Stoves in the house have not lost their relevance to this day; they successfully solve the problem of heating a home. If the house is too large, then using only one furnace device it is difficult to achieve a comfortable temperature in all rooms. In such cases, it is impossible to do without installing an effective heat exchanger and multiple radiators. The coolant is usually water or steam. As a result, the air, walls and floor are heated evenly throughout the building, creating a microclimate quite comfortable for people.

High efficiency of steam heating is possible only if high-quality equipment that meets all standards and requirements is used for its installation. Source plasportal.com

Principle of operation

When installing steam heating in a dacha, a stove or boiler is used as a heat source. With their help, water is heated to boiling point, then the evaporation process begins. The steam penetrates the batteries through the pipeline, gives off heat, and gradually condenses. The resulting water flows into the heat exchanger through the return pipe.

Steam boiler

When choosing a water heater, it is extremely important to pay attention to the performance of the unit. The larger the area of the heated premises, the more powerful the heating device should be.

In houses with steam heating, a solid fuel boiler is often used. A modern gas heat generator is comparatively more efficient. Using an electric device to heat a home is not economically profitable, which is associated with high costs for electricity.

Household steam boilers are used as a heat source for heating a house: they heat a container of water and drive the resulting steam into heating pipes Source eurosantehnik.ru

Bake

If the house has a stove, it can serve as a heat source when installing steam heating. This will save you from additional waste on dismantling the device and repairing the premises. It’s also worth remembering: coal and firewood are inexpensive fuels. When using it, there is no dependence on centralized electricity and gas supplies.

The steam generator is a heat exchanger; you can make it yourself or order it. The design itself is quite simple, consisting of interconnected metal pipes.

If you plan to use a wood stove as a heat source, you should immediately calculate and design a special heat exchanger Source 1-teplodom.ru

Boiler room arrangement

Obviously, for the boiler in which water will turn into hot steam, it is necessary to allocate a separate room. This is necessary for safety reasons, and the equipment is quite noisy. Maximum removal of the main element, i.e. the boiler, from living rooms will reduce the noise level or completely eliminate it.

The boiler room must be spacious enough so that the necessary manipulations with the boiler can be carried out comfortably. If necessary, additional noise insulation work can be carried out.

There is also a list of requirements for a technical room that it must meet:

- The distance from the boiler to the walls must be at least 1 m

- The ceiling height must be at least 2 m 20 cm

- Compliance with fire resistance requirements for the materials used: for doors 30 minutes, for walls 60 minutes

- Equipment for a high-quality ventilation system

- Presence of windows and doors leading to the street in the technical room

- The location should be on the 1st-2nd floor

Ceramic tiles are usually used as a fire-resistant material. And given the fact that the heating system is steam, and if the circuit breaks, water will fall on the walls and floor, ceramic tiles are an ideal option. In addition, it is easy to lay out and does not require additional processing.

Making heating yourself is not difficult; the most important factor is full compliance with all legal norms and requirements, as well as fire safety provisions.

All this, taken together, guarantees uninterrupted operation of the equipment and safety for the entire home. Also, we must not forget about routine inspections and maintenance.

Advantages and disadvantages

Equipped steam heating at the dacha has the following advantages:

- provides intensive heating of rooms;

- steam instantly reaches all areas of the heating system, regardless of its complexity or the size of the building;

- pipes never freeze;

- does not require large expenses for the device;

- can be used in buildings for seasonal residence, for heating several floors;

- maximum heat transfer coefficient;

- Can be used together with heated floors.

Flaws:

- circulating along the circuit, steam creates a lot of noise;

- pipes and batteries can heat up above 100°C, which creates a risk of burns upon contact;

- it is difficult to regulate the indoor air temperature;

- the system is susceptible to corrosion, so it does not last very long;

- in the event of a pipeline breakthrough, a dangerous emergency situation is created (the coolant temperature reaches high values).

Important! Steam heating can be used to heat a house with several floors. The steam rises independently to any height, cools, and returns as condensate. Moreover, the installation of expensive pumps is not required at all.

What are the disadvantages

Steam heating is not suitable for everyone due to existing imperfections.

The hot steam heats up the batteries so much that you can get burned from touching them.

When steam and water are mixed, rust forms inside the pipes, gradually clogging the space, increasing the likelihood of sudden depressurization.

If the joints are broken, a steam stream escapes, which can cause severe burns.

If the homeowner is allergic to dust, it is not recommended to install such heating, due to the acceleration of air circulation.

The air space inside the room dries out greatly, which can lead to frequent colds and a cough that does not go away for a long time.

The choice of pipes and building materials for finishing is very limited, since not every type of raw material can withstand a high degree of heat.

A simple connection diagram eliminates temperature control. Separate switching on or off of parts of the circuit is allowed.

The problem may be the noisy operation of the boiler.

Scheme

The heating system operates thanks to natural circulation. Therefore, the heat exchanger must be installed below the level of the radiators. The circulation pump ensures constant operation of the thermal circuit.

There are open and closed steam heating circuits: in the first case, the system is connected to the atmosphere (open), in the second, it is completely isolated from the effects of atmospheric pressure Source s-proms.ru

Steam heating in a house involves the installation of a one- or two-pipe heating system. The optimal choice of the latter depends on the area of the building that is planned to be heated.

Single-pipe

With single-line wiring, radiators are connected in series. The resulting steam passes through a pipeline from one battery to the next. As a result, the first radiator is always the hottest, the last one is almost cold. The single-pipe system is suitable only for small-sized rooms (no more than 80 m²).

