Design work on the creation of heating systems requires a clear understanding of the dimensions of heating elements, including radiators. Considering the significant diversity of the latter, such systematization is a truly important task. There are three large groups of radiator sizes:

- standard for the former USSR;

- low radiators;

- tall and non-standard.

Based on the type of materials, radiators are classified as follows:

- aluminum;

- cast iron;

- steel;

- bimetal

Non-standard radiator sizes

In addition to standard heating devices, radiators of other sizes are widely available on the market.

They are intended for use in atypical buildings or to give a room a special style. The following types and dimensions of radiators are distinguished:

Low or small heating radiators have a high heat transfer per unit surface area; they can be placed under low window sills or in buildings with stained glass. These include all heating devices with a center distance of less than 400 mm. Based on the material used, they can be either cast iron, aluminum or bimetallic.

Low horizontal cast iron heating radiators predominantly have section dimensions (W x D x H) of 93 x 140 x 388 mm, their heat output is 106 W at an operating pressure of 9 atm. Foreign manufacturers also produce more compact models with center distances of 200 and 350 mm. Bimetallic compact heating devices are available with a wide range of center distances, the width of such a section starts from 40 mm, the height is in the range of 150-450 mm. The depth compensates for the compactness of the remaining dimensions and is 180 mm. Thermal power varies from 80 to 140 watts at an operating pressure of 25-35 atmospheres.

Aluminum radiators have dimensions similar to bimetallic ones with connection distances from 150 to 400 mm in 500 mm increments, thermal power ranges from 50 to 160 W.

The normal operating pressure for them is 16 atmospheres, which can be increased to 24 atmospheres during pressure testing. It should be noted that such narrow horizontal bimetallic and aluminum heating radiators do not have water flow through the middle sections; they are heated only due to thermal conductivity from the collectors, while circulation is ensured by the outer flow section.

There are tall and narrow heating radiators, which are used in cases where there is a need for high heat transfer when, for various reasons, it is impossible to occupy a significant length of the wall. Cast iron high heating radiators are found only among products of foreign manufacturers; their section width is 76 mm. with a possible height of 661-954 mm, the depth of such devices reaches 203 mm. The working pressure is 10 atmospheres, and for the largest ones it cannot exceed 6 atmospheres. heat transfer, depending on the size, ranges from 270 to 433 watts.

Narrow bimetallic heating radiators are mainly designer designs with non-standard dimensions and are not intended for central heating systems; they are used in private houses with individual heating. As a rule, these are not sectional, but monolithic structures. If we take a section, then an example of its size could be (W x D x H) 80 x 95 x 880 mm. at a working pressure of 4 atmospheres. When crimping, it is not recommended to exceed this figure more than 6 atm.

For those who want to make the most efficient use of room space, flat heating radiators with a shallower depth are available on the market. Their choice is not as large as that of the above heating devices. Sold thin heating radiators can only be made of aluminum. Their depth starts from 52 mm with thermal power from 105 to 161 W. Flat radiators also include panel radiators, the depth of which is 60 mm.

Design Features

Water contains a large number of impurities. When in contact with aluminum, they cause corrosion. Over several years of use, these processes will lead to leakage of the device.

The design feature of these radiators is the presence of an internal stainless steel core, which is surrounded on the outside by an aluminum alloy. This way, water does not come into contact with aluminum, which significantly extends the service life of the system.

There are two manufacturing options:

- Pseudobimetal. In this case, the steel core is located only inside the vertical channels. So aluminum is not completely protected, but only in the weakest places. These models are cheaper and have a standard service life of up to 10 years if used in systems with high water pressure (for example, in city apartments).

- Bimetal. It has a solid inner casing made of steel, which is filled with aluminum alloy under pressure. Here the aluminum is protected on all sides. These are more expensive models and their service life under similar operating conditions is up to 30 years.

Design of a bimetallic batteryThe manufacturing method directly affects the volume of water in the section of the bimetallic radiator.

