Insulation of the foundation base from the outside should be considered as a stage of general work on thermal insulation of the building. Each enclosing surface has its own characteristics in terms of the nature of operation, the physics of heat transfer and influencing factors. This affects the choice of materials and insulation methods. What “works” well on the roof or attic is completely unsuitable for the foundation and its visible part - the plinth.

General scheme of complex insulation of the foundation of a house Source stroy-dom-pravilno.ru

No. 1. Basement insulation: outside or inside?

The basement is called one of the most vulnerable parts of the house, because it bears not only a large load in the form of the weight of all the walls and ceilings, but also often high humidity. The base is the continuation of the foundation, which rises above ground level and extends into the outer walls of the house. Simply put, this is the connecting element of the foundation and walls of the building, starting from the floor level of the first floor. It protects the house from the penetration of moisture and cold, and also plays a decorative role, since a house without a base looks somehow squat.

Theoretically, it is possible to insulate the base of the foundation both from the inside and from the outside , but the effectiveness will vary greatly. If you carry out internal insulation , then to a certain extent it will be possible to achieve insulation of the room from low temperatures, but condensation will accumulate between the wall and the insulation, which will damage the base. In addition, the latter will not be protected from the harmful effects of cold. The result will not be long in coming - the appearance of microcracks from freezing, their expansion, constant wetting, and later deformation and crumbling, a decrease in strength characteristics.

External insulation allows you to protect both the room and the base material from the cold, and the dew point shifts towards the insulation, which is much more resistant to moisture and low temperatures than the base. As a result, we get a warm room and an extended service life of the structure. Thermal insulation work is best carried out during the construction of a house, but even after its construction it is possible to carry out effective insulation, although it will be a little more difficult.

No. 2. Is it necessary to insulate the basement of a house?

The peculiarity of the domestic mentality is such that you want to save on everything. Hence the popular question: is it always necessary to insulate the basement of a private house? Thermal insulation may not really be needed in the following cases:

- if the house is intended only for summer living;

- if the house does not have a basement, but the basement is small (0.5 m) and is arranged to avoid flooding;

- if the house is located in an area where there is no severe winter.

In all these cases, you can get by with an insulated floor. If the climate in the region is harsh, the house is used for permanent residence, and the basement is supposed to store food, arrange a garage, boiler room or other utility rooms, then insulation is indispensable.

No. 3. Materials for insulating the base

In the recent past, a mixture of clay and straw was used to insulate the base of the foundation. Over the past few decades, many new, more advanced and convenient ways to perform thermal insulation have appeared. requirements are put forward to them :

- low thermal conductivity . Thermal insulation properties are better for those building materials that have a lower thermal conductivity coefficient;

- low water absorption rates . When insulation absorbs moisture, it loses some of its important performance qualities. The accumulation of moisture is especially dangerous during periods of frost, when water increases in volume and can damage the structure of the insulation;

- high compressive strength, because the material must withstand soil pressure.

In addition, the insulation must be durable, vapor-permeable, resistant to mold and rodents.

Today the following materials are used for insulation:

- thermal insulation boards (foam plastic, extruded polystyrene foam, mineral wool);

- polyurethane foam, which is applied by spraying;

- expanded clay is the most popular option for bulk thermal insulation;

- warm plaster;

- thermal panels;

- priming.

Comparison of average prices in the Russian Federation for heat insulators

The market for base thermal insulators represents both domestic and foreign products . The latter has a higher cost and service life. Prices vary by region by 10-15%, the highest in Moscow.

Comparison of price indicators for base insulation based on material efficiency:

- Akterm Standard white 10 l, from - 60 to +150 C, thermal conductivity 0.0011 W/(m*K), 3,650 rub./bucket

- Sprayed insulation Polynor professional 1000 ml, from -45 to +90 C, thermal conductivity 0.024 W/(m*K), steam permeability 0.045 mg/(m•h•Pa), from 490 rub./piece.

- Penoplex Fastfix, sprayed, from -80 to +115 C, thermal conductivity 0.025 W/(m*K), from 500 rub./piece.

- Penofol A-10, polyethylene foam, 15.000x1.200x10 mm, from -40 to +100 C, heat capacity 1.95 J/kg*K, thermal conductivity 0.04 W/(m*C), vapor permeability 0, 0011 mg/m*h*Pa, from RUB 1,450/piece.