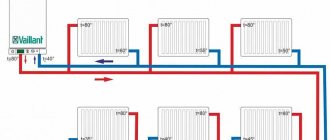

Two-pipe

If the house has a huge area, a two-line heating option should be used. A constant supply of hot steam is carried out through the upper pipe. The cooled condensate returns to the heating unit through the lower pipeline. Regardless of the distance from the boiler, all heating batteries heat up evenly.

A single-pipe heating system is more suitable for heating a summer house or a small house; for a spacious cottage or two-story building, it is recommended to use a two-pipe system Source gubernia.media

Materials and equipment

To properly equip steam heating, you need to prepare:

- heat exchanger;

- radiators;

- pipes (preferably galvanized steel, copper);

- pressure reducing valve;

- brackets;

- valves;

- clamps, elbows, fasteners;

- welder;

- hydraulic valve;

- reduction-cooling device;

- pump;

- container for collecting condensed steam.

Advice! To minimize the cost of organizing steam heating, expensive equipment can be rented.

Radiators for steam heating are selected in accordance with the characteristics of the material from which they are made, taking into account the operating temperature Source otoplenieblog.ru

Heat exchanger

When building a brick stove, a heat exchange device will have to be ordered or made on your own. To do this you will need a welding machine and metal pipes. The thickness of the walls of the latter should be more than 2.5 mm. By welding they must be connected in the form of a coil. In addition, it is worth taking care of the tightness of the joints. It is important to take into account that 1 m2 of the surface of a curved spiral produces about 9 kW.

After creating the structure, it is important to check for permeability: fill it with kerosene, then outline the seams with chalk. Darkening of the latter will indicate penetration of a flammable liquid into the heat exchanger. Therefore, it is unacceptable to use such a device for heating with steam.

Self-manufacturing of a heat exchanger is only possible for people who have certain skills, tools and knowledge Source heatylab.com

Installation process

Steam heating in a private house from a stove should be installed in this way:

- When building a stove, place the heat exchanger in the combustion chamber. If the stove device is planned to be used for cooking, there should be no pipes left on top.

- Install radiators and connect the pipeline to them. To ensure natural circulation in the future, it is necessary to maintain a slope (3 mm per 1 m).

- All converters must be equipped with valves designed to remove air.

- For safety reasons, install a shut-off valve in front of each battery or one for the entire system.

- At the beginning of the circuit, install a cooling device, a pressure reducing valve.

- Connect a container to collect condensate. From it, water will flow at an angle back into the heat exchanger. It is not advisable to use a membrane expander: it is not designed for temperatures exceeding 85°C.

- When using forced circulation, install a pump directly in front of the stove (in the return circuit).

Important! Heating systems with natural circulation of steam do not require the installation of a tank or pumping equipment. Therefore, their work does not depend on the presence or absence of electricity.

If heating is planned to be done with solid fuel (for example, wood), then metal pipes must be used to install the system Source 1poteply.ru

Useful tips

When selecting equipment for creating a steam heating system, during its installation it is advisable to take into account the following recommendations:

- You cannot use used heating radiators. They are highly likely to have hidden damage, which will subsequently cause the system to depressurize.

- It is not advisable to use cast iron batteries. Under the influence of large temperature changes, they begin to collapse.

- Installation of the circuit must be carried out by workers with certain knowledge and skills. Otherwise, the created design may be ineffective.

- If you install a steam generator in a conventional wood-burning stove, you can significantly save usable space. In addition, home heating costs will be minimal.

- When using natural circulation, it is recommended to install the stove in the basement of the house. This will ensure that condensation quickly drains to the lowest point.

- For safety reasons and to prevent emergency situations, you cannot refuse to install valves.

The installation of steam boilers in a central heating system is prohibited by law. In private homes, this type of autonomous heating can function for decades without requiring replacement of the main structural elements.

The chimney of a stove with a built-in heat exchanger gets dirty faster than a conventional stove, so it needs to be cleaned more often Source roof-tops.ru

Liquid fuel stove

Liquid fuel stoves are rarely used in Russia. In Europe, on the contrary, they are popular among owners of private houses. Stove heating is characterized by high efficiency: losses during fuel combustion are insignificant.

- Fuel enters the combustion chamber through the nozzle. The vapors spread quickly in the chamber and ignite. A fan burner is provided for this purpose. It heats the fuel and pumps it into the combustion chamber. The ignition transformer supplies the spark.

- A heat exchanger is located on the side wall of the firebox. It is designed in the same way as a radiator, which allows you to increase the heating area. Water supply and condensate lines are connected to it. A separate outlet is made for hot water or steam.

- The thermal chamber is made of durable materials. It has a chimney for exhaust gases. A separate channel is provided for supplying air from the atmosphere.

- The system is fully automated and equipped with software.

The boiler is installed behind the furnace. The heating system line is built from it. The system is most often made double-circuit to provide residents with hot water. A stove with installed steam heating will last more than 50 years. To generate a power of 10 kW you will need 1 kg of diesel fuel per hour. Manufacturers offer liquid fuel stoves that can be converted to use gas.

How does steam heating differ from water heating?

In a water heating system, the coolant is often water. It moves inside the pipeline and gradually cools there. In the case of steam heating, the liquid being poured evaporates and hot steam moves through the pipes. After cooling, it condenses and then flows through the return pipeline back to the heating unit.

When the coolant is steam, the thermal output of heating devices is significantly higher, rooms heat up three times faster. Such a system starts up quickly even after a long break in use.

Additionally, it is worth noting the lower cost of materials for steam heating devices. This is explained by the use of compact and ergonomic equipment during installation (for example, pipes of relatively small diameter).

Unlike water heating, steam heating gives greater heat transfer and warms up the room three times faster Source pechiexpert.ru