Induction electric boilers are not as in demand as heating element or electrode boilers due to their high cost. In addition, the use of induction electric boilers for heating a private home is simply unjustified either from an economic or practical point of view. However, many intermediary sellers promote the equipment as an excellent option specifically for an individual heating system, which misleads many people.

Induction electric boilers do have some advantages, but they are not entirely significant in domestic operating conditions. Let's approach the choice of heating equipment wisely.

Read in the article

Comparison with fossil fuel boilers

- From an economic point of view, electric devices for space heating are inferior to fossil fuel boilers, because the price of 1 kWh of electricity is much more expensive than that obtained from fossil fuel.

- The absence of emissions of combustion products into the atmosphere, which means maintaining cleanliness during operation, is an advantage of electric boilers.

- A higher degree of fire safety is also an advantage of electric boilers.

- There is no need for storage facilities for solid fuel reserves.

- If possible, automatic control devices for heating the room, modern gas boilers are not inferior to electric ones.

- The use of double-insulated cable products for connecting electric boilers with a power of 3 kW or more is a necessary condition for their reliable operation.

- Strict attachment to the home's electrical supply system reduces the degree of independence of individual heating.

- Installing a gas boiler involves a lot of troublesome approvals and constant monitoring of the gas service, because it is an object that poses an increased danger to human life.

Solid fuel heating boiler

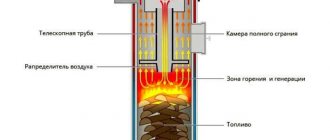

Solid fuel heating boilers come in several types: pellet, pyrolysis, long-burning and traditional. All of them run on available solid fuel and differ only in the combustion method.

Pellet boilers use special compressed wood pellets – pellets – as fuel. Pyrolysis heating devices are equipped with two combustion chambers. In one of them, when there is a lack of oxygen, wood is burned, as a result of which the fuel releases pyrolysis gas, which is sent to the second chamber for afterburning, thereby generating more heat. Long-burning boilers are capable of operating without additional loading from several tens of hours to several days.

Models of electric boilers

The principle of any electric boiler is the conversion of electricity into heat. Electric units are not the most cost-effective, but the efficiency of their use is 95-99%, which is quite good for such units. Such boilers are divided into three types according to the type of coolant. Let's talk about each of them in more detail.

Electric heating element boiler

Electric heating boilers equipped with heating elements operate on the principle of an electric kettle. Water passes through tubular heating elements - heating elements. Acting as a coolant, it passes through the entire heating system, circulating using a pump.

One of the advantages is its compactness, neat appearance and the ability to be mounted on a wall. The installation process will not cause any particular difficulties, and operation is comfortable and simple, thanks to thermostat sensors. Automation allows you to maintain the required heating, focusing on data from sensors that measure the ambient air temperature.

The coolant can be not only water, but also a non-freezing liquid, thanks to which scale will not form on the heating elements, which cannot be avoided by using water.

Attention. Scale formed on heating elements impairs the heat transfer and energy-saving properties of an electric heating boiler. This option for heating a house is also good because it has a low cost.

For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately

This option for heating a house is also good because it has a low cost. For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately.

Electrode electric boiler

The operating principle of an electrode electric boiler for heating a house is completely different from the previous model. The liquid is not heated by a heating element. An electrode installed in the housing gives the liquid an electrical charge, under the influence of which the molecules are split into negatively and positively charged ions. The coolant has its own resistance, which provides intense heating. Either water or a special compound (similar to antifreeze) is poured into the system.

This type of electric unit for heating a house is completely safe; if a liquid leak occurs, it will simply turn off. Electrode models are very compact (looks like a small cylinder with pipes), equipped with sensors for measuring ambient air temperature, and controlled automatically.

Maintenance of this model comes down to replacing the electrode, since they gradually dissolve as they work, which worsens the heating of the house. It is also necessary to ensure that the circulation pump is working properly so that the liquid in the system does not boil. Correct and efficient operation of an electrode electric boiler for heating a private house is only possible with prepared water - it must have the required resistivity value. Measuring them yourself is not always convenient and easy, just like preparing water. Therefore, it will be easier and more reliable to buy a liquid specially designed for use in electrode boilers.