- Polyethylene foam Tepofol NPE 10 mm, from -60 to +80 C, thermal capacity 1.94 J/kg*K, K thermal conductivity 0.04 W/(m*C), steam permeability 0.001 mg/m*h*Pa, from RUB 1,115/piece

- Isover, quartz-based slab 1.170x610x100 mm, 7 slabs per package, from -50 to +110 C, thermal conductivity 0.04 W/(m*K), vapor permeability 0.7 mg/m*h*Pa, from 800 rub./pack

- Ursa GEO M-11 10.000x1.200x50 mm 2 pcs. in a bag, from -50 to +260C, thermal conductivity 0.038 W/(m*C), vapor permeability 0.64 mg/m*h*Pa, from RUB 1,450/pack.

- Ursa Heat Standard, extruded polystyrene foam, 1.230x610x50 mm 12 pieces per bag from -60 to +220 C, density 35 kg/m2, thermal conductivity coefficient 0.04 W/(m*K), from 475 RUR/pack, 4000 RUR ./m3.

No. 4. Base insulation with extruded polystyrene foam

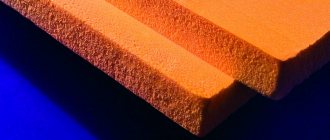

Extruded polystyrene foam is the most popular material for insulating foundation plinths. It is often also called penoplex after the name of the company that produces the material under the brand name of the same name. The insulation resembles the polystyrene foam familiar to us all, but is stiffer and more durable, withstands soil pressure well, does not wrinkle or sag.

Advantages:

- excellent thermal insulation qualities and low thermal conductivity;

- resistance to moisture and inability to absorb it, which is explained by the closed cellular structure;

- sufficient compressive strength;

- high durability, which reaches 50 years or more;

- the material is not damaged by rodents and is not affected by mold;

- ease of installation and processing, the ability to carry out insulation work on your own and without the use of mechanical fasteners;

- affordable price.

Moreover, penoplex has noise-insulating properties, and thanks to impregnation with fire retardants, it is resistant to fire. The disadvantages include a large number of joints - a minus of all tile materials. Even the largest sheets of expanded polystyrene do not allow you to create a monolithic insulation structure, and the joints will have to be carefully covered or foamed. It is better to take sheets with a lock, thanks to which they fit together more tightly, reducing the risk of cold bridges. In regions with a harsh climate, it may be necessary to install penoplex in two layers, with the slabs of the second layer covering the seams between the slabs of the first.

In addition, although the material is not as fragile as polystyrene foam, it can withstand decent loads, but it crumbles when cut. Installation is simple, but requires care and attention, and takes a lot of time. It is better to do this in the summer, in warm, dry weather.

A more affordable analogue of the material is polystyrene foam , which is not produced by extrusion. It holds heat well, but has a lot of disadvantages. Firstly, it is fragility, so to protect the material from earth pressure, they build a wall half a brick thick. Secondly, it is damaged by rodents. Moreover, the material is capable of absorbing moisture, so you can’t do without high-quality roll or bitumen-polymer waterproofing, and the need to carry out all this work negates all the benefits of buying polystyrene foam, so the material is used less and less for insulating walls and basements.

Technology of work during foundation construction

Installation of a thermal insulation layer

Insulating the base during construction of the foundation is the cheapest and most effective thermal insulation option. Methods for insulating the basement from the outside are best suited during the construction of the foundation, because digging out the foundation of a house in use, especially an old one, is a labor-intensive and dangerous task (the structure can only become more deformed). In the case of finished houses, the method of insulation from the inside is much more suitable. In this case, the base is insulated in one of three ways.

Application of permanent polystyrene foam formwork

This method is considered the most effective, because when it is used, double-sided thermal insulation occurs: the base and foundation of the house are insulated simultaneously both outside and inside. Of course, this method cannot be applied to already constructed buildings.

Reliable monolithic design

Application of extruded polystyrene foam

This method, unlike the first, is well suited both for insulating the outside of houses during the construction process, and for already built houses.

Expanded polystyrene is mounted on top of the waterproofing layer

Extruded polystyrene foam is glued to the base directly on top of the waterproofing. If the house is quite old, you will also have to open the foundation, dig around it, re-waterproof it and then insulate it. In addition, it is also advisable to insulate the blind area, which will prevent freezing of the soil in contact with the foundation and reduce the risk of seasonal deformations of the house. If you act even more thoughtfully, you can combine the process of insulating the blind area with the installation of a drainage system (if you take care of the outflow of groundwater from the foundation, you won’t have to worry about its safety for a very long time).

