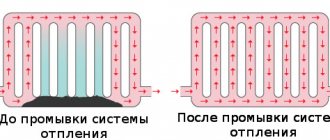

The microclimate in the house depends on heating. During operation of the system, deposits in the form of scale, silt or rust form on the walls of the pipeline and heating devices.

Examples of scale formation

The system needs regular cleaning and flushing. In order to remove dirt, you need to prepare so as not to damage the heating and clean the radiators.

How to flush the heating system in a private house

Chemical system cleaning

Chemical washing involves the use of special preparations that may have:

- biological origin;

- chemical origin.

The biological product purification technology is highly effective and environmentally friendly. The action is based on the principle of introducing microbiological agents into the heating system, after which deposits are broken down. This technology does not require disassembling and turning off the entire heating system of the house.

An undoubted advantage of chemical cleaning with biological products is the possibility of painless use in old heating systems. Cleansers are made on a water basis; the preparation serves to separate dirt from the walls. The desired cleaning result is achieved after a few days.

The advantages of this technology are:

- no need to turn off the heating system;

- Possibility of use in old heating systems;

- high efficiency and achievement of the desired result in a few days;

- safety;

- no negative impact on the pipe material.

The mechanism of chemical flushing is the effect of the drug on the contamination of the heating system of the house and cleans it by dissolving sediments and scale. Chemicals act on deposits, which are subsequently removed from the heating along with the liquid flow.

The cost of a chemical reagent depends on the composition and reputation of the manufacturer. The most popular drugs are:

DOCKER TERMO

The cost for 1 liter is 180 rubles; the drug cannot be used for aluminum.

Metalin

The price for 1 liter is 105 rubles; the drug cannot be used for non-ferrous metals.

Master Boiler Power

The price for 0.6 kg is 475 rubles, the drug has no contraindications for use.

Compositions of the SP-OM brand

They have no contraindications for use and can be used with aluminum and non-ferrous metals. The main advantage of the SP-OM brand washing liquid is the ability to use it for washing systems containing polymer components, non-ferrous metals and aluminum. SP-OM is also relatively harmless when draining the used solution. Each SP-OM grade is intended for use with certain metals and under certain conditions. More detailed information about the application and brands of the SP-OM composition can be found on the website https://spomcom.ru/

Significant disadvantages of the method include the difficulty in independently selecting the correct volume of the drug. The possibility of using chemicals is complicated by the fact that in most cases the components of the heating system are made of different materials. Chemicals have varying degrees of impact on metal or polymer materials. In most cases, preference is given to the method of mechanical action on contaminants in the heating network.

Physical cleaning methods

Physical cleaning methods are:

- hydrodynamic flushing;

- pneumohydropulse washing.

For hydrodynamic washing you will need special equipment, including special nozzles and thin hoses.

The cleaning mechanism consists of supplying water under pressure to a nozzle, which is responsible for generating thin jets of water.

The advantage of hydrodynamic flushing is considered to be its effectiveness, but in practice the method is used quite rarely due to its high cost.

Cleaning using the pneumatic-hydropulse flushing method is an effective means of combating contaminants in the heating system. For better cleaning, it is recommended to carry out the procedure several times. The essence of the method is to create increased pressure, due to which dirt breaks off from the walls.

Flushing chemicals

Chemical compounds are used to remove scale, which forms mainly on the internal surfaces of steel and copper pipes. These solutions prevent foaming of the coolant, which provides protection against corrosion processes and thereby increases the life of the circulation pump.

The chemical used changes color. The active composition is colored red, and the spent one has a yellow-orange tint. To prepare a water-based solution, you will need to use 10-30% of the chemical. It is prohibited to drain the waste into the sewer; the composition must first be neutralized. Read also: “Do-it-yourself device for washing heat exchangers.”

Hydrodynamic type of flushing

The heating flushing scheme in this way involves active action of water on scale and deposits. This happens thanks to a stream of water, which is directed under extreme pressure to the desired area.

Water is supplied through special nozzles of the required size and diameter. This type of washing is more expensive than chemical washing, but the result is much more satisfactory.

