In most cases, when we talk about thermal insulation materials used for insulating residential buildings, the first thing that comes to mind is mineral wool in one form or another, expanded polystyrene, expanded clay. Few people remember vermiculite, and many do not even know about its existence.

Vermiculite insulation

And completely in vain. Undeservedly given a “secondary role,” vermiculite is an insulation material of natural origin, the production of which does not use not only harmful, but also no chemical compounds at all. And, at the same time, its thermal insulation and performance qualities are not only comparable, but in some cases seriously exceed those of other widely used insulation materials. In a word, this material deserves to get to know it as closely as possible.

Vermiculite insulation features and application

Composition and processing of vermiculite

Vermiculite contains several components connected by one chemical formula. It contains the most silicon - about 35%; there is also 10% magnesium, iron, potassium, calcium, etc.

Natural vermiculite comes in the form of large, scaly crystals. When exposed to high temperature, they are transformed into winding twisted threads-columns, increasing in volume up to 10 times.

When the material is heated above 1000 degrees, expanded vermiculite is obtained - a light bulk material, brownish, golden in color.

Hygroscopicity

The main distinguishing feature of expanded vermiculite (hereinafter simply vermiculite) is its high hygroscopicity. 100 grams of material can absorb up to 500 ml of water. But vermiculite dissolves just as easily with water.

In fact, it is a natural hydraulic accumulator. Therefore, it is mainly used in crop production, as a soil additive.

Thermal insulation

Another feature of the material is its high thermal insulation qualities. The thermal conductivity coefficient of bulk vermiculite is in the range of 0.05 – 0.07 W/ (m*K) depending on the size of the fractions and compaction density. This makes it possible to use the material as an effective insulation material.

1 mm, 120 kg/m3 – 0.059

2 mm, 110 kg/m3 – 0.057

4 mm, 95 kg/m3 - 0.054

8 mm, 65 kg/m3 – 0.052

The use of vermiculite as insulation

It is effective to use vermiculite as bulk insulation for thermal insulation of floors and ceilings. And also for filling various cavities in walls, partitions, pipeline ducts....

When used on attic floors, reliable waterproofing on the roof side is required, as well as covering the material layer with a vapor-permeable membrane (paper layer). On the side of the room, there should be a vapor barrier film under the material

During installation, special attention is paid to ensuring continuity

Special Use

Rigid slabs are made from vermiculite. They are more expensive, but can be used instead of mineral wool, as they have similar characteristics to it.

Flaws

The main disadvantage of vermiculite is its ability to absorb moisture 3-4 times its own volume. However, it gives it away with the same ease, unlike natural materials (cellulose, wood) or polymer insulation.

When using vermiculite, it is especially important to ensure good ventilation to remove excess moisture. Since this is a natural requirement when arranging a roof and roofing when using absolutely any insulation material, strong water absorption is considered a disadvantage among the features that should be remembered and taken into account when designing a house.

Nomenclature

Expanded vermiculite is produced in accordance with TU 5712-091-00281915-2007 and is divided into grades depending on the volumetric bulk density and grain size of the main fraction.

VVF means Expanded Fractionated Vermiculite. Grade 100 means that the volumetric bulk density of vermiculite is no more than 100 kg/m³.

St. Petersburg Mica Factory offers expanded vermiculite:

Most thermal insulators have one or more flaws - they are either fire hazardous, expensive, or not environmentally friendly. In search of the optimal option, developers are often interested in the idea of using vermiculite in this role - a layered mineral that, at high temperatures, changes its structure and acquires new properties, which at first glance are quite suitable for insulating a building. How versatile is this insulation, does it have any disadvantages, and how to use it correctly?

What is zonolite

The mineral vermiculite is actually just a raw material for the production of expanded vermiculite - zonolite, which is occasionally found in deposits. Natural vermiculite is a product of natural erosion of mica biotite from the phlogopite series of hydromicas. When they say or write that windows were made from these micas in the old days, this is not true - phlogopite micas are opaque. Before the mass production of silicate glass, windows were glazed with the almost transparent mica muscovite, which began another mineralogical series of mica. Over 90% of the world's production of top-quality muscovite came from Russia, which in the West was called Muscovy; hence the name muscovite.

Natural and expanded vermiculite (zonolite)

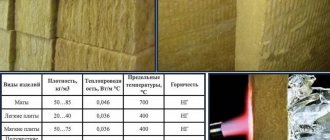

Vermiculite in natural deposits is a layered mineral of color from dirty yellow to almost black with green. During firing at 400-1000 degrees, it loses crystallization water, swells across the layers 15-20 times and changes color - this is already zonolite. For agricultural technology, medium-burnt expanded vermiculite is used, see fig. or highly burnt; after firing, it is crushed into granules according to its intended purpose, see below.

