Unfortunately, we live in an area where we have to think about how to stay warm in winter. But this applies not only to people, but to everything that surrounds us on the farm. It is very important to know how to insulate a water pipe. If this is not done on time, then at some point you may be left without water supply in the house. And trying to carry out repair work in the cold season is not only unpleasant, but also quite labor-intensive. Let's take a closer look at how to insulate a water pipe with your own hands.

Primary requirements

Water pipe in the ground

Until a certain point in construction, materials were used that were at hand. But human needs and demands are becoming greater, so the approach to the components must be appropriate. If we talk about what kind of insulation should be used for pipes, here are the main requirements that apply to it:

- Durability. An important factor, because insulation is not carried out with a view to a year or two. This would require frequent excavation work, which is quite exhausting.

- Strength. If the pipe is in the ground, then there is sufficient pressure on it. If this is not taken into account, then the insulator will simply lose its elasticity and its effectiveness will be reduced to zero.

- Corrosion resistance. Exposure to external factors can be detrimental to some coatings, so either the insulation itself must have an inert layer, or care will need to be taken to have one.

- Heat capacity. It should be minimal. This means that the temperature of the insulation should not change when exposed to external factors.

- Ability to absorb water. It is desirable that the material has a water-repellent effect. This will make it possible to prevent the penetration of moisture from the soil or during precipitation. Otherwise, when it accumulates, the protective layer may be destroyed due to freezing.

- Fire resistance. This factor plays a very important role when used indoors, as well as in cases where the water supply is made of plastic pipes.

- Maintainability. It’s good if if any area is damaged, it can be replaced modularly, without involving the rest of the canvas.

- High temperature resistance. This indicator will be indispensable when it is necessary to supply hot water from the house to another room.

Must be able to withstand pressure

Characteristics of insulation ↑

When choosing the best option for yourself on how to insulate a pipe, you should know the main characteristics, advantages and installation features of the materials used for this:

Merilon is used for insulation and protection against condensation

Merilon. Made of polyethylene foam.

Has good heat-insulating qualities. Prevents the occurrence of condensation. It is used both for laying in trenches and for protecting pipes indoors.

The material is easy to work with and is light in weight. There is a cut along the entire length of the Merilon tube; once cut to the end, you can put it on the pipe. Merilon will need to be secured with clips, tape or other means so that the tubes do not move.

When working with fiberglass, safety precautions must be observed.

Fiberglass. A somewhat outdated method of insulation, although it has an optimal set of characteristics. It has one of the highest thermal insulation rates. The main disadvantage is the possibility of destruction from a humid environment, so it is necessary to attach an insulating material to it.

Working with fiberglass is quite simple, but labor-intensive compared to more modern materials. It needs to be cut into strips of the required length and wrapped around the pipe, then secured and covered with insulating material. In this case, you need to ensure that the insulation layer is the same on all sections of the pipe from the well to the house.

The presence of turns, tees and other fittings makes the foam shell easier to install

Foam plastic. Has high thermal insulation, moisture resistance, durability (does not collapse in a humid or chemically active environment). To insulate pipelines, today they produce special foam “shells” that are easy to put on the pipe and secured with special rivets.

The installation method is one of the simplest and fastest. You can also use sheets of foam plastic laid on top of the main line running from the well to the house. They will create a barrier to the penetration of cold.

You can minimize installation time by choosing foil-coated basalt fiber

Basalt fiber. We can say that the material combines all the positive characteristics of the types described above, due to its structure: fibrous, but dense. It is characterized by high cost.

Basalt has higher characteristics than Merylon. Compared to fiberglass, it benefits from quick installation, while the insulation layer will be uniform along the entire length from the well to the house. If there are bends in the line, the foam may need to be cut into smaller pieces, which increases the number of joints (possible places for cold air to enter), and the basalt will easily mold to the shape of the pipe.

What can be used

In principle, any material listed below can be used to insulate water pipes. But the choice should fall on the one that is most suitable for specific conditions. It may not meet absolutely all the requirements listed above, and this is not always necessary.