If we compare it with any other battery, the volume of one section here will be significantly lower. The disadvantage is compensated by the presence of two alloys. As a result, the inner steel core prevents the aluminum shell from cooling quickly. There are different ways to join two metals. It is preferable if aluminum is poured over steel under pressure. This battery model will last longer. There is an option when metals are joined together by welding.

According to the technical type of design, radiators can be:

- Collapsible. This means that using a radiator wrench you can unscrew any number of sections and screw them to another radiator. This type is most often installed in private houses with an autonomous heating system, where there is no high water pressure.

- Non-separable. The radiator is monolithic, it cannot be untwisted, cut, or attached to another. Perfect for use in a city apartment, where there is always a high level of pressure.

Dimensions of standard radiators

Depending on the material from which the radiators are made, their dimensions also differ. The most common standard sizes of heating devices are considered as basic, refer to the center distance of 500 mm and are:

- The standard dimensions of cast iron heating radiators according to the specification are for one section (width x depth x height) 93 x 140 x 588 mm. In various modifications, the depth can also be 85, 90 and 110 mm, and the width – 108 mm. For exotic cast iron radiators in “retro” style, the standard sizes are even more varied. It is not difficult to determine the dimensions of the heating device assembled from them - 10 mm of the thickness of the paronite gasket is added to each section. Also, if the radiator is installed in a niche or in cramped conditions, you should take into account the length of the mandatory installed flush valve. The heat output of one section is about 160 W. with a difference in room air temperature and coolant temperature of 70 C, the maximum permissible operating pressure in the system is 9 atmospheres.

- The standard dimensions of bimetallic heating radiators (width x depth x height), due to the wide range and significant number of manufacturers, are as follows: 80-82 x 75-100 x 550-580 mm. The average heat flow from a section of such a device is about 160-200 W; due to the presence of a steel core in the design, the operating pressure in the system can reach 25-30 atm. and during pressure testing, pressure testing up to 35-50 atmospheres is possible.

- Aluminum horizontal heating radiators, even with the same dimensions, can differ significantly in technical parameters. The standard dimensions of their sections are (W x D x H) 80 x 80-100 x 575-585 mm. The heat transfer of a section of this type of heating device depends on the fins and the depth of the structure, being in the range of 180-200 watts at a maximum operating pressure of the system of 16 atmospheres. Such radiators are pressurized under pressure up to 24 atm.

ATTENTION! When installing a heating system, an important condition is to use pipes of equal strength to the radiators, otherwise emergency situations may be created.

Review of manufacturers

This review of leading manufacturers of aluminum heating radiators is presented for informational purposes. It should not be regarded as a kind of rating.

Lammin is a Russian company, one of the leading domestic manufacturers of plumbing equipment for heating and water supply. Specializes in the manufacture of radiators from high-quality aluminum alloys. The internal volume of each section is covered with zirconium, which provides additional protection against rust and sedimentation of small dispersive particles contained in water.

Aluminum radiator Lammin Source www.termokit.ru

Oasis is a holding company whose full name is Oasis Investment Company. It is owned by one of the largest conglomerates in the UAE. Specializes in the production of household heating equipment with sales on the market of Russia and some countries of the Eurasian Economic Union. Production is established in China and the Russian Federation. Known for inexpensive and relatively good quality products.

Aluminum radiator from Oasis Source sima-land.com

Tropic is another Russian manufacturer of household heating equipment. The products sold under this brand are highly efficient, reliable and fully adapted to operating conditions in Russia.

Aluminum radiator Tropic Source pstm42.ru

Halsen is a Russian manufacturer of aluminum batteries based in Volgograd. The company specializes in the production of household heating equipment that meets all the requirements of domestic and international standards.

Aluminum cast radiator Halsen Source st26.stpulscen.ru

Royal Thermo is an industrial company that produces radiators, boiler equipment, smoke removal systems and a wide range of other equipment for domestic and industrial use. It is the largest brand in Eurasia specializing in the manufacture of goods in this category. It has its own production site in Russia.

Aluminum radiator Royal Thermo Source images.by.prom.st

Radena is a company engaged in the production of aluminum sectional radiators using Italian technology with an eye to operation in Russian conditions. The presented equipment complies with European and domestic standards and regulations.

