The use of liquid heating systems in private homes today is based on several system operation schemes. One of the most reliable, simple and time-tested schemes is the gravitational heating system. Based on the laws of thermodynamics, gravitational heating has become widespread due to the small number of elements and simplicity of work, both in terms of design calculations and practical installation. But, despite its apparent simplicity, for proper operation it is necessary to take into account many points, which will be discussed in this article.

The essence of the system

How does circulation pressure occur?

The flow movement of the heat-carrying liquid through the pipes is due to the fact that when its temperature decreases and increases, it changes its density and mass.

The temperature of the coolant changes due to heating of the boiler.

The heating pipes contain a colder liquid, which has given up its heat to the radiators, so its density and mass are greater. Under the influence of gravitational forces in the radiator, the cold coolant is replaced by hot one.

In other words, having reached the top point, hot water (this can also be antifreeze) begins to be evenly distributed over the radiators, displacing cold water from them. The cooled liquid begins to sink into the lower part of the battery, after which it completely goes through the pipes into the boiler (it is displaced by the hot water coming from the boiler).

As soon as the hot coolant enters the radiator, the process of heat transfer begins. The walls of the radiator gradually heat up and then transfer the heat into the room itself.

The coolant will circulate in the system as long as the boiler is operating.

How it works

Principle

Let's try to more clearly imagine the mechanism of operation of such a system.

Simply put, it consists of two communicating vessels connected by pipes (heating circuit) into a single ring. The first vessel is the boiler, the second is the heating system itself, consisting of radiators, bottling and hoses. The height of both vessels is the same.

After heating the heat exchanger, its contents rush upward, displaced by colder masses. Having reached the top point of the accelerating manifold, the hot coolant begins to go down, passing through the heating devices along the way and gradually giving them thermal energy.

As it cools, it increases its density and at the lowest point of its route is ready to displace the heated liquid located in the boiler heat exchanger into the accelerating manifold, starting a new cycle of system operation.

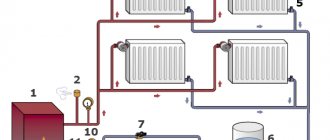

The principle of operation of the gravity system.

Factors

Obviously, the higher the circulation speed, the more uniform the heat distribution in the circuit will be, the smaller the temperature spread of the batteries will be. How is this speed determined?

The balance of two factors opposing each other: the pressure created during operation of the system and the hydraulic resistance of the circuit.

What does each factor depend on?

Pressure

- From the height of the accelerating section of the circuit (that is, the total height of the boiler - accelerating manifold section). To increase it, the boiler, if possible, is mounted in the basement, and the upper part of the bottling is moved to the attic.

- From the pouring slope. As a rule, it is made permanent: from the top point the bottling goes down to the boiler, losing at least a centimeter of height above the floor level per linear meter of length. Thanks to the slope, the cooled coolant makes its way, carried away by its own gravity.

The bottling is laid with a constant slope.

Hydraulic resistance

The lower it is, the easier it is for water or other coolant to make its way at a fixed pressure.

What affects the hydraulic resistance of the system?

- Filling diameter. The larger it is, the less resistance the pipe has to the flow of water. The absolute minimum diameter is 32 millimeters; More often, when constructing a gravity system with your own hands, a pipe measuring 40–50 mm is used as filling.

- Bottling length. A circuit more than a hundred meters long with a reasonable diameter will simply be inoperable. Typically, gravity heating systems are not made longer than 40-50 meters.

- Number of bends and diameter transitions. Each of them increases resistance to water movement.

- Number and type of shut-off valves. The less turbulence on the throttling devices, the better.

The body of the screw valve creates significant resistance to the movement of water flow.

Finally, the pipe material and its age have the strongest influence on the resistance to flow. To be precise, the determining factor is the so-called roughness coefficient. Compare its value for different pipes.

| Description of the pipe | Roughness coefficient |

| Polymer or metal-polymer | 0,1 – 1 |

| New steel | 6 |

| Galvanized steel after 5 years of operation | 15 |

| Black steel after 5 years of operation | 20 |

| Black steel after 20 years of operation | 200 |

Detailed analysis of gravity heating

During the analysis process, we propose to consider a single-pipe scheme, which can later help you when building your heating system.

