Competent design of engineering systems in full compliance with building codes and regulations not only guarantees a comfortable temperature in a private home even in the most severe winters, but also protects you from various breakdowns and incidents, including those dangerous to life and property. In addition, correct installation of cottage heating and hot water supply will save you in the future from problems with acceptances, inspections, approvals and other bureaucratic procedures. The most important component of engineering systems is the boiler room in a private house - about the selection of equipment for it and complete installation diagrams, which heating boilers to choose for a private house, you can get basic information here in this article.

Boiler room in a private house - selection of equipment, complete installation diagram

Boiler room in a private house - main types

There is no single boiler room design that is mandatory for all private houses - the size, location and parameters of the room may vary significantly. They depend on the goals and objectives set for the heating equipment, the size of the cottage that needs to be heated, the budget allocated for construction, and the personal preferences of the owner of the land. Based on location, we will highlight four types of boiler rooms in a private house. You can read the calculator for calculating the power of a gas heating boiler in our article.

- A boiler room built into the house without a separate room. The boiler, boiler, pumps and other equipment are located in the kitchen or in the hallway. The cheapest option to install. Suitable only for small boilers - placing more powerful equipment in the kitchen or hallway will not only create serious inconvenience for residents, but is also simply unsafe.

Heating boiler built into kitchen furniture

- Boiler room built into the house in a separate room. As a rule, this is a small room, decorated with non-combustible materials, inside which there is a double-circuit gas boiler, boiler, pumps, sensors and other equipment. Convenient from the point of view of maintenance and replenishment of fuel (if we are talking about a heating system that runs on solid fuel).

- Boiler room in an extension - this option is perfect for systems that create a lot of noise, which makes it undesirable to place them in the house. But at the same time, you will have to spend some effort and, what is important, money to build an extension from non-combustible materials and in full compliance with SNiP and gas service standards in your region.

- The boiler room is in a separate building - in this case, the “heart” of the heating system is located outside the house that it heats. Such premises are built in cases where a high-power gas heating boiler is used, placing which inside the cottage is not the best solution from the point of view of safety and building codes. Obviously, a boiler room in a separate building is the most expensive and complex option.

A heating boiler in the kitchen is a classic option for small houses in villages or the private sector of cities

Interesting! For a gas or solid fuel boiler room in a separate room of a house or an extension to it, the term “furnace” is often used.

The built-in boiler room is a separate small room located inside the cottage. Please note that the floor and walls are tiled, which is a non-flammable material

Extension to the house with a boiler and other equipment for heating and hot water supply. Has a separate entrance door

Heating equipment located in a separate boiler room building. As in the case of a built-in room in the house, the floor and walls are tiled

What does it mean to heat with air?

This kind of heating method has been known to ordinary people for a long time. Previously, ordinary houses were warmed by heated air, which from the stoves that were heated went through channels specially made for these purposes. And these days, many owners of country houses are thinking about how to make air heating for their homes with their own hands, since this heating method has many advantages over others.

To heat rooms, both internal and external air masses are used. If air is taken only from the street, then this kind of system will be called a supply air system. For this purpose, supply-type fans are used; they drive air directly to the heating unit.

The complete recirculation scheme looks like this: the internal air is in motion all the time, moving from a hot state to a cold state, after which it goes to the heating device, where it heats up again and moves into the room to release heat and a new cooling stage.

Air heating is a type of heating that you need to pay attention to if the choice is made first in order to save money. The most economical method is designed for the air to be heated in a heater or heat exchanger and distributed throughout the rooms through special channels

In each room, several holes can be placed near the floor, through which the air will fill the room with heat.

The most economical method is designed for the air to be heated in a heater or heat exchanger and distributed to rooms through special channels. In each room, several holes can be placed near the floor, through which the air will fill the room with heat.

Description of heating type

First, you need to stock up on three main ingredients.

- Heat generator. For this purpose, a heating boiler or furnace is most often chosen. The boiler will operate on any known type of fuel or be powered from the home electrical network.

- A network of air ducts that are usually made of galvanized steel. They may look unsightly, but are often decorated with all sorts of finishing materials to match the design of the room.

- Supply fan.

This heating design, equipped with your own hands, will heat any room well and fairly quickly. Climate control devices can be built into such a system, which in the summer will serve as air conditioning and air purification. The location of air conditioning devices is carried out both at the top of the room and at the bottom - this depends on the selected air heating scheme.