Carefully read the characteristics Source aqua-santehnika.ru

We remind you that this review should not be considered as a rating.

Self-installation of an aluminum radiator Source eurosantehnik.ru

Heating devices of single-pipe systems

An important feature of the horizontal “Leningrad” is the gradual decrease in temperature in the main line due to the admixture of coolant cooled by the batteries. If 1 ring line serves more than 5 devices, the difference at the beginning and end of the distribution pipe can reach 15 °C. The result is that the latest radiators emit less heat.

Single-pipe closed circuit - all heaters are connected to 1 pipe

To ensure that long-distance batteries transfer the required amount of energy to the room, make the following adjustments when calculating heating power:

- Select the first 4 radiators according to the instructions above.

- Increase the power of the 5th device by 10%.

- Add another 10 percent to the calculated heat transfer of each subsequent battery.

Classification of heating devices

Depending on the material used for manufacturing, heating radiators can be:

- steel;

- aluminum;

- bimetallic;

- cast iron

Each of these types of radiators has its own advantages and disadvantages, so it is necessary to study their technical characteristics in more detail.

Cast iron batteries - time-tested heating devices

The main advantages of these devices are high inertness and fairly good heat transfer. Cast iron batteries take a long time to heat up and are also able to release the accumulated heat for a long time. The heat output of cast iron radiators is 80-160 W per section.

These devices have many disadvantages, among which the most serious are:

- a large difference between the flow area of the risers and batteries, as a result of which the coolant moves slowly through the radiators, which leads to their rapid contamination;

- low resistance to water hammer, operating pressure 9 kg/cm2;

- heavy weight;

- requirement for regular care.

Aluminum radiators

Batteries made of aluminum alloys have a lot of advantages. They are attractive, do not require regular maintenance, and are not brittle, which makes them better resistant to water hammer than their cast iron counterparts. Working pressure varies depending on the model and can be from 12 to 16 kg/cm2. Another undeniable advantage of aluminum batteries is the flow area, which is less than or equal to the internal diameter of the risers. Thanks to this, the coolant moves inside the sections at high speed, which makes it almost impossible for dirt to accumulate inside the device.

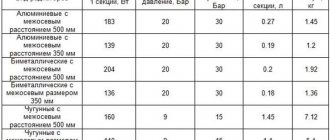

Many people believe that a small cross-section of radiators leads to low heat transfer. This statement is incorrect, since the heat transfer of aluminum is higher than, for example, that of cast iron, and the small cross-section in the batteries is more than compensated by the area of the radiator fins. According to the table below, the heat output of aluminum radiators depends on the model and can range from 138 to 210 W.

But, despite all the advantages, most experts do not recommend them for installation in apartments, since aluminum batteries may not withstand sudden pressure surges when testing central heating. Another disadvantage of aluminum batteries is the rapid destruction of the material when other metals are used in conjunction with it. For example, connecting to radiator risers through brass or copper pipes can lead to oxidation of their inner surface.

Bimetallic heating devices

These batteries do not have the disadvantages of their cast iron and aluminum “competitors”. A design feature of such radiators is the presence of a steel core in the aluminum fins of the radiator. As a result of this “fusion”, the device can withstand colossal pressure of 16-100 kg/cm2.

The flow area of the device is, as a rule, smaller than that of risers, so bimetallic radiators are practically not contaminated.

Despite its many advantages, this product has a significant drawback - its high cost.

Steel radiators

Steel radiators are perfect for heating rooms powered by an autonomous heating system. However, such radiators are not the best choice for central heating as they may not withstand the pressure. They are quite light and resistant to corrosion, with high inertia and good heat transfer rates. Their flow area is most often smaller than that of standard risers, so they rarely become clogged.

Among the disadvantages are the rather low operating pressure of 6-8 kg/cm2 and resistance to water hammer, up to 13 kg/cm2. The heat transfer rate for steel batteries is 150 W per section.

The table shows the average heat transfer and operating pressure for heating radiators.

What actually makes up the choice?

