Tell me, what documents specify the standard service life of water supply risers? The risers are almost rotten, and the housing and communal services are not moving. We need to turn them to face the people.

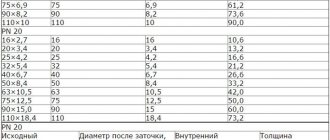

The standard service life of water supply risers in an apartment building can be found in Appendix No. 2 to VSN 58-88 (r) (departmental building codes, which are entitled as follows: ““Regulations on the organization and conduct of reconstruction, repair and maintenance of buildings, public utilities and socio-cultural purposes"). In the section “Elements of residential buildings, municipal and socio-cultural facilities” it is stated that cold water pipelines from black gas pipes must be changed after 15 years, and from galvanized pipes - after 30 years.

The standard period for the operation of water supply risers (vertical pipes are risers, many people confuse them) is specified in the document “Departmental Construction Standards” VSN 58-88(r)

The third appendix has the information you need.

Galvanized steel pipes (both hot water riser and cold water riser) manufactured in accordance with GOST, service life is 25 years.

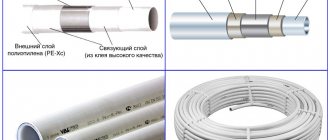

If you have risers, for example, made of polypropylene, then their service life is much longer (50 years or more).

Risers belong to the common property of the residents of the house, but the user is obliged to keep them in good condition. If your neighbors have the same story, then it is better to write a collective statement (written, in duplicate) and attach photographs of rotten risers to it.

The housing office will accept the application, and then you can contact higher authorities, who will force the housing office to move.

And the application will be your “insurance” in case the replacement deadline has expired, the housing office has not replaced the risers and they have failed.

Service life of steel water pipes

The reality of our life is that there is no regulatory document regulating the service life of steel water pipes, although there is an instruction from 1971, which, unfortunately, is better not to refer to, because it is outdated in every way. There is a term “average standard service life of a pipe,” defined as 20-25 years, which is used in most calculations. And the point is not in bad technical “legislation”, but in the pipe itself, since the same pipe under different operating conditions can last for different times.

Despite the fact that plastic is everywhere replacing traditional materials, all important structures are still made of metal, including water mains. For some reason, we have adopted a “standard” for water pipes that the degree of wear is the complete failure of the system, when repair clamps are installed on the clamps. However, before determining the service life of steel water pipes, it is necessary to clarify that this period is calculated from the moment the pipeline is launched, and not from the manufacture of the pipe, since there are “stale pipes” on sale.

Useful information about steel communications

There are several methods for galvanizing steel pipes: diffusion and hot. The hot-dip galvanizing method is a process where the entire surface is immersed directly in liquid zinc at a temperature of 450 degrees. This is a very labor-intensive process.

And diffuse coating is a process where the pipe is coated directly with zinc atoms at a temperature of 400 degrees. During this, zinc atoms penetrate into the intercrystal lattice of the heating pipe and form a fairly strong bond. This coating is carried out in special powder containers. That is why a galvanized steel pipe receives the necessary electrochemical protection. While other options for metal structures behave completely differently when galvanized, therefore they get a completely different result.

Installation of steel heating systems usually occurs in two ways: welding and twisting threads. The most common option is for heating, which occurs when using self-shielding wire. Its diameter ranges from 0.8 to 1.2 mm. In some cases, it is possible to use electrodes whose diameter can reach up to 3 mm.

But non-galvanized pipes are welded mainly with overlap. If there is, of course, a diameter of 25 mm. Enterprises sometimes use butt joints for pipes of this diameter. The main difficulties are caused by welding metal heating pipes that are under pressure, because they are almost always located close to the walls of the building. When installing a heating system, special requirements are placed on the welding seam, the outer surface of which must be uniformly welded without any cuts, cracks or sagging.

Steel pipes have a good 50-year history of use, significant advantages and look quite good against the background of new modern technologies. But still, the use of metal pipes slightly lost its relevance when polymer pipes began to be actively used in heating systems.

It is very difficult to name those areas in which steel pipes are not used. They are used in oil pipelines, heating mains, main water pipelines, heating systems and many others. Many people are interested in how long a steel pipe can last. Their service life depends greatly on operating conditions.

How long can steel heating pipes last?