Mineral wool and polyethylene foam

One of the options that has been used for quite a long time and is constantly being improved is mineral wool. There are several varieties of it. Glass wool is made from glass, about 35% (usually recycled glass containers, etc.), soda ash, sand and other additives. Therefore, it can be called quite environmentally friendly. Its positive aspects are:

- minimal thermal conductivity;

- ease of installation;

- light weight;

- ease of transportation;

- not food for rodents;

- protection from noise exposure.

The disadvantages include:

- poor resistance to moisture, which leads to loss of thermal insulation properties;

- the need to use personal protective equipment during installation;

- the fiber is easily damaged and breaks with little force applied;

- shrinkage may occur over time;

- instability to fire.

Basalt wool

A peculiar subspecies is basalt wool. It is made from crushed stone. In addition to all the advantages listed above, we can highlight resistance to high temperatures, as well as immunity to moisture.

Foam rubber

Foamed rubber is a synthetic product that appeared on the market not so long ago. It was developed specifically for insulating pipelines indoors and outdoors. Its characteristics:

- high elasticity;

- resistance to high temperatures;

- moisture resistance;

- ease of installation;

- vapor tightness;

- self-extinguishing when exposed to an open flame.

If we talk about the disadvantages, then this is most likely only the difficulty of delivery, because it takes up a fairly large volume and is light in weight.

Insulation for polyethylene foam pipes

Polyethylene foam is often used as a substrate for various floorings. But some of its types are designed specifically for pipeline insulation. The choice of masters falls on him because he:

- does not support the development of bacteria and fungi, which is very important for a humid environment;

- easy to install;

- has low weight;

- UV resistant;

- fireproof;

- does not require special installation skills.

With prolonged use, the material may shrink to a certain extent, which reduces its original performance. In addition, certain problems arise when sealing seams. It is very difficult to achieve a perfect fit in some cases.

Expanded polystyrene

Penoplex and expanded polystyrene have many similar properties. They are derivatives of the polymer component. This means that they practically do not interact with organic matter. These materials:

- are easy to install;

- are light in weight;

- have zero heat capacity;

- resistant to moisture;

- characterized by compressive strength.

At the same time, the products are very unstable to open fire. Rodents love to damage such insulation materials.

Foamed polyurethane

Polyurethane foam shells are products in the form of semicircles, which are put on like a cover on a pipe. Usually it is covered with a protective layer of waterproofing on top. They use it relying on:

- ease of selection for a specific diameter;

- lack of thermal conductivity;

- light weight;

- assembly in the form of a constructor;

- possibility of repeated use;

- the possibility of carrying out insulation work even in winter.

The downsides are: sufficient transportation costs, as well as a maximum temperature limit of 120°C.

Warming paint

A relatively new, but quite interesting development is insulation using special paint. Even a small layer of it has good insulating properties. If it is increased several times, then losses will be significantly reduced. This product:

- easy to apply on surfaces of any shape;

- has excellent adhesion to metal;

- not affected by salts;

- endowed with anti-corrosion properties;

- eliminates the formation of condensation;

- does not place additional load on the pipes;

- after coating, all valves or inspection units remain freely accessible;

- ease of repair;

- high temperature resistance.

Among the negative aspects, one can highlight the need for additional insulation in case of severe freezing of the soil or the external location of water supply pipes.

Thermal insulation for outdoor heating pipes

A variety of insulation materials makes it possible to choose exactly the one that is best suited for a specific location of application (outdoors, in the ground, in the basement, in the attic) and budget.

The selection of a heat insulator is carried out taking into account the following factors:

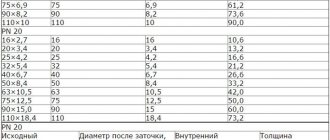

heating system pipe diameter;

operating conditions (location of the heating system);

average heating temperature of the coolant;

thermal conductivity indicator of insulation (the lower, the better);

water absorption rate. Shows the ability of the insulating material to perform its functions in a humid environment;

resistance to combustion, biological and chemical activity, ultraviolet radiation and other environmental factors;

life time;

ease of installation (provided that sufficient tightness is ensured);

price.

Insulation with mineral wool

The process of insulation with mineral wool

This method is more suitable for indoor use, as well as for above-ground street water supply. The sequence of actions will be as follows:

- The total material consumption is calculated. In addition to the cotton wool itself, you will also need waterproofing in the form of thick construction foil or ultraviolet-resistant polyethylene.

- The pipe needs to be treated well. To do this, it is cleaned, degreased and covered with enamel. This step is necessary so that the pipe under the insulation does not begin to collapse.

Mineral wool insulation schemeNext, you should prepare segments from one sheet. Their size should be such as to wrap the pipe once. The cotton wool must be laid so that it fits tightly to the plane. In this case, the required level of insulation will be ensured.

- Aluminum tape can be used to temporarily fix the insulation.

- The insulation also needs to be inserted into the holes where the pipe enters the wall; often this is where freezing occurs.

- After the entire area has been covered, you will need to provide protection for the cotton wool itself. To do this, it is wrapped in plastic film or aluminum foil. The sheets must be laid so that there is an overlap of 15 cm. This will prevent moisture from penetrating into the middle and destroying the insulation.

- For additional fixation, reinforcement is made using a nylon cord or steel knitting wire, which is applied like a snake to the entire pipe.

Mineral wool cylinders

If you use ready-made elements made of mineral wool, which come in the form of cylinders, then they are put on the pipe, and the joints are well glued using aluminum tape. To better insulate the faucet, you need to unscrew the handle from it. Cut a hole in the insulation for the fastening element. Put it on, and after that screw on the handle.

Material selection

*

Questions about how to insulate a metal or plastic water pipe on the street, what materials are cheaper and what free options are available are what are primarily of interest to those who independently build or maintain their home. When choosing insulation, it is important to understand that using highly specialized materials is more convenient, but they are a little more expensive. First of all, let's look at free insulation options.

Free insulation for external water supply

One of the cheapest, and for many people completely free, insulation is sawdust. Their use allows you to minimize the cost of insulation, but complicates the process a little, because To insulate the water supply from the cold using sawdust, you will need to additionally make a box into which they are poured.

Sawdust

Manure can be used as free insulation for water pipes. During the process of rotting manure, a large amount of heat is released. It can not only protect the water supply from the cold, but also warm it up a little. As with sawdust, manure requires an additional box.

In some cases, slag is used as insulation. It is porous, contains a large amount of air and does a good job of protecting the pipeline from freezing. In private houses where individual heating boilers are installed, slag is available in sufficient quantities, so using it you can not only minimize the cost of insulation, but also save money, because Removing slag requires certain costs.

Insulation with foam rubber

Advantages of foam rubber

This material, like the previous one, can be produced in sheet modification and ready-made tubes. The advantage of the first option will be the ability to independently select the thickness of the insulation for any pipe. In many ways, the installation is similar to what was described for mineral wool. The difference is:

- Possibility of installation not only on the surface or indoors. The material tolerates staying in the ground very well. But at the same time, it will definitely need to be additionally wrapped in plastic film.

- In order to better fix the sheets wrapped around the pipe, you can use special glue or double-sided tape. A piece of the required length is measured and cut. It wraps around the pipe. The ends are coated with the compound, after which they are pressed tightly until they set. Individual elements can be fixed together in the same way. In this case, you will get a monolithic structure. For greater reliability, you can also use aluminum tape.

- When using ready-made tubes when passing corners, it is necessary to create a small seal in the place where it will bend. If you do not do this, the wall may stretch and its thickness will be less, which will increase the likelihood of freezing.

The following video shows the technology of thermal insulation of pipes with foam rubber:

Glass wool

Those who have been involved in repair and construction work for a long time remember glass wool. It is still used at construction sites for both thermal insulation and sound insulation. The option, of course, is quite cheap, but do not forget that this material penetrates into clothing and then into the person himself, causing severe itching and painful sensations. Today, glass wool is sold in strips or slabs that are wound into a roll. It is for this reason that glass wool has gained particular popularity among builders.

Glass wool

It is worth adding that this insulation has a relatively low density, therefore, it is better not to use it without additional insulators. After the pipe is insulated, roofing material or fiberglass should be placed on top.

Return to content

Penoplex insulation

Penoplex

When using this material, the least amount of time will be spent. This, like the previous method, can be used for pipes that are laid in various conditions. The degree of moisture absorption is minimal. This means that penoplex can be in the ground without harming it. Products made from it are usually the so-called shell. These are two half cylinders. In order for them to fit together well, a special tongue-and-groove lock is provided at the ends. The radius of the inner circle is equal to the outer one on the pipe for which the specific sample is intended. During installation, they can be coated with suitable glue or reinforced tape. In this case, there is a guarantee that moisture will not seep inside and destroy the pipe.

Protection of wells and wells in winter

In winter, water comes into the water supply system at the dacha from a well, a well or the main water supply system, if one is available. Most often, the source of water in dachas, and even in the private sector, is an ordinary well of not very deep depth. The advantage of such a source is that a high-power pump is not required to supply water.

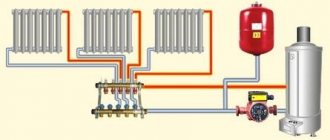

In addition to the pump for such a water supply system, it is advisable to use a hydraulic accumulator, which is a large-capacity barrel. It accumulates a certain supply of water, which can be used at any time. This is especially true during a power outage.

In addition, the hydraulic accumulator helps protect the water supply from water hammer and pressure surges. It and the pump are best installed in a warm utility room where they can be easily maintained.

In addition to pipes, water sources need protection from frost: wells and wells. In order to prevent the water in the well from freezing, a caisson well or pit with a depth of one and a half to two meters is installed, where a person can safely go down the stairs to carry out maintenance on the pump or the well itself.

Caisson well or pit

The walls of the pit can be made of brick, plastic, cast from concrete and made of concrete rings.

They must be sheathed with foam boards, the thickness of which reaches more than 10 cm, or lined with mineral wool. The top of the well must be covered with a powerful lid, well insulated with glass wool or other material. Waterproofing is also carried out to prevent water from entering the coffered well.

Water in wells lined with wooden beams rarely freezes in winter. To protect such wells, a thick protective wooden cover is installed during the winter.

But concrete wells require quite powerful insulation, especially if the water is above the freezing level of the soil. To do this, the well ring is dug out to the freezing level, and then insulated with polystyrene foam compressed in the form of half rings.

Before starting work, the seams in the concrete are treated with a special sealant, then foam plastic is installed. To protect the insulation from sunlight, it is covered with plaster or paint.

It will be useful to read:

Insulation with paint

Some paints can be applied over rust

It seems that scientists have finally managed to develop a unique method that requires minimal time, effort and money. But it’s worth mentioning right away that for pipes that are laid on the surface or above ground freezing, this option is more likely to be an additional solution than the main one. If such paint is used, it will be possible to reduce the thickness of the main insulation. In order to treat the surface, you will need to do the following:

- Before opening the container, it is necessary to check the integrity of the seals. This will guarantee that the material arrived in factory quality.

- The consistency of the composition is such that the liquid base sinks to the bottom, and the solid component rises to the top. Therefore, before starting any work, it is important to mix. If it is carried out using a mixer or drill, then the speed of the tool should not exceed 150 per minute. You need to move the nozzle not only in a circular motion, but also in a reverse translational motion.

- If the paint has been standing for a long time, it can be diluted with distilled water.

- Application to the surface can be done with an ordinary brush or a special sprayer. If you use the latter, it is important to ensure that all modules will have no filters. This is very important to do, because... the paint contains small spheres, which are the secret component. If they pass through the mesh, they will be destroyed, which will turn the composition into ordinary facade paint. Spraying should also be carried out at a pressure not exceeding 8 atmospheres.

- Some paints can be applied directly to rusty surfaces. This will avoid preparatory work.

Note!

If the liquid has stood for more than 5 minutes without being used, then it must be stirred again for a few seconds until a homogeneous mass is formed.

Important conditions for laying underground water supply

Prerequisites for water freezing in pipes arise even at the stage of installation of external water supply. Construction rules directly indicate that the depth of underground water supply lines must be below the standard freezing point of the soil.