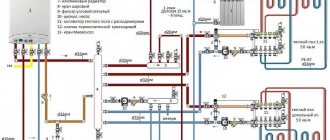

Scheme of using the hydrodynamic method of cleaning the heating system. Click to enlarge.

This type of flushing is best suited for batteries made of cast iron. Removing scale from cast iron using chemicals is very problematic due to the properties of the material itself, and sometimes even impossible.

However, the hydrodynamic system does an excellent job in such cases.

Another undoubted advantage is the environmental friendliness of such washing, since no acids or solvents are used. But only water.

To achieve the desired effect, specialists must have a special mechanism that will create a pressure of two hundred or more atmospheres.

Naturally, all scale is removed solely by exposure to water. No additional liquids or reagents are needed.

But here, too, everything is not as simple as it seems. Before flushing using this method, you must take the radiator to a service center. There it will have to be treated with a special liquid so that the layer that needs to be removed becomes softer and more pliable.

Only after this can the walls be treated with a jet of water operating under pressure. Using this method, you can remove almost everything: grease, scale, rust, dyes, carbon deposits, etc.

Methods

Cleaning the system

Methods:

- Water-pulsating mixture. The method is based on the use of pulsating flows of liquid and compressed air bubbles. Deposits, rust, silt, sand are removed. Costs for energy resources are reduced and the service life of heating devices is increased. Performed with special equipment.

- With the help of biological products. The product penetrates deep into the accumulated layers and begins to act from the inside. The biological product acts on scale, oil and mud, hard crystalline, corrosive and organic deposits.

- Pneumohydraulic hammer. Requires special equipment. There is no need to disassemble the heating equipment. Operating principle: using technology, a pneumohydraulic shock is performed that destroys deposits. The layers crumble and dissolve in the coolant. The method does not cause ruptures or cracks.

- Chemicals. The mixtures are based on acids of organic and inorganic origin. The products begin their action by completely destroying the formation of scale and rust.

When the system should be cleaned

The system will require an initial flush after installation to remove any remaining flux or pipe joining material, as well as any metal particles such as swarf left over from recent installation or changes to the piping.

If the system is properly maintained, well designed, and regularly treated with a corrosion inhibitor, unscheduled flushing is unlikely to be required unless significant changes are made to the system.

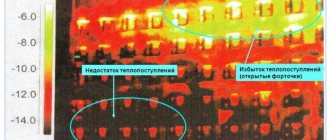

However, not all of these requirements are common and sludge can build up in the system very quickly. Here are a few clues that indicate that sludge has already begun to accumulate in the heating system:

- cold “spots” on the bottom of radiators;

- parts of the heating circuit that do not heat up correctly;

- Excessive noise (bumps, clicks, pops) made by the boiler when it heats up.

The heating circuit should also be thoroughly flushed before installing a new high-efficiency condensing boiler, as the heat exchangers in such boilers are particularly susceptible to damage from contaminants in the heating system.

General information

Before cleaning, you should check the system to determine its configuration. You also need to determine the “age” and general condition of the components in order to select the required system flushing mode. For example, the procedure may remove corrosive debris blocking openings in radiators, which can lead to coolant leaks. If there is any doubt as to whether the system will withstand any cleaning methodology, replacement or repair of the relevant components will be required before proceeding.

Cleaning procedure

There are several ways to clean a system and there are a number of cleaning products on the market designed to help flush heating systems. Many products are designed to be added to the circulating water some time before flushing and help mobilize contaminants prior to flushing. Here you need to follow the instructions from the manufacturer of these products.

Basic flushing procedures:

- Powerflushing.

- Overpressure flushing.

- Flushing with a circulation pump

Positive pressure flushing is probably the most effective procedure (although it is important to check the boiler manufacturer's instructions to determine whether flushing the system using the boiler in the heating circuit is acceptable). Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge. Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge.

Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge.

Please note that with all methods, changing the direction of coolant flow will help remove debris that could otherwise remain in the system and cause it to fail.

Preparation

Before flushing with any method, there are several general preparation steps. Typically these involve adding a suitable detergent to a running heating system and letting it sit for some time before actually flushing. The cleaner is usually flushed (while hot) from the system and the system is primed to begin the final flushing process.

Before flushing, you may also need:

- Turn off all electrical controls and electrically isolate the system.