A heating system that uses steel pipes has always been considered durable and reliable, capable of withstanding fairly heavy loads. The service life of steel heating pipes is thirty years. But why do some owners of newly built houses refuse steel pipes and prefer to make heating from plastic? The whole point is that the pipes are chosen incorrectly. There are two types of steel pipes:

— suture

. This is the cheapest type of steel pipe. The choice of this type of pipe for heating is doomed to failure in advance, since its service life is only a few years and they will not live up to thirty years. This is because when installing a heating system, it is very difficult to bend such a pipe and the seam simply bursts at the bend. Also, the inside of the seam cannot be properly processed; a leak may appear and the pipe will need to be replaced. Therefore, it is not suitable for heating systems;

— seamless

. Such pipes are much more reliable. For individual heating, such pipes with a diameter of 25 mm are recommended; when tested, they can withstand loads of up to 20 atmospheres. Therefore, for at least twenty years, such pipes will last without problems.

Remember that previously only steel pipes were installed for the heating system. And often, when installing autonomous heating and replacing steel pipes with plastic ones, it turned out that they could serve for a long time, despite the fact that they were installed twenty years ago.

How long can steel water pipes last?

The service life of steel water pipes and sewer pipes made of the same metal is fifteen years. The same galvanized steel pipes can last for thirty years. During the first five years of operation, the inner surface of the water supply pipes becomes overgrown, and wet condensation appears on the surface, not to mention the fact that they withstand high dynamic loads. And galvanized steel pipes are coated with an anti-corrosion coating, so they can last much longer.

Advantages and disadvantages of steel pipes

Advantages:

- low cost, however, this is compensated by the high cost of installation work;

- strength;

— with increasing temperatures there is slight deformation;

- durability.

Flaws:

— corrosion. However, to delay it, a zinc coating is used, which is found on galvanized pipes, which can last the longest;

— to work with pipes, welding is required;

- do not bend well;

— with a sharp increase in pressure, the pipe may rupture.

Without pipes it is impossible to imagine the life of not only an individual home or business, but also entire districts and cities. Pipes are used to move cold and hot water, to create heating mains, sewerage systems, and for many other purposes. Not only their service life, but also the ecology of both an individual section and the country as a whole depends on the quality of pipes.

The length of networks (in single-pipe measurement) in Russia is impressive - it is more than 1 million km! At the same time, about 30% (!) of pipelines are so worn out that they need urgent replacement and repair.

Let's take a closer look at the different types of pipelines (water supply, heat supply, sewerage), their condition and problems arising due to their wear and tear and poor quality.

Water supply pipelines

The total length of water supply networks is more than half a million km and approximately 30% of them need replacement and repair. What are the dangers of old steel pipelines overgrown with rust?

Firstly: with leaky pipelines, it is impossible to ensure the supply of water from its intake to the tap without reducing the quality. Contamination of water during its transportation occurs both by corrosion products and as a result of groundwater suction through leaks. Polluted water worsens health and affects the life expectancy of every Russian at the genetic level.

Secondly: overgrowing of the inner surface of pipelines entails an increase in the energy required for pumping. The internal surfaces of approximately 80% of water pipelines have such deposits that their throughput compared to the design one is reduced by 2-2.5 and even 3 times! According to calculations by the Academy of Public Utilities, overgrowth of the inner surface of pipes leads to an increase in the cost of 1 m 3 of water by up to 50%, and the cost of electricity for the production and sale of 1 m 3 of water is 30% higher than the average European level.

Thirdly: through the holes formed in old rusted pipelines, water enters the ground, causing an increase in the level of groundwater, which in turn contributes to corrosion damage to the outer surface of the pipeline. It is obvious that rising groundwater levels due to leaks from pipelines also threaten the safety of utilities and buildings.

Fourth: losses of water during its transportation through leaky pipelines, amounting to tens of percent, lead to the fact that the consumer is forced to pay for water that he does not receive. Russia annually takes about 80 billion m 3 of water from open and underground sources for municipal, industrial and agricultural needs. If we accept losses in the amount of 30% of the volume of water supplied to the network (25 billion m 3), and the cost of 1 m 3 of water is 30 rubles, then the cost of annually lost water will be 225 billion rubles.

District heating pipelines

These pipelines supply hot water for heating and hot water supply systems. Of approximately a third of a million km of heating networks (in single-pipe measurement), approximately a sixth are in need of replacement and repair. Obviously, in heating mains, in addition to the problems described in the story about pipelines for water supply (overgrowth and leaks), another important component is added - heat loss during the transportation of hot water from the heat source to its consumer. The following truly depressing figures indicate the deterioration of modern heating networks:

- in some regions there are up to 400 accidents per 100 km of networks,

- due to leaks in networks, over 70 million tons of standard fuel are lost without use, the total cost of which (at a cost of 1 t.u.t. 2100 rubles) is 147 billion rubles.

- According to the Association of Manufacturers and Consumers of Pipelines with Industrial Polymer Insulation, about 300 thousand accidents occur in heating networks every year in the country. With the average cost of eliminating one accident being 30 thousand rubles. annual costs may amount to 9 billion rubles.

