Types of heating boilers used in a private home

There are different types of boilers for the homeowner to choose from:

- — Electric heating that does not require the installation of a chimney. They are as easy as possible to manage.

- Gas heating. The main advantage of such a boiler is its efficiency.

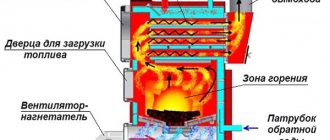

— Solid fuel devices, which are considered the simplest. The solid fuel boiler runs on coal, coke, and wood.

Regardless of which boiler is chosen - gas, electric or solid fuel, it must be grounded in any case.

Why is it necessary to ground the boiler in the house?

In the old days, no one did grounding when constructing buildings, because there was no particular need for it.

The grounding that a solid fuel or any other boiler receives is a certain wiring that connects the heating system in a private house with a grounding device.

Grounding the boiler will allow:

- - eliminate the possibility of electric shock to a person who touches the body of a working device;

— ensure stable operation of the gas boiler (as mentioned above, it can also be a solid fuel or electric device);

— reduce electromagnetic radiation and the amount of interference in the network.

According to safety rules, you can connect a gas, electric or solid fuel boiler only if there is grounding.

Grounding of a gas boiler must be done regardless of its service life. It must be taken into account that static voltage is generated on its body, which under certain conditions can lead to:

- - Possibility of fire. This is the most important reason why it is necessary to ground a gas boiler in the house. One random spark will be enough to cause an explosion or fire of natural gas.

— Failure of automation, the replacement of which will be expensive.

To carry out work on zeroing or grounding boilers with your own hands, you must have certain electrical knowledge.

They will get the job done as quickly as possible. In addition, experienced craftsmen know the requirements for grounding conductors:

- — no more than 50 Ohm for sandy soils;

- no more than 10 Ohms for clay soils.

Main process

Installing the unit

First you need to install an electric boiler indoors. As we have already said, the unit can be floor-mounted or wall-mounted. In the first case, the kit includes a special stand, on which the “landing” is performed.

In order to hang the boiler on the wall, you need to prepare anchors with dowels and a drill with a suitable drill bit. First, mark the wall using a tape measure and a marker. The holes must be placed perfectly level in a horizontal plane. Next, we drill out the marked places, drive dowels into them and screw in the anchors. After the anchor is firmly seated inside the wall, you can hang the electric boiler.

We draw your attention to the fact that the installation of the electric boiler must be carried out perfectly level in both horizontal and vertical planes. Any misalignment can affect the performance and service life of the equipment.

We connect the electrical wiring

Since an electric water heater has more power, it is necessary to connect it not from an outlet, but directly from the mains. To do this, a separate line must be drawn from the distribution box in the room, going to the boiler connection point. It is better to use hidden cable routing, because... in this case, the line will be protected from mechanical damage and the appearance of the room will not deteriorate.

It should be noted that to power the boiler it is necessary to use a large cross-section cable that can withstand fairly high current loads. We talked about how to correctly calculate the cable cross-section in the corresponding article, which we strongly recommend that you read.

So we draw your attention to the fact that small-power water heaters (up to 7 kW) can be connected to a single-phase network, which is often found in Khrushchev-era buildings and old-style apartments. Well, the last nuance at this stage that you should know about is that electric boilers up to 3.5 kW can operate from an outlet, and not from a separate line from the distribution box. Low-power boilers are ideal for connection in an apartment, because in this case the electrical wiring is usually single-phase and making new cable wiring is not always a practical solution.

We install protective equipment

When all the input wires are connected to the electric boiler, it will be necessary to additionally protect it with a circuit breaker and an RCD installed in the main panel. The purpose of the first device is to protect equipment from short circuits and wiring overloads. Connecting an electric boiler through an RCD will protect you from leakage currents.

It is also recommended to connect a voltage stabilizer, because even small surges can damage the unit. I don’t think it’s worth talking about the need to ground an electric boiler. The main requirement is that the ground wire runs directly from the bus to the equipment frame.

We are launching

When all wiring elements are connected, it is necessary to check all connection points. There should be no exposed contacts, as well as damaged insulation.

It is also necessary to check all couplings, taps and pipe joints. Only after a high-quality inspection of the heating system can you proceed to its start-up. First, we open the valves connected to the equipment, and then turn on the electric boiler.

Pay attention to the functionality of the temperature and pressure sensors. The nominal values are indicated in the instructions included in the kit. In case of obvious deviations, it is better to call a specialist.

We also provide for your attention a clear example of installation work:

How to properly ground a gas boiler?

Before grounding the boiler, you need to select a ground electrode. It is in direct contact with the earth and is part of the entire system. Grounding electrodes can be artificial and natural. Which one to use depends on your own preferences.

Natural grounding conductors are various metal structures in contact with the ground. Such grounding conductors must be connected to the boiler by several conductors (at least there should be two of them).

Artificial grounding conductors are steel pipes and angle steel, which are located in the ground in a vertical position.

Connecting the boiler to grounding is more difficult than with conventional devices (washing machine, refrigerator, electric stove). It is necessary to check in advance both the total resistance of the structure and the conductivity of the soil.

Grounding a heating boiler involves a number of works:

1. Making a ditch model on the ground. To do this, draw an isosceles triangle, the distance between the corners of which is two linear meters.

