodestruction and thermal destruction. The destruction of the surface can be caused by sunlight, namely ultraviolet radiation. On warm sunny days, when the surface of the facade is heated above 70 ° C, the EPS begins to evaporate and decrease in size, these processes cause breaks in the thermal insulation circuit, such a system begins to lose its thermal insulation qualities and will quickly collapse.

Impact of external factors

Drying oil, acetone and certain types of varnishes can damage the structure of the material and even dissolve it. In this regard, any products obtained from the distillation of oil pose a danger. The same applies to certain types of alcohol.

Exposure to varnishes and alcohols can have a detrimental effect on polystyrene foam

What substances does the material not react to?:

- mineral fertilizers;

- soap;

- soda;

- cement;

- gypsum;

- bitumen.

The material does not like direct sunlight. Under the influence of ultraviolet irradiation, it loses its strength and elasticity. An additional destructive factor is weather phenomena such as rain, wind and snow.

How to choose polystyrene foam correctly

Expanded polystyrene is one of the most popular building materials. It is light, warm and cheap, and very easy to work with. Since the demand is great, there are more and more offers from manufacturers. And each of them assures that their polystyrene foam is the best, and its quality is beyond praise.

1. Lost by countless offers, do not rush to buy material. First, carefully study its parameters. If you need to insulate a facade, take polystyrene foam PSB-S, which is positioned as self-extinguishing. Its brand must be no lower than forty. And if the brand has a number of 25 or less, then don’t look in the direction of such material - it is only suitable for packaging, but not for construction work.

2. When purchasing material, check to what standards it is made. If a manufacturer manufactures products not according to GOST, but according to its own specifications, then the characteristics of the material may differ. For example, expanded polystyrene PBS-S-40 (grade forty) can have different densities - from 28 to 40 kilograms per cubic meter. It is beneficial for the manufacturer to mislead the buyer in this way - less money is spent on the production of polystyrene foam of lower density. Therefore, you cannot rely only on the number in the brand name, but you must ask to see documents confirming the technical characteristics of expanded polystyrene.

3. Before purchasing, try breaking off a piece of material from the very edge. If it turns out to be low-grade packaging foam, it will break with a jagged edge with small round balls visible on the sides. The material obtained by extrusion has regular polyhedra at the site of a neat break. The fault line will run through some of them.

4. As for expanded polystyrene manufacturers, the best of them are European ones, Nova Chemicals, Styrochem, BASF. Russian manufacturing companies, such as Penoplex and TechnoNIKOL, are not far behind them. They have a production capacity that is quite enough to produce polystyrene foam of very high quality.

What does it consist of?

Polystyrene is predominantly used in the production of insulation. An alternative raw material is polydichlorostyrene or polymonochlorostyrene. Copolymers of styrene with other monomers (butadiene/acrylonitrile) are less commonly used.

The structure of expanded polystyrene is cellular. They teach it with the help of foaming agents. Low-boiling hydrocarbons or gas-forming agents cope with this task. The substances listed in the table are most often used in the manufacture of expanded polystyrene.

| Hydrocarbons | Gas formers |

| isopentane | ammonium nitrate |

| dichloromethane | diaminobenzene |

| pentane | azobisisobutyronitrile |

| petroleum ether |

To reduce flammable properties, flame retardants are used in production. To give the material elasticity, plasticizers are used. Other fillers include dyes and other substances that impart certain properties to the polymer composition.