The need to paint modern radiators and heating system pipes arises only if you want to change their color in accordance with the overall color scheme of the interior. But many houses still have cast iron batteries with steel liners that need decoration, and some developers deliberately choose them, considering them more reliable and efficient. In any case, repairs require paint for heating pipes and radiators. To select the appropriate composition, you need to make sure that its properties correspond to the operating conditions.

Large diameter steel pipes instead of batteries Source odstroy.ru

Requirements for paintwork materials for heating systems

It would seem that choosing a product for painting pipes in a store is not difficult, you just need to make sure that the can is marked “For radiators” or similar, indicating the special purpose of the composition. However, there will probably be a lot of such cans, and they will differ not only in manufacturer and volume, but also in the type of paint. Therefore, you need to decide on the characteristics that it should have.

- Heat resistance.

All radiator paints have the ability to withstand high temperatures without damaging the coating. Elements of heating systems usually have a temperature of 50-90 degrees, so the heat resistance of the paint should be at least 80-90 degrees. More is better, some reserve never hurts.

Paint with heat resistance of 120 degrees Source kraski-pingam.ru

Advice! If repairs are planned during the heating season, you need to choose compounds that can be applied to a hot surface.

- Presence of odor.

When painting is carried out in non-residential premises, the presence of an unpleasant odor during work and before the coating dries does not matter. If people live in the house, it is better to choose odorless paint for heating pipes. A specific pungent aroma directly indicates the presence of harmful volatile substances in the composition that are hazardous to health. As a rule, they stop being released into the air after the paint has completely dried, but if the pipes are very hot, this process can be repeated. When using paint with a smell, it is necessary to ventilate the room or use respirators during work.

- Anti-corrosion properties.

They must have paints intended for metal pipes and radiators. However, if you need to change the color of modern aluminum or bimetallic devices with high-quality factory coating, this property can be neglected.

To protect against rust, you can apply a special enamel primer under the paint. Source wooood.ru

See also: Catalog of companies that specialize in finishing materials and related work

- Adhesive properties.

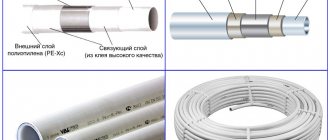

Pipes can be steel, copper, plastic, etc. The paint is selected so that it has high adhesion to the material.

- Durability.

Painting heating pipes is not the easiest or most enjoyable task; few people would like to do such work every year. Therefore, it is necessary to pay attention to the paint’s resistance to detergents, abrasion, and moisture resistance so that it can withstand wet cleaning and dry cleaning from household dirt.

- Decorative properties.

To ensure that pipes and radiators fit into the style and color scheme of the room, paint is selected according to color or the white base is tinted in the chosen tone. Matte or glossy also matters.

The choice of paints in color and texture is almost unlimited Source blogspot.com

On a note! Pipes painted in dark colors give off more heat than light ones.

Technology for painting polymer pipes

You can paint hot pipes made of polymer materials only after preliminary preparation. This is due to the fact that the glossy surface of the pipe prevents high-quality adhesion of the paint, and the coating will leave much to be desired, which will entail the need to apply several layers of paint. To prevent this, the surface of the pipe is cleaned with sandpaper.

Note! To process pipes, fine-grained sandpaper is used and the work is carried out without the use of power tools, since it is necessary to create only a slight roughness. Using a power tool can scrub the pipe too deep. During the heating season, polymer pipes can be painted only after sandpapering.

At the next stage, the pipes are wiped with a damp cloth after sanding to remove dust. Make sure the pipes are dry and clean before painting. After this, it is necessary to cover the floor and walls with protective material (film) to prevent paint from entering.

Types of heat-resistant paints

Paint for pipes and radiators is available on different bases. These are acrylic and silicone water-dispersion compositions, alkyd enamels, oil paints.

Acrylic

The most popular are acrylic paints. They dry quickly, have virtually no odor even at the time of application, do not emit harmful substances when heated, and at the same time have an affordable price. But when purchasing them, you need to pay attention to heat resistance - for such compositions it often does not exceed 80 degrees.

A fairly thick solution is easy to apply and does not spread, forming a smooth surface without smudges, but subject to preliminary priming of the base and a two-layer coating. The texture of such compositions is matte and glossy. The main disadvantage of acrylic paints is their low resistance to abrasion and mechanical damage.

Mode of application

When using an aerosol, you must shake the can periodically. An indicator of its readiness for use is the free movement of balls inside it, which serve to mix the composition.

When spraying, the can should be held in a vertical position, evenly making back-and-forth movements. The work is carried out from a distance of 20 cm.

The use of aerosols is possible in a temperature range from +5 to +32 degrees Celsius.

If necessary, remove paint; fresh paint can be removed with acetone, and dried paint can be removed with a special remover.

Video description

This video describes in detail the criteria for choosing paint and how to paint heating pipes:

Another type of paint can be considered the most advanced option in terms of quality, durability and durability of the coating. This is powder paint. But it cannot be applied under normal conditions; this requires special spraying equipment and a heat chamber for drying at a very high temperature.

In principle, batteries can be painted using this method if you temporarily dismantle them and negotiate with a car service center that performs body painting work. This cannot be done with pipes: the joints will remain visible after installation.

How and with what to paint gas pipes so as not to rust in a private house or apartment

The question often arises about how to paint a gas system, and whether this is allowed at all. You need to understand what colors of paint to paint pipes, what types of dyes are allowed for painting and how to apply paint to the surfaces of pipes.

What is this for?

Painting gas communications is far from an aesthetic matter. This is required in order to:

1. Identify the gas pipeline by color, do not confuse it with other types of pipes. This is especially necessary in industrial enterprises and boiler houses. Naturally, it is much easier to determine the desired line based on the external signs and color of the pipes, as opposed to studying all the documents for the junction.

An important nuance is that marking gas pipes by color is only necessary for industrial enterprises or when laying a gas pipe above ground. There are no government requirements for residential premises, either indoors or outdoors.

How much paint do you need?

The paint consumption per layer is always indicated on the packaging. But this is an average value, which depends on the composition, the quality and type of surface, and the method of applying paint - manually or by spray.

Before you buy paint and paint a pipe, you will have to calculate the area of the surface to be painted by multiplying the circumference by the total footage of the pipe system. It is even more difficult to calculate the area of sectional batteries. If the product is new, this parameter can be found in its passport or search for information on the Internet.

Characteristics of a cast iron suspended radiator Source retrorossia.rf

Advice! If you have any difficulties with calculations, you can use an online calculator.

Preparing the work surface

- Surface treatment for aerosol painting is carried out in the same way as for rust enamel in the form of a suspension.

- The surface is cleaned with a stiff brush to remove dirt deposits, loose rust and old paint residues.

- Then it is degreased using gasoline or acetone.

- After this, the surface is washed with soapy water and dried.

Cleaning pipes from rust

What tools and materials will still be needed?

Heat-resistant silicone enamel in a can requires only a respirator and gloves. The application job is done quickly.

As for tools and materials for preparing the surface, a regular cord brush, a little acetic acid to remove rust and a couple of rags will do.

Preparing batteries for painting

I started by removing dust and dirt from the battery, then proceeded to remove the rust stain on the radiator. I rubbed the problem area several times with a vinegar rag and cleaned the surface with a cord brush.

Tip: Once the surface is prepared, do not forget to protect the wall behind the radiator. Attach cardboard or oilcloth to the wall with masking tape before you begin painting the radiator.

I used regular wrapping paper and glued it to the window sill. It wasn't wide enough for the radiator, but I just moved it as I moved towards the end of the battery.

Popular manufacturers

Here is a list of proven, popular and reliable paints for heating pipes:

- Dufa Heizkorperlack;

- Radiator Paint;

- Elementfarg Alkyd;

- Millertemp;

- Mipatherm 600;

- Radiator;

- UNIPOL enamel;

- GF-0119;

- VD-AK-1179.

Each of these paints and varnishes has its own composition, properties and technical characteristics. In addition, they have different prices. It is necessary to select a coloring solution based on financial capabilities, available shades of dye and personal preferences.

Coloring Tips

So that after painting the result is good, and the work does not need to be redone, again wasting time, money and effort, it is best to learn the painting technology and follow the advice of specialist painters. Professionals say that the quality of the final result largely depends on how correctly the preliminary preparation of metal heating pipes was carried out. By properly preparing the surface before painting, the paintwork will be beautiful, durable and wear-resistant.

Conclusion

When choosing a dye for heating pipes, you need to make sure that the dye composition can withstand heating to high temperatures and will not harm human health. You should not purchase cheap, low-quality products that will not last long. It is better to buy paint and varnish material once from a reliable, trusted manufacturer, and follow all recommendations for surface preparation and painting. In this case, the painted pipes will be protected from damage and corrosion for a long time, and will remain attractive for many years.