2. After this, a ditch is dug 35-40 cm wide and 50 cm deep.

3. At the corners of the triangle, holes are drilled, for which a motor drill can be used.

4. Three-meter corners (sixty millimeters wide) are hammered into the holes.

5. Next, the triangle is scalded with a four-centimeter strip. A similar strip is stretched from the ditch to a private house.

6. Next, a 10 mm pin is welded at the end of the strip. It is hooked to the plinth in the building. If you want to hide the hairpin, you can use a polyvinyl chloride box. From the stud, the wires are led to the grounded heating device.

To quickly install grounding, you can buy ready-made kits. They can be easily found on sale.

By taking care of grounding the boiler with your own hands, you can count on reliable and, importantly, safe operation of this heating device.

Cost of specialist work

Prices for assembly, installation and connection of the grounding loop depend on the specialist or company, region, and type of soil on the site. In Moscow and the Moscow region, the cost of work is about 4,500-6,000 rubles, in St. Petersburg - 3,900-5,500 rubles, in the regions - on average from 3,000 to 4,000 rubles. Please note that the price does not include the price of the grounding kit (another 6-10 thousand).

Most companies carry out turnkey installation and indicate prices taking into account the cost of the finished grounding kit.

Gas boilersInstructionsBoilers

Installation and connection of an electric boiler to the heating system

Heating using electricity is not very profitable, but it provides a lot of advantages: comfortable operation, relatively low price of equipment, safety. This article is devoted to the installation and connection of an electric boiler in a private house. After studying our detailed guide, any skilled homeowner can easily install an electric boiler with their own hands.

Equipment installation

Before starting work, you need to prepare the following tools:

- a hammer drill or a drill to create holes for fastening equipment;

- mounting plate or anchor for attaching the boiler;

- cable for connecting devices;

- flanges, couplings, pipes for creating a heating system.

The manufacturer's drawings and instructions will help you install the electric boiler yourself.

Before you begin installing the equipment, you need to make sure that the wall can support its weight. The installation location is selected in such a way that there is enough space near the boiler and above it to carry out repair work, which will still have to be carried out after years of operation (about

If you have not yet chosen an electric boiler

The choice of a heater operating in conjunction with a water heating system is made based on power and operating principle (the cost of the equipment depends on the latter). Electric boilers have no problems with functionality - any model is equipped with an automation unit. If desired, various peripheral devices can be connected to it - weather sensors, room or overhead thermostats and GSM modules for control from a mobile phone or via the Internet.

Important note. Some, Protherm or “Evan” require in the operating instructions that the installation and connection of the electric boiler to the network be carried out by specially trained personnel. Self-connection will result in a waiver of warranty obligations.

Before choosing and purchasing a heating device, check how much electrical power is allocated to your home by the management company. It may happen that it is not enough for individual electric heating. Point two: a single-phase 220-volt network is capable of powering boilers that consume up to 12 kW/h inclusive. More powerful water heaters are connected to a three-phase 380 V power supply.

Determination of thermal power

This indicator is calculated using the standard formula: calculate the heated area of a country house or cottage, then multiply the quadrature by 0.1 kW. Obtain the thermal energy demand that the electric boiler must cover.

Consider a number of nuances:

- the height of the ceilings of the rooms is up to 3 m, otherwise the calculation is carried out according to the volume of the premises: the cubic capacity is multiplied by 40 W;

- the heat generator must be selected with a minimum margin of 20%;

- if the heating unit is planned to be used to provide domestic hot water, the reserve must be at least 50%;

Dividing a quadrature by 10 is the same as multiplying by 0.1, the result is the same

- in the northern regions, the square footage of the building is multiplied by 0.2 kW, in the southern regions - 0.08 kW;

- The power of the boiler, which operates only at night and charges the heat accumulator, is assumed with a double margin.

Example. A small house of 100 m² on average requires 100 x 0.1 = 10 kW of heat. The power of the electric heating installation is 10 x 1.2 (20%) = 12 kW. We need to heat water for household needs - multiply by a factor of 1.5 and get 15 kW.

To obtain more accurate results, we suggest studying the methodology for calculating the load on the heating system

Which type of heater is better

Next, you need to select a water heating device based on its operating principle. What types of household electric boilers can you buy:

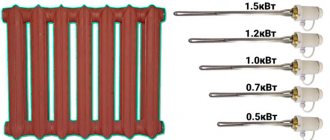

- Traditional, equipped with tubular electric heaters (TEHs).

- Electrode, where the salted coolant is heated by passing current through the water.

- Induction devices heat the liquid using Foucault eddy currents that arise in the metal core of a multi-turn coil.

Electric mini-boiler room with tubular heaters (TEN), fully equipped

Valuable advice. Do not listen to the tales of salesmen praising the efficiency of certain electric boilers. They like to use the expressions “energy-saving”, “eternal”, “economical” and so on. Remember: all types of heaters are equally effective at converting electrical energy into heat with an efficiency of 98-99%.

The first place in the user rating is occupied by heating element heaters. The only weak point - the heating element itself - has long been protected with ceramics, and in addition it is easy to replace. Modern models of heat generators are wall-mounted mini-boiler rooms with a built-in expansion tank and circulation pump. There are simpler versions that include only heaters and an automation unit.

The cheapest and most reliable option is an electrode boiler with a control cabinet, shown in the photo. Its disadvantages:

Induction electric boilers for heating a private home are quite expensive, and there are questions about the reliability of the devices. There are known cases of phase burnout inside the coil, the power of the heat generator dropped by a third. Fixing the breakdown is very problematic.

An induction heater heats water with a metal core located in the vortex field of the coil