When building a house, the most important task is its thermal insulation, the quality and durability of which determines not only comfort, but also heating costs. In suburban housing construction, ecowool is becoming an increasingly popular thermal insulation material, the pros and cons of which will be discussed in detail in this article, along with issues of installation and the feasibility of use on different structures.

Ecowool can be used to insulate almost all parts of the house Source green-agency.ru

Table of contents

What are we comparing?

Designed to keep you warm. Seamless installation. Not like fish in water Density and weight Does not burn or does not support combustion? Do you need a vapor barrier? Silence in the home Conclusion Ecowool is a modern thermal insulation material with a low shrinkage rate, good resistance to water, and has high sound insulation properties. A similar characteristic can be found about almost any thermal insulation product, but it is only possible to evaluate how effective the material really is by comparison. In this article we will try to compare ecowool with the most common insulation materials.

Ecowool

Specifications

To compare the quality indicators of mineral wool and ecowool, the characteristics and properties must be considered first.

Thermal conductivity

The main task of insulation is to prevent or minimize uncontrolled air exchange between the room and the street. This property is clearly demonstrated by the thermal conductivity coefficient: the lower it is, the more efficient the material.

| Insulation | Coefficient |

| Ecowool | 0,038…0,041 |

| Glass wool | 0,03…0,052 |

| Slag | 0,46…0,48 |

| Stone wool | 0,077…0,12 |

In the battle “ekovata or isover” it is difficult to determine the winner. All except cinder fiber have a similar ability to retain heat in a room.

The thermal conductivity of ecowool does not change when exposed to moisture: the fibers easily evaporate it and acquire their original appearance and properties. The same cannot be said about mineral wool: at the slightest wetness, the thermal protection is reduced, water evaporates poorly, the structure begins to freeze, and the shape of the mat is not restored.

Airflow

An important indicator demonstrating the effectiveness of insulation when exposed to strong winds. The lower the value, the warmer the room will remain.

- Ecowool – 75×10 -6 m 3 /m*s*Pa

- Mineral wool – 120×10 -6 m 3 /m*s*Pa.

Flammability

Fire safety is one of the most important operational characteristics. It is necessary to distinguish between the ability of a material to burn and smolder.

Does ecowool burn or not? – this ability of paper is suppressed by treatment with fire retardants. The material melts under the influence of temperatures, so it should not be used near fire sources.

Mineral wool does not ignite, but smolders and releases dangerous binders.

What are we comparing?

For comparison, let's take insulation materials that are often used to insulate a house: basalt wool and fiberglass-based mineral wool. The choice fell on these materials, since their scope of application is quite wide. They are suitable for insulating walls, floors, roofs, soundproofing partitions, etc.

- Ecowool - 80% consists of cellulose fibers, the raw material for which is recycled paper. The remaining 20% is boric acid and borax. The latter is a fire retardant, which increases the fire resistance of the material. The insulation is made in the form of a loose mixture.

Insulation of the facade using ecowool

- Basalt mineral wool is made from straightened rocks with the addition of phenolic resins; the material is produced in the form of slabs.

Basalt mineral wool has a characteristic brown tint

- Fiberglass mineral wool is made from molten glass or sand. It has a fibrous structure. Often produced in roll form.

Personal protective equipment is required when working with fiberglass

Which insulation to choose - cellulose or mineral wool?

Mineral and cellulose wool (ecowool) are two popular insulating materials that are used as insulation. Thanks to their use, a reduction in heat transfer and, accordingly, the cost of heating a particular facility is achieved.

Mineral wool

This type of insulation is distinguished by a high level of heat and sound insulation, due to which it is widely used in industry. They are isolated:

- interfloor ceilings, walls and facades;

- surfaces heated to high temperatures;

- partitions, roofing structures and much more.

According to production technology, mineral wool is divided into three main types:

- Stone - from the melt of igneous rocks.

- Slag - from metallurgical industry waste.

- Glass - from broken glass formed during its production.

Each of them has its pros and cons, while stone (basalt) wool is considered the safest for human health, therefore more popular than other subspecies. In turn, slag insulation has a minimal price, and glass insulation has better tensile strength and high reliability.

Cellulose wool (ecowool)

This is a modern and environmentally friendly material, which is made from paper production waste and is used for thermal insulation of various building structures. It also contains a fire retardant component (fire retardant) and boric acid, which prevents rotting of the insulation.

The range of applications for ecowool is very wide - residential and commercial premises, warehouses, public buildings and other facilities. By spraying, it is used to insulate building structures that are extremely difficult to insulate using other methods. As a result, a solid, dense layer is formed that prevents heat loss.

In European countries, this material is used for thermal insulation of frame houses; its share in this market is about 70%. It is noteworthy that it has been actively used there since the 1950s, when the need arose for large volumes of effective insulation for the construction of individual housing. In Russia, ecowool began to gain popularity only relatively recently - since the early 1990s.

What to choose?