For our northern country in most regions this value exceeds 1.2 meters. You usually don’t want to dig such a deep trench and take it as a truth (hope) that the soil does not freeze to such a depth, and as a result, the water supply is placed at a depth of half a meter, thereby making a grave mistake. One winter, the water in it will definitely freeze. And digging frozen soil in winter... Draw your own conclusion.

Freezing depth by region.

Heating cable

Self-regulating cable

The use of an active heating system brings with it a huge number of advantages. Thanks to it, it becomes possible not only to prevent freezing, but also to defrost an area that has already been subject to it. You need to choose from two main types of such products:

- self-regulating cable;

- resistive cable.

Each of them has a number of advantages over the other. The first conductor operates completely automatically. Its design implies varying degrees of heating in a certain area. This is due to how the internal layer between the cores is arranged. When the temperature is low, resistance drops and heating increases, and vice versa. Such a wire can be laid even on an uneven area, and its performance will not be affected in any way.

The resistive cable has a constant heating temperature, so uniform heating of the entire area can be ensured. It requires more attention during operation, but its cost is significantly lower than the previous option. By design, it can be with one core or two. The second one is easier to install.

Resistive single-core

There are two main ways to install the cable:

- Interior. In this case, the conductor is placed directly into the pipe and, in contact with water, prevents it from freezing.

- External. The cable is located along the outer contour. For such options, a wire with a flat configuration is usually selected, since it is more difficult to damage and takes up less space.

Products have different power densities, which is also important to calculate correctly. In the first installation option, they usually stop at a value of 10 W/m. In order for a cable located outside to have the required efficiency, two basic rules must be followed:

- for pipes with a diameter of up to ¾" a capacity of 17 W/m will be required;

- for diameters from ¾" to 1½" - 27 W/m.

Higher power is also available, which can reach 31 W/m, but such values are usually used to prevent damage to sewer pipes that have a diameter of 110 mm or more.

Connecting the heating cable

If you decide to carry out external installation, then you should proceed as follows:

- A place is determined where the cold cable can be powered.

- A separate machine is mounted in the power panel. The rated withstand current should be less than that of the main one.

- A conductor is laid from the machine to the installation site of the thermostat. It is important that its cross-sectional area is sufficient for the heater power.

- Using a hammer drill or drill, a box is mounted on the wall where the thermostat will be located. It is better to place it indoors. This will allow for faster setup and will also eliminate operational failures.

- Next, a hole is drilled in the wall through which the heating cable is laid. There is no need to connect it yet; it is enough to leave a certain part indoors.

- The pipe must be painted and also degreased.

Installation of heating cable outsideThe conductor can be laid along the pipe in a straight line, or it can be wound like a snake. The second option is more effective, but will require a longer cable length. You will need to make a figure 8 loop around the tap.

- In order to fix the material on the pipe, you will need aluminum tape. It can be used with periodic arrangement. If the heating cable is laid in a straight section, then it must be completely covered with adhesive tape.

- It will also be necessary to connect a temperature sensor to the supposedly coldest section of the pipe if a resistive cable is used. The wire from it is connected to the thermostat.

- From above, the entire surface is covered using one of the types of external insulation.

- If a single-core resistive cable was laid, then it is necessary to return the second end in order to loop the entire network, or stretch the cold cable to the second edge.

- Once everything is in place, you can begin connecting the power. The circuit will be the same for two types of conductor. The first step is to remove the outer insulation. This should be done approximately 6–10 cm. The shielding braid is gathered into a bundle or the drainage core is trimmed. The insulation for the conductive cores is removed. One of them is shortened by 1 cm compared to the other. Two pieces of heat-shrinkable tubing are placed on the main cable. One should be of such a diameter that 2 cores fit into it, and the other - so that 3 can fit in. One more piece is put on each core. Using metal sleeves, one core of the cold cable is connected to the core of the hot cable. Sealing is carried out using a heat-shrinkable tube. The same procedure is performed for the second element. The cambric is pulled over the top and compacted using a lighter or hair dryer. A ground connection is made with the shielding braid. The thermotube is also shrinked. And the final step is to place all the connections together inside the last piece of tube.