Let's agree that in the diagram we will consider water as the coolant. For year-round use in heating systems, it is recommended to use compounds that do not freeze at temperatures below zero (antifreeze, etc.)

By using antifreeze, you will eliminate the possibility of your system defrosting.

Gravity heating systems by their name indicate their operating principle. In such a system, hot water moves without the use of a pump. This happens due to different temperatures of the coolant at the inlet and outlet of the boiler.

As mentioned above, such a system is outdated and rarely seen in operation.

This is explained by significant disadvantages:

- high cost;

- low efficiency;

- not economical.

But if you look from the other side, this is one system with which you can heat a country house or a small private house without electricity. There are practically no such houses, but anything can happen.

Selection of boiler, pipes and consideration of the diagram

Therefore, the best choice in our case would be iron pipes.

As a result, there are immediate disadvantages:

- low efficiency;

- expensive and complex installation of the system;

- the size of the pipes is not aesthetic;

- the price of pipes is high.

It is also necessary to take into account that when entering the first radiator, the water will have the highest temperature. Therefore, at the beginning you need to install fewer radiator sections than at the end. The large volume of radiator sections compensates for the low temperature of the water (coolant).

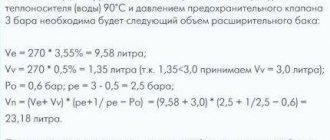

The expansion tank is an important element of the heating system. It must be taken into account that when heated, water, like any material, tends to expand. In order not to deform the system, an expansion tank is installed. The instructions will help you choose the right volume.

The expansion tank is installed at the highest point of the heating system.

Flaws.

Like everything man-made, the gravity heating system has its disadvantages, which are expressed in the following:

- The system has a fairly low circulation pressure, which is why its range of action is reduced to thirty meters horizontally.

- The same factor, along with the high heat capacity of water, determines the low startup speed of the equipment.

- Often, an expansion tank for water is installed in an unheated room, which can cause the said liquid to freeze in winter. This is fraught with undesirable consequences, manifested in the destruction of pipes.

Heating scheme for a private house with forced circulation

Two-pipe forced circulation circuit

If we consider the advantages of a scheme using forced circulation, then the main disadvantages of a gravity system are its obvious advantages. You should not pay special attention to a single-pipe system, since it is practically no different from a gravity-flow system. Unless it is the presence of a circulation pump and a closed expansion tank, which creates the pressure necessary for the reverse movement of the cooled coolant. Therefore, we are more interested in the two-pipe version of the forced circulation scheme. It is beneficial both from an economic aspect and from a design point of view, since in this case there is no need to create a pipe slope - they can be hidden in the walls, floor, and even under the ceiling.

This became possible due to the fact that heating radiators are connected in parallel, which allows you to regulate the temperature in each of them separately, up to complete shutdown. This is also very beneficial in terms of savings

You just have to be careful when using this advantage. In particular, to install such a system when working on solid fuel boilers, a serious approach to installing automation systems that can protect the system from the consequences of overheating is required

In the case of gas boilers, this is a win-win option.

Speaking about a forced circulation scheme, it would be wrong not to touch upon the circulation pumps themselves, which ensure the operation of the system. It goes without saying that you need to buy only pumps from a trusted manufacturer. By the way, in modern double-circuit gas boilers, circulation pumps are an integral part of the design. As for the power that circulation pumps use, we can note the fact that they are very economical. Thus, a standard circulation pump consumes power equal to that needed to operate a regular indoor light bulb.

Considering that in a forced circulation scheme it is not important that the boiler is located below the radiators, more careful attention should be paid to the installation of the pump itself, which circulates the liquid. It is very important to choose a place to install it in the system. In most cases, the pump is installed on the return line - immediately before it enters the heating boiler. Although this issue is not so important, and the pump can be installed anywhere in the system

As for the durability of the device, installation on the return line will extend the life of the pump

Although this issue is not so important, and the pump can be installed anywhere in the system. As for the durability of the device, installation on the return line will extend the life of the pump.