To begin with, we will provide a list of the main types of heating devices offered by modern stores. Some of them can only be installed in an autonomous heating system with clean water and low pressure. And others can easily withstand a brutal battle with water hammer and chemically active water in centralized heating systems. Let's see what and how.

Cast iron – we can’t live without it even today

Let's start with the cast iron radiators mentioned at the beginning of the article. Don't think anything bad about them - modern radiators made from this metal look quite nice. Budget models have flat, neat surfaces and compact (compared to Soviet batteries) sizes. And exquisite retro models with beautiful injection molding designs are the highlight of the interior. Standing on graceful legs near the window, they give the room a special charm and a touch of antiquity.

Retaining heat for a long time and not suffering from corrosion, cast iron products can last for several decades. The disadvantages of these devices can be considered their weight and the associated complexity of installation, inertia and large volume of coolant. In addition, the fragility of cast iron does not always allow it to withstand water hammer.

Cast iron radiators from domestic and foreign manufacturers.

Influence of aluminum radiator size

Aluminum batteries are made in a wide range of sizes. Length has a primary influence on power.

Accordingly, to achieve the required heating it is necessary to increase the number of sections. The total length of the battery depends on the calculations.

Depth and height also change the indicators because they affect volume. Unlike length, these two values are variable, which is why there are many different models.

The next indicator is the center distance. It is responsible for the heating rate of the radiators, since it means the gap between the supply and return pipes.

The performance is also affected by the manufacturing method:

Metal casting increases the strength and durability of the device. In this case, each section is a single unit from which the device is assembled. This is done in a certain sequence: first the upper parts are welded, then the lower ones. The extrusion method involves pressing heated aluminum through a lattice plate of metal. Thanks to this, a profile of a given shape is obtained, which is divided into parts and assembled into a radiator

Attention! Such heating devices are rarely found and are usually made to order. This is due to the impossibility of making changes to the design after production has ended.

Center distance

The indicator represents the gap between the axes of the radiator. They are located symmetrically, one on top, the other on the bottom. They are adjacent to pipes through which they are connected to the heating circuit.

Photo 1. Aluminum radiator model 350/80, center distance 350 mm, China.

Depending on the manufacturer, the value ranges from 150-2000 mm. For most devices, this figure is set to 500. This is due to heating systems in apartment buildings: in old buildings, calculations were made for cast iron radiators. When replacing batteries, the cost of digesting the pipeline is undesirable.

Reference! Most models have a number in their name indicating the center distance.

Depth

Depends on the material from which the battery is made. The minimum value is 52 mm. It is enough to create high power in small sections. The maximum value is 180 mm. It is quite rare and requires strength. There are models with greater depth, but their use is impractical due to insufficient heating.

Determining the volume of a section

To calculate, you need to know the value described above, as well as the length and height. The first value, visually, is width.

It is 80 or 88 mm, which is indicated in the passport.

The second is variable. Typically, the vertical component of the section dimensions is 570 mm.

To find the volume, just multiply the three indicators.

Terminology

The main selection parameters are the width and height of the radiator.

Documentation discussing the dimensions of heating radiators often talks about the center-to-center distance. This parameter indicates the length of the gap from the center point of one connecting hole to a similar place in the other. Sometimes this value is called the center-to-center or inter-nipple distance. If the pipelines supplying the radiator are in working condition and there are no plans to change them, the new heater purchased should have the same center-to-center indicator as the old one, so that changes to the connections do not have to be made. Sometimes the names of models - both Russian and foreign - contain three-digit numbers. They indicate this parameter in millimeters (for example, Modern 500).

Linear dimensions include:

- installation height of the radiator - it must be selected so as to ensure the required distances to the window sill and floor;

- depth;

- width - for models with a sectional design, it, like the previous parameter, also refers to the dimensions of the elements, but if the depth of the radiator and its individual sections is the same, to calculate the total width you need to multiply the indicator of an individual unit by their number and add approximately 1-2 cm, attributable to sealing gaskets.

Knowing the linear parameters of the radiator, you can purchase a protective screen for it. When installing floor-mounted flat options, dimensions are important for selecting suitable components of the heating system.

How to choose the correct size of radiator sections

Determining the dimensions of the sections and their number is the most important step in creating a classic heating system.