Vermiculite and perlite

One of the main tasks of vermiculite in plant culture is to absorb excess soil moisture and release it back into the soil as needed. In the range of moisture sorbents, vermiculite ranks after hydrogel and zeolites. Compared to gels, the exchangeable moisture capacity of vermiculite is small (up to 400 ml of water per 100 g of dry matter), but it does not disturb the soil structure and does not worsen, but on the contrary, increases its permeability. Compared to zeolites, vermiculite is cheaper, but has less moisture absorption and does not have ion-exchange properties. The closest competitor to vermiculite in all respects is expanded perlite. It lacks some of the disadvantages of vermiculite (see below), but is much less stable in the ground (2-5 years). For more information about the comparative qualities of vermiculite and perlite, see the video:

Properties of expanded clay

- high strength

- fire resistant

- frost-resistant

- does not contain harmful impurities;

- does not absorb water;

- durable

- does not lose its properties and is not destroyed when frozen

- not subject to rotting

Absolutely safe for humans and the environment.

Expanded clay is a product of rapid firing of low-melting clays. From Greek, the word “expanded clay” is translated as “burnt clay,” which is absolutely true. Despite heat treatment, it not only does not lose the properties inherent in the clay itself, but also acquires additional ones, becoming porous.

Photo: Properties of expanded clay material. Application area

On their basis, expanded clay concrete blocks are made, the thermal insulation and mechanical properties of which allow them to be used for the thermal insulation construction of floors, walls, ceilings, foundations and basements. Thanks to the expanded clay filler, these blocks also acquire its properties. They are lightweight, durable, fireproof, acid resistant, etc.

Main advantages

So, we found out that vermiculite consists of crystals connected in certain groups. The material is durable, does not compress and does not collapse over time, which cannot be said about the same mineral wool. Thanks to all its advantages, the material is significantly superior to its competitors - perlite or expanded clay.

In terms of thermal conductivity, the material is similar to mineral wool, and its resistance to flame and aggressive environmental influences is approximately the same. But the sound insulation properties are an order of magnitude higher than those of any other insulation. But the main advantage of vermiculite is its low price and availability (more on prices a little later).

Areas of application

Discovered relatively recently, the mineral vermiculite and its derivatives have found many different applications today:

- Ecology, oil and chemical industries. Few people can answer when asked about vermiculite that it is an excellent sorbent capable of binding alkalis and acids. This property allows it to be used to neutralize a variety of chemicals in industries, as well as to limit oil spills.

- Nuclear industry and energy. It is used as an absorber of radioactive elements such as cobalt-58, strontium-90 and cesium-137, and also as a reflector of gamma radiation.

- Automotive and aviation industry. A variety of sound-absorbing and heat-insulating materials and products are made from vermiculite.

- In industrial and civil construction vermiculite is used as follows:

insulation, as well as sound and heat insulators for roofs and floors;

- for backfilling as insulating material into hollow panels;

- as a component of various plasters, lightweight concrete and dry building mixtures;

- in the manufacture of concrete and cement blocks, as well as heat-insulating mastics as a filler;

- in the production of fire-resistant and heat-resistant slabs, panels and other wall materials;

- when installing self-leveling floors.

5. In industrial and private plant growing and horticulture. Let's take a closer look at how vermiculite is used for plants.