- The cold cable is connected to the thermostat. The signal wire from the sensor is also connected to it.

Sealing a self-regulating cable

In a self-regulating cable, it is important to take care of high-quality sealing of the second end. To do this, a heat-shrink tube is put on it, heated with a hairdryer, and the end is tightly compressed with pliers.

Note!

For conductors with independent temperature adjustment, special thermostats are produced that are already built into the cold cable. They turn on when the lower limit reaches +5°C, and turn off at +15°C. All you need during assembly is to connect them together and plug them into a power outlet. There is no need to purchase additional modules.

Internal installation of heating cable

Internal installation can also be done independently. For these purposes, all the necessary adapters are usually included with the cable. You can also easily purchase them yourself. The process will be like this:

- A convenient place is selected to insert the conductor into the pipe.

- The first step is to install a tee through which the dive will be carried out.

- The end of the conductor that will be inside must be well sealed. To do this, the top insulation is removed by 1 cm. The shielding braid is collected into a bundle and bit off using side cutters. A 6 cm long heat shrink tube is cut off. Half of it is put on the wire, heated with a hairdryer, and the protruding part must be compressed using pliers. A special silicone plug is put on top, and again everything is secured using heat-shrinkable cambric.

- The conductor is passed through a fixing sleeve, a silicone seal, 2 metal washers and a clamping nut. It fits into the pipe.

- The part required for connection is left on the surface.

- A locking mechanism is clamped into the tee.

- The connection to the electrical part is carried out in the same way as described above.

Installation diagram inside the pipe

Note!

It is imperative to take care of high-quality grounding. If this is not done, then the slightest breakdown can cause serious harm to any of the residents of the house. Additionally, you can think about installing an RCD. This device will detect the slightest leak and stop the power supply.

Heating cable entry

Video

Heating with electric cable

We can’t help but talk about a new technical method. A special cable is used for this. Today you can find various versions of such a device on sale.

The use of a cable provides some advantages: the pipeline itself does not need to be laid to a significant depth; you can independently turn the heating on and off. Today, such systems are available in two versions. The cable can be placed inside the pipe or wrapped around the outer surface. In any case, the result will be unchanged, your water supply will not freeze even in the most severe frosts. There is one feature here.

The cable will run on electricity. This means that your electricity bill will increase slightly. Everything will depend on how correctly you use such a system. The cable should not be plugged in all the time.

If there is a slight minus outside, then the pipes will not freeze, which means the heating system can be turned off. When it is severely frosty outside, then the cable must be connected to power. This is especially important at night. During this period, little water is used, which means it is most likely to freeze.

Other ways to prevent freezing

Another method that is successfully used in areas where the winter temperature drops below zero to critical values. It is called the umbrella or air gap method. Its essence lies in the operation of physical laws. The temperature underground will always be higher than outside in winter. In order to use this useful property, a larger diameter pipe is first laid, which will serve as a sleeve. The one that will serve as a highway is placed in it. The trench is filled with soil. The layer that remains between the two pipes will compensate for the temperature difference and prevent freezing.

Pipe in pipe

High blood pressure can also help in such a situation. The usual pressure value for a household network is 2 atmospheres. Water stops freezing at 4 atmospheres. On a section of pipe that will be located at negative temperatures, it is necessary to ensure this level. To do this, a special storage device and a supercharger are installed on one of its parts. A gearbox is mounted at the other end, which will prevent damage to household appliances.

What methods are used to protect water pipes from freezing?

It doesn’t matter whether a private house receives water distribution from a central collector (and this also often happens), or whether an autonomous source (well or borehole) will be used, a pipe laying area is still expected where negative external temperatures are likely. The only exceptions can be considered those rare cases when the well is drilled directly in the basement of the house. And even then, on the way to the points of consumption there may also be sections where the water supply runs through an unheated basement or basement. But in order to disable the water supply system, a very short uninsulated section is enough.

What approaches are used to protect water pipes from freezing?