Electric induction boiler

This type of electric heating unit for the home operates on the basis of induction heating of liquid with ferromagnetic alloys. The inductive coil is located in a sealed housing and does not have direct contact with the coolant, which flows around the perimeter of the device. Based on this, not only water, but also antifreeze can be used as an energy carrier for heating a house. This electric boiler for home heating is not equipped with a heating element or electrode, which improves its efficiency. Also, the absence of heating elements ensures complete safety during operation. This version of the boiler for heating a home is not subject to scale formation, practically does not break and does not leak.

The only disadvantage of induction models is their higher cost and larger dimensions. But over time, the size problem is eliminated - the old ones are replaced by improved models.

In addition to this classification, electric boilers for heating a private home are divided into:

- single-circuit (intended only for heating the entire house);

- double-circuit (provide not only heating throughout the house, but also water heating).

You also need to highlight:

- wall-mounted boilers;

- floor-standing boilers (high-power models are produced).

Operating principle

First, let's talk about the general operating principle of such heaters. As you know, when a direct current circuit is turned on or off, an electromagnetic field is formed, which, in turn, creates a current in conductors located in a certain way. This action heats up the conductor on which it acts.

If we now imagine the action of ordinary alternating current having a frequency of 50 Hz , we will see that the action of the field will lead to even greater heating of the metal core. It is clear that, in some cases, high-frequency electric current can be applied, which is even more capable of producing heat.

This idea was used to create induction heating boilers. Now let's look at how exactly they are arranged.

The entire device is located inside a metal casing.

The heating element is seamless metal pipes that are located inside it. They are located inside a coil, which is placed inside a closed housing. An alternating electric current is passed through it, as a result of which the metal pipes and, accordingly, the liquid that flows through them are heated.

For this purpose, ordinary water or other specialized types of liquids can be used. Typically, in order to circulate the liquid, a pump is used to push water through the pipes.

An important feature of this type of heating is the presence of microvibration, which plays an important role in preventing scale formation in pipes. In addition to water, antifreeze or, for example, machine oil can also be used as a coolant.

How to calculate boiler power

A number of factors influence the final capacity of the installation. On average, ceilings up to 3 meters high are accepted. In this case, the calculation comes down to the ratio of 1 kW per 10 m2, in a climate typical for the middle zones. However, for an accurate calculation, consider the following number of factors:

- the condition of windows, doors and floors, the presence of cracks in them;

- what are the walls made of?

- the presence of additional insulation;

- how the house is illuminated by the sun;

- climatic conditions;

If you have blowing from all the cracks in your room, then 3 kW per 10 m2 may not be enough for you. The path to energy saving lies in the use of quality materials and compliance with all construction technologies.

You should not take a boiler with a large reserve, this will lead to high energy consumption and financial costs. The margin should be 10% or 20%.

The operating principle also affects the final power. Take a look at the comparison table, it will certainly help you:

Chimney for solid fuel boiler

Chimneys for solid fuel boilers can be located inside or outside buildings. In order for smoke removal to be as effective as possible, it is necessary to correctly calculate the height of the chimney, select the diameter of the pipe, take into account the length of the acceleration section and insulate the chimney. All these parameters are already taken into account by the manufacturer, so during installation you must strictly follow the instructions.

If the length of the chimney is too short, then the draft in the boiler furnace will be insufficient, but if it is increased too much, the heat will simply fly into the pipe without returning to the heat exchanger. The diameter of the pipe affects the hood quite strongly; an increase or decrease of 2-3 cm greatly impairs the traction efficiency. It is worth keeping in mind that when the chimney is placed externally, its insulation will reduce heat loss.

The chimney can be made of brick, steel, ceramic or even glass. The best option is a chimney with ceramic sections. Such a pipe is not subject to corrosion, it is not afraid of condensation, ceramics are fire-resistant and durable.

Advantages and disadvantages

Heating devices such as induction boilers, like other similar units, have their pros and cons. It is necessary to familiarize yourself in detail with both their positive and negative sides if you are going to install such equipment in your home. First, let’s look at what is good about induction types of heating boilers.

The main advantage of such units is their reliability. If such products have automation, then they can operate autonomously, and the owners do not have to constantly monitor them. In this case, only the absence of a thermal fluid can lead to a breakdown of the device - then the core body in the system can overheat too much and, as a result, melt.