Specific gravity of building materials - Sergey Chervach

Material specific weight, kg/m3 Concrete Reinforced concrete 2500 Concrete on gravel or crushed stone from natural stone 2400 Tufobeton 1200-1600* Pumice concrete 800-1600* Concrete on volcanic slag 800-1600* Expanded clay concrete on expanded clay sand and expanded clay foam concrete 500-1800* Ceram zito concrete on quartz sand with porosity 800-1200* Expanded clay concrete on perlite sand 800-1000* Shungizite concrete 100-1400* Perlite concrete 600-1200* Slag pumice concrete (thermozit concrete) 1000-1800* Slag pumice foam and slag pumice gas concrete 800-1600* Concrete on granulated blast furnace slag 1200-1800* Agloporite concrete on fuel (boiler) slags 1000-1800* Concrete on ash gravel 1000-1400* Vermiculite concrete 300-800* Gas and foam concrete gas and foam silicate 300-1000* Gas and foam ash concrete 800-1200* Mortars Cement-sand 1800 Complex (sand , lime, cement) 1700 Lime-sand 1600 Cement-slag 1400 Cement-perlite 1000 Gypsum-perlite 600 Porous gypsum-perlite 500 Gypsum slabs 1000-1200* Gypsum cladding sheets (dry plaster) (plasterboard) 800 Brickwork Clay ordinary (GOST 530-80) on cement-sand mortar 1800 Clay ordinary on cement-slag mortar 1700 Clay ordinary on cement-perlite mortar 1600 Silicate (GOST 379-79) on cement-sand mortar 1800 Trepelny (GOST 648-73) on cement-sand mortar 1200 Slag on cement-sand mortar 1500 Ceramic with a density of 1400 kg/m3 ( gross) on cement-sand mortar 1600 Ceramic hollow with a density of 1300 kg/m3 (gross) on a cement-sand mortar 1400 Ceramic hollow with a density of 1000 kg/m3 (gross) on a cement-sand mortar 1200 Silicate eleven-hollow on a cement-sand mortar 1500 Silicate fourteen-hollow on a cement-sand mortar 1400 Stone Gra nit, gneiss and basalt 2800 Marble 2800 Limestone 1400-2000 Tuff 1000-2000 Wood and other natural Pine and spruce 500 Oak 700 Plywood (GOST 3916-69) 600 Facing cardboard 1000 Multilayer construction cardboard (GOST 4408-75*) 650 Wood-fiber and particle boards (GOST 4598 -74 *, GOST 10632-77*) 200-1000* Fiberboard slabs (GOST 8928-81) and wood concrete (GOST 19222-84) on Portland cement 300-800* Reed slabs 200-300* Peat thermal insulation slabs (GOST 4861-74) 200 -300 Tow 150 Thermal insulation Mineral wool mats stitched (GOST 21880-76) and with a synthetic binder (GOST 9573-82) 50-125* Soft, semi-rigid and hard mineral wool slabs with synthetic and bitumen binders (GOST 9573-82, GOST 10140-80 , GOST 12394-66) 50-350* High-hardness mineral wool slabs with an organophosphate binder (TU 21-RSFSR-37276) 200 Semi-rigid mineral wool slabs with a starch binder (TU 400-1- 61-74 of the Moscow City Executive Committee) 200 Glass staple slabs fiber on synthetic binder (GOST 10499-78) 50 Stitched glass fiber mats and strips (TU 21-237275) 150 Expanded polystyrene (TU 6-05-117878) 100-150* Expanded polystyrene (GOST 15588-70*) 40 PVC-1 foam ( TU 6-05-117975) and PV-1 (TU 6-05-1158-78) 100-125* Polyurethane foam (TU V-56-70, TU 67-98-75, TU 67-87-75) 40- 80* Plates made of resole-formaldehyde foam (GOST 20916-75) 40-100* Perlite plastic concrete (TU 480-114574) 100-200* Backfill Expanded clay gravel (GOST 9759-83) 200-800 Shungizite gravel (GOST 19345-83) 400-800 Crushed stone made of domain slag (GOST 557876), slag pumice (GOST 9760-75) and Agloporite (GOST 11991-83) 400-800 gravel and sand from perlite switched (GOST 10832-83) 200-600 Vermiculit Vooked (GOST 12865-67 ) 100-200* Sand for construction work (GOST 8736-77*) 1600 Other Foam glass or gas glass (TU 21BSSR8673) 200-400* Flat asbestos-cement sheets (GOST 18124-75*) 1600-1800* Petroleum construction and roofing bitumen (GOST 6617-76*, GOST 9548-74*) 100-1400* Asphalt concrete (GOST 9128-84) 2100 Products made of expanded perlite with a bitumen binder (GOST 16136-80) 300-400 Ruberoid (GOST 10923-82), glassine (GOST 2697-83), roofing felt (GOST 10999-76*) 600 Polyvinyl chloride multilayer linoleum (GOST 14632-79) 1600-1800 Polyvinyl chloride linoleum on a fabric base (GOST 7251-77) 1400-1800 Reinforcing rod steel (GOST 1088 4-81) 7850 Cast iron 7200 Aluminum (GOST 22233-83) 2600 Copper (GOST 859-78*) 8500 Window glass (GOST 111-78) 2500

Technologies for laying vermiculite building materials

Work with mineral insulation is not difficult or harmful - in terms of the degree of impact on the human body, vermiculite coating, according to GOST 12.1.007-76, belongs to class IV (low-hazard substances). To prevent dust from getting into the eyes and respiratory system, before using vermiculite, the worker should protect them with goggles and a respirator. Provided the building material is stored in dry, indoor areas, its shelf life is unlimited.