- the durability of heating networks is 1.5-2 times lower than abroad and does not exceed 12-15 years.

It is worth noting that the quality of heating mains is most relevant specifically for Russia, because We have the highest level of centralized heating supply (up to 80%).

The predominant method of laying heating networks in the Russian Federation is laying in non-passable channels with mineral wool thermal insulation (80%). Channelless installation, carried out from factory-made structures using reinforced foam concrete insulation and bitumen-containing masses (bitumen-perlite, bitumen-overmiculite, bitumen-ceramsite), accounts for 10% of the total length of heating networks.

Due to the moistening of the materials used during operation, the heat-protective properties of thermal insulation structures are sharply reduced, which leads to heat losses that are 2-3 times higher than the standard ones.

The total heat loss in district heating systems is about 20% of the supplied heat, which is 2 times higher than the same figure in advanced countries of Western Europe.

Water disposal (sewage) pipelines

More than 150,000 km of pipelines are used for drainage, of which more than 30% require replacement and repair. Worn out and old systems are depressurized, which creates a risk of contamination of water bodies. In addition, sewer networks are often laid next to water supply lines, and given that there are leaks in both of them, sewerage or soil contaminated by them is sucked in and gets through aquifers into water supply systems. Worn underground pipelines are one of the main causes of intestinal infectious diseases, which have long been forgotten in developed countries!

We have reviewed the current deplorable situation. Question: “Who is to blame?” We’ll leave it for other authors and other publications, but here we’ll try to answer another eternal question:

What to do?

One of the main problems is that approximately 70% of existing engineering networks in Russia consist of steel pipes.

The main advantage of steel pipes is their strength. This is important when moving high-pressure media through pipelines. At the same time, in the housing and communal services sector, the strength properties of steel pipes are used by no more than 30%. Thus, the main advantage of steel pipelines turns out to be practically unnecessary, and the disadvantages (corrosion, and as a result through damage, loss of pumped liquid, groundwater suction, deterioration in the quality of transported water, overgrowing of the internal surface and a decrease in the internal cross-section, and as a consequence an increase in the energy spent on pumping water, etc.) take a lot of money.

In recent years, throughout the civilized world, steel pipes have been replaced by pipes made of polymer materials. This is not at all strange, because they are not subject to corrosion, and their service life is many times greater than the “life expectancy” of steel ones. This is clearly visible in Table 1.

Service life of water pipes

- High level of flammability. During a fire, plastic pipes not only burn, but also release a lot of toxic substances into the environment.

- Poor structural rigidity. Polymer pipes cannot resist either transverse or longitudinal deformations.

- Susceptibility to mechanical damage. The pipe can be damaged by any sharp or heavy object.

- High-carbon, structural, unalloyed steel without corrosion protection, otherwise known as “black.”

- Copper of a high purity level with a minimum amount of impurities of antimony, lead and arsenic (less than 0.001 percent).

- High-carbon, structural steel with a zinc-based anti-corrosion coating, otherwise known as galvanized steel.

- Steel alloyed with chromium, or “stainless steel”.

Properties of polyethylene structures

The main advantage of polyethylene pipes is the high level of plasticity. Only these pipes can freeze along their entire length in winter and thaw in summer without losing their tightness.

A high ductility index ensures good seismic stability of the system.

Polyethylene water pipes are not afraid of any movements or shocks in the ground.

The disadvantages of this material include low heat resistance; a polyethylene pipe can only pump cold water, the temperature of which does not exceed 40 degrees Celsius.

Standard service life of steel pipes according to GOST

Galvanized steel products overgrow much more slowly. Firstly, the smoothness of the wall is much higher, and secondly, there is much less “garbage” itself - particles of rust, scale, sand. But if the taps in the plumbing system are not fully opened and there is not a sufficiently dense flow of water, scale and sand can accumulate.

- the service life of steel water pipes - riser or liner - is 15 years;

- the heating system assembled from gas steel pipes is suitable for use for 10 years;

- heated towel rails in the bathroom can “work” for 15 years;

- According to GOST, the standard service life of a gas pipeline made of steel pipes is 30 years.

Operational requirements for metal heating pipelines

It is necessary to take into account the most important characteristics of steel pipes. This:

- mass of products;

- sizes according to GOST and according to individual order (TU);

- outer and inner diameter (section of the coolant nominal diameter and wall thickness);

- metal properties.