The supply fan forces warm air into the ducts. It is installed immediately under the combustion chamber of the boiler and, using a filter, cleans the air from all kinds of impurities and dust in order to supply it to the heating site - the heat exchanger. After it passes through the duct network, the cooled air is returned to the heat exchanger.

List of equipment required for a boiler room in a private house

In addition to the room itself, the most important component of the boiler room is the equipment located in it. Not only the functionality, power and durability of the heating system, but also its safety for your health, life and property depends on its competent selection. To begin with, we present a list of equipment for a boiler room in a private house.

You may be interested in information about do-it-yourself geothermal heating at home

Table. A boiler room for a cottage is the necessary equipment.

| Name of equipment | Function performed |

| Heating boiler | The basis of the heating and hot water supply system. By burning gas, wood, coal, pellets or electricity, it heats the coolant, which is ordinary water. |

| Boiler | A device that heats water used for domestic purposes - for showering, washing dishes, etc. |

| Expansion tank | A container that receives water that is displaced by the heating system as the temperature rises. With it, pipes and radiators are protected from a sudden increase in pressure, which could cause a breakthrough. |

| Heat accumulator | A container containing water or other coolant. Collects “extra heat” generated by the boiler and releases it to heating radiators in severe frosts. |

| Chimney | Engineering communications designed to remove combustion products from the fuel of a heating boiler. |

| Distribution manifold | A device that evenly distributes coolant throughout all radiators. Without it, maintaining the same comfortable temperature in all rooms is an extremely difficult task. |

| Circulation pump | A device used in a heating system with forced circulation of coolant. Provides the necessary pressure in the line. |

| Security control devices and sensors | A set of instruments that record the temperature and pressure in the boiler, boiler and pipelines, as well as monitor the concentration of hazardous substances in the air of the boiler room. |

| Shut-off valves | Various taps and valves necessary to control the flow of coolant in the heating system. |

| Pipelines | The main element of the heating system is that the coolant flows from the boiler and collector through them to the radiators. |

| Automation | A set of sensors and equipment used to maintain user-specified temperature and pressure in the system. |

| Filter | A device that purifies water before entering the heating boiler and heating system lines. |

The following sections of the article will discuss the nuances of selection and placement rules for the most important equipment for a boiler room from the table above. “You can read the selection of an expansion tank online in our article.”

Diagrams by type of coolant supply

The radiator will work effectively if the coolant is evenly distributed across all sections.

Warm and cold water have different densities. The heated coolant always tends upward. In the system it is replaced by cold, denser water. This feature is taken into account when supplying coolant to the batteries.

Coolant supply diagram

Upper eyeliner

Each radiator has vertical channels connecting the horizontal upper and lower manifold. The presence of these elements allows the coolant to circulate in the device.

With the top connection, mainly only the top of the battery heats up. To prevent such an effect, a jumper is installed after the first rib in the direction of flow of the coolant. Therefore, the heated water first falls into the lower collector.

Then it passes through all sections of the radiator and enters the return pipeline. As a result, the top connection turns into a diagonal way to connect the battery.

If there is no jumper in the radiator, the supply pipe is connected at the top, and the return pipe at the bottom from the opposite end of the battery. This option is called diagonal strapping.

Bottom eyeliner

This is the easiest way to tie. The scheme involves installing the boiler in the basement or on the ground floor. From the heat generating unit, the main pipeline is led to the attic, where the expansion tank is installed. A starting line is laid from the tank, but not lower than 1.5 m to the first radiator.

The supply and return are connected to the batteries at the lowest points on opposite sides. All radiators in the system are connected to pipelines in the same way and installed in series.

When installing a heating circuit with natural circulation, the pipes are laid at an angle. The last battery must be located above the boiler. The height difference between the final radiator and the heat generating unit should not exceed 3 m.

Connection in progress:

- circulation pump;

- bypasses;

- shut-off valves;

- Mayevsky cranes.

Pumping equipment runs on electricity.

When it is turned off, circulation of the coolant is possible only in a natural way. Therefore, it is better to lay pipelines at a slope. Date: September 25, 2022

Heating boiler - installation diagram

Let's start with the heating boiler - the “heart” of the heating and hot water supply system of most country houses. As an introduction, we present a classification of heater placement and connection schemes.

There are a huge number of different types of boilers

Let's start with the first - according to their location, heating boilers are divided into two types:

- wall;

- floor

As the name implies, the first type of heaters are placed directly on the wall of a residential building. In most cases, such devices also include a boiler, pump, distribution manifold, sensors and other equipment. From the user's point of view, this design is extremely convenient - everything is in one place and for one price. In addition, a wall-mounted boiler is perfectly installed in the kitchen or hallway, does not take up much space and does not require the installation of a long and complex chimney - combustion products can be removed through a short pipe placed in the wall directly behind the heater.