Heating scheme with natural circulation

Heating schemes with natural circulation of coolant are not particularly popular today due to their “morally old age”, low efficiency, bulkiness, high cost of materials and installation, the impossibility of differentiated temperature control in individual radiators, etc.

But they are indispensable in those houses where there is no electricity, since such systems, equipped with a solid fuel boiler, can operate autonomously (with occasional human presence, of course).

The principle of operation of a heating system with natural circulation (it is also called gravity) is to create a temperature difference between the coolant at the outlet of the boiler and its inlet. Due to the different densities of the coolant at different temperatures, it moves through the pipes by gravity, without the use of a circulation pump, that is, warm water rises up, and already cooled water “comes” from the return pipe in its place. As the coolant sequentially passes through the radiators, it lowers its temperature, releasing heat to the environment, and after a “full circle” and returning to the boiler heat exchanger, it heats up again, and the cycle repeats.

The volume of coolant in such systems is quite large and depends on the diameter of the pipes and the length of the system. On average, the volume of water will be 3 times greater in a system with natural circulation than in a system with forced circulation. And this is with an equal area of heated premises.

A large amount of coolant in the system increases its inertia. There is also a positive aspect to this: if the boiler goes out, the heat in the system will remain for some time. And if you use antifreeze in the heating system, you will simply pay for additional tens of liters of this substance.

The sequential passage of the coolant through the heating radiators leads to its cooling. Thus, those radiators that are located at the beginning of the system (from the central riser) will heat up more than those that are located at the end of the heating line (in front of the boiler). It is almost impossible to regulate the degree of heating of radiators with such a connection.

Another feature of such a system is its “choosiness” regarding the material of the pipes used. They must be metal - usually steel. Polymer pipes simply cannot withstand the high temperature that can arise in the system when the coolant in the boiler overheats. The consequences of such a “limitation” in the choice of materials are the low efficiency of the entire system as a whole, the high cost of installation and the nullification of the aesthetics of modern heating devices by the large diameter of steel pipes and the bulkiness of the entire system as a whole.

A mandatory element of such a heating system is, which must be located at the top point of the system. Its volume should be approximately 1/10 of the volume of coolant in the system. For example, if the coolant volume in the system is 200 liters, the tank capacity should be 15-20 liters. The open type of tank assumes that the system is constantly in contact with atmospheric pressure. This is also a prerequisite for the existence of the system.

Let's summarize.

Gravity has the following advantages:

- possibility of autonomous use;

- quite high thermal inertia.

Flaws:

- large volume of coolant (antifreeze);

- unaesthetic “bulkyness”;

- low efficiency;

- expensive (difficult to do independently) installation;

- quite high cost;

- lack of ability to adjust temperature.

Parallel two-pipe version of the heating system of a private house

In the system, the diagram of which is shown in the figure, the temperature of individual radiators will no longer depend greatly on location; you can already regulate the temperature of individual radiators, but not all! The slope of horizontal pipes (risers) and their sufficiently large diameter are also required.

Let's move on to the next heating system diagram.

Selection of components

The appearance of polymer pipes has become a rather important event in the field of installation of gravity boilers. This material is easy to process, and when connecting individual sections of the pipeline, a minimum set of equipment is required. However, not all polymer pipes are suitable for use in heating systems. The main aspects to pay attention to are:

- Presence of a reinforcing layer. The temperature of the coolant can reach 95°C, so the pipes must be heat-resistant and retain their original rigidity. For strengthening, a layer of foil or fiberglass is usually used;

- Wall thickness. High pressure is an integral part of gravity systems, so to avoid emergency situations, products of at least PN20 class should be used. The wall thickness will depend on the selected diameter.

Such pipes should be laid when installing the accelerating manifold. It is recommended to assemble the return line from steel products - they will further reduce the temperature of the coolant and reduce the hydraulic resistance.

Despite the expanded expansion of cast iron floor-standing gas boilers and indirect heating boilers, gravity gas heating equipment is still in steady demand among the larger rural population.

How can this fact be explained?