All parameters for this product are reflected in the symbols. The length of the pipe is measured in meters, the diameter of the section and walls of the pipe is in millimeters, the mass is in kilograms, the pressure is in Pascals, the temperature is in Kelvin and Celsius. The parameters for pipe formation and welding type are indicated by a capital letter. The service life, measured in years, is quite arbitrary and depends on a number of factors mentioned earlier.

One of the advantages of metal pipes is their resistance to high pressure, which is present in any heating system.

Service life of metal water supply pipes: standard and actual service life of the water supply system

In the author’s memory, the minimum trouble-free service life of a steel cold water supply system in a new building was only 10 years. The house was built and delivered shortly before the collapse of the Union, in conditions of austerity on building materials and the actual inoperability of Soviet norms and standards. Lightweight VGP pipes, purchased for reasons of economy, quickly and en masse began to leak at welded joints and threads.

Please note: a steel line overgrown with deposits can often be cleaned with a steel cable or string. Even more effective destruction of deposits is ensured by chemical flushing of the water supply system: an alkaline or acidic environment dissolves lime and iron oxides.

Standard service life of water supply pipelines

The main document establishing the standard service life of utilities in a residential building is VSN (departmental building codes) number 58-88, adopted in 1988. They regulate the timing of maintenance, reconstruction and repair of buildings. The document regulates the procedure for repair and reconstruction of buildings. Appendix No. 3 to the document provides the following figures: What factors limit the service life of VGP pipes without anti-corrosion coating: Service life of steel structures

Not a single facility can be built without pipelines; these durable and strong profiles made from a wide variety of materials are used in almost all sections of the construction industry. A variety of materials are used to make pipes, and their service life depends not only on the properties of these materials, but also on the chemical activity of the medium transported through the pipes and in contact with the inner surface. The service life of pipes is also directly dependent on the temperature indicators of both the media passing inside and the conditions in which the structures operate.

Properties of polypropylene products

Water pipes and fittings made of polypropylene have the following set of advantages:

- The ability to withstand the high temperature of the transported substance (up to 95 degrees Celsius), so polypropylene pipes can be used not only to transmit cold, but also hot water.

- Very low cost. This applies both to the pipes themselves and to their installation. Polypropylene water supply will cost the buyer less than all others.

The disadvantages of this material include the difficult process of installing dismountable connections in pressure systems. The method of installing polypropylene pipes is based on either gluing joints or soldering. To arrange a dismountable unit, you can use a special fitting, which, in addition to a polypropylene body, also has a metal fitting.

PVC pipe service life, service life of plastic pipes

- Safety, non-toxic and non-flammable raw materials.

- Practicality in use and when laying highways.

- Light weight.

- Possibility of long-term operation without clearing blockages.

- Absolute neutrality to corrosion and aggressive substances.

- Resistance to various living microorganisms.

- High durability.

The service life of PVC sewer pipes, according to manufacturers, is more than 30 years. However, when purchasing such polyvinyl chloride products, it is necessary to take into account the conditions under which the pipeline model will be operated and what potential factors affecting it exist. For example, it is necessary to take into account the exposure of collectors to external environmental influences (weather conditions, ultraviolet light, etc.) and indoor humidity levels. It also doesn’t hurt to assess the likelihood of mechanical impact from outside and the risk of microorganisms multiplying inside the system.

Ferrous metals for plumbing

Compared to materials that have a variety of protective coatings, water supply structures made of ferrous metals are a budget-friendly and not the most reliable option for arranging a water supply system.

Carbon steel lines have the following disadvantages during operation:

- They are susceptible to condensation, so additional insulation of the outer layer is required. Excess steam promotes corrosion.

- Reduction in internal diameter due to sediment in areas where the water contains salt impurities. Deposits on the internal walls reduce the performance of water pipes made from steel pipes.

- Makes installation work difficult.

- They have an unaesthetic appearance.

- The service life declared by the manufacturer does not correspond to the actual one, and the pipes have to be replaced faster. It is impossible to predict how long the structure will last.

The advantages of steel water supply are:

- low cost;

- high resistance to temperatures and deformations;

- resistance to mechanical damage.

According to GOST, pipe lines must operate for a maximum of 20 years, but much depends on the quality of installation work and the chemical composition of the transported liquid.

What is the service life of steel pipes for water supply and heating - material characteristics

This pipe product is characterized by good thermal conductivity, and the insignificant expansion coefficient due to temperature changes makes it possible to lay water pipes in the wall. Steel pipes, in addition, are excellent for arranging radiant types of water heating.

The service life of heating pipes made from steel is more than 20 years. They are laid both underground and in the basements of multi-story buildings, where very hot coolant moves along them with an internal pressure exceeding 6 atmospheres.

What to consider when choosing heating pipes?