Thermal insulation of house enclosing structures with backfill vermiculite

To protect the attic ceiling and the surface of the pitched roof from heat leaks, you need to follow a simple algorithm:

- Cover the inner lining with an overlapping vapor-proof film, which will prevent moisture from entering the vermiculite from the inside.

- Pour dry vermiculite into the resulting cavities in the roof frame.

- Lay a windproof super-diffusion membrane on top of it, the purpose of which is to prevent the material from weathering and at the same time allow vapors to circulate freely.

- Install the counter-lattice and lay the roof covering.

The insulation scheme for attic floors is, in principle, similar:

- Reliable waterproofing is laid on the lining between the beams.

- A log system is installed in a layer of 100–150 mm.

- Bulk insulation for the floor is introduced, which must be immediately covered with a vapor-permeable film.

- After installing the plank or plywood covering, the floor is ready for finishing.

- To reduce the cost of the material, vermiculite can be mixed with sawdust in a ratio of 1:1 or 3:2.

Model of insulation of frame wooden walls

Filling the walls with vermiculite is possible at the stage of their construction using frame or well technology or during the process of external insulation. To do this, as the load-bearing wall and facing layer are erected, the space between them is filled with vermiculite granules with light tamping. The approximate layer thickness is 100 mm (for Moscow). Additional vapor and waterproofing is not required, ventilation gaps in the external wall are also not needed.

Another way to create an insulated wall is to fill the cavities of building blocks with vermiculite. The thermal insulation effect of such a design increases sharply, and the free exchange of vapor in the wall is not disturbed, and it remains light and breathable. If necessary, the outer wall can be further insulated if it is built from concrete panels based on quick-hardening cement with the addition of loose wall insulation.

Proportions of solutions for screeds

Insulation with dry vermiculite is a rather expensive solution, so in private construction they prefer to add this material to construction and finishing mixtures. To prepare a solution for a thermally insulated screed, you need to stock up on standard M400 Portland cement, sand and fine- or medium-fraction vermiculite. Due to its high water absorption, the solution must be used within 30 minutes after mixing.

For reliable insulation of the floor above an unheated space, 100 mm of screed is usually sufficient, and for interfloor ceilings, 30 mm is sufficient. It must be remembered that the poured floor, due to the small mass fraction of cement, is not frost-resistant, therefore such screeds are recommended only for heated rooms.

Recipe for plaster mortars for exterior use

To plaster the walls from the inside, you can use the same composition, but for their external treatment, the proportions of the solution must be slightly changed. Both external and internal plasters have high vapor permeability, facilitating normal self-regulation of the internal microclimate. Warm plasters based on vermiculite have a natural golden or silver tint, but if desired, pigment of the desired shade can be added to their composition.

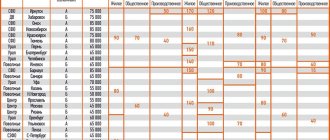

Plaster for interior decoration: C – cement, I – lime, G – clay, V – vermiculite

When laying walls, it is advisable to use modern thermal insulation materials (gas, foam blocks, vermiculite concrete), and the seams between them should be made of masonry mortar with a low thermal conductivity coefficient. You can knead it using the same vermiculite, having previously decided on the optimal composition.

Thus, the demand for vermiculite in construction is obvious: excellent manufacturability and a unique combination of properties bring vermiculite backfills and slabs to the forefront among fire-resistant insulation materials. The only significant obstacle to expanding the scope of their application is the high price, but increased production gives hope that this will soon be eliminated.

The principle of insulation of vertical structures

Vertical structures (walls) can be insulated in two ways:

- Backfill;

- Using slabs.

The first option can be used both during the construction of walls and in the finished structure. Backfill is used to fill voids and air gaps formed during brickwork or (more often) when using cellular concrete blocks. The finished walls will be multi-layered, consisting of a load-bearing base, facing material and insulation. For this purpose, fine- and medium-grained vermiculite is used.

Attention ! The coarse fraction is suitable for the production of refractory concrete mixture.

To insulate walls made using the well masonry method, the outer and inner parts of the structure are first laid out. It is tied in increments of 60–90 cm using jumpers. As an option, lay a mesh of reinforcement in increments of 4–6 rows of masonry. All that remains is to fill the space between the walls with vermiculite. At the same time, it is compacted a little.

Advice ! If hollow blocks are used, then it is enough to gradually fill the voids with vermiculite.

If we talk about the backfill method of insulating an already built house made of logs, timber, OSB or fiberboard, then it is necessary to build an additional partition. And fill the resulting space with insulation, tamping it down. The disadvantage of this method is that it reduces the total area of the building. But the advantage is that even a beginner can handle the job.