- Avoid supplying cold water to the central heating system.

- Manually close all heating circuit vents.

- For systems with open ventilation, close or temporarily connect the open ventilation and cold water supply to the supply and expansion tanks.

- When draining a vented system, the collection tank may have quite a large portion of floating sludge. It must be removed to prevent it from being drawn into the pipeline.

- Mark the operating position of any shut-off valves or other control valves, and then open all valves fully.

- Remove all thermostatic radiator valve (TRV) heads to ensure maximum flow through the valves.

- Set any diverter or zone valves to their manual open position.

- Where check valves are present, they must be closed, bypassed or temporarily removed, otherwise this will prevent flow reversal.

Conclusions and useful video on the topic

Video #1. The effectiveness of using hydropneumatic radiator flushing can be assessed by the amount of dirt thrown out:

Video #2. The subtleties of performing a chemical type of flushing of the heating system are outlined in the following story provided by the owner of a private household:

Any of the considered options for flushing heating systems does not represent an overly complicated procedure. If you have some experience in plumbing work and, in some cases, special equipment that can be rented, you can perform this operation yourself.

Would you like to talk about the effectiveness of flushing or tell us how you flushed the heating circuit in your home? Do you have valuable recommendations or important nuances that you would like to share with site visitors? Please write comments in the block form below.

Compressor for washing: means and equipment, reagent

When choosing equipment, familiarize yourself with the characteristics and features of the heating circuit

Pay attention to the size of the heating system and how many heating devices are installed in it

There are other parameters that affect the compressor installation.

Often, specially prepared coolant is poured. In this case, the pipeline will remain in normal condition for a long time. But this happens rarely, and usually ordinary running water is poured in, containing salts of microelements, which gradually settle on the walls. A simple example is a kettle with scale that has formed.

In addition, silt and dirt accumulate inside, and rust forms. A number of problems arise:

- Reduced heating quality. Since salt layers have low efficiency, they become an obstacle to the transfer of thermal energy to radiators.

- Due to the reduction in the internal diameter of the pipes, the passage of coolant becomes less intense.

- Any type of pollution helps reduce the operating period of heating.

After such problems occur, coolant circulation deteriorates. This is reflected in a decrease in air temperature in the heated room.

The best preventive measure to combat this problem is regular cleaning of the circuit. Cleaning methods:

- Using chemical reagents that can dissolve dirt and scale.

- Jets of liquid supplied under high pressure wash away the plaque on the inside.

- Using the hydropneumatic pulse method.

Compressor for hydropneumatic flushing of the heating system

The compressor is connected using hoses. First, a thorough analysis of the structure is needed to identify areas that are severely affected by layers.

Then the compressor operating mode and cleaning method are selected.

Hydropneumatic flushing is performed in the following ways:

- Filling the circuit and supplying compressed air under pressure. After the procedure is completed, the drain valve opens.

- Flow-through method: water is supplied continuously.

In order to protect the receiver from liquid entering it, a check valve is used.

The device is turned off and dismantled. The results are checked: a small section of the pipe is cut off, with a clean inner coating.

Models are top sellers

Popular brands of washing equipment:

- Ropuls. The compressor cleans heating appliances, water pipes, heated floors and solar collectors. Among the advantages is the disinfection of drinking water.

- Rockal. Small heating cleaner (no more than 300 l).

- Cillit-Boy. Universal equipment: with its help, heating circuits, hot water supply and hot water supply pipes, drinking water pipelines and the “Warm Floor” system are freed from dirt. Controlled by an electronic module.

The supply of compressed air with liquid is under pressure. This loosens all the accumulated layers.

Cleaning methods

Several methods allow you to quickly and inexpensively clean your heating system of dirt and deposits.

Chemical washing

The method does not require removing batteries. Store-bought mixtures are used for cleaning. Make them at home by mixing a few essential ingredients.

If the circuit is slightly clogged, the following means are used:

- caustic soda;

- vinegar 9%;

- some acids;

- milk serum.

Ready-made mixtures are the best option; the packaging contains complete information about in what cases to use it and what dosages to use.

When using reagents, you must maintain the recommended time specified in the instructions. Remember to start the pump to ensure even distribution of the mixture throughout the circuit.