There are no universal pipes that would be equally suitable for installing a heating system in different rooms. When choosing pipes for your home or apartment, you need to consider the following factors:

- Water temperature and pressure. In individual systems, pressure is usually maintained at no more than 2-3 atmospheres, and in centralized systems - up to 16 atmospheres.

- External or hidden type of system.

- Possibility of installation without the involvement of specialists.

About 95% of all heating systems are installed on the basis of plastic pipes. Of course, classic types of pipe products made of steel, copper, and iron also have a right to exist, but they have many disadvantages, the main ones being high cost and complexity of installation.

The following types of pipes are used for heating in modern houses:

- Metal-plastic - used for underfloor heating systems. Since a metal-plastic pipe can delaminate from prolonged exposure to high temperatures, it is used for coolant having a temperature of no more than +40°C - +50°C.

- Polypropylene is an inexpensive, simple pipe that does not conduct heat well. It is used for self-installation of an external heating system, but not for heated floors.

- PEX is flexible, resistant to high temperatures and stress, and is an excellent conductor of heat. Excellent for organizing external and hidden heating systems. The homogeneity of the material prevents its delamination. Assembly is carried out manually using fittings.

PEX-EVOH is one of the latest developments that provides an oxygen barrier. Oxygen, which penetrates into the coolant through plastic in minute quantities, promotes the growth of bacteria. It has been noticed that over 20 years of operation of the heating system, so many microorganisms form in the pipes that they can completely clog the lumen. This does not happen in a pipe with an oxygen barrier.

Standard service life of external steel water supply pipes

In this article we will look at several types and characteristics of pipes for home plumbing. Modern pipe manufacturers use a range of structural materials in the manufacture of their products. However, currently, only plastic or metal pipes are used in water supply systems.

The documents for the pipe according to GOST 3262-75 do not provide a service life. When using galvanized steel pipes in accordance with GOST 3262-75, their service life will depend on the operating conditions. Duration of operation before major repairs (replacement)": Cold water pipelines from galvanized pipes - 30 years (residential buildings), 25 years (municipal facilities).

Copper

The next metal on our list is copper.

Copper water supply: stylish and durable

How long can these metal hot water pipes last? There are no regulatory documents establishing specific service periods. Manufacturers promise a vague “50+” years.

In practice:

- The oldest copper water pipes have been in service for more than a century and are still in perfect condition;

- Copper does not degrade over time, is not subject to corrosion and is only afraid of significant mechanical stress: the metal is very plastic, and the pipe walls are only about a millimeter thick.

Destructive factors

As they say in the hero city of Odessa, “there are some”:

- The service life of copper plumbing may be reduced if press fittings with rubber O-rings are used instead of soldering when installing it. Over 20-30 years, rubber loses its elasticity (primarily in hot water) and is capable of leaking;

Press fittings for copper pipes. The service life of the water supply is limited by the durability of the O-rings

- Banal erosion can lead to destruction of the walls of copper pipes. At high flow rates, sand and other suspended matter rapidly destroy soft metal;

Note: the problem is solved by installing coarse filters and limiting the water flow speed to 2 m/s.

The coarse filter at the entrance to the house is capable of purifying water from sand and suspended matter.

- Theoretically, water hammer and freezing of water in it can break a copper water supply. However, the water hammer must be truly extreme (the destructive pressure for copper pipes is 200 - 240 atmospheres), and defrosting must be repeated at least 5-6 times: the plasticity of copper allows it to withstand a slight change in diameter or length without destruction.

Service life of steel water supply pipes according to GOST

- practically not subject to corrosive destruction;

- has high resistance to chemically aggressive substances;

- from an environmental point of view it is absolutely safe;

- has the highest mechanical strength and heat resistance;

- the coefficient of thermal expansion of steel is 1.5 times lower than that of copper, and 6 times lower than that of plastics, which allows such pipes to be laid directly in the floors.

- corrosion and the tendency to accumulate biological deposits, resulting in a decrease in the throughput of the system;

- the need for systematic preventive maintenance (painting, cleaning the internal surface);

- when laying external networks, the use of special equipment is required;

- installation requires significant time and labor costs;

- relatively short service life of steel water pipes (25–30 years).

The history of metal-polymer pipes

One of the oldest materials for the manufacture of pipelines for various purposes is iron, and later its alloys (steel and cast iron), copper and other non-ferrous metals.

Copper water pipes began to gain particular popularity in the 1950s, first in the USA and Europe, then throughout the world.

Advantages of copper products:

- no risk of rust;

- better waterproofing of joints compared to steel or cast iron;

- less clogging of the internal volume.