Gravity cast iron boilers can effectively heat living spaces without additional electricity supply. It is enough to have a stable gas pressure (at least 5-6 atmospheres), and the gravity boiler will operate with high power and excellent performance in terms of gas fuel consumption. Gas consumption in these types of boilers is relatively small. Even the most powerful (up to 17-20 kW) gravity boilers are rarely capable of consuming natural gas in a volume of more than 3-4 cubic meters per hour! Fuel savings are achieved by installing the gas boiler on a reinforced concrete floor in a separate room. And the lower the boiler is installed, the better the draft will be observed - the fuel will burn almost completely.

The main advantage of gravity boilers is the type of material used. After all, it is still customary to produce gravity-type boilers from good old cast iron, which is practically not susceptible to corrosion processes. Ordinary steel tends to corrode at an average rate of 0.1 mm/year. That is why steel gas boilers have a maximum service life of no more than 8-10 years! When it is important for the owner of the house that his boiler can operate for at least 30-40 years, it is initially recommended to buy exclusively a gravity boiler, entirely cast from cast iron!

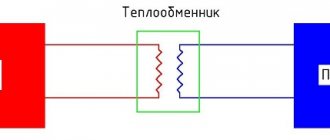

The latest versions of gravity boilers are most often produced by manufacturers in double-circuit form. What does this mean in practice? In this case, manufacturers, in addition to the main heat exchanger made of anti-corrosion gray cast iron, install a second one, in which a phenomenally impressive (up to 6-9 liters) volume of hot water will be heated continuously. You will no longer have to buy and install different versions of electric water heaters or indirect heating boilers, which are expensive.

Disadvantage of gravity boilers:

- Boilers need to be cleaned from time to time

- they are not capable of heating the second or third floors of private houses, since the coolant needs to be heated to 100 C, after which it will begin to expand and rush upward. But for one-story houses that use a one- or two-pipe heating system, this option will be the most optimal. Especially if you install heating pipes of impressive diameter (up to 80-100 mm), thanks to which the coolant can circulate much more efficiently in the internal system of the house.

Advantages of gravity heating

Scheme of the occurrence of circulation pressure.

However, this scheme has advantages that determine their choice in individual cases:

- relative ease of operation of the device;

- independence from electricity supply;

- absence of circulation pumps, noise and vibration;

- comparative durability (operate without major repairs with proper operation for 35-40 years or more);

- increased thermal reliability due to the action of quantitative self-regulation.

We should focus on quantitative self-regulation. In the gravitational system, a unique regulation mechanism is created: when carrying out qualitative regulation, that is, when controlling temperature, quantitative regulation occurs spontaneously - the water flow changes. In fact, if you change the temperature of the heating water depending on the temperature of the outside air, due to a different density distribution, the natural circulation pressure and, accordingly, the volume of the circulating liquid changes.

Increasing or weakening the circulation of liquid in a two-pipe system in the circulation ring of all heating devices changes the heat transfer into the room, which, changing, in interaction with the heat loss of the room, itself affects the flow of liquid, changing the circulation pressure and the temperature of the return water. As a result, the correspondence between the heat transfer of the device and the heat loss of the room is maintained, that is, the reliability of the thermal characteristics of each individual device and, accordingly, the entire heating system is ensured.

Hot and cold water distribution pipeline diagram.

Thus, the natural circulation pressure, which causes thermal vertical misalignment in the pump two-pipe heating system, maintains the thermal reliability of the two-pipe gravity system.

In a single-pipe vertical system, there is a quantitative similar self-regulation, but in the circulation rings not of a specific device, but of entire risers with their devices connected in series. In this case, the weakening or strengthening of fluid circulation occurs more intensively than the optimal regime schedule requires. As a result, during the warm period of the heating season, one can observe a deviation from the required heat supply of some devices: when moving from top to bottom in a riser of a greatly reduced volume of liquid, the lower devices do not heat the room. This phenomenon gets worse as the number of floors of the building increases.

Thus, the circulation natural pressure, which contributes to the thermal reliability of the vertical pump single-pipe heating system, causes thermal vertical misalignment of the single-pipe gravity system.

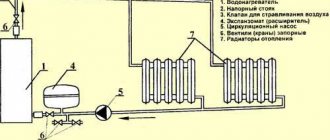

Heating installation diagram in the house.