To evaluate these popular materials, we will use several criteria that determine the choice of thermal insulation composition. Among them:

- Coefficient of thermal conductivity. For mineral wool, the range of values of this indicator is 0.035-0.040, for cellulose wool - 0.037-0.042 W/(m*K). As you can see, in terms of their heat-insulating properties, the materials can be called equally effective. In this case, the exact value of the indicator is determined by the density and production technology. For example, slag wool has higher thermal conductivity than stone wool.

- Fire hazard. Both mineral and cellulose wool can withstand open fire for a long time. The latter can be of different flammability groups: G2 (moderately flammable), B2 (moderately flammable), D2 (moderately smoke-generating), RP-1 (flame spread over the surface “0”). This indicator depends on the manufacturer's specifications.

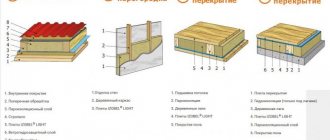

- Installation. Mineral wool slabs can be laid manually. In the case of ecowool, special equipment is needed to blow it in, ensuring a uniform layer of insulation and preventing its shrinkage in the future. At the same time, cellulose wool can fill any cavities, which is unattainable when using mineral wool boards. Also, when using wet technology, ecowool can be applied from below to the ceiling. And the most undoubted advantage of ecowool is seamless installation, which cannot be achieved when insulating with mineral wool. Heat savings due to seamlessness are 36-40%.

- Environmentally friendly. To be fair, we note that this is a rather slippery parameter; it largely depends more on the quality of a particular product than on the type of insulation. And yet, ecowool is the leader in terms of environmental friendliness, since it does not contain volatile and harmful chemicals. In addition, it itself serves as protection against the harmful effects of carcinogens released by polystyrene foam and glass wool.

Seamless installation.

Ecowool differs from “traditional” heat-insulating materials in the installation method. Basalt mineral wool and fiberglass are produced in rolls or slabs. They are cut into rectangular pieces and laid between joists, sheathing or rafters, depending on the place where the insulation is installed. Installation of ecowool is carried out using the “dry” or “wet” application method. Thanks to this, a continuous insulating layer is obtained without seams or joints. When laying mineral wool and other slab materials, the seams remain “cold bridges”.

The use of specialized equipment allows you to lay ecowool in hard-to-reach places

Ecowool is laid manually or automatically. Manual is more labor-intensive and does not always allow achieving the same insulation density in all areas. Automated installation is carried out through a blowing machine with a corrugated hose. “Wet” or “dry” application method is selected depending on the surface.

When it comes to installation, it is difficult to choose an undisputed leader. On the one hand, the seamless application method allows you to get rid of “cold bridges”; on the other hand, the installation process itself becomes more complicated. In addition, “wet” styling will require drying time (2-3 days).

Not like fish in water

The relationship between moisture and insulating materials can be described as complex. Here we need to return to thermal conductivity again. Under normal conditions, as we have seen, this figure is approximately the same for different thermal insulators, but everything changes when moisture gets on the insulation. All materials behave differently. The most moisture-sensitive material is basalt mineral wool; when moistened by 1%, its thermal conductivity increases by 9–8%. Fiberglass also does not tolerate water well, but recently products with enhanced moisture resistance have begun to appear.

Moisture distribution inside ecowool and mineral wool fibers

What's going on with ecowool? It absorbs water, but thanks to the fibrous structure, all the moisture gets into the fibers, and the empty space with air (which is the main heat insulator) remains free, as a result, when humidified to 20%, the thermal conductivity remains unchanged.

Ultimately, the water resistance parameter is relevant only in the event of force majeure (roof leakage, waterproofing breakthrough, etc.). Subject to compliance with building codes and regulations, water should not get on the insulation, so this indicator should not become decisive when choosing a particular insulation material.

Density and weight

The higher the density of the insulating material, the greater its weight per unit area. With greater weight, the requirements for supporting structures increase. This is especially true when installing a roof. Also, in the case of ecowool, the density is affected by the uniformity of application.

Read about the features of choosing insulation for a roof in the article: “How to insulate a pitched roof.”

- Basalt mineral wool – 25 – 50 kg/m3 depending on the brand

- Fiberglass – 15 – 20 kg/m3

- Ecowool - 35 kg/m3 for horizontal structures and 65 kg/m3 for horizontal ones.

Thus, from the point of view of numbers, the materials do not differ much, but at the same time, applying ecowool to vertical surfaces with insufficient density can lead to subsequent shrinkage. Due to the specifics of application, the density in different areas is not the same.

Specifications

In the process of comparing two insulation materials, it is necessary to evaluate the performance characteristics, as well as the individual properties of the products.

Thermal conductivity

The main purpose of insulation is to maintain the optimal temperature inside the building by completely preventing or partially reducing the air exchange process between the street and the building. Each of the two materials has its own thermal conductivity coefficient. The higher its value, the better the efficiency.

Indicators:

- ecowool – from 0.038 to 0.041;

- mineral wool: glass wool – from 0.03 to 0.052; slag wool – from 0.46 to 0.48; stone wool - from 0.077 to 0.12.

The first option does not change its indicator during interaction with moisture. Dampness easily evaporates due to the special structure of the fibers, and the material returns its original properties and appearance.

Another insulation behaves completely differently. Even with the slightest interaction with moisture, the effectiveness of mineral wool is reduced significantly. The finish begins to freeze, and the shape is restored with difficulty over a long period of time.

You will learn more about how insulation materials behave when interacting with moisture by watching the following video.

Air capacity

Airflow is also of great importance. It means the effectiveness of insulation in strong gusts of wind. A lower indicator indicates better heat retention inside the building.

- Ecowool – 75×10-6 m3/m*s*Pa.

- Mineral wool – 120×10-6 m3/m*s*Pa.

Flammability

Fire resistance is an important factor from a fire safety point of view. When describing this performance characteristic, it is necessary to understand the difference between combustion and smoldering.

Mineral wool smolders, but does not ignite. During the smoldering process, the material releases substances that have a detrimental effect on the health of people and animals. Other insulation melts when exposed to high temperatures. Therefore, the product should not be placed near open flame sources.

Life time

As a rule, buildings of various types (residential buildings, commercial facilities, public institutions, etc.) are built for many years.

It is advisable to use durable and reliable finishing materials so as not to spend money on frequent repairs.

The service life of ecowool varies from 65 to 100 years, depending on the manufacturing company and the quality of the material. The correctness of the installation process and the organization of ventilation of the working layer also play an important role.

Doesn't burn or doesn't support combustion?

Flammability is a parameter that you need to pay close attention to; the overall fire resistance of the entire building depends on it. According to GOST, there are 5 flammability classes: NG (non-flammable), G1 (low-flammable), G2 (moderately flammable), G3 (normally flammable), G4 (highly flammable).

Ecowool does not support combustion, so fire does not spread into the material

- Basalt mineral wool is NG, while slabs containing phenolic binders can emit toxic smoke.

- Fiberglass-based mineral wool is non-flammable, but at temperatures above 500 degrees the material begins to melt, so the flame can spread to other objects.

- Ecowool - G2, upon contact with an open flame, the insulation burns, but does not support combustion (the fire does not spread deep into the material). The advantage is the absence of toxic smoke.

Based on the results of comparing flammability classes, ecowool cannot be called the most fire-resistant material. It should not be used near chimneys, stoves or fireplaces.

Is vapor barrier necessary?

A vapor barrier protects the insulation in a wall or roof from vapors that escape from the house. Warm air, meeting cold air, condenses at the dew point, which usually falls right on the insulation. As we have already figured out, moisture does not have the most favorable effect on thermal insulation material. You can often come across the opinion that when insulating with ecowool, a vapor barrier is not needed. This is not entirely true, because moisture may not damage the insulation itself, but will cause rotting of other structural elements (walls, sheathing, etc.).

- Basalt mineral wool - vapor barrier needed

- Fiberglass-based mineral wool - vapor barrier needed

- Ecowool - it is recommended to use vapor barrier in places with high humidity.

Video description

The extent to which the positive characteristics of ecowool declared by the manufacturer correspond to reality is described in the video:

Flaws

There are no ideal materials without flaws, and ecowool is no exception. It also has its downsides.

- Shrinkage of the thermal insulation layer.

Over time, the loose fibrous material shrinks, becomes denser, loses volume, and its thermal insulation properties decrease. On horizontal surfaces, this problem is solved by making the layer thicker than the calculated one and organizing high-quality ventilation to evaporate moisture. But with vertical insulation, it will no longer be possible to fill the resulting voids.

- Installation problems.

When purchasing ecowool insulation, you should find out in advance what it is and where it is used. As well as the way in which it is laid on different structures. If you want to insulate monolithic walls or fill the cavities of a frame house, you will need special equipment and experienced operators, which are not yet available everywhere. And when insulating floors manually, the compressed material, freed from packaging, must be loosened using a drill with an attachment. This creates a lot of pervasive debris and allergenic dust.

Before installation, the material is “beaten” with a mixer Source obustroeno.com

Conclusion

Based on the results of comparison with other thermal insulation materials, we can highlight the positive and negative aspects of ecowool.

Advantages:

— Seamless application does not form cold bridges.

— Adhesion to the frame provides increased heat and sound insulation.

— Thermal conductivity does not increase when wet

— Good vapor permeability (0.35 mg/(m h Pa)

— Filling hard-to-reach places by blowing cotton wool

— Environmentally friendly - does not contain formaldehyde resins, consists of 80% cellulose

Ecowool

Ecowool is an environmentally friendly . Does not contain harmful or toxic substances. Made from natural raw materials (wood fibers and minerals). Used quite often.

Advantages:

- Absorption.

- Evaporation of moisture.

- Good thermal insulation.

- Soundproofing.

- Environmentally friendly.

- Moisture resistance.

- Lightness of the material.

- Affordable price.

Flaws:

- Increased thermal conductivity during operation.

- The need for additional equipment during installation.

- Possibility of shrinkage deformations.

- Labor intensive installation.