Despite the obvious advantages, copper products also have several significant disadvantages:

- welding (soldering) of pipes requires special expensive equipment, which is not always available;

- high cost of copper: this material is more expensive than steel, aluminum, and all types of polymers.

Thus, although copper had excellent ductility and was easy to process, it was necessary to offer another, cheaper material.

It became aluminum. At first, immediately after discovery, it is very expensive, but after some time, thanks to the development of mining, refining and processing technology, the price of the metal has dropped significantly.

Among the disadvantages of aluminum it is necessary to note:

- excessive softness: small abrasive particles found in any tap water inevitably spoiled the inner surface of the pipes, even to the point of a breakthrough;

- there is a large difference in electrochemical potentials with copper and iron: upon contact with these metals or even with water, aluminum pipes begin to rapidly deteriorate, which ultimately reduces the benefits of using the metal to nothing.

However, a complete abandonment of aluminum did not happen: with the discovery of a method for producing high-molecular compounds, that is, polymers, the idea arose of isolating the easily degradable metal with layers of plastic - both outside and inside. This is how multilayer metal-polymer pipes appeared.

The resulting products had a number of significant advantages compared to both steel and copper products:

- Much smoother interior surface. In this case, even small abrasive particles in the water are not dangerous: they only polish the plastic, giving it even greater smoothness.

- Due to their smooth surface, metal-polymer water supply pipes have excellent throughput capacity, exceeding similar parameters of metal products. In addition, the internal smoothness does not allow various types of contaminants to settle in the pipes, therefore, the internal clearance of such products practically does not decrease over time.

- Due to their dielectric properties, metal-plastic pipes do not collapse upon contact with metals and water and do not conduct current, that is, they do not require additional insulation.

- Minimal heat loss: plastic releases thermal energy worse than metals, therefore, heating circuits made of this material will save money.

- Easy to connect pipes to each other. You can use various fittings (with split rings and union nuts) or solder (weld) polymer products.

How long can steel pipes last in an apartment building?

The massive use of steel water pipes in Soviet times and in modern Russia is explained by their availability, manufacturability and the quite acceptable standard service life of pipelines made from them, providing water supply and sewerage drainage in apartments of multi-storey buildings. Rolled metal can withstand loads resulting from pressure surges.

Among the disadvantages of metal pipelines, it is worth noting the significant costs of installation work. To arrange communications, gas welding equipment is required. In addition, the significant weight of the pipes imposes additional difficulties on the process of transporting and lifting them to the work site in a high-rise building.

The service life of pipes is directly dependent on the properties of the materials used.

Such network systems behave well under water, in the ground, and in workshops; they are even used for systems operating under pressure. Plastic is interesting because of its speed of installation, low weight, and good strength and toughness. A win-win option is to use these profiles for indoor or outdoor sewerage.

Such pipes are very promising because they do not require any maintenance, they are chemically neutral, salt does not accumulate on the walls, condensation does not form, heat loss is minimal, and this allows you to do without thermal insulation. All these properties, combined with service life, make polypropylene systems the No. 1 material .

Articles on the topic

The condition of water pipes requires special attention from plumbers working in the management organization. In the article we will talk about the types of metal pipes, their features and service life - both those prescribed in regulatory documents and real ones. To help the Criminal Code, we also provide a list of mandatory work that must be carried out as part of the maintenance of water pipelines in multi-storey buildings.

15-20 years ago, polymer pipelines began to appear in residential buildings. Previously, during construction, exclusively metal communications were used, which continue to be used in a significant part of the apartment complex. As the resource is exhausted, they are replaced with modern materials. This is a long process that will continue in the public utilities sector for many more decades.

Specialists of management organizations need to understand how metal pipes behave in operation, what their service life is, and also how to carry out maintenance of metal water supply, sewerage and heating systems.

Corrugated stainless steel pipe

How long will corrugated stainless steel last in a water supply?

According to one of the leading manufacturers, the Lavita company - indefinitely. Lavita explicitly states that its products have an unlimited service life.

Characteristics of Lavita corrugated pipes. Please note maximum pressure and service life

However: silicone seals in press fittings will still have to be changed after 30 years. This work is not difficult: the fitting can be disassembled to replace the seal with a pair of adjustable wrenches in 30-60 seconds.

What is the actual service life of stainless steel in water supply cannot yet be said simply because of the limited time of its operation.

Destructive factors

The only thing that can cause damage to a stainless water supply is rough mechanical impact. Thin (only 0.3 mm) walls are easily crushed by a strong impact.