- First of all, if possible, the water main should be laid below the freezing level of the soil in a given region. At this depth of the route (and it is taken with a reserve - the freezing level plus another 300÷500 mm), the temperature should never reach negative values. That is, the probability of getting an “ice jam” tends to zero.

Protecting a water pipe from low temperatures may involve laying a route below the freezing depth of the soil.

However, this approach is not always fully feasible. In some regions, the soil freezes to a very significant depth, and digging such deep trenches significantly complicates the implementation of the project. It is not uncommon to find areas where the soil characteristics completely exclude such an arrangement of pipes.

In many regions, the level of soil freezing reaches very significant depths. It is not always possible to dig such deep trenches for laying water pipes.

In addition, the pipe, one way or another, must be lifted up in order for it to enter the house. And in any case, it will pass through “dangerous” areas - the upper sections of the route, passage through the foundation, through the basement, basement, or even just an unheated room, where negative temperatures can be observed in winter.

How to build an autonomous water supply system in a private house

Much depends on the source of water, its location on the site, distance from the residential building, the climatic conditions of the region and the design features of the building itself. more about how to bring water from a well into a house in a special publication on our portal.

- Those same “problem areas” of the water supply route can be artificially heated using electrical energy. For these purposes, special heating cables are used, which are laid on the pipe walls under a layer of thermal insulation, or even placed directly in the pipe cavity.

The heating cable can be laid along the outer walls of the pipe, under a layer of thermal insulation, or located directly in the pipe.

There are many varieties of such cables on sale these days, as well as automatic heating control units that turn on the power when required.

How to organize heating of water supply?

The advent of heating cable systems has eliminated many problems when organizing autonomous water intakes in private homes. By the way, if you strictly follow the instructions of the manufacturers of such products, then heating the water supply yourself. More details can be found in a special publication on our portal.

- In the basement, basement or other areas of the house, where negative temperatures are not excluded, laying a “thermal satellite” is sometimes practiced. This is a pipe running parallel to the water supply and enclosed in a common thermal insulation shell, which is nothing more than one of the branches of the general heating circuit of the house.

One pipe can be used for water supply, the second - as a thermal satellite connected to the heating system of the house.

Such a hike, of course, complicates both the plumbing and heating systems. But you no longer have to worry about the integrity of areas with such heating. True, only when the heating is on.

- One of the radical ways to prevent water from freezing in pipes is to maintain a constant high pressure in them. To do this, the autonomous water supply system is supplemented with special equipment, and the pipes themselves must be able to withstand these increased loads.

The approach, although effective, is quite complex in organization and in everyday use. In addition, it turns out to be more expensive in terms of energy consumption. Such systems have not gained much popularity.

- The most common method is thermal insulation of pipes, that is, what this publication is essentially devoted to. The use of various insulation materials helps to avoid freezing of the water supply system, if, of course, the material and thickness of the insulation are selected correctly.

All this will be discussed in more detail below.

A special type of insulation sometimes includes the creation of a stationary air gap between the water pipe and the casing, which prevents direct contact of the pipe with the ground. In a nutshell, this can be described as a “pipe within a pipe.”

An integrated solution - a “pipe in a pipe” with a layer of insulation between them and forced heating with an electric heating cable

But, to be honest, this method is not used in its “pure form”. The hollow space, at least in order to accurately position the water pipe inside the outer shell, is still filled with insulating material. Which, in principle, is insulation only because of its ability to create a layer of immobilized air. So the result is classic thermal insulation of the pipe with the creation of an external casing. And by the way, it is always welcome to protect both the insulation and the pipe itself from mechanical influences, from ground moisture, and from damage that can be caused by rodents living underground, attracted by the winter heat.

In practice, a combination of most of the listed methods for protecting water pipes from freezing is usually used. That is, they try to deepen the route from the well or well as much as possible, insure the most vulnerable areas with additional heating and, of course, provide reliable thermal insulation, usually along the entire length of the water pipe.