With standard arrangement

The power they can develop depends on the size of the batteries and the material.

The length is almost always the same and is 80 mm. First determine the height. To do this, choose the installation location, which determines the available space.

And design also plays a big role. Using these parameters, the vertical component is determined. Usually decide between 350 and 500 millimeters.

Depending on the characteristics of the room, you can purchase devices from 200 mm. If a radiator is purchased for a bathroom or toilet, we recommend a narrow model that can completely cover the space between the floor and ceiling. High-altitude devices have different variations from one and a half to three meters.

Having determined two linear characteristics and the material, we move on to calculating the depth and number of sections. The number of the latter is usually taken to be 10, but others also occur. The thickness is found from the volume. The cubic value is divided into length and height. The determination of power is also closely related to these indicators: knowing the required power, you can find the number of sections.

With original interior

To create a design, manufacturers often sacrifice technical characteristics.

First of all, this applies to cast iron products. Domestic radiators look serious, but are simply covered with paint.

European ones are more elegant, but weaker in heating. In any case, you need to find out from the documentation about the power that they are capable of developing, since you need to select devices based on heat transfer.

Reference! There are batteries in “retro” style. They have a pleasant appearance, but are expensive.

Aluminum ones have the same shape, with the exception of custom ones, but they differ in a variety of colors. In addition, a wide range of dimensions helps them fit into almost any area of the room.

Bimetallic radiators, unlike their analogues, are made not only straight, but also curved. This makes them look good in rooms with smooth angles.

Regardless of the material chosen, before purchasing you should read the technical documentation and find out the dimensions of the internal parts of the sections containing the coolant.

This will help you decide on the batteries not only by their external appearance, but also by their ability to heat.

You should remember the possibility of combinations. So, if a certain device suits the design, but its power is not enough, you can install additional heating by hiding it behind the side panel. Or combine radiator heating with warm floors.

A good option for guest rooms would be to install a fireplace. Although the latter more often serves a decorative role, it is also capable of reducing the number or size of sections installed in the room. Sometimes it's better to sacrifice beauty than to freeze every winter.

If you want to create a special design, you should contact the battery manufacturers. They will help you do the calculations. Thanks to this, the finished product will look beautiful and perform its direct function.

Heat transfer of one section

Today there is a wide range of radiators. While most are similar in appearance, thermal performance may differ significantly. They depend on the material from which they are made, on the dimensions, wall thickness, internal cross-section and on how well the design is thought out.

Therefore, it is possible to say exactly how many kW in 1 section of an aluminum (cast-iron bimetallic) radiator only in relation to each model. This data is provided by the manufacturer. After all, there is a significant difference in size: some of them are tall and narrow, others are low and deep. The power of a section of the same height from the same manufacturer, but of different models, may differ by 15-25 W (see the table below STYLE 500 and STYLE PLUS 500). There may be even more noticeable differences between different manufacturers.

Technical characteristics of some bimetallic radiators

Please note that the thermal power of sections of the same height may have a noticeable difference. However, for a preliminary assessment of how many battery sections are needed for space heating, we calculated the average thermal power values for each type of radiator

They can be used for approximate calculations (data are given for batteries with an interaxial distance of 50 cm):

However, for a preliminary assessment of how many battery sections are needed for space heating, average thermal power values were calculated for each type of radiator. They can be used for approximate calculations (data are given for batteries with an interaxial distance of 50 cm):

- Bimetallic - one section produces 185 W (0.185 kW).

- Aluminum - 190 W (0.19 kW).

- Cast iron - 120 W (0.120 kW).

More precisely, how many kW can you have in one section of a bimetallic, aluminum or cast iron radiator when you choose a model and decide on the dimensions. The difference in cast iron batteries can be very big. They are available with thin or thick walls, which causes their thermal output to change significantly. Above are the average values for batteries of the usual shape (accordion) and those close to it. Retro-style radiators have significantly lower thermal output.