As for thermal insulation with vermiculite slabs, this process is reminiscent of working with foam plastic, mineral wool and similar materials. The essence of the work is to fix the slabs on the wall using one of the selected methods (on the frame or using screws with umbrellas). Next, the seams are sealed so that the surface does not have cracks that can become cold bridges. At the end, the vermiculite layer is protected from moisture and a decorative layer is formed.

Properties of vermiculite insulation

Vermiculite insulation is a material that is widely used in construction and finishing work during the construction of new buildings, and carrying out major and ongoing repairs of old buildings. It is used in the form of pressed slabs, as a filler and as an additive to plaster mixtures. It is used for insulating walls, floors, attics and ceilings. Insulation with vermiculite is carried out during the construction of pipeline systems and highways for various purposes, which significantly extends their service life. This has a positive effect on the operation of equipment and pipeline fittings installed for the smooth functioning of the entire system.

Technological features

Vermiculite in the form of slabs and in bulk.

Vermiculite is an environmentally friendly material created by nature. Belongs to the minerals of the hydromica group. It has a crystalline form of golden brown, yellowish or bronze color. It was found that when vermiculite plates are heated, they transform into threads or worm-like columns. Actually, this property made it possible to give the material such a name, because vermiculite means worm in Latin. After examining its physicochemical properties obtained after heating, vermiculite insulation began to be used in various industries, agriculture and construction. Also read: “Choosing the best insulation for the roof.”

The main advantages of the material include:

- fire resistance (1350 0 C);

- density (not higher than 150 kg/m3);

- low thermal conductivity (no more than 0.12 W/m*K);

- resistance to aggressive environments, bacteria and does not form mold on the surface;

- hygroscopicity;

- ability to absorb sound (sound absorption coefficient up to 0.8);

- environmental friendliness;

- service life (60 years).

Before pouring antifreeze into the heating system of your home, you need to clean the pipes and radiators from all kinds of contaminants.

Here you can read what equipment is needed to pump the heating system with antifreeze (antifreeze liquid).

Methods for insulating walls with vermiculite

View of a wall plastered with mortar containing vermiculite.

Vermiculite insulation of walls is carried out during the construction of new buildings and old buildings constructed from different materials. Thermal insulation in bulk form can serve as a filler in the manufacture of heat-resistant concrete and is used for plastering surfaces. It is produced in different fractions (from 0.5 to 12 mm) and is sold in retail chains in paper bags, most often weighing 25 kg.

Granular vermiculite can be poured into inter-wall voids. The pressed slabs are secured using special fasteners and can be cut before installation. The slabs can serve as good insulation when lining fireplaces, stoves, chimneys and pipes. Vermiculite for ceiling insulation additionally performs soundproofing functions in multi-story buildings.

Vermiculite insulation, the properties of which remain unchanged regardless of its type, is also used for plastering vertical surfaces. To do this, it is added to concrete mixtures in certain proportions. You can make them yourself or buy ready-made ones. Comprehensive home insulation with vermiculite (walls, floors, attic) will save on heating bills.

The method for installing an electric heating boiler consists of two parts: inserting the circuit and connecting to the network.

Vermiculite insulation of floors and attics

The technology for insulating floors and attics with vermiculite is the same. In this case, the thermal insulation is protected with special films. A vapor barrier should be installed on the side of the warm room, and waterproofing on the side of the street or unheated attic.

When performing thermal insulation with vermiculite, the presence of waterproofing and vapor barrier is mandatory

It is extremely important to place these protective layers correctly

Insulation of a pitched roof

When insulating the floor, waterproofing is placed under the vermiculite.

With such insulation, it is important to correctly select the thickness of the vermiculite poured. It depends on temperature conditions and ranges from 10 to 20 cm

The technology for insulating a pitched roof is as follows:

- a vapor barrier film is laid on the rafters;

- granular vermiculite is poured in;

- covered with a layer of waterproofing and a counter-lattice;

- the roof is spreading;

- Internal lining is carried out with any material.

Vermiculite insulation, the properties of which have been well studied, is a modern material that has a wide range of applications.

Advantages

Vermiculite can be bought in bags.

Vermiculite is a mineral based on plate-like crystals, combined into three-dimensional groups. It is durable and, unlike mineral wool, is not subject to destruction, does not compress, and does not precipitate under its own weight. This makes it a much better insulation material than expanded clay or perlite, to which it is essentially closer.

In terms of thermal conductivity, it is on par with the most commonly used mineral wool, has the same fire and environmental resistance, but does not compress over time. Sound insulation characteristics are noticeably better than any of the listed materials. The main advantage is its low cost and availability.