The idea is to supply chemical reagents together with a corrosion inhibitor. The preparations accelerate the dissolution of deposits, and the inhibitor covers the inside of the pipes with a protective layer that prevents the development of rust.

After flushing, the service life is extended by 10 years, the heating functions better, and the cost of heating the premises is reduced.

Sparging: pneumohydraulic cleaning

The method is harmless, as it does not contain any impurities. To create high pressure, a compressor is needed to supply a water-air mixture that removes deposits accumulated inside from the walls.

Flows are created inside the circuit, passing in the form of short pulses created by a pneumatic gun. It is better to connect the compressor to a check valve. This is necessary to prevent liquid from entering the device.

If the radiators are not removable, then at the very end you need to open the cap, a hose is connected through it to discharge dirt, which is lowered into the toilet.

Compressor unit

When starting for the first time, it is necessary to supply air in the direction opposite to the movement of the coolant. Then the direction changes. To do this, it is necessary to change the discharge and supply hoses.

After cleaning, the hoses are removed and a plug is installed. Only after this the heating is operated.

Ram: hydropneumatic shock cleaning

The method is based on the formation of a shock wave, which is capable of passing along the contour at a speed of 105 km/sec. It is recommended to use with a total pipeline length of no more than 60 m. As a result, the layers begin to peel off and fall off, being washed away with the liquid.

Flushing agents

Various reagents are used. Before purchasing, find out what layers the drug is designed for.

Using acidic preparations, they clean the pipeline, but alkaline mixtures are safer for metal pipes.

By carefully studying the instructions on the label or packaging, you can understand which metals the drug should not come into contact with. Some destroy the materials from which the pipes are made.

How to flush your heating system

Before you start washing, you should prepare the necessary materials and tools for work. Since special equipment for cleaning pipes is quite expensive, and their use requires certain knowledge, you can purchase cheaper material.

For self-washing you will need the following material and tools:

- A container for draining liquid from pipes.

- Rags, old rags.

- Keys.

- Gas-burner.

- Kerosene lamp.

- Hose to match the diameter of the hole in the pipes.

- Iron brush.

After all the material has been prepared, you can begin to wash the battery.

Rent of washing cleaning equipment

| WE OFFER EQUIPMENT WASHING UNITS FOR RENT | |

| Using this pumping station, you will be able to service a hot water boiler, remove lime deposits from the heat exchanger, and also perform comprehensive maintenance of heating systems, air conditioning systems, chiller refrigeration systems, vertical industrial water heat curtains, water boilers and other equipment requiring servicing, underfloor heating system , water heat pumps, industrial reverse osmosis systems. Our pumping station has pump protection against dry running, as well as automatic pump control, which makes it more practical and convenient when working on cleaning heat exchange equipment. IN CASE OF ANY DIFFICULTY, OUR SPECIALISTS CAN GO TO YOUR SITE AND CARRY OUT MAINTENANCE WORK. | |

| CHEMICAL CLEANING OF THERMAL POWER EQUIPMENT | |

| TECHNICAL CHARACTERISTICS OF THE PUMP GEL BOY C 190 | |

| Electric motor 220 V – Hp 0.75 | |

| Connected power W 559.5 | |

| Head height, max. m in.st. 22 meters | |

| Max, circulation rate 150 l/min (9000 cubic meter per hour) | |

| Protection type IP 54 | |

| Capacity volume 100 liters | |

| Amount of acid to be filled, max, l Measuring lines | |

| Temperature, max. 50°C | |

| Empty weight 14 kg | |

| Centrifugal pump | |

| RENT FULL SET 15,000 TR with VAT PER DAY | Overall dimensions, Width 53 cm x Height 72 cm |

| Number of hoses 2 pcs. | |

| Connection inches 1 Inch (25mm) | |

| With additional equipment - a complete set of washing equipment may include: | |

| 1. Installation for washing heat exchange and boiler equipment2. A device for measuring the pH of a solution, range 0-14 ph - for measuring the pH of the washed solution3. Pump for pumping chemical liquids from a canister4. Consultation in the selection of a reagent, neutralizer, passivator, etc. | |