Induction boilers are distinguished by high efficiency (over 90%). Of course, the specific value mainly depends on the design of the heat exchanger in the unit and other structural features of a particular model. The advantages of such units include the fact that their efficiency does not decrease over the years, so even after a long time you will not notice that your heating system has become less efficient.

Induction heating equipment is not subject to breakdowns - it will not require frequent and expensive repairs. To install such a unit, there is no need to additionally construct ventilation or a chimney, which often costs users a tidy sum.

Such equipment serves for quite a long time. If you use these types of heating boilers correctly, they can last more than 30 years, since there is nothing to burn in them, because the inductor is hermetically sealed in the housing and is reliably insulated from contact with the coolant. In addition, the coils are not twisted tightly and are filled with a special protective compound. For this reason, the possibility of damage to the turns is minimized.

The liquid in such systems is heated to high temperatures. The minimum value is 35 degrees Celsius. Such units are installed quite simply. Household models are a small piece of pipe, which is sealed on both sides. There are 2 fittings on the housing, which are necessary for connecting the coolant supply and return. There is also a cord to connect the automation. Connecting such systems is not particularly difficult - you can cope with this simple work without the involvement of specialists.

Induction heating systems are characterized by high operating efficiency. They are characterized by low inertia, so heating of the coolant begins very quickly (immediately after the system starts). Such boilers turn off just as quickly. In such a device, the waste coolant does not need to be changed too often. It is enough to do this once every 10 years.

These types of heating devices, as a rule, do not leak, since they do not have detachable internal connections. These units are capable of operating at both direct current and low voltage. According to experts, harmful scale does not accumulate on the heating element in such devices. This occurs due to the vibration of the core (because of this, excess particles cannot be deposited on it). In addition, scale will not accumulate due to the temperature of the coolant (not higher than 90 degrees Celsius) and the closed nature of the system, in which a limited number of carriers may be present.

Now it's time to get acquainted with their disadvantages:

- First of all, a number of disadvantages of such devices include their high price. They cost several times more than devices with heating elements. However, the high cost is due to the presence of automation.

- Usually these devices have an impressive weight. For example, a cauldron with a diameter of 12 cm and a height of 45 cm will weigh as much as 23 kg.

- These boilers are suitable exclusively for closed heating systems.

- Such units can create wave interference at a short distance. For this reason, experts advise installing them as far as possible from any household appliances.

- If you are going to install an induction boiler in a large house with 2-3 floors, then you will have to additionally install a high-power circulation pump - this is necessary for the device to operate stably.

- Induction units are energy dependent. If the electricity in your home is turned off, the heating will also stop working. Of course, this problem can be solved - you can purchase diesel generators, but this will be an additional expense.

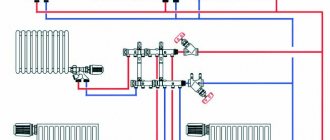

Installation (piping) of solid fuel boilers

Installing a boiler is a rather responsible and complex procedure, because it determines how long and efficiently the heating equipment will last. A solid fuel boiler must be installed on a heat-resistant floor, for example, on a specially prepared concrete pedestal.

Connecting solid fuel boilers involves connecting all the necessary elements of the heating system. This is a pipeline, a coolant and air temperature control system, sensors, a pump and various valves, as well as an expansion tank or boiler. Solid fuel boilers can be installed in an open or closed heating system. The final stage of installation is connecting the boiler to the chimney. Proper piping and correct connection of a solid fuel boiler can not only extend the life of the equipment, but also increase the burning time of the fuel.

How much electricity does an air conditioner consume for heating?

It is important to understand that there is no absolute calculation formula. The point is the impossibility of accurately predicting the street temperature and the required temperature value in the room

In addition, it is difficult to understand how often the user will turn on the device. It is possible to find out approximate indicators.

Heating uses less electricity than cooling. Here the COP coefficient is used for calculation. For class A it is approximately 3.60. With a heating power of 2.2 kilowatts, it will take approximately 0.61 kilowatts per hour. Judging by the above calculations, heating a room with a split is more profitable than with a heater. The latter consumes an approximate number of kilowatts, as in the case of rated power.