With natural circulation of liquid, preference should be given to two-pipe heating systems. A vertical single-pipe system makes it possible to increase the natural circulation pressure and the speed of fluid movement in comparison with a two-pipe system, as well as to locate specific heating devices lower than the heat exchanger.

The diagrams of gravity systems are similar to the diagrams of pumped heating systems. Understanding the dependence of the circulation natural pressure on the vertical distance between the heating and cooling centers and the patterns of horizontal movement of air accumulations in pipes, it is possible to determine whether it is necessary to use the upper distribution in the gravity circuit of the supply line. In this case, the expansion tank is connected directly to the main riser, the supply line is sloped towards the movement of the liquid, and a tank is used to remove air. In heating devices, the most rational pattern of fluid movement is obtained for a two-pipe circuit - from top to bottom.

Features of design and installation

The main components of the gravitational system include:

- heating boiler in which water or antifreeze is heated;

- pipeline (double or single);

- heating batteries;

- expansion tank.

When designing, as well as directly during installation of the system, it is very important to meet one mandatory condition: the pipe through which the coolant will move must be sloping towards the heating boiler. The slope must be at least 0.005 m

per one linear meter of pipe.

In general, if the boiler and radiator are located on the same floor, then the pipe entrance to the radiator should be slightly higher.

Scheme of a gravity system with pipe slope

The presence of this bias is explained by the following factors:

- through an inclined pipe, cold coolant will flow faster into the boiler;

- the presence of a slope is also necessary so that the air bubbles that appear during the heating process of the coolant rise more efficiently into the expansion tank, from which they evaporate into the atmosphere.

The expansion tank creates additional pressure, which has a beneficial effect on the speed of water movement through the pipes.

The speed of movement of the working fluid directly depends on the difference in such quantities as mass, density and volume of the coolant in cold and hot states. The speed of flow movement is also affected by the level of radiators relative to the boiler.

The gravitational pressure in the heating system is used to some extent to overcome the resistance of the pipeline. Additional obstacles include turns and branches in the system, and additional radiators.

Therefore, in order to maximize room heating, when designing a gravity system, you need to ensure that there are as few such obstacles as possible.

Why is a pressure loop needed in a gravity heating system?

To make it clear, we can give a simple example with a ball. Let's take a rubber ball, drown it with our hand in a bath of water to a shallow depth, and release it. The ball will fly out of the water, float up, measure the distance at which it flies out. Let's do the experiment again, only we'll drown the ball as deep as possible and let it go in the same way, again we'll measure how much it jumps out. In the second case, the ball will jump higher. The same thing happens with the coolant when it comes to a heating system with gravitational or natural circulation. Hot water is lighter than cold water, which means it will rise. The boiler heats the water, and the higher it rises along the riser from the boiler, and if it is straight and its diameter is not underestimated in comparison with the outlet from the boiler, the more the water can accelerate inside the riser, and therefore create pressure.

The hot water will rush upward and will pull cold water from the return line into the boiler, where it will heat up again. Thus, natural circulation will be realized in the heating system.

The faster and better the circulation, the smaller the difference in supply and return temperatures in the system will be. The water speed with a well-functioning system can reach 1 m/s. From the lowering, the bottling of the future heating system is brewed.

What pipes can be used?

To install the system, you can use not only steel pipes. You can also use polypropylene, copper, stainless steel, etc. The main thing when using polymer pipes is to look at the temperature at which it is permissible to use this pipe. To fill the system, risers are then welded, which serve to connect radiators.

Moreover, bottling in a gravitational system can be on floors and lower ones, which is everyone’s favorite. But for this, a condition must be met: the top of the boiler must be lower horizontally than the bottom of the radiators. That is, the boiler must be in the basement or, as already mentioned, be buried. But nothing prevents you from making a mixed distribution, the first floor with an upper filling, and the second and upper floor with a lower one. Moreover, the lower bottling of the second or other upper floor can be either single-pipe or double-pipe.

What pipes should I use?

The length and diameter of the pipes will be known at the end of the project. It remains to decide on the material. For installation, steel, copper, stainless steel and polypropylene pipes are used. The latter has a number of advantages over the others. This material is light in weight, it is also convenient during installation, has high noise insulation, anti-corrosion effect and resