Updated: 02/19/2021 18:42:46

Expert: Andrey Nikolaevich Kuznetsov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Polypropylene pipes are becoming more and more popular material in the construction industry every year. They are used for installing water supply systems, heating systems, pipelines for pumping aggressive liquids, etc. A distinctive feature of PP pipes is resistance to corrosion, resistance to temperature and pressure changes, and durability. Precipitation does not accumulate on the smooth surface, so there are no problems with pipeline maintenance. To choose the most suitable polypropylene pipes, experts advise paying attention to several parameters.

Features of PPR pipes

Main advantages:

- Long service life.

- Low price.

- Absence of corrosion processes typical of metals.

- The smooth inner surface allows for increased fluid pressure.

- Quiet transport of water or other liquids.

- Easy to perform installation work.

- It is possible to install taps without using threaded connections using soldering equipment.

- There is no need for periodic maintenance of pipe and butt joint blocks. This allows you to install it under the floor or under the plaster finishing layer and forget it for a long period.

Along with the positive qualities and features, we must not forget about some disadvantages when choosing polypropylene pipes. The pipes have low ductility and bend poorly, which does not allow for corner wiring. Intermediate couplings of the appropriate profile are required, bent at the angle at which the pipeline needs to be rotated. If damage to the material occurs during installation, the product will have to be thrown away and replaced with a new one. If a defect occurs, the structure can no longer be repaired. The entire section of assembled pipes will have to be cut out and reinstalled. For installation work, you need special pipe cutting scissors and soldering equipment.

Some of the problems are eliminated thanks to the packaging: a large number of auxiliary parts - fittings and couplings - makes it possible to assemble and create structures from pipes of various configurations, up to the most complex ones.

Types of PPR pipes

Products vary in layering factor. Main groups:

Single-layer pipes are widespread, this is due to their low price. At the same time, they cannot be used for pipelines with high heating temperatures. If the liquid is heated above 70 degrees Celsius, significant linear elongation of such products occurs. Single-layer polypropylene pipes can have different chemical compositions and use different polymers. The type of chemical compound determines the performance properties of the product. Therefore, you should always take a closer look at the markings of pipes in order to understand for what purposes they should be used. How single-layer pipes are marked:

| Marking | Name | Description | Areas of use |

| RRN | Homopolymer | Hard material. · Low resistance to low temperatures. | · Transportation of cold and hot water. · Ventilation devices. · Production pipelines. |

| RRV | Block copolymer | Flexible material. · Frost-resistant. | Cold water supply. "Warm floor". |

| PPR | Statistical copolymer | Durable material. Withstands simultaneous short rises in temperature up to +110 degrees. WITH. Restores after defrosting. Resistant to aggressive environments. Good soundproofing properties. | Transportation of cold and hot water. Heating in an individual house. |

| P.P.S. | Special polymer |

Multilayer pipes, otherwise called reinforced. Reinforcement is an option to increase the load-bearing capacity of a product by using additional layers of materials; they strengthen the product and prevent the walls from excessively expanding and lengthening.

Reinforcement of PPR pipes to reduce elongation is of two types:

- Aluminum.

- Fiberglass

The metal in polypropylene pipes is an excellent material that increases strength. Ways to work with it:

- Adhesive application of a strip layer of foil on the outside of the pipe, which is overlapped or butted.

- External application of perforated metal sheet.

- Lining the interior with a layer of foil also with glue.

- Welding AL sheet at the joint to create a sealed space inside the pipe.

- Fiberglass reinforcement. It is located on the inside of the pipe; composite material can also be used - with the addition of polypropylene. The material increases resistance to high temperatures and reduces costs during assembly work.

- Reinforcement with basalt fiber. This is a relatively new material on the market. It has a number of advantages over existing options. It is believed to be more durable, resistant to pressure changes and high temperatures. The pipe capacity is higher with less weight. Basalt is an environmentally friendly material

Review of the best brands

There is a certain list of the best manufacturers. The rating (10-point system) included the following companies:

- Contour (9.2). A domestic brand that produces many varieties of polypropylene pipes. Advantages: large selection, low price. Negative features: made of Russian material, inferior in quality to European ones.