Alternatives with the same properties are perlite and ecowool. However, perlite is inferior in cost and availability, and ecowool is significantly inferior in terms of fire safety and over time gets into the room in the form of cellulose dust.

Vermiculite area of application, pros and cons, installation features

When solving the pressing issue of thermal insulation of a home, one has to face the problem of choosing a thermal insulation material.

The range on the market is quite wide, but almost every option has significant drawbacks. In one case, the flammability deters, in the other, the high hygroscopicity rate.

The article discusses the characteristics and advantages of vermiculite, which is the golden mean of price and quality.

Description and scope of vermiculite

Vermiculite is a natural crystalline mineral with a layered structure. Belongs to the group of hydromicas. It contains: silicon, iron, magnesium, calcium and other mineral components.

The main advantages due to which the material is used in construction are resistance to aggressive influences, high acidity, retains its integrity for a long time, and does not decompose.

Many gardeners are familiar with vermiculite; it is often used as a mulching material, a substrate component, and an aerator. It is not used so often in construction work, although its properties and physical characteristics are of great interest for this field of activity. Among the developed areas:

• production of paint and varnish products, soft roofing;

• when installing a “warm floor” system;

• as a filler for heat-insulating and decorative plaster mixtures;

• for insulation of individual areas in the house (chimney, floor, roof, etc.);

• as a component of a screed mixture.

Vermiculite has good insulating characteristics, due to which it is used in regions with warm climates as backfill in three-layer walls to prevent overheating of the house, and in northern regions - for thermal protection of housing.

The ground in the regions of the middle zone and the Urals freezes strongly in winter, which often causes cracks to form in the concrete bowls of swimming pools. Vermiculite helps correct the situation. It is poured to the bottom, as well as into the cavity between the bowl and the edge of the trench during the construction process.

Insulation is produced in the form of backfill, compressed slabs, blocks, pipe segments, and liners.

Pros and cons of vermiculite

To appreciate the material, you need to familiarize yourself with its advantages and disadvantages.

Among the main advantages of vermiculite:

• environmental friendliness, during operation no toxic substances are released during heating;

• low thermal conductivity (0.055–0.098 W/m•°C);

• fire resistance (operating temperature range from minus 260° to plus 1200°);

• does not shrink over time;

• has good vapor permeability, which eliminates the formation of condensation in the room;

• resistance to microbiological processes, rodents and insects do not show interest in the material;

Specifications

The parameters of vermiculite depend on the size of the fraction; in addition, its exact composition has an impact. Key characteristics of expanded vermiculite:

- thermal conductivity;

- hygroscopicity;

- sound absorption;

- heat resistance.

Fractions smaller than 4 mm are mainly used in construction. The coarse fraction is used as a filler for refractory concrete. The fine fraction of 0.5-1 mm is used as a bulk heat insulator, which is used to fill voids in walls or as a fill for insulating floors. The characteristics are presented in the table.

More details on properties.

Thermal conductivity.

The layered structure of the material after swelling under the influence of temperature has a dominant role on this parameter. The individual plates remain firmly connected, but the direct contact between them is broken and filled with air. The material itself has a thermal conductivity of the order of 2-2.7 W/m*K; due to the breaking of bonds between the crystalline plates, this figure is reduced to 0.03-0.12 W/m*K, which puts it on a par with mineral cotton wool and extruded polystyrene foam. At the same time, it is used in bulk, from which the material is able to fill all the irregularities and niches.

Hygroscopicity.

A property that explains the demand for vermiculite in agriculture and even hydroponics. The gaps between the crystallized plates are filled with equal ease by air and water. The material is highly hygroscopic. For example, 100 grams of vermiculite can hold up to 500 ml of water. More importantly, water and moisture enter and exit the material with equal ease. When using vermiculite as insulation for building envelopes, this must be taken into account and it is advisable to use it as an advantage, and not as a disadvantage.

Sound absorption.

Vermiculite has proven to be an excellent material for creating soundproof barriers. High absorption, lack of settling in the material during compression and increased elasticity allow reverberation to be controlled over a wide range. Simply put, vermiculite is able to absorb sound waves without producing secondary waves or extraneous sounds under the influence of friction or deformation. When vermiculite is compressed and pressed by approximately 10-20%, maximum absorption of sound waves is achieved.

Heat resistance.

The melting point of vermiculite exceeds 1300 degrees. After swelling, the material no longer undergoes modifications and is not subject to decomposition, changes in composition, etc. This makes it a heat-resistant material that can be used to insulate stoves, fireplaces, pipes and chimneys.