Such an integrated approach is also necessary for the reasons that even high-quality insulation often does not guarantee complete protection of the water supply system. The table below shows the volumes of heat loss calculated for pipes of different external diameters, enclosed in a layer of thermal insulation of different thicknesses. The thermal conductivity coefficient of the insulation is taken to be average, characteristic of most thermal insulation materials used in this role - 0.04 W/(m×K).

Naturally, the amount of heat loss depends directly on the difference in ambient temperatures and the liquid pumped through the pipe. The table shows several options - from Δt = 20 ℃ to Δt = 60 ℃. For example, if the temperature of water from a well (well) in winter is +2 ÷ 4 ℃, and in the winter the pipe passes through the base of the house, frozen to - 15 ℃, then the temperature difference can be considered 20 degrees.

| Insulation layer thickness | Temperature difference (Δt, °С) | Pipe outer diameter (mm) | |||||||||

| 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 150 | ||

| Average heat loss (W per linear meter of pipeline) | |||||||||||

| 10 mm | 20 | 7.2 | 8.4 | 10 | 12 | 13.4 | 16.2 | 19 | 23 | 29 | 41 |

| 30 | 10.7 | 12.6 | 15 | 18 | 20.2 | 24.4 | 29 | 34 | 43 | 61 | |

| 40 | 14.3 | 16.8 | 20 | 24 | 26.8 | 32.5 | 38 | 45 | 57 | 81 | |

| 60 | 21.5 | 25.2 | 30 | 36 | 40.2 | 48.7 | 58 | 68 | 86 | 122 | |

| 20 mm | 20 | 4.6 | 5.3 | 6.1 | 7.2 | 7.9 | 9.4 | 11 | 13 | 16 | 22 |

| 30 | 6.8 | 7.9 | 9.1 | 10.8 | 11.9 | 14.2 | 16 | 19 | 24 | 33 | |

| 40 | 9.1 | 10.6 | 12.2 | 14.4 | 15.8 | 18.8 | 22 | 25 | 32 | 44 | |

| 60 | 13.6 | 15.7 | 18.2 | 21.6 | 23.9 | 28.2 | 33 | 38 | 48 | 67 | |

| 30 mm | 20 | 3.6 | 4.1 | 4.7 | 5.5 | 6 | 7 | 8 | 9 | 11 | 16 |

| 30 | 5.4 | 6.1 | 7.1 | 8.2 | 9 | 10.6 | 12 | 14 | 17 | 24 | |

| 40 | 7.3 | 8.3 | 9.5 | 10.9 | 12 | 14 | 16 | 19 | 23 | 31 | |

| 60 | 10.9 | 12.4 | 14.2 | 16.4 | 18 | 21 | 24 | 28 | 34 | 47 | |

| 40 mm | 20 | 3.1 | 3.5 | 4 | 4.6 | 4.9 | 5.8 | 7 | 8 | 9 | 12 |

| 30 | 4.7 | 5.3 | 6 | 6.8 | 7.4 | 8.6 | 10 | 11 | 14 | 19 | |

| 40 | 6.2 | 7.1 | 7.9 | 9.1 | 10 | 11.5 | 13 | 15 | 18 | 25 | |

| 60 | 9.4 | 10.6 | 12 | 13.7 | 14.9 | 17.3 | 20 | 22 | 27 | 37 | |

As you can see, even with a fairly thick insulation layer of 40 mm, a pipe with a diameter of 32 mm under the example conditions taken above will lose almost 5 W of thermal energy per linear meter. It doesn’t seem like much, but if there is no water movement in the pipe for several hours, an ice plug may appear in such an area. This means that these heat losses will have to be replenished in one way or another.

That is, when designing your water supply system, you need to carefully analyze theoretically vulnerable areas, and strengthen thermal insulation on them (if possible) or take steps to heat these “dangerous” areas. Which, by the way, are usually located in close proximity to the house or even directly in it. Although, it also happens that the entire route from the source to the house has to be heated, since, for example, rocky soil or high groundwater makes it impossible to dig trenches below the freezing level.

But even in this case, the importance of pipe insulation only increases. The heat generated by the heating system should not be wasted, but should fulfill its intended purpose. And without high-quality thermal insulation it is impossible to achieve this.