Thermal insulation of the plinth and base with bulk building materials

From the outside, the foundation of the house will have to be opened, then, just as in the previous method, the blind area will be insulated and the drainage pipes of the drainage system will be laid at the bottom of the opened trench, expanded clay will be poured into this ditch, separating it alternately with layers of sand or fine crushed stone.

Thermal insulation of the blind area and plinth

No. 5. Foamed polyurethane foam for base insulation

Foamed polyurethane foam can be safely called an ideal insulation in terms of performance. The application of the material is carried out by special installations in which polyol and isocyanate are mixed under pressure, which leads to the synthesis of the polymer and the formation of carbon dioxide. The latter creates bubbles isolated from each other. Spraying is carried out in a thin layer on a previously prepared base.

Advantages:

- high thermal insulation properties, which are ensured in particular thanks to carbon dioxide bubbles, because its thermal conductivity coefficient is lower than that of air;

- resistance to mold and mildew;

- solidity of the insulation layer, filling of all cracks and defects, absence of seams;

- strength, rigidity, elasticity and lightness of the material;

- high degree of maintainability. If something happens, the damaged area can be repaired with a new portion of polymer;

- high speed of work - thermal insulation of the base is completed within one day.

Disadvantages include the high price of the material and the inability to carry out the work independently - you need special equipment, reagents and the ability to handle them. In addition, the insulation is afraid of sunlight, so it is better to try to finish the facade as quickly as possible.

The main stage is the formation of the base of the thermal insulation surface

At the preparatory stage, a number of works should be performed:

- Clean the base surface from dirt.

- Seal cracks and level out uneven areas.

- Cover the surface with penetrating primer.

To seal local defects, gypsum, cement-sand or lime plaster is used. Apply the plaster composition in an even layer and clean it after drying.

The work of cleaning the surface from contaminants begins

No. 6. Mineral wool for basement insulation

basalt wool is usually used to insulate the foundation base . Rocks are used as raw materials, which are melted and drawn into thin threads, from which insulation is created. It is produced in rolls and slabs; you can use both: rolls allow you to get a minimum number of seams, and slabs are characterized by increased strength.

Advantages:

- low thermal conductivity coefficient achieved due to the fibrous structure;

- soundproofing;

- fire resistance, since it is based on mineral substances;

- high vapor permeability rates;

- strength and resistance to mechanical damage;

- mildew resistance;

- high durability;

- easy installation.

Manufacturers say that mineral wool allows water to pass through well and does not absorb it, but this is not entirely true. The material tends to accumulate moisture , which significantly reduces its thermal insulation properties, so special water-repellent substances began to be added to it. But even this does not free you from the need to install powerful waterproofing, and this is tedious, time-consuming and expensive, so mineral wool is used very rarely for basement insulation - but it is perfect for walls and balconies.

The most popular manufacturers, packaging price

In Russia there are about a hundred enterprises of varying capacities that produce polystyrene foam insulation boards.

List of popular polystyrene foam manufacturers.

TechnoNikol

Russian manufacturer, its facilities are located in 7 CIS countries and the EU. "TechnoNikol XPS" with a thermal conductivity of 0.028 W/(m*K), is produced in packages of 4 slabs, dimensions 100x580x1180 mm, total area of 2.74 m2, packaging cost - 1200 rubles.

URSA

A product of a Spanish concern, production is also located in Russia in Serpukhov. “URSA XPS G4”, with a thermal conductivity of 0.030 W/(m*K), package of 4 slabs with dimensions 100x600x1180 mm, total area of 2.83 m2, packaging cost - 1500 rubles.

Penoplex

Produced by a company in St. Petersburg. “Penoplex Foundation”, with a thermal conductivity of 0.030 W/(m*K), package of 4 slabs with dimensions 100x585x1185mm, total area of 2.77 m2, package cost 1540 rubles.

Theplex

Nizhny Novgorod plant are produced in the form of slabs. “Teplex 35”, with a thermal conductivity of 0.030 W/(m*K), a package of 4 slabs with dimensions 100x600x1200 mm, a total area of 2.88 m2, packaging cost - 1350 rubles.