In addition to these characteristics, vermiculite can be described by a number of useful properties:

Environmentally friendly, without harmful emissions in the entire range of permissible operating conditions. Prevents condensation. It quickly absorbs moisture and then just as easily releases it as steam.

It is important to create optimal conditions for removing excess moisture. High turnover. Easily fills voids, niches and surfaces of complex shapes. Does not attract rodents

It is not an attractive food for them and, due to its high hygroscopicity, quickly absorbs the odors of rodent marks, which makes them quickly lose interest in the space filled with vermiculite. Does not cause allergies. It is not radioactive and reflects part of the radiation spectrum, has a neutral pH.

Expanded vermiculite is sold as insulation in bags of 50 liters. This is enough so that with a layer thickness of 10 cm, two bags are enough to fill 1 m2.

Material with a fraction of 0.5-1 mm for insulating floors is supplied to the installation site via air ducts, just like, for example, ecowool. Otherwise, it is filled directly from the bags. There is no need for additional fluffing for filling.

Application of expanded clay gravel

| Indicators | Fractions of expanded clay gravel, mm | ||

| 8/20 | 4/10 | 0/4 | |

| Thermal insulation of pitched roofs | + | ||

| Thermal insulation and creation of a slope of flat roofs, lawns on terraces | + | ||

| Production of ultra-light concrete and light ceramic concrete blocks | + | + | + |

| Thermal insulation and sound insulation of floors and ceilings | + | + | |

| Thermal insulation and reduction of foundation depth | + | + | |

| Soil thermal insulation | + | + | |

| Thermal insulation and drainage in earthen embankments of roads laid in water-saturated soils | + | + | |

| Hydroponics, creating an optimal microclimate for the root system of plants | + | + | |

| As a dry backfill for gypsum fiber board floors to improve the heat and sound insulation properties of the floor | + | ||

| Production of warm solution | + | ||

| Production of facade and paving slabs | + |

Expanded clay will also be useful for those who lay heating networks near their home. Firstly, you will be sure that your pipes are heating you, and not the cold ground. Secondly, in the event of an accident, you will not have to dig long and tediously in search of a leak. Thirdly, after a successful repair, nothing prevents you from using the material again, and it will not lose its properties.

Expanded clay can be used not only in construction. With its help, they improve paths in their summer cottages and even increase the yield of fruit trees, creating a kind of drainage system for their roots. The same applies to indoor flowers and plants. For these purposes, expanded clay is used that is smaller in size.

The use of expanded clay as a concrete filler when pouring a foundation is not recommended. In this case, it is better to use any crushed stone, be it crushed stone or granite. Expanded clay is bad in this quality because it has smooth rounded edges, and this does not prevent the occurrence of shear (shear-fracture) work on the concrete mass. And the foundation must specifically exclude cracks (shifts) of the tape in the cross section.

Manufacturers

Among the well-known manufacturers of vermiculite-based materials and boards, the following domestic firms and companies stand out:

- LLC PKO Dmitrovskaya Thermal Insulation (city of Dmitrov). The main activity is the production of pierced and shaped products from vermiculite.

- Group of companies SFR (city of Kolpino). The main activity is the production and wholesale distribution of a wide range of various insulation materials.

- Specialists from the Leningrad region produce dry construction mixtures, expanded vermiculite, as well as a number of samples of materials for electrical purposes.

- The Vermit trading house from Chelyabinsk is engaged in the production and sale of fire retardant compounds and boards using vermiculite.

To this list can be added NPO Organika from Chelyabinsk and several other small companies that do not deserve special attention.

Scope of expanded clay

In addition, expanded clay is also used as insulation, but it must be a highly porous material, and before using it as a backfill insulation, calculations that are not very complex, but accessible only to specialists, should be made. Regarding its capabilities in the field of heat conservation, we will only say that as a backfill option it is inferior to other insulation materials. The calculated thickness of expanded clay backfill with a density of 600 kg/m3 is approximately 40 cm. This is not entirely effective.

At the same time, used in the manufacture of expanded clay concrete blocks, it significantly increases their heat-saving characteristics.

Expanded clay is also actively used in the construction of dry screeds. Nowadays this method is very popular, as it allows you to get a solid base for laminate, linoleum, and cork in the shortest possible time, literally in a flash.

Also, due to its unique properties, including immunity to moisture and frost, it is actively used for filling the foundation during the construction of various buildings and structures. This makes it possible to reduce the depth of the foundation by almost 2 times - from 1.5 m to 0.8 m, which leads not only to savings in building materials, but also to the prevention of freezing of the soil near the foundation of the building. The latter is fraught with distortion of the doors and window frames of the building.