Wall heater and other equipment for a boiler room built into the house

Arrangement of a combustion room with a wall-mounted gas boiler. Main lines and equipment signed

Installation diagram with a wall-mounted Havien boiler

But, like any complex device, a wall-mounted boiler has its drawbacks. The first is the high complexity of the entire system - a large amount of equipment is placed in a small volume. And it has a high probability of failure, especially if installed incorrectly and improperly used. The second disadvantage of wall-mounted heating boilers is their relatively weak power. Due to its design, such a device is unable to provide the amount of heat that would be sufficient to heat a very large country cottage. But for small houses in villages or the private sector, a wall-mounted heating boiler will be just right.

You may be interested in information on how to choose a convection heater for your home

Floor-mounted devices have exactly the opposite advantages and disadvantages. They have high power, sufficient for even the largest buildings. In addition, floor heating boilers are designed for maximum reliability, even at the expense of size and quiet operation. At the same time, it is better for them to allocate a separate room, called a furnace room, or build their own boiler room. Also, floor heating boilers will require a chimney and a whole range of equipment necessary to deliver coolant to the radiators and ensure reliable operation of the entire system.

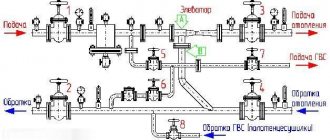

Complete installation diagram for heating and hot water supply of a private house with a floor-standing boiler

As for the circuits for connecting lines to the heater, they are classified according to the method of circulation of liquid in it (can be natural or forced). In the first case, the coolant moves in the pipes due to the difference in density and temperature. Arranging a heating system with natural circulation of water allows you to save on pumps, but the total length of the lines is limited to 30 meters.

Important! With natural circulation of coolant from the boiler to the radiators, all pipes should be installed at an angle. Some owners of country houses consider this a disadvantage - inclined highways do not look the best from an aesthetic point of view.

Scheme of a single-pipe horizontal heating system with natural circulation

You may be interested in information about connecting a boiler

Connecting a heating system with forced circulation of coolant has exactly opposite advantages and disadvantages. One of the advantages should be noted that the length of the lines does not have any restrictions, in addition, the pipes themselves can be laid in the way you consider convenient and beautiful. Also, a constant and high fluid pressure will be maintained in the system itself. But for all this it is necessary to purchase a set of pumps, which, in addition to their cost, will require electricity to operate.

Installation diagram of a boiler room and heating system with forced circulation

Another feature by which heating boiler connection diagrams are classified is the method of laying inlet and outlet pipes. According to this characteristic, heating systems are divided into single-pipe and double-pipe. In the first case, the inlet and outlet lines are represented by one pipe - the coolant from the boiler is passed sequentially through all radiators. In this case, the owner of the house will gain in the cost of the entire system, but will lose in the quality of its functioning - the batteries closest to the furnace room will be too hot, and the furthest ones, on the contrary, will be cold.

Approximate diagram of a one-pipe heating system

Important! Another problem with the standard single-pipe design is the inability to regulate the temperature in the radiators. This shortcoming is eliminated when installing a heating system according to a scheme called “Leningradka”. You can see its device in the image below.

Scheme of the Leningradka system

The two-pipe circuit for connecting the lines to the heating boiler ensures uniform distribution of the coolant over the radiators and the ability to regulate the power of each individual battery. But at the same time, the owner of a private house will have to invest more money and effort into laying utility lines during the construction or renovation stage.

You may be interested in information - stove heating

In turn, the two-pipe scheme is divided into the following subtypes:

- vertical with top wiring;

- vertical with bottom wiring;

- horizontal dead-end;

- horizontal tailwind;

- horizontal beam.

Two-pipe vertical heating schemes

Two-pipe horizontal radial distribution of the heating system from the boiler and collector is today very popular in the construction of private houses

The process of arranging a boiler room in a private house can be presented in the form of step-by-step instructions.

Heating system sketch

Step 1. On your own or in a design organization, draw up a diagram of the installation and location of the boiler, boiler, expansion tank, other equipment and lines.

Step 2. The project is approved by various inspection organizations, including the regional gas service.

You may be interested in information about which boiler is best to buy for your home

Step 3. A chimney is laid in a building or room dedicated to the boiler room.