Polyspen

The plant is located in Kirov. This is foamed polystyrene, which is produced by extrusion. “Polyspen 35 G4” has a thermal conductivity of 0.028 W/(m*K), the package consists of 7 sheets measuring 50x600x1200 mm, with a total area of 7 m2, the cost of packaging is 950 rubles.

No. 7. Insulation with expanded clay

Expanded clay is a lightweight material that looks like fairly large granules. It is produced from low-melting clays in drum units, in which swelling and hardening occur. The result is an environmentally friendly and completely safe material, which is called one of the most budget-friendly insulation materials. It is usually used for thermal insulation of the foundation base in houses that are not used for year-round use.

Advantages:

- the porous structure provides good thermal insulation and sound insulation;

- low weight;

- fire resistance, because it is based on clay, and frost resistance;

- environmental friendliness;

- low price.

The porous structure leads to the ability to absorb moisture, which is not recommended for the base. However, if you try and carry out thermal insulation according to science, then the influence of this property can be reduced to nothing. Expanded clay insulation requires mandatory drainage : a ditch is dug deeper than the foundation, geotextiles are laid on one, crushed stone is poured and a pipe is installed with holes to drain moisture. Crushed stone is poured on top, geotextiles are laid again and covered with sand. After the preparatory work, wooden formwork is installed at a distance of about 1 m to the depth of the base, roofing felt is laid so that it covers both the walls of the house and the wall of the trench, and the seams are taped. Expanded clay is poured into a heterogeneous fraction and compacted as it is poured. After the formwork is completely filled with expanded clay, it is closed with a lid at an angle of at least 45 degrees - this is done to protect the base from the accumulation of precipitation.

How to work with wooden floors?

When wooden beams act as a grillage, they must first be treated with an antiseptic compound, and then with a water-repellent solution. To protect the seams of the structure, any waterproofing material is placed between them.

Next, they begin to build the basement structure. It has the form of a frame or a solid thin brick wall is built. Another option is to dig a trench between the driven piles.

Afterwards, a reinforced concrete foundation is poured into it. When it reaches the required strength, a brick base is laid on top of it. When it is built, guides made of a metal profile are mounted on the brick, with foam sheets secured between them.

No. 8. Insulation with thermal panels

Thermal panels are a German invention, which are based on rigid polyurethane foam with properties already familiar to us, on top of which decorative overlays are mounted, imitating any noble material: stone, brick, tile, etc. The result is the most natural sandwich panel, which greatly simplifies installation and copes with several functions at once.

Advantages:

- good thermal insulation and moisture resistance;

- excellent appearance;

- resistance to mold and rodents.

Modern and seemingly perfect material has some disadvantages, and it’s not just the high price. Firstly, special care and pedantry are required during installation: the panels should be firmly secured with strong glue; some also use dowels to ensure this. Secondly, thermal panels can only be mounted on a perfectly flat base, otherwise it will be necessary to install a sheathing. But all these difficulties are more than compensated for by excellent energy efficiency.

Installation of thermal insulation and waterproofing of the foundation

Perform installation operations in the following order:

- Try the sheet insulation on the base surface.

- Trim the material.

- Apply a layer of glue along the contour of the back side of the slab.

- Place the sheet on the base, align it and press firmly.

Carry out work starting from the corner part of the building, ensuring tight joints during installation. Remove any protruding adhesive using a spatula. After installing the insulating panels, blow foam into the gaps and remove any remaining foam with a knife.

No. 9. Insulation with warm plaster

Warm plaster is a name given to dry adhesive mixtures that have little in common with its decorative counterpart. The heat insulator may include sawdust, vermiculite or polystyrene foam.

Advantages:

- solidity of thermal insulation;

- ease of installation, because you can start applying warm plaster immediately after the preliminary primer layer has dried. If you plan to apply thermal insulation in one layer, you can even do without reinforcing mesh;

- relatively low price.

disadvantages :

- water absorption, so careful waterproofing is necessary;

- it is impossible to make a layer thicker than 5 cm, otherwise you will have to apply insulation not only outside, but also inside;

- heavy weight;

- warm plaster cannot serve as a finishing material.

Finishing the insulated basement base

Various finishing options are possible:

- plastering;

- decorative panels;

- tiles.

Plastering sequence:

- Prepare the plaster mixture.

- Apply plaster to the surface of the insulation.

- Cut the reinforcing mesh.

- Place the mesh on the surface.

- Smooth it with a spatula, sinking it into the solution.

After the plaster has dried, sand the surface to remove any unevenness.