Per month

To find out how much an air conditioner consumes per month, you need to know how many hours the system has worked. In hot weather, the device can operate for no more than 10 hours. If the air conditioner is class B and needs 0.78 kilowatts per hour to operate, then in 10 hours it needs 7.8 kilowatts per day. For a month of continuous operation in the specified mode, 234 kilowatts will be required. With a tariff for electricity of 14.04 rubles per day, per month you will need to pay 421 rubles per month. This calculation is schematic and inaccurate, since the final amount will depend on the size of the room, heat inflow, desired cooling or heating parameters, and other things.

You can also use the second calculation method, based on the indicator of hourly electrical consumption and specific air conditioning operation, a typical split operation scheme. So, in a few hours, the type B inverter model will work with 100% performance. Within 3 hours this figure will be 75%, within 4 hours - 50%, and 5 hours - 25%. Then per day a figure of 5.85 kW/hour will be obtained. The monthly cost will be 758.16 rubles.

Considering this indicator in one way or another, you need to know that each air conditioner has several characteristics of consuming and heating power (cooling and heating capacity). These values are specified in the device passport and may vary depending on specific conditions. The higher the number of heat and cold indicators, the lower the consumption will be. It is also interesting that any device consumes 3 times less electricity than it produces. The point is the cost of freon circulation and its conversion.

It is worth understanding that these figures, written with the help of the manufacturer, may differ from the real ones. This can only mean one thing - they are approximate. In the conditions of the enterprise there were no factors influencing the increase in the indicator. In practice, conditions are not ideal.

Owner reviews

Sergey Kaluga : “I don’t understand why induction boilers are so expensive. I made the device myself and it cost me no more than six thousand rubles. The base of the boiler is a regular transformer coil. Of course, it is not necessary to use copper wire to wind it. It is enough to use ordinary knitting wire, which has a thickness of 2 millimeters. However, I agree that induction heating boilers are the most efficient among similar devices.”

Andrey Penza : “The purpose for which I needed a heating system was to maintain a certain temperature in the room. It is enough for me that it is seven or eight degrees. I don't plan to use induction heating on a permanent basis. It's too expensive for me. Due to the fact that I have the opportunity to use gas heating for this purpose. It will cost a little less. But here the reliability and safety of induction boilers comes to the fore. I am afraid to heat with gas during the seven days of my absence and use induction heating for this purpose. I use a 3 kW per hour boiler and use antifreeze as a coolant. This way, if the power goes out, the system will not freeze. I have been using this heating system for 10 years. The system has proven its safety and reliability.”

Advantages of induction heating boilers

Induction boilers have many absolute and comparative advantages, including the following:

- the highest efficiency among all electric boilers;

- constancy of energy characteristics;

- minimum coolant requirements;

- increased reliability;

- record long service life;

- ability to work autonomously;

- simple installation without ventilation system;

- automatic control system;

- there is no need for fuel delivery and storage:

- heating the coolant to 95 degrees;

- high level of security.

The device converts electrical energy into thermal energy with an efficiency of 98-99%. It takes 7-10 minutes to heat the coolant. A simple design in which there are no moving mechanical parts, steel alloys used as manufacturing materials make induction boilers record-breakingly durable.

Such equipment can only be damaged by damage to the electrical insulation. But as the practice of operating transformers, which in their design are in many ways similar to induction boilers, shows, they can really last for many decades.

According to manufacturers, units operating due to the effect of electromagnetic induction provide uninterrupted heating of rooms for 100 thousand hours, that is, 30 heating seasons. At the same time, their power does not decrease over time, which cannot be said about electrode and conventional heating element boilers.

Induction boilers can be used both as main and additional equipment. For example, preparing coolant for an irregularly used underfloor heating system

The same reasons that determine the durability and increased reliability of induction heaters also reduce operating costs. The induction boiler does not require regular maintenance and repair, which saves money.

Compared to many other fuels, using electricity to heat homes remains the most cost-effective. This is especially true for non-gasified settlements.

The design of the certified induction boiler prevents short circuits. Manufacturers claim that any model has the highest electrical safety class. An induction boiler should not be confused with a microwave oven, since it uses a different frequency of electric current to operate.

Heating of the coolant in an induction boiler occurs evenly - the temperature difference in the system is no more than 30°C. That is, there are no local overheats that could lead to fire, which makes such units fireproof.

Thanks to the magnetization of the coolant, fine vibration, invisible to others, and turbulent turbulence, virtually no mineral deposits form in induction boilers, which has a beneficial effect on efficiency. Let us remember that a thick layer of scale slows down the speed and efficiency of heating the coolant.