| HYDRODYNAMIC CLEANING OF THERMAL POWER EQUIPMENT | |

| Compressor for flushing Rothenberger Ropuls drinking water systems with a pulsating water-air mixture in accordance with EN 806 and DIN 1988 part 2, as well as dirty floor heating systems and water heaters. | |

| TECHNICAL CHARACTERISTICS ROTHENBERGER ROPULS (ROPULS) | |

| Pipe connection: R 1″ Geka coupling | |

| Maximum pipe diameter: DN 50/2″ | |

| Maximum water flow: 5 m3/h | |

| Maximum water pressure: 7 bar | |

| Maximum water temperature: 30°C | |

| Protection degree: IP 22 | |

| Oil separation rate: 99.9% | |

| Particle filtration: 0.3 micron compressor | |

| Maximum operating air pressure: 8 bar | |

| Motor power: 1.5 kW | |

| Power: 230 V - 50 Hz | |

| Dimensions (H x W x D): 630 x 380 x 340 mm | |

| RENT FULL SET 15,000 TR with VAT PER DAY | |

| PORTAFLOW 220A LIQUID FLOW METER | PORTAFLOW 330 LIQUID FLOW METER |

| PRINCIPLE OF OPERATION OF THE DEVICE: When ultrasound is transmitted through a liquid, the speed of sound propagation in the liquid increases slightly if the sound is transmitted in the same direction as the flow, and decreases when propagating in the opposite direction. Therefore, the difference in the time of sound propagation over the same distance in the forward and reverse directions will be directly proportional to the speed of fluid flow. | |

| RENT FULL SET 15,000 TR with VAT PER DAY | RENT FULL SET 15,000 TR with VAT PER DAY |

| Read more >>> | Read more >>> |

| PRESS TONGS FOR METAL-PLASTIC PIPES VALTEC (VALTEC) | LASER INFRARED THERMOMETER -50 ~ + 280 |

| FULL SET 500 TR PER DAY | FULL SET 150 RUB PER DAY |

| Read more >>> | |

| SALE OF NEW EQUIPMENT 1500 TR | |

| DEVICE FOR MEASURING PH SOLUTION RANGE 0-14 PH | PUMP FOR PUMPING ACID TO ALKALI FROM A CANISTER |

| FULL SET 100 RUB PER DAY | FULL SET 300 RUB PER DAY |

| SALE OF NEW EQUIPMENT 800 RUB | SALE OF NEW EQUIPMENT 1500 TR |

Equipment types

Timely cleaning of the system allows you to get rid of problems such as rust, scale and sediment. There are several types of heating system flushing equipment used for varying degrees of system blockage.

Hydroflushing

This method involves supplying compressed air and water to the heating system. High pressure and frequent pulses allow small air bubbles, which actively fill a separate section of the system, to quickly and effectively separate deposits on the walls.

To achieve maximum effect, cleaning takes place in separate, relatively small areas (for example, one riser). Before starting the cleaning process, you should determine the amount and speed of water required for cleaning, as well as the amount and level of air pressure. When making calculations, it is necessary to take into account both the length of the section of the system selected for flushing and the diameter of the pipes used in this section.

Hydroflushing of heating systems can be carried out in two ways - flow and filling. The flow-through method involves completely filling the heating system with water. In this case, the air collector valve must be open. After the system is filled as much as possible, the valve closes and the compressor begins supplying compressed air to the system. Hydropneumatic flushing of heating systems ends when exclusively clean water without impurities begins to flow from the open pipe. For further operation, the system must be cleared of the water-air mixture.

First of all, the area of the system selected for cleaning should be filled with water. Next, the air collector valve closes. After this, the supply of compressed air begins through the second valve. You should first check the level of contamination - the duration of the air supply depends on it, as well as on the length of the area being cleaned. After stopping the air supply, it is necessary to close the shut-off valves. Next, the mixture of water and sediment formed in the system should be drained into the drainage. After using this method, the system must be flushed several times with water.

Devices used

Pipeline cleaning can be done in different ways, and a specific unit is selected for each of them. The price of some devices can be quite high, since their efficiency is at the proper level. Some work can be done with your own hands using inexpensive tools.