These are the technical characteristics of cast iron radiators from the Turkish company Demir Dokum. The difference is more than significant. She could be even bigger

Based on these values and average standards in SNiP, the average number of radiator sections per 1 m2 was calculated:

- the bimetallic section will heat 1.8 m2;

- aluminum - 1.9-2.0 m2;

- cast iron - 1.4-1.5 m2;

How to calculate the number of radiator sections using this data? It's still simpler. If you know the area of the room, divide it by the coefficient. For example, a room of 16 m2, to heat it you will need approximately:

- bimetallic 16 m2 / 1.8 m2 = 8.88 pcs, rounded - 9 pcs.

- aluminum 16 m2 / 2 m2 = 8 pcs.

- cast iron 16 m2 / 1.4 m2 = 11.4 pcs, rounded up - 12 pcs.

These calculations are only approximate. Using them, you can roughly estimate the costs of purchasing heating appliances. You can accurately calculate the number of radiators per room by choosing a model, and then recalculating the number depending on the temperature of the coolant in your system.

Euro-cast iron: modern cast iron batteries

Cast iron is a material with many excellent performance characteristics, so radiator manufacturers did not completely abandon its use. Let's just say that the internal components of the batteries remained the same, but the design has changed to suit the times.

A modern cast iron radiator also consists of sections; they are connected to each other by sealing gaskets. But what the design will be depends on the manufacturer. Today's models can be very original; beautiful cast iron heating radiators in a retro style are especially popular.

Advantages of Euro-cast iron:

- The material is durable, it will last at least 50 years;

- The fins of the batteries are vertical, which increases their heat transfer;

- Modern models also have high temperature resistance;

- The structures are very durable, withstand pressure up to 18 atmospheres;

- The batteries are coated with a special compound that prevents corrosion;

- Radiators can work with any type of coolant - both water and antifreeze;

- The hydraulic resistance of such a battery is small, which means that the circulation pump does not need to be used at all.

Modern cast iron batteries look great in an interior made in modern or high-tech style

Finally, the price of the battery is very attractive. They are inexpensive, and if you consider the life of the battery and the fact that it rarely needs repairs, the purchase is quite economical. And an attractive appearance can be another compliment to the interior.

Infrared heated floors.

Read in detail how to install it in this article. I recommend placing an additional layer of aluminum foil underneath it on a wooden base.

And be sure to always follow the rules for electrical installation on combustible substrates.

- Video 24. Installation and connection of heating.

- Connection and installation of heated floors.

- Installation of heated floors.

- How to calculate a heated floor

Working and testing pressure

When it comes to the technical characteristics of radiators, pressure indicators are always listed among the first. The usual operating pressure of the coolant is 6-9 atmospheres. Any radiators can cope with this pressure; for cast iron batteries, the standard load is considered to be just 9 atmospheres.

There is also the concept of “pressure testing” - this is the maximum pressure in the system that can occur during its initial startup. For the MS-140 model, this is 15 atmospheres.

Various design solutions for cast iron radiators

According to the regulations, when starting the heating system, it is imperative to check the possibility of smooth starting of centrifugal pumps. In a good way, all pumps should be equipped with automatic equipment that ensures this smooth start. Well, in fact...

In fact, most homes either do not have one or are in poor condition. But even in such a case, the instructions provide a corresponding point: the initial start-up must be carried out with the valve closed, which can be opened (smoothly!) only after the pressure in the line has been equalized. Considering who starts the heating in our homes and how, it is not difficult to imagine the percentage of compliance with these instructions.

If the regulations are violated, the same water hammer occurs, in which an instantaneous pressure surge causes the permissible value to be exceeded, and one of the radiators along the flow of the coolant cannot withstand the load.

The further course of events is clear - its service life is not as long as we would like. Date: September 25, 2022

Possible problems during operation

Bimetal devices have a large number of advantages. Which of their features can be considered disadvantages?

- Despite the possibility of using bimetallic batteries in a system with any coolant, the low quality of the latter negatively affects the service life of the device.

- Different coefficients of expansion of the metals present in the battery design can, over time, lead to instability of heat transfer and a decrease in the strength of the device.

- The use of low-quality coolant in the system can lead to clogging of channels, corrosion, and deterioration of heat transfer.