To increase power, it can use a cascade of three or more induction boilers with a common control cabinet. This solution will help heat a two-story mansion

If you follow the operating rules specified in the instructions, then after installation and setting the temperature regime you will not have to think about the boiler throughout the entire heating season. Unlike solid fuel “brothers”, induction devices do not require regular loading of firewood and coal and removal of ash. No pipe cleaning is required, which distinguishes them from other types of electric boilers.

The boiler itself and its additional equipment take up little space and can be installed in a small room. The control system components allow the use of induction boilers in conjunction with other climate control equipment.

Induction boilers can be integrated into an intelligent home equipment control system called “Smart Home”

Russian-made solid fuel boilers – buy

The share of domestic boilers on the market is about 30-40%, the rest are of German and Czech production. Despite this, Russian-made boilers are worthy competition to imported manufacturers, since they are not only adapted to our conditions, but their requirements for wood quality are much lower. Russian-made solid fuel boiler models meet all safety standards. buy a solid fuel boiler not only of domestic but also foreign production, but their price is an order of magnitude higher than their Russian counterpart, so when choosing a boiler you should pay more attention not to the manufacturer, but to the offered characteristics - power, reliability, automation and ease of operation.

Lemax brand produces simple, compact and reliable equipment at an affordable price. Fuel is loaded from the end or from above. Boilers can operate on any type of fuel - brown coal, wood briquettes. However, it is worth considering that in such boilers the fuel burns out very quickly.

Teplodar boilers occupy a leading position on the market, since they can operate from 30 hours to 5 days on one load, depending on the type of fuel loaded - firewood, coal or briquettes. The entire line of heating equipment is divided into two types - the budget “Comfort” and the universal “Kupper” . The latter can be converted to a pellet or gas heating system.

Solid fuel boilers in Siberia are primarily attractive due to their price. In addition, they are compact and quite easy to use. These boilers require periodic monitoring of the combustion process and timely supply of fuel. But you can use any type of solid fuel, as well as connect a heating element to organize hot water supply. The boilers are equipped with a hob, so they fit perfectly into the kitchen space. Buderus boilers are durable and reliable devices that allow you to heat large areas.

They are easy to maintain and operate and are completely energy independent. These heating devices occupy leading positions in the Russian market. View materials...

Construction of a water heater made of plastic pipe

You will need a thick-walled plastic pipe with an internal cross-section of 5 cm and 7 mm copper wire. Adapters are also needed to connect the inlet and outlet of the boiler and the pipeline. Power is provided by an inverter for welding from 15 A.

Procedure:

- On one side, a fine metal mesh is attached to the pipe to prevent the wire from falling inside.

- At the same time, an adapter is welded to connect the heating to the boiler.

- The wire is cut into pieces 1-6 cm long and placed in the pipe tightly to each other.

- At the second end of the pipe, a mesh is also attached and an adapter is installed for insertion into the system.

- 80-90 turns of wire are wound onto the pipe with equal intervals between the rings.

- The opposite ends of the winding are connected to the poles of the inverter.

- The connection points are isolated.

- The heater is connected to the heating system so that the liquid enters it from below.

- To circulate fluid in the system, a pump is installed.

- A thermostat is also connected to the inverter so that the system operates automatically.

Scheme of solid fuel boilers

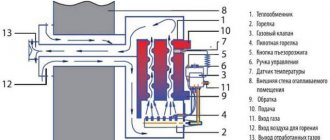

Solid fuel boiler systems may differ depending on the presence of a water circuit. Any boiler of this type has a combustion zone, above which there is a fuel loading door, and below there is a ventilation hole; in some models, a blower fan is installed. Each solid fuel boiler is equipped with an ash chamber and technical doors for cleaning the furnace from soot. A heat exchanger and an outlet pipe for the chimney are usually installed in the upper part of the boiler.

Popular models

If you want to choose a good induction electric heating boiler, read the following information - we will tell you about the most successful and popular models. As for the choice of power, focus on the area of the premises. Remember that for every 10 sq. m. area requires 1 kW of heat.

Boilers VIN-3

Here we have the simplest vortex induction boiler, designed for heating small buildings. Its power is 3 kW, heated area is up to 30 sq. m (or from 90 to 140 cubic meters of heated volume). It is made in the form of a small diameter pipe with side pipes for connecting the heating system. At the bottom there is a contact for grounding connection. The control unit is connected through a contact group in the upper part of the housing.