Hydrodynamic installations

The main equipment is water jetting machines that supply liquid under high pressure. With their help, it is possible to eliminate deposits in pipelines with a diameter of 20 mm and above. The high efficiency of the method is achieved through the use of special nozzles.

Compact size water jet.

Hydrodynamic technology for removing scale and other contaminants is considered the most gentle, since when carrying out work inside the communication system, excessive pressure is not created. This operation is completely safe for installed elements.

Its features are discussed below:

- The advancement of the nozzle is ensured by jet thrust, which is created under the action of high-pressure water flows coming out of the holes in a special nozzle.

- This installation for flushing heating systems works most effectively when using high-performance nozzles. Their choice should be made depending on the nature of the blockage.

- For the most difficult jams, chain carousels and rotary tips are used. The resulting traffic jams in the communication network are successfully removed using punching nozzles.

This is what the pressure cleaning nozzle looks like.

Pneumohydraulic units

The main device is a compressor for flushing the heating system or a pump, which allows the accumulation of compressed air and a sudden release at a certain point in time. In this situation, purification is performed by creating a kinetic impulse in a liquid medium. The swirling water removes deposits from the surface of the pipeline.

The pneumohydraulic design has a special container designed for compressed air, which is usually pumped by a compressor. However, a special pump can also be used to flush the heating system. It is a cylinder equipped with a piston.

One side of the device is in contact with air, and the other with water.

A unit for pneumohydraulic flushing is demonstrated.

- At the very beginning, the device is connected to the heating elements through a switch and adapter hoses.

- After this, water is poured into the system, which enters directly into the cylinder of the main device, moving the piston to its original position.

- Next, the cylinder is charged until the required pressure is created.

- At the main stage, a shock wave is created using a piston, which makes it possible to clean the pipes.

Mechanical impact devices

In this case, flexible shafts with a drive are used, on one side of which metal brushes are placed. The tool that rotates the rod is usually a drill.

The following are instructions describing the procedure for carrying out the work.

The flexible shaft is presented in assembled form.

- At the initial stage, the system is prepared for cleaning activities. The coolant is completely drained, the pipe fittings are unscrewed in the right places.

- A structure is being assembled that will mechanically remove scale and other contaminants from pipelines. A metal brush of suitable size is attached to one end, and a drill to the other.

- Gradually, the flexible shaft is introduced into the interior of the conductive elements of the system. When the device rotates around its axis, scale will fall off the pipe walls.

Electrohydraulic devices

The operating principle of such installations is based on the fact that a coaxial cable is inserted into the liquid medium, which is connected to a high-voltage pulse device. The device creates repeated electrical discharges with a frequency of 1 to 10 Hz. Thanks to this, accumulated deposits are destroyed.

Example of an electrical installation.

Many models of cleaning equipment of this type are capable of cleaning pipelines whose diameter ranges from 10-100 mm. Additional devices may be supplied with the equipment.

Do-it-yourself heating flushing mechanically

For self-flushing radiators, mechanical cleaning technology is most applicable. In this case, you will not have to use any special equipment or specific chemicals.

Before you wash the heat exchanger of a gas boiler with your own hands, you should prepare the necessary materials:

- rags or old thick clothes. With their help, it will be possible to protect the bathtub from damage during the process of flushing the radiators in it;

- fum tape or plumbing linen with a tube of sealing paste;

- a pipe that allows you to connect a hose to threaded connections.

The equipment you will need is the following:

- two hoses;

- a set of keys;

- brush;

- steel wire brush;

- buckets, basin and rags.

The actual cleaning of the heat exchanger and lines consists of several stages.

- A hose of the appropriate diameter is connected to the drain pipe of the heating system. The other end of the hose is discharged into the sewer.

- A second hose is connected to the highest point of the system. As a rule, such a point is either a branch to the expansion tank or a safety group. The tank or safety group is unscrewed and a pipe is screwed into its place, onto which a hose is put. The second end of the hose is connected to the water supply.

- When everything is ready, water is supplied to the system. This makes it possible to get rid of scale and contaminants deposited in the system lines.

- Start draining the coolant. To do this, remove the hose through which tap water was supplied. The connection point to the system is not blocked. Under the influence of gravity, water begins to drain through the drain pipe at the lowest point of the line.