The wall thickness of the corrugated pipe is only a third of a millimeter

But you don’t have to be afraid of the notorious water hammer and defrosting:

- The combination of a tensile strength of 210 atmospheres (according to the Lavita company) in combination with corrugated walls that act as a damper will allow the water supply system to withstand any short-term pressure surge;

- When water freezes, corrugation will allow the pipe to lengthen and accommodate the volume of ice that has increased during crystallization without destruction.

Thanks to corrugation, the stainless pipe can withstand water hammer and defrost without destruction.

Metal water pipes

Until recently, metal water pipelines were the only possible option for arranging engineering systems for supplying and draining water in mass construction. Pipes can be made from various metals.

- High carbon steel, not protected from rust, also called black. This is the cheapest material, but the standard service life of such steel water supply or sewer pipes is the shortest; they are made according to GOST 3262-75.

- Galvanized steel and pipes made from it are manufactured according to the same standard as from “ferrous” metal.

- Stainless steel, that is, alloyed with chromium. The cost of such pipelines will be higher, but they will also last much longer in comparison with communications that are susceptible to rust.

- Corrugated stainless steel pipes. They have all the advantages of stainless steel and are additionally characterized by high ductility. Such a corrugated pipe can be easily bent, for example, for the purpose of laying communications in the most accurate and compact manner. In this case, the flow area of the pipeline does not change, and there is also no risk of microcracks and other defects.

- Highly purified copper. An expensive option, usually used in individual residential construction.

Announce the entire list

First, let's remember exactly what types of metal pipes are used in cold and hot water supply systems.

Actually, there are currently only four of them:

- Black steel (water and gas pipes GOST 3262-75);

- Galvanized steel, produced to the same standard;

- Copper;

- Corrugated stainless steel.

It’s interesting: just a few decades ago, cold water supply lines were massively laid with cast iron pipes. However, now they have been almost completely replaced by pressure polyethylene ones.

A cast-iron water supply system, built more than two centuries ago, feeds the famous fountains of Peterhof

Features of communications using steel pipes

The massive use of steel water pipes in Soviet times and in modern Russia is explained by their availability, manufacturability and the quite acceptable standard service life of pipelines made from them, providing water supply and sewerage drainage in apartments of multi-storey buildings. Rolled metal can withstand loads resulting from pressure surges.

However, metal pipes also have disadvantages, due to which today they are increasingly being replaced by polymer analogues. The main one is the limited service life of steel pipelines; the average lifespan of such water supply systems is about 20 years. It fluctuates depending on various factors, which we will discuss below.

Metal-plastic and polymer pipes last much longer. For pipelines made from these materials, the service life is 50-80 years.

The main disadvantage of metal is the appearance of corrosion upon contact with water. The inner surface of the pipes gradually ceases to be smooth, as small pockets of rust form on it. In such areas, salt deposits, which are always present in tap water, accumulate over time. As a result, pipelines lose their original performance in two ways:

- the metal becomes thinner as a result of gradual rusting. When the wall thickness becomes critical, a breakthrough occurs. If signs of such wear and tear are not noticed in a timely manner, a serious accident may occur;

- The flow area of the pipe is reduced due to overgrowing with salt deposits. This is a fairly lengthy process, but in houses built several decades ago, management organizations regularly face its consequences. It is dangerous not only to completely block the pipe passage, but also to significantly narrow it. If a large enough piece of rust comes off the wall, it can completely block the hole through which water previously passed.

Metal pipes conduct heat well and at the same time only slightly change their dimensions when the temperature of the transported water changes. This allows you to lay them in walls if necessary.

Among the disadvantages of metal pipelines, it is worth noting the significant costs of installation work. To arrange communications, gas welding equipment is required. In addition, the significant weight of the pipes imposes additional difficulties on the process of transporting and lifting them to the work site in a high-rise building.

Cink Steel

Thanks to its anti-corrosion coating, galvanizing should be more durable than black steel. How much?

Standard service life

We can find data about him in the same VSN 58-88:

| Engineering system element | Standard service life, years |

| Riser or liner in a cold water supply system | 30 |

| Riser or hot water supply in a house with a closed heating system | 20 |

| The same, in a house with an open heating system | 30 |

The photo allows you to compare the condition of black pipes and galvanized pipes after storage under the same conditions

Destructive factors

How and why can a galvanized metal pipe for water supply fail?

While working as a plumber, the author observed the only scenario for the appearance of fistulas on galvanized water pipes: they occurred at a welded joint. Strictly speaking, galvanized pipes cannot be welded “at all”: in the area of the seam the zinc burns out completely. You see, it evaporates already at 900 degrees, and steel melts at 1400-1500.

As a result, the owner of a galvanized water supply system mounted on welded joints receives a pipeline made of corrosion-resistant (albeit in some places) material, but at twice the price.

A serious mistake: the installation of a galvanized water supply riser was made using welded joints

How to properly install galvanization with your own hands to ensure maximum service life of the water supply system?

Here are the instructions that plumbing equipment installers used in the 50-60s of the last century:

- All connections are made only and exclusively on threads (cut by hand or on a lathe) using cast iron threaded fittings;

Galvanization is mounted exclusively on threads

- The connections are sealed with plumbing flax and the windings are impregnated with red lead.

Do galvanized water supply pipes become overgrown? Deposits and rust do not linger on their walls, but the formation of a water-impenetrable plug is still possible under certain circumstances. It goes like this:

- Debris accumulates in the water supply (usually cold) - sand, welding scale and rust flakes. A blockage is formed if the water supply taps are always opened only partially, and the speed of the water flow does not allow it to carry debris into the mixer and further into the sewer;

Along with the water, a lot of debris flies into the water supply pipes. To verify this, just open the mixer aerator

- Over time, the accumulation of debris is cemented with lime and iron oxides, gradually turning into a material with the strength of stone.

Actual service life

The author of the article must repent to the reader: he cannot name either the minimum or maximum service life of galvanized water supply. The fact is that he has never encountered a galvanized pipe that needed replacement due to natural wear and tear.

The lines and risers, which were opened after 50-70 years of operation, were invariably in impeccable condition and were no different from new ones.

Galvanized water supply risers in the basement of an apartment building

Service

In accordance with Decree of the State Construction Committee of the Russian Federation No. 170, specialists of the management company must carry out certain work related to the maintenance of the water supply system. This is necessary, among other things, to extend the service life of steel pipelines. As part of the service, the following actions are carried out:

- Inspections and preventive measures are regularly carried out, as well as scheduled preventative repairs and additional equipment of communications when construction defects are detected;

- Excessive noise and vibrations caused by the operation of the water supply system are eliminated, the pressure in the pipes is brought to the norm by adjustment;

- Leaks, blockages, leaks and other defects are eliminated in a timely manner;

- prevents the appearance of condensate on the surface of the pipes;

- The pumps present in the system are serviced.

Plumbers working in management companies must study the water supply and sewerage systems available in houses, both directly and from technical documentation. If there are no documents describing communications in detail, they are drawn up anew.

Service life of metal pipes

There are no regulatory documents that clearly define the service life of metal pipes. Here you can focus on departmental building standards VSN 58-88 (r), which prescribe the minimum useful life of each building element, including pipelines.

Setting strict deadlines is not possible, since the operating conditions of metal pipes vary greatly. The technical literature usually indicates that they last about 20 years. In reality, this period ranges from 10 to 50 years. It is determined by several significant points:

- the quality of the metal from which the pipe is made. Steel without alloying additives in an aggressive environment can completely lose its performance qualities after just a few years;

- pipe manufacturing technology. Solid drawn ones will last significantly longer than those connected using welded seams. Areas affected by welding are weak points that are more quickly susceptible to corrosion and overgrowing with deposits;

- water quality. This is the most important point that determines the service life of metal pipes. The most aggressive environment for steel is an acidic environment.

A few more benefits

It is worth mentioning the lifespan of steel pipes in Stalin-built houses, where they are used in the heating system at a temperature not exceeding 50-60 degrees. Heating systems that are equipped with cast iron radiators can easily last for more than a century. Although they can’t even do it, they still serve. There are cases when such heating systems were built at the end of the 19th century and functioned perfectly until the mid-80s of the 20th century.

It is worth noting another good property of steel. It is difficult to overestimate - this is the lowest coefficient of thermal expansion among other pipes. So, for example, for copper it is 2 times greater, and for plastic it is 15-20 times greater. In simple terms, this is the stability of their sizes.

So, no other pipes should be hidden in the walls or floor, since they increase or decrease in size when the temperature changes (this is especially important if heating is being considered). And this already leads to a violation of the integrity of the coating in which they are mounted

Therefore, when using non-metallic pipes, compensating structures such as, for example, soft thermal insulation are used.

A steel pipe, like many metal pipes, is best suited for the construction of radiant (not to be confused with radiant) water heating systems. If we talk about disadvantages, the most important ones include a high level of corrosion, as well as damage of various types. All steel pipes used in heating rust very quickly and become clogged with various deposits. The best way to protect is to use galvanizing technology and laying pipes of larger diameter.

Perhaps the only and main disadvantage of using galvanizing is the impossibility of using antifreeze in this system, on which operation, that is, service life, depends. If we consider in more detail, zinc coating increases their resistance to corrosion, which can cause their service to deteriorate. This helps to extend the “life” and service life of metal structures by approximately several years.