Step 4. After the chimney, the remaining utility networks are laid - sewerage, electrical wiring, inlet and outlet lines of the heating system, gas and water supply, ventilation.

Ventilation of a boiler room in a private house

Step 5. In accordance with the requirements of SNiP and the gas service of your region, the boiler room is finished with non-combustible materials.

Step 6. The boiler, boiler and expansion tank are installed and connected.

Main elements of a heating system with a solid fuel boiler

Heating boiler prices

boiler

DIY installation technology

It is better to entrust the installation to gas service specialists, but if necessary, you can do it yourself. It is important to strictly follow the installation instructions for different types of boilers.

Floor standing boiler

A concrete foundation is built for a floor-standing boiler.

Before installing floor-standing gas boilers, you need to check their components. There should be no dents or chips on the surface of the device. The technical characteristics indicated on the device body must match the data specified in the data sheet.

Work order:

- Removing plugs from the boiler and cleaning the pipes from debris that got there during the production stage.

- Installation of the unit on a prepared base or foundation. Its level can be adjusted using adjustable legs or non-flammable elements.

- Connection to the chimney. The holes for arranging the structure should already be prepared. Corrugated materials must not be used to connect the boiler to the chimney. Areas of the floor and roof that will be in contact with the structure must be insulated with fireproof materials. Clamps are installed at the junction of the pipe and elbows.

- Connection to the heating circuit and water supply. First, heating pipes are installed, on which coarse filters are installed. Shut-off valves are mounted on them. All connections are reliably sealed. The water supply is connected in the same way. If the liquid is very hard, you will have to install equipment to soften it. To seal connections, you should not use rubber seals, as they quickly crack and begin to leak gas.

- Connection to power supply. It is better to arrange the outlet at a minimum distance from the unit. If the model is unstable to voltage surges, a stabilizer or uninterruptible power supply must be used in the system.

After installation, gas service specialists check the system and carry out a test run. The coolant is pumped into the system gradually to prevent the formation of air pockets. The procedure is carried out until a suitable pressure is reached - 2 atm. All connections are checked for water or gas leaks.

Wall boiler

Anchor hook for mounting the boiler on the wall

To hang the wall-mounted unit correctly, you need to mark the base. The complete set of equipment is also checked. Brackets and mounting accessories must be included with the boiler. All pipes and pipes of the heating system are washed. This procedure is necessary to eliminate production waste.

The base on which the unit is mounted must be perfectly level. It must also support the weight of the boiler. The fastening strips are fixed at a distance of 0.8-1.6 m from the floor. Before connecting the product to the heating system, the plugs should be removed, the supply pipes should be equipped with a filter, on both sides of which ball valves should be mounted.

During installation, you need to ensure that the level of the unit is maintained. Even the slightest distortion will prevent it from being connected to the pipes, and will also disrupt the functionality of the system. Gas pipes are connected only with metal elements through a connector or “American”. The connection must be tight. No rubber gaskets or seals should be used here - the elements must be paronite.

Gas heating boiler - installation requirements

You may be interested in information - heating boilers for a private home

Heating boilers that produce heat by burning gas are now widespread. This is largely due to the availability and low price of fuel for them. But at the same time, such heat generators have one serious problem - if installed and used incorrectly, there is a risk of fire or even explosion. Therefore, the installation of gas heating boilers requires taking into account many fairly strict standards. Without compliance, heaters will not be accepted by the relevant organizations. Are you planning to install a gas boiler room in your cottage? Then be sure to check out this section of the article. Here we have collected the basic regulatory requirements for the installation of gas heating boilers. They are presented in three lists. The first applies to heaters installed in the kitchen or hallway, the second - for those devices that are located in a specially designated room in the house. The last list contains requirements for the boiler room as a building separate from housing.

Diagram of a wall-mounted gas boiler

Connecting wall-mounted gas boilers

You can install a gas heating boiler in the kitchen or in the hallway if the unit’s power is less than 60 kW. The requirements for its placement are as follows.

- The height of the room where the gas boiler is located must be at least 2.5 m.

- The minimum volume of the room is 15 m3.

- For every cubic meter of room there should be 0.03 m2 of window.

- Availability of natural ventilation. It means a regular window. It is acceptable (and even desirable) to have other air circulation systems, but there should always be an option in the event of a power outage.

- The passages between the furniture and to the boiler must be at least 0.7 m wide - without complying with this requirement, servicing the boiler by residents or gas service specialists will be difficult.

Connection diagram for gas and solid fuel boiler

- The door to the room with a gas boiler should go either to the street or to the corridor. It is advisable that the door be treated with a fire-resistant coating.

- The finishing of walls, ceilings and ceilings of a kitchen or corridor with a gas boiler must be made of non-flammable material - for example, tiles. If for some reason this is not possible, a screen made of fire-resistant material should be located behind the heater.

- A floor-standing gas boiler requires a strong base made of non-flammable material and protruding 10 cm beyond the front, rear and side edges of the heater.

Gas boiler in the kitchen. Note the non-combustible material on the wall behind it

If a gas heat generator has a power of more than 60 kW, but less than 350, then it cannot be placed in the kitchen or in the hallway (and given the dimensions of all the equipment and the noise produced, it will also be uncomfortable). There is a need to arrange a furnace room - a separate room where the boiler, boiler, manifold and everything else will be located. Of course, such a boiler room for a private home must meet a set of requirements.

- It is necessary to have natural light and ventilation - a window with a window is required.

- The minimum volume of the room is not less than 15 m3.

- The height of the combustion chamber is 2.5 m, no less.

- The finishing must be made of non-combustible materials. Most often, stone and tiles are used for this.

- The ventilation system must be of such capacity as to provide three changes of air in the room in 60 minutes.

- It is desirable to have a separate entrance door from the street to the boiler room.

- If a double-circuit wall-mounted gas boiler is used (how to choose), then the construction of a small base or foundation is mandatory.

Floor standing gas boiler

Advice! Regardless of the installation location of the heating boiler, be sure to equip it with a sensor that responds to increased gas concentrations in the room.

Gas heating boiler

For boilers with a power of 350 kW or more, a separate boiler room building is required. When equipping it, be sure to pay attention to insulating the hot water pipes running from this building to the main house - this way you will reduce heat loss and save fuel and money. As for the requirements for a separate gas boiler room for a private home, they are as follows.

- The boiler room has its own separate foundation.

- The walls must be made of material with high combustion resistance.

- Interior finishing of floors, walls and ceilings must be non-flammable.

- The presence of a window and a vent is required.

- The width of the door to the boiler room is at least 0.8 m.

- Electrical wiring in the boiler room must be protected from ignition and sparking.

- Under a floor-standing gas boiler, it is necessary to have a substrate with a height of 15 to 25 cm. In its length and width, it must protrude beyond the edges of the unit by at least 10 cm.

- The requirements for the volume and height of the boiler room are the same as in the previous lists.

Basic requirements for installing a gas boiler

Calculator for calculating pressure at the required power of a gas boiler

Exact standards and regulations for placing a gas boiler room in a private house can be obtained from the regional gas service. It is also advisable, before starting the arrangement of the combustion chamber, to familiarize yourself with the documents, the indexes of which are presented in the list below.

MDS 41-2.2000. Instructions for the placement of thermal units intended for heating and hot water supply of single-family and semi-detached residential buildings. Downloadable file (click the link to open the PDF in a new window).

MDS 41-2.2000

SNiP 2.04.08-87. Gas supply. Downloadable file (click the link to open the PDF in a new window).

SNiP 2.04.08-87

SNiP 42-01-2002. Gas distribution systems. Downloadable file (click the link to open the PDF in a new window).

SNiP 42-01-2002

SP 42-101-2003. General provisions for the design and construction of gas distribution systems made of metal and polyethylene pipes. Downloadable file (click the link to open the PDF in a new window).

SP 42-101

How to Perform Preventative Maintenance.

- Check and lubricate the external and internal gas pipeline valves.

- Inspect thermostats in floor-standing boilers.

- Wash or change filter elements.

- Monitor the nozzles, the tightness of the door, and the igniter on floor-standing boilers.

- Prevent the formation of ice near the coaxial pipe on wall-mounted boilers in winter.

- Replace worn parts promptly.

A competent preventive inspection can improve the service life of equipment and reduce gas consumption.

Do you have any questions about installing gas boilers? TeploMoskva specialists will help you decide on the equipment, calculate its optimal power and install a high-quality turnkey heating system. Trust your comfort and safety to professionals!

5 / 5 ( 1 voice )

Solid fuel boiler and electric heating boilers - installation requirements

The second place in popularity after gas ones is occupied by boilers that burn coal, wood and pellets. The requirements for them are less stringent, but they must also be met - remember that an illiterate choice of location for the heater and improper installation can cause a fire in the house. The basic installation standards for solid fuel heating boilers are given below.

- Natural ventilation is required. The glazing area in the room where the solid fuel boiler is located must be at least 0.0008 m2 of window per 1 kW of heater power.

- The chimney that discharges combustion products from the boiler to the street must have the same cross-section along its entire length.

- There must be a distance of at least 10 cm from the edges of the solid fuel boiler to the walls. The walls themselves are made of non-combustible material or protected by a sheet of steel or asbestos.

Some tips regarding room requirements for a solid top

Installation of electric boilers

- If coal is used as fuel, then a dust and carbon monoxide sensor is required.

- Before firing, solid fuel boilers must be installed on the floor, which must be protected from ignition. To do this, tiles or any other non-combustible material are laid there.

- Passages in the room where solid fuel boilers are installed must have a width of at least 0.7 m. There must also be enough space in front of the heater firebox for maintenance, inspection and repair of the product.

- The chimney must have a hatch for cleaning ash.

- It is desirable to have heat-resistant insulation around the chimney pipe.

- To store coal or pellets you need a special bunker.

- To prevent coal dust explosions, electrical wiring protection and sealed lighting fixtures are required.

Solid fuel boiler installation example. Note the location of the device - there are large gaps between it and the walls. You can also notice screens made of non-flammable material on the floor and on one of the walls

Options for connecting to the chimney

As for the electric heater, the boiler room with it is subject to the least stringent requirements. The main thing is that the electrical wiring is designed for the power of the equipment and has fuses. In addition, the installation of a boiler powered by electricity should only be carried out by specialists with the appropriate approvals and permits.

PB 10-575-03. Rules for the design and safe operation of electric boilers and electric boiler houses. Downloadable file (click the link to open the PDF in a new window).

PB 10-575-03

Connecting an electric heating boiler to the network

Video - Boiler room in a private house of 130 square meters. m. Installation secrets

Types of boilers and their operating principles

All solid fuel boilers are divided into several types, which differ in many respects. But according to their main characteristics, they are divided into four types:

- Classic;

- Pyrolysis heating boilers;

- Long burning boilers;

- Automatic;

Classic boilers - the operating principle of a classic solid fuel boiler is that heat is provided by flaming combustion of fuel. It has two doors, through one of which fuel is loaded, through the other the boiler is cleaned of ash and other combustion products. They can operate on two types of fuel - wood and coal.

They differ in the material used to make the heat exchanger; they can be made of cast iron or steel. Cast iron is a higher priority in terms of durability, its service life is more than 20 years. Among the disadvantages, one can note the fact that it is afraid of mechanical shocks and is very sensitive to temperature changes, which can lead to destruction. A steel heat exchanger is more resistant to temperature changes and damage, but its service life is much lower - a little more than 6 years.

Pyrolysis (gas generator) boilers—this type of boiler operates on the principle of pyrolysis, that is, the decomposition and gasification of solid fuel. This process occurs with a closed chimney and a closed combustion chamber. After the wood gas produced by the pyrolysis process is released, it is directed into the burner nozzle, where it is mixed with secondary air, which is pumped by a fan. After this, the gas mixture enters the combustion chamber, where it ignites. Combustion occurs at a temperature that sometimes reaches 1200°, and the process will continue until the solid fuel is completely burned.

Long-burning boilers—in this type of boiler, a long combustion process is ensured by special techniques. Currently, there are two long-burning systems (the Canadian Buleryan system and the Baltic Stropuva), but the second has not found widespread use due to its high cost, complexity of operation and many other technical parameters.

Long-burning boilers can be classified as pyrolysis boilers, but the operating principle will be slightly different. The first system (Burelyan) is a furnace consisting of two chambers, where smoldering and gas formation occur in the lower chamber. After the gas enters the second chamber, it mixes with air and then completely burns it (afterburning the fuel). The design of such a solid fuel boiler is a cylinder with pipes welded into it for half a circle. The arrangement of the pipes from bottom to top ensures good air circulation, thereby increasing heat transfer. They are installed mainly in non-residential premises, perfect for heating a garage or cottage. The price for such a boiler is adequate, it is possible to choose a standard size suitable for a particular area.

The boiler according to the Stropuva system has two cylinders, one of which is located inside the second, according to the matryoshka principle. The entire space between them is filled with water, which gradually heats up. The inner cylinder of the system plays the role of a firebox, into which air is supplied using a distributor. After loading fuel, it begins to burn from top to bottom, thereby heating the coolant. The price stated by the manufacturer, the long burning time, from 2 to 4 days, depending on the fuel, the required cooling of the boiler and further cleaning before re-ignition, double the task and cause inconvenience. Therefore, this type of boiler did not become widespread.

Automatic boilers - in this type of boiler, the process of loading fuel and removing ash is fully automated. The boiler is equipped with a screw or conveyor hopper for fuel supply and automatic ash removal. The automatic coal boiler option involves movement of the fuel combustion layer, which is necessary for complete combustion. To do this, the automatic boiler is equipped with movable grates, or chopping and moving mechanisms. The coolant heating and fuel combustion parameters are provided by forced charging.

The benefits and features of automatic boilers can include;

- Do not require labor-intensive maintenance and close attention to the combustion process;

- Equipped with a temperature regulator included in the kit;

- Many are equipped with a sensor that monitors the temperature in the boiler itself;

- The efficiency of an automatic boiler is up to 85% of the total;

- Long-term operation, limited only by the capacity of the hopper for automatic fuel supply.

It is worth considering that fuel consumption, in particular coal, is much less than in traditional solid fuel boilers.

Choosing a boiler for a boiler room in a private house

It should be understood that it is undesirable to use hot water from the heating system for washing dishes, showering, and washing - its quality may not meet the standards. Therefore, if a double-circuit boiler is not equipped with a built-in boiler, the latter must be purchased separately. For private homes, a model with indirect heating is most often purchased - a sealed tank with good thermal insulation, inside of which there is a spiral tube, and through it, in turn, the coolant from the heating boiler circulates. The device heats drinking water, which is then sent to the household needs of residents of a private house.

Diagram showing the connection of the boiler to the boiler and the principle of operation

When choosing such equipment, you should pay attention to how much hot water the family living in the cottage needs, how long the boiler can prepare it, and how much of the boiler’s power will be spent on this. For two people, a device with a volume of 50-70 liters is enough, for three – 100 liters, and for a larger number of residents or with a higher level of hot water consumption, 150-200 liters will be needed. You can see how to install a boiler yourself (video) in our article.

Preparation of devices

To install and subsequently start up such heating devices, the following tools and materials are required:

- American type detachable connections, ball valves. These elements are used to connect pipes with cold and hot water.

- Self-tapping screws, brackets, dowels.

- Pipes for the heating circuit and chimney.

- Filter with a deep cleaning system on a magnetic basis. This extends the service life of the boiler, since particles of debris and dirt will not enter the internal compartment of the system.

- Three-core cable, sockets, 2A automatic switch.

- Hacksaw, screwdrivers, set of keys, drill, file.

The classic connection diagram for a gas boiler allows even a beginner to install all the necessary equipment.

If plastic, copper or metal-plastic pipes are installed, the list of parts and tools may change.

Connecting all pipes

Choosing an expansion tank for a boiler room in a private house

You may be interested in information: double-circuit floor-mounted gas boiler

The expansion tank is a container in which a movable membrane is placed, dividing the internal volume into two parts - one is filled with coolant from the heating system, the second with inert gas or air. If the pressure in the lines becomes higher than normal, excess water enters the expansion tank and the membrane rises. When cooling, the reverse process is observed. It is highly desirable to use such a container for a boiler room in a private house - its presence will prevent accidents associated with excess pressure in the heating system.

Expansion tank for a boiler room in a private house

Construction of closed expansion tanks

The principle of operation of the expansion tank and its condition depending on the pressure and temperature in the heating system

The expansion tank must have a volume equal to 3-10% of the total volume of liquid circulating in the boiler, supply/discharge pipes and all radiators. This volume, in turn, can be calculated as follows: per 1 kW of heating heater power there are 13-15 liters of coolant. You can read how convector heaters are installed in our article.

Calculator for calculating the volume of an expansion tank for a heating system

As for pipes, shut-off valves and manifolds, they must be selected based on the average temperature and pressure in the lines. Moreover, all products must have a certain “reserve” for these parameters so as not to fail in the event of any malfunction of the heating system.

Components of the collector unit

Proper selection of equipment, selection of the optimal installation scheme and thorough adherence to SNiP and other documented standards are the key to long and trouble-free operation of the boiler room, as well as high-quality and efficient heating in the house where it is located.

Wall mounted

Nuances of installing wall-mounted boilers:

- To operate, you will need two heat exchangers and four pipes, which are necessary for reliable fixation of the pipes. One such element heats the coolant for the heating system, but the second is installed to supply water to the hot water compartment.

- Installing a double-circuit wall-mounted gas heating boiler in a private wooden house is more difficult than in a stone one. The requirements for installing equipment are related to the fact that the basic heat exchanger is connected to the heating, and the second such element is connected to the water supply. Each model has its own network installation points, so you must first read the equipment installation instructions.

Connection to a high-quality automated double-circuit heating boiler should be entrusted to a specialist, since the automation is hidden inside the housing. This rule also applies to the circulation pump, shut-off valves, and three-way valve.

The coolant circulates from the base heat exchanger to the additional compartment and back. According to this scheme, the liquid reaches the optimal temperature for operation, in this case we can safely speak of high efficiency in heating water for domestic needs (heating the liquid up to +85 °C).

Self-installation

To correctly connect all the connecting elements, you need to place the boiler in the prepared place. This could be fireproof slabs, a concrete base, or even a small podium. If a durable wooden podium is mounted, then it is covered with a metal sheet, which at the final stage should protrude beyond the body by at least 28 cm.

Reliable connection of a wall-mounted boiler depends on the correct installation of the unit, so the horizontal level is carefully checked with a building level. If the floor-standing boiler was installed incorrectly, the position is corrected using movable legs, or fragments of a steel sheet can be placed under the body.

Connecting the system

The current standards are designed to control the quality of the system. Experts recommend installing a special coarse filter to ensure guaranteed protection of the boiler from scale and debris. The connection of all parts for heating a private house must be carried out strictly according to the rules with mandatory sealing of all joints. To seal the threads of parts, you can use tow and paint.

If a novice master has not yet figured out how to connect a floor-standing gas boiler to a water main, then he needs to take into account that all actions correspond to standard manipulations with a regular pipeline. Shut-off valves are installed.

It is best to use universal “American” ones with detachable connections for work, since in this case the technician will have the opportunity to quickly replace a broken piece of equipment.

How to calculate heating (boiler power)

The second issue, which requires detailed consideration even before starting any action to connect a heating boiler in a private house, concerns the performance of the equipment. Different types of boiler equipment have their own formulas for calculating optimal power based on the heated area and functionality of the system, as well as weather conditions in the region.

A universal approach (the simplest, but very approximate) suggests starting with a power of 1 kW per 10 square meters of house area. A 15% reserve must be added to them to prevent system overloads.

A more accurate formula for a gas boiler looks like this:

MK = Shome*0.1*UMK, where:

- MK – required power of boiler equipment;

- Shouse – area of the house;

- UMC - specific boiler power - a coefficient that takes into account the climatic characteristics of the region where the facility is located. The MCI is assumed to be 0.7–0.9 for the south of Russia, 1–1.2 for the middle zone and 1.5–2.5 for the north and Far East.

If the house was made according to an individual project or there are doubts about the quality of its thermal insulation, you can use the formula taking into account actual heat loss. In this case, the required power is determined as the product of these losses and the safety factor (from 15 to 20%, that is, 1.15–1.2).

The heat loss itself can be calculated using the formula:

TD = Vp.*Pt*Kr/860, where:

- Vp. – the total volume of each heated room in the house;

- Рt – temperature difference inside and outside the home (average in the cold season);

- Kr – dispersion coefficient (from 3 for wooden houses to 1–1.9 for brick houses).

Important. In any calculation (using a formula or “by eye”, focusing on a similar house with heating already installed), it is important to include a reserve of at least 10%. If the rooms of large premises have doors that are constantly used, this reserve should be increased by 2–5%.

Chimney installation

The operation of gas heating boilers involves the construction of holes in the roof and ceiling to remove harmful gases. Only after this a special adapter is carefully placed on the outlet pipe, which in the future will be connected to the chimney.

To operate wall-mounted models, it is prohibited to use corrugation, only sheet material. After fixing this part, they proceed to the tee and a specific inspection, through which it will be possible to inspect the chimney and clean it of soot during operation of the equipment. Only compliance with all installation conditions helps to extend the life of the boiler.

Attention! The chimney pipe brought to the roof surface is raised to the optimal height, and a special tip is installed that protects the chimney from rain and snow.

Boiler room in the basement of the cottage

Launch

Boiler installation

Before the first start-up, gas technicians check the entire system for leaks, the visually normal condition of the device and the correct connection of communications. The heating system is then filled with water. A special system replenishment unit is already built into modern gas appliances, so the procedure does not require additional effort.

Stop filling when the pressure gauge reads 2 atmospheres. Then the accumulated air is released from the main components, circulation pump and radiators. As soon as air stops coming out of the system and water starts flowing, the equipment is ready to start at full power.