To completely drain the coolant, it is necessary to ensure that the outlet end of the hose is below the level of the heating system lines. In a private house, it will be possible to achieve such a configuration if you drain the water into buckets installed in the underground.

- Radiators are removed from the dehydrated system. Care must be taken when doing this. It is likely that the threaded connections on them are coked and you will have to make some efforts, trying not to damage the threads.

- The removed radiators are transferred to a bathtub, previously covered with rags or thick fabric. Here they are washed with running water, treated with a brush and a steel wire brush. After flushing the radiator, it is carefully inspected again for any remaining contaminants.

- The radiators are installed in place.

- The lines are filled with fresh water through the drain pipe. At the same time, monitor the formation of air pockets in the pipes and radiators. You can get rid of air bubbles by slightly opening the Mayevsky valves on the radiators. As soon as the air stops hissing and water begins to ooze from the tap, close it. As the lines fill, it is advisable to repeat this procedure several times.

- After the actual washing of the gas boiler heat exchanger is completed with your own hands, the heating system is put into operation.

- As the coolant begins to circulate, air pockets in the radiators may re-form. To eliminate them, the Mayevsky cranes are manipulated again. Some of the air will be removed independently through the air vent.

- As the pipelines and radiators are freed from air, the coolant pressure will drop. To level it, it is necessary to additionally pump water from the water supply. In addition, you should check the pressure in the expansion tank.

Hydroflushing

The process itself is based on simultaneously supplying water and air under pressure to sections of the pipeline. The resulting mixture cleans the heating system due to the many pulses that the compressor produces to flush the heating system.

Small bubbles form, which gradually destroy various deposits on the walls of pipelines.

Pipes before and after cleaning

Methods

Flow-through. The return and supply pipelines are first filled with water, with the valve on the air collector open. After filling the pipelines, the valve is closed and compressed air is supplied. The air and water mixture is supplied to the pipelines simultaneously (see also the article on hydropneumatic flushing of the heating system). Flushing ends when clean water begins to flow through the nozzle. The water is then drained into the drain. This method is used for flushing hot water supply and heating systems;

Fillings. This method has some consistency in actions. First, the pipelines are filled with water and the valve is closed. Compressed air is supplied to the second pipe for twenty to twenty-five minutes (depending on contamination and pipe diameters). After the air supply is stopped, the shut-off valves are closed and the water is drained through the drain pipe. At the end, the system is washed a couple of times with clean water.

Typical scheme for carrying out work

Features of the heating system and hot water supply

According to SNiP and GOST standards, such technology should guarantee a stable temperature range of 20-22 degrees and humidity parameters of 30-45% in apartments.

The principle of operation of the system is as follows: water flows from the thermal power plant to the house, its indicators are 131-151 degrees. It follows a pressure of 6-10 atm. This ensures its appearance at all levels without loss. Getting through the return pipeline, the water can have a temperature of 60-75 degrees.

Water with a reading of 130 degrees is not suitable for everyday use. And the reduction in parameters is ensured using an elevator unit. This device ends the heating supply and passes to the return circuit.

Through this channel, water is sent for recycling into the network. As a result, the coolant reaches the required temperature to heat the apartments on each floor.

Heat exchanger flushing frequency

If the system does not have a filter, the heat exchanger needs to be cleaned once every 2 years.

The frequency of cleaning heat exchangers is specified in the operating instructions that come with the product. Most manufacturers recommend doing this every 2 years. However, if water saturated with lime is used, a thick layer of plaque can boil in just one heating season, even if the boiler has a stainless steel circuit. When a filtration system is installed in the harness, the procedure can be carried out at intervals of 4-5 years. Water needs to be changed annually, as it changes its structure and acquires properties that are aggressive towards metal.

It is best to calculate the required frequency of cleaning the heat exchanger experimentally. After the end of the heating season, you need to disassemble the boiler, remove the circuit and assess its condition. The plaque will tell you how long it will take for its thickness to reach a critical state.

Signs that a flush is needed

The following factors may indicate the need for flushing:

- Filters are dirty. A properly assembled heating circuit must contain coarse filters in a transparent flask. In this case, intense contamination of the cartridge indicates the need to flush the heating circuit.

- A signal about the need for flushing can be the low temperature of radiators, heated floor circuits, or their prolonged heating.

- Increased electricity consumption by a heating boiler for heating premises in comparison with the previous period indicates the formation of a layer of scale on its heat exchanger.

Tips/Tricks

To increase the cleaning effect, bleach is added to the input. This allows you to disinfect not only water, but also the inner surface of the pipes.

During self-washing, the technician needs to keep in mind that radiators and pipelines are washed separately from the boiler. If communications have a complex, branched structure, cleaning is carried out separately for each circuit.

For preventive purposes, the water is softened, but if this is not possible, the heating system is regularly flushed. Without maintenance, the system quickly deteriorates, and then the owners will have to replace all communications.

Signs of circuit contamination

The system must be flushed in the following cases:

- the temperature in the room dropped without reason while the boiler was on;

- pipes heat up slowly;

- with a hot pipeline, the radiators remain cold;

- the integrity of the pipes is compromised, fistulas appear and ruptures occur;

- The boiler is noisy.

In addition, the heating system must be flushed immediately after installation. During equipment installation, debris, oils, and other products may have gotten inside.

The heating system must be flushed immediately after installation.

How to choose the optimal flushing pump?

Modern washing equipment is represented by units with a variety of functionality. The main manufacturers that have earned the approval of the international market are German factories (Rems, Rothenberger), Italian concerns (Manta Ecologica) and American (RIDGID). But, despite the high quality of each device, it is short-sighted to buy a flushing pump without assessing its operational capabilities. When choosing the optimal model, experts advise studying the specification of the unit.

- For the private sector, preventing and eliminating deposits in the system is a big problem. Utility workers stand guard over the apartment building. In a cottage, the costs fall on the homeowner. The Ridgid DP-24 or DP-13 descaling flushing pump will help the owner deal with the annual problem on his own.

- Inexpensive pumps from Rothenberger compete with compact “Americans”. The popular Rocal and Romatic washing devices do an excellent job of removing scale in installations with a capacity of 300 liters. At the same time, the technical characteristics of Rothenberger and Ridgid units allow the equipment to be used for commercial purposes.

- In the Pump Eliminate model line, professionals will find devices for removing scale from heat exchangers. Any flushing pump from Manta Ecologica is distinguished by high productivity and good throughput. A wide price range and variety of functionality mean you can purchase a unit that meets different tasks.

- Ropuls compressors from Rothenberger are devices on a different scale. They allow you to buy a flushing pump in conjunction with many additional options. In addition to their direct specialty, the units sanitize water pipes, are suitable for testing pressure in the system, and even for connecting pneumatic tools.

- A separate category is pressure testing devices with hydropneumatic pumps. REMS units open up wide scope for the work of specialized enterprises.

How is pressure testing carried out?

After hydropneumatic flushing, and indeed before each heating season in an autonomous heating system, it is necessary to check the tightness and carry out routine maintenance to improve the tightness of pipeline connections. Day after day, the connections of your heating system wear out and in order not to have an accident with a breakthrough in the cold season, that is, the tightness of the pipes must be prepared in advance. This operation is called crimping.

heating radiator crimping

Note that, as a last resort, pressure testing can be carried out during the heating season; usually such an operation is performed after accidents on pipelines. In addition, pressure testing and monitoring of the condition of pipeline connections is carried out during the first start-up of the system after its installation.

The process of crimping heating system pipeline connections consists of the following stages:

Slowly fill the system with cold water. Please note that the pressure in the system must be increased gradually, not abruptly. The fluid pressure level in the system is controlled using a pressure gauge. When the operating pressure of the system is reached, it remains under pressure for about half an hour. During this time, you can visually inspect the condition of the pipelines and their connections, make sure that there are not only leaks, but even the slightest leakage of water. The easiest way to control leaking moisture is to place pieces of toilet paper or napkins under the joints, on which drops of water or silt will be clearly visible.

In addition, the condition of the system is monitored by pressure gauge readings. This is done because pipelines can leak in places inaccessible to visual inspection. If there is no decrease in pressure on the pressure gauge and there are visual signs of damage to the pipes and system, you can begin to operate it. For additional confidence, the pressure in the system can be increased by 10-15 percent above the calculated one.