- RBK (9.4). Quite an old company, but it has recently announced itself. It produces high-quality products that are even used in construction at sites of national importance. Pros: well-equipped pipe manufacturing enterprises, large production capacity, high-quality raw materials. Cons: shortage in domestic stores.

- Valtec (9.6). The brand's products have been known since 2002, a Russian-Italian project. Advantages: high quality, ease of installation, good strength. Disadvantages: high price.

- Pro Aqua (9.7). A Russian company that has been producing polypropylene pipes at its factories since the late 90s. With the advent of the new millennium it became very popular in the market. Pros: low price, quality, supplied to all regions of the Russian Federation. Cons: short service life in high pressure systems.

- Sinicon (9.8). The best Russian manufacturer. Has a wide range of plumbing products. Foreign technologies and high-quality European materials are used in production. Pros: large assortment, decent quality, the best choice for a private home, products meet European standards. Cons: high prices for most products.

The rating included only domestic manufacturers. The choice is large, so there will be no problems with the search.

Marking of multilayer pipes

This group has a complex naming system

| Marking | Indication of the type of reinforcement |

| PPR-AL-PPR | Aluminium foil |

| PP-RCT-AL-PPR | Modified polypropylene, aluminum foil, polymer outer layer. |

| PPR-FB-PPR | Fiberglass layer on the inside. |

| PPR-FB-PPR, PPR/PPR-GF/PPR | Composite material: fiberglass + polypropylene. |

| PP-RCT+BF | Basalt layer |

Product color

There are PPR pipes on the market made from materials of different colors. Is there a difference when choosing? Can we say that a gray pipe is better than a white one?

Experts are divided over this indicator: some believe that shades do not affect anything and that this is just a marketing ploy. However, there are many descriptions of products that differ in color, which present different operational, performance and economic characteristics.

For convenience, the estimates are tabulated:

| Pipe color | Performance properties |

| White | Long service life. The maximum pressure withstand is twenty-five bar. Low cost. Not subject to corrosion. |

| Grey | Ability to withstand elevated temperatures Ability to withstand aggressive environments: acidic and alkaline. Long period of operation. Environmentally friendly. High level of tightness. |

| Black | Immunity to ultraviolet rays. Ability to withstand aggressive environments. Resistance to drying out. Increased strength |

| Green | Cheap option, low operating pressure. Suitable, perhaps, for a country shower and watering the garden. |

Selection of pipes for water supply

Polypropylene piping components are a practical and relatively inexpensive option for installing water pipes in homes.

To supply cold water, a simple version of polypropylene pipes without special layers that strengthen the element is suitable. These are inexpensive single-layer pipes without reinforcement. Feel free to choose them.

RPH single-layer pipe made of solid homopropylene, durable, can withstand heating up to 60 degrees C, higher temperatures are not recommended

PPV single-layer pipe made of flexible block copolymer, resistant to defrosting.

PPR single-layer random copolymer pipe, more durable and resistant to temperature rise, recovers after defrosting.

They differ in diameter - from 20 to 40 mm, and shell thickness - from 1.9 to 6.7 mm. The shell thickness is indicated by the parameter PN10 or PN20. These parameters affect the hydrodynamic properties of the system and the throughput of the water supply system. Pipes ⌀ 32 mm are connected to the central water supply; for internal communications, ⌀ 16 - 25 mm are sufficient.

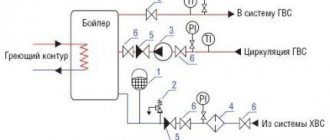

To supply hot water, it is possible to choose the connection of single-layer inexpensive polypropylene pipes:

- PPR, PPRC from a copolymer of propylene and ethylene - coolant temperature less than 70 degrees C

- PPS – made of special polypropylene – heating no more than 95°C

However, for greater reliability it is worth using reinforced pipes. Experts recommend pipes reinforced with fiberglass:

PPR-FB-PPR – propylene sandwiched with fiberglass fiber

PPR/PPR-GF/PPR – three-layer pipe, inside and outside made of polypropylene, the middle layer is made of a composite material in which glass fiber is distributed in a polypropylene matrix. A colored intermediate layer on a light background is a distinctive external feature of these pipes.