The induction electric boiler is designed for use in closed heating systems with forced circulation of coolant. It is so small that it does not take up much space in the room. But the wall mounting must be reliable - the weight of the unit is 30 kg. It is powered by a single-phase network with a voltage of 220 Volts. The control unit includes circuit breakers and is extremely compact.

The boiler is supplied to the market in several configurations. They include additional components - control units, control valves, flow sensors and much more that may be needed for installing a heating system.

Miratron boilers

Miratron induction boilers are designed to work in heating systems in buildings up to 360 square meters. m - models with power from 6 to 36 kW are supplied to the market. They are made in the form of rectangular vertical cabinets with built-in control systems. The equipment is distinguished by its information content - it shows the number of sections operating at a given moment, measures the supply voltage, displays the current power and temperature of the coolant in the supply and return pipes.

Thanks to the presence of advanced automation, boilers allow you to save a little due to precise temperature control. And the multi-section design reduces the load on the electrical network. The required temperature mode of heating operation is set using buttons located on the control panel of induction boilers. Here we will see the “Turbo” button, which starts the fast warm-up mode.

Sav PROF boilers

If you have a need to buy a small-sized induction boiler to organize heating in a small building, be sure to pay attention to the Sav PROF series boilers. They are made in neat metal cases, including everything necessary for heating systems - automatic starting, thermomanometers, manual air vents, flow sensors, control modules and circulation pumps

From the piping you only need to purchase an expansion tank and a safety valve.

The power of Sav PROF induction boilers is 2.5, 3.5, 5 or 7 kW - at the choice of the consumer. Accordingly, the heated area reaches 70 square meters. m. when using the most powerful sample. All models are powered from a single-phase network with a voltage of 220 Volts. Thanks to its compact design and the presence of some piping elements, the equipment is extremely easy to install - assembling the heating will not take much effort and time.

The presented induction boilers have an important advantage - they have contact groups for connecting external heating controls.

They are connected to external temperature sensors, additional remote controls (including those controlled by telephone and via the Internet), as well as programmers. Date: September 25, 2022

Calculation of other indicators when choosing a boiler

The main element of individual heating is a boiler, and which one should you have, gas or electric? boiler depends on a number of factors. Such as distance from the energy source (whether gas or electricity), time of residence according to the seasons (dacha, residential building). The price you are willing to pay for the device itself and its installation is also important.

But the most important thing when choosing is always the thermal calculation, because based on it, home owners give preference to one or another device with the required power. A single-phase electrode electric boiler is installed, as a rule, by owners of houses with an area of no more than 300 m2.

Approximate scheme for heating a house with electricity

It is enough to have access to a 220 V outlet and a small installation space; it can serve as both the main source of heat and work during the inter-heating period for heating. But first, it wouldn’t hurt to delve into the structure of the device in more detail; this will help to more accurately calculate the desired model.

Also pay attention to the following indicators:

- Purpose of the boiler, heating or also hot water for domestic needs.

- Storage tank volume.

- Coolant volume for the heating circuit.

- The area of the heated room.

- What current is the network designed for?

- Device power.

Should they be used for heating a private home: let’s look at known misconceptions

As we said earlier, the use of induction electric boilers is justified only in industry. However, it is worth confirming the words by analyzing all the known myths in more detail.

Efficiency and profitability

An example of compact piping of an electric induction boiler in the heating system of a private house.

Despite sellers’ assurances of high efficiency, all modern electric boilers have about 99%. This means that, for example, at maximum load, a boiler producing 9 kW of thermal energy will consume 9.091 kW of electricity. However, over time, due to scale formation, the efficiency of heating element models decreases to 90 or even 80%, since more time and power are required to ensure the same heat transfer through the scale layer. In induction boilers, scale does not form and the efficiency remains unchanged.

But even in heating element models the problem can be almost completely solved:

- filtering the coolant being poured;

- installing softening filters;

- using the same coolant without draining it every season. Minerals will settle once on the heating elements and turn into an insignificant layer of scale, which practically does not affect the heating efficiency, after which they will simply have nowhere to come from.

We will deal with it later, but for now we can conclude that the efficiency of all modern electric boilers is the same, and the absence of scale is not worth an overpayment of more than 50%.

Reliability

Another frequent argument in favor of electric induction devices is their reliability: the design is as simple as possible, which means there is simply nothing to break in it.

This is true, but it applies to absolutely all high-quality electric boilers, since, unlike gas boilers, the only element that can fail under proper operating conditions is the heating element. But even with cleaned and soft coolant, they last at least 5-7 years.

Safety

Even with modern models, safety is not easy, since powerful inductive electric boilers create a serious load on the electrical network and distort the sine wave. It is necessary to connect the boiler unit only if the wiring is in excellent condition, preferably through a voltage stabilizer. In addition, the magnetic field is not isolated in any way, which can negatively affect the operation of nearby electronics.

Automatic and temperature control

Typical control cabinet for an induction boiler.

An induction electric boiler is controlled using a separate control panel, which has fairly precise settings, but does not imply programming the operation of the boiler for the next day or week.

In well-known heating element models, the temperature is controlled more precisely: by degrees, thanks to a temperature sensor. In addition, in many models it is possible to install a room thermostat, which allows you to more efficiently and correctly regulate the operation of the boiler according to the temperature of the air in the room, and not the coolant at the outlet.

Weight and dimensions

An example of using several low-power electric boilers in one system.

The dimensions of induction boilers are really small, which allows you to install them almost anywhere in the house. However, this is not such a significant advantage over the already compact heating element models or extremely small electrode boilers, slightly larger than the main pipe.

How to make it yourself

The manufacture of a heating circuit using the phenomenon of electromagnetic induction should be considered only as an experiment. Despite its apparent simplicity, the design of industrial samples has a complex structure, and the models themselves undergo dozens of safety tests before being put into mass production.

Required materials and tools

Following the instructions, you can assemble the system yourself.

To make your own induction structure and use it for heating, you will need:

- induction cooker;

- corrugated stainless steel pipe 1.5 m long;

- battery or radiator;

- 20-25 cm copper tube;

- soldering devices;

- set of fittings for connection.

Making a simple boiler

Manufacturing a primitive heater, the functioning of which is based on electromagnetic currents, requires no more than half an hour.

For this:

- The corrugation is wound into a spiral of 4 turns.

- The beginning and end of the spiral are connected by a copper tube, the ends of which are soldered at the junction.

- The free ends of the corrugated tube are connected to the radiator using fittings.

- Water is poured through the top hole of the radiator, the level of which should be several centimeters below the top edge of the hole.

- The plug with the Mayevsky tap is installed in place.

- An induction cooker is placed under the spiral and connected to the network.

After turning on the stove, the standard radiator in 4 sections heats up to 70-80 degrees. Celsius happens in just a few minutes.

Assembly of a vortex induction unit

The assembly of industrially produced vortex units is carried out in accordance with the attached instructions.

To do this you need:

- Install the fastening.

- Assemble the boiler body.

- Prepare the connection points to the system using fittings and install the unit in place.

- Connect power and control electrical networks. Find out the Evan electric boiler at the link.

Water heaters type VIN

The heart of the unit is a coil consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical housing in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed at the top and bottom with welded lids, and the terminals for connection to the electrical network are brought out. Cold coolant enters the vessel through the lower pipe, which fills the entire space inside the body. Water heated to the required temperature goes into the heating system through the upper pipe.

Coolant heating circuit

Due to its design, when connected to the network, the heat generator constantly operates at full power, since it is irrational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown/on with a water temperature sensor. You just need to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the water heating induction element when it is reached. After the time has passed and the water has cooled by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the heat generator winding provides a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying large cross-section cables, which in itself is very expensive. To increase power, it is enough to put three water heating units in a cascade and use a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each device in the cascade; the photo shows a similar example of the operation of induction heating.

Heating with induction boilers

Design features of heaters of the “Sibtekhnomash” type Using the same effect of electromagnetic induction, another company develops and produces water heating devices of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial shape and spreads from it in all directions. If in VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides a spiral-shaped heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the turns of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate, collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- Heat exchanger piping is accessible for cleaning and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its operating efficiency is 98%, as in heaters of the “VIN” type, this efficiency value is declared by the manufacturer itself. The durability of the units in both cases is determined by the performance of the coils, or more precisely, by the service life of the winding and electrical insulation; manufacturers set this indicator within 30 years.