Insulation of horizontal structures

Horizontal structures include the floor, attic ceiling, and roof slope. To insulate them, a vapor barrier film is used, laid both below and on top of the insulation layer. This is done to maintain the insulation layer in the desired condition. The film is wound under the logs.

All that remains is to pour vermiculite into the space between the joists and level the layer. Ideally, make a backfill layer with a thickness of 10 to 15 cm. The insulation pad is covered with a vapor barrier film.

Advice ! If instead of backfill material you lay slabs in the space between the joists, then you do not need to use a vapor barrier.

Some builders use a trick to save money: mix vermiculite and sawdust in a ratio of 1:1, 3:2. Thanks to this, the composition will not lose its insulating properties, while its cost will decrease.

Expanded polystyrene crumbs

Styrofoam crumbs.

The first bulk insulation we will consider is polystyrene foam. If you look closely at a sheet of polystyrene foam, you can see that it consists of many balls. These component parts may not be fastened together, and their density decreases. If you take a sheet of polystyrene foam and loosen it into individual balls, they will take up much more space. Naturally, as the density decreases, the material’s resistance to heat transfer decreases somewhat, so unless absolutely necessary, it is better to use sheets. Also read: “Technological features of insulating facades with foam plastic.”

Bulk insulation for walls made from foam spheres is used only when it is necessary to fill the cavities of already built structures. The crumbs are simply blown out using a special machine, trying to achieve maximum density. The disadvantage of crumbs is that the insulation can shrink. In addition, the material:

- burns;

- emits toxic smoke;

- Rodents feel great in it.

This bulk wall insulation is transported in plastic bags. Can be used to insulate floors, ceilings, and pitched roofs.

We study all known varieties

There are only 4 forms of release of this heat insulator: backfill (it is also called sand), slabs (outside identical to extruded polystyrene), roofing models and dry repair mixtures. These varieties have certain properties that you need to know.

Backfill insulation

The first form factor of Perlite sand to appear is a loose heat insulator

. The main task of this material during the construction of houses is to soften the structure (it is lighter than a conventional cement-sand mixture) and increase its insulating qualities. In most cases, this layer is used for backfilling floors and interfloor layers. It is also often used to fill empty spaces in wall masonry. Less commonly, it is used in combination (or instead) with warm plaster.

The most functional and functional form is slabs

According to official statistics, about 60% of all perlite sand produced on earth is used to create insulation boards. They are obtained as a result of hydraulic pressing, as a result of which they are quite convenient to use. The binder differs depending on the individual type (bitumen, lime, polymer compounds, cement, liquid glass, etc.).

This category of materials has very high hygroscopicity. Due to this, it is mostly used for interior decoration. Still, when laying an additional waterproof layer, it can also be used for finishing on the outside. However, this is not very justified from an economic point of view.

Roofing models

From the name, it is clear that such analogues are used mainly for roofing. For this task, in other words, bitumen perlite is used. This kind of material provides an excellent opportunity to create a layer of insulation of various shapes, due to which it is sometimes used for buildings of original design.

Main! There is no need to heat it before applying this coating!

The average thermal conductivity standard for this variety is 0.067 W (m*C), which is considered the most ideal result. This indicator makes it possible to use this coating even in the north. It is also necessary to emphasize the non-flammability of this heat insulator, which ensures the overall safety of the building.

Dry repair mixtures based on Perlite sand

As a result of mixing cement and perlite, a very productive dry mixture for construction work is obtained. The solution is prepared very simply - it is very easy to add water (in other words, no additional additives, such as ASG or gypsum, are required). For the most part, this composition is used to fill cavities in brickwork, grout seams and cracks, and also create a layer of plaster with very high thermal insulation characteristics. At the same time, it makes it possible to easily straighten the surface.

Insulation - bulk perlite thermal insulation, segments, slabs, plaster

Wood sawdust

The thermal conductivity of sawdust is 0.07–0.08 W/m*C. Sawdust is rarely used as an independent insulation material, as it is prone to absorbing moisture and further rotting. Therefore, they are mixed with other materials:

- clay;

- expanded clay;

- perlite;

- vermiculite

The ability of these materials to remove moisture prevents sawdust from being blocked even when laid in a thick layer. By the way, you can only use small sawdust, which is obtained when processing wood on modern machines with high speeds.

Having examined all types of bulk insulation, we can conclude that heat insulators made from rocks and clay have proven themselves to be the best. In terms of price/practicality/heat transfer resistance, the best option is penoizol. An outsider in our rating, ecowool is poison in its purest form, nothing less.