They are produced, for example, by the Italian-Chinese company Valtec and the Russian company Kontur. They are superior to aluminum-coated options in a number of characteristics; they are easier to install, do not need to be cleaned during assembly, and do not swell during operation or collapse from the inside.

Meanwhile, aluminum pipes are impermeable or almost impermeable to oxygen. This is an important property, since oxygen, saturating the coolant water with bubbles, creates so-called cavitation processes in all metal components of the water supply system. They destroy the walls of pumps, valves and other parts.

Price

Approximate prices per linear meter for PN25 pipes reinforced with glass fiber:

- Fora Ø 25 — 92 rub.

- Metak Ø 20 x 3.4 – 118 rub.

- Ø 25 x 4.2 – 181 rub.

- Ø 32 x 5.4 – 317 rub.

PN25 Aluminum reinforced products cost:

- Ø 20 x 3.4 mm – 58 – 78 rub.

- Similar for 25 mm - 80 - 110 rubles.

- Ø 32 – about 125 rub.

The use of PN20 products for heating is not advisable, but is possible in gentle conditions.

The cost of PN20 compared to PN25 is about a third lower (with similar diameters).

If you need to buy PP-RCT PN25, the prices will be as follows:

- Ø 20 – approx. 90 rub.

- Ø 25 – approx. 130 rub.

- Ø 32 – approx. 197 rub.

So. The best pipes for heating are PPR, or PP-RCT. It is most correct if it is a reinforced version (fiberglass, or aluminum). Pressure design - PN 25 (or S 2, SDR 5). Temperature – 90 °C, and size – according to calculation (most often from 25 to 32 mm).

PP pipes have long been used instead of cast iron and steel products, and quite successfully replace them. Polypropylene pipes for heating: technical characteristics, as well as the advantages and disadvantages of this type of product, read on.

You will learn which pipes are best to choose for organizing a ventilation system in a private home by reading this article.

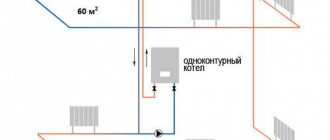

Selection of heating pipes

The choice of heating system components is influenced by the same properties of polypropylene pipes, which are important for the supply of hot water. First of all, the quality of the polymer itself.

Inexpensive single-layer block copolymer PP pipes can be used in low-temperature heating systems

P.P.S. made of a special polymer without reinforcement are used for heating, provided that the temperature in the system is less than 95 degrees C

However, reinforced products for heating purposes are more reliable and acceptable.

PPR-AL-PPR – with an outer layer of aluminum film. PP-RCT-AL-PPR – a new type of propylene is used, sandwiched with aluminum with an external polymer coating.

PPR-FB-PPR – propylene layered with fiberglass fiber.

PPR/PPR-GF/PPR – three-layer, inside and outside made of polypropylene, the middle layer is made of a composite in which glass fiber is distributed in a polypropylene matrix.

PP-RCT + BF is a pipe with basalt fiber, characterized by low weight and good throughput.

Reinforced pipes are more expensive, but also more reliable; they are initially produced for coolants with a wide temperature range.

How not to make a mistake

If you have chosen polypropylene pipes for yourself, go to the manufacturer’s official website before purchasing. You will need:

- Remember what the logo looks like, what font is used, what letters it contains, what color they are written in, how many capital letters. In general, you need to study the logo and its spelling. Those who make fakes deliberately make some mistake in the name, change/omit/double some letter. This is done so that claims cannot be made - the letter is different, the brand is different.

- Next, you need to study the assortment and choose what you want to purchase. Then carefully examine the color and location of the markings. If the store offers you a product of the desired campaign in a different color, size, etc., but this is not available on the official website, they are selling you a fake. It's better to leave and look for another store. All walls must be perfect

- Please review product samples before purchasing. Pipes and fittings from normal companies have smooth walls (both external and internal). There should be no sagging, depressions or other signs of poor-quality casting.

- Look at the cut of the pipe or fitting. The wall thickness should be the same. If these are reinforced products, then the reinforcing material is surrounded by polypropylene rings of equal thickness. If the difference is noticeable even by eye, you should not buy such products.

Overall, you should have a positive impression of the quality of the products. Only if all the “tests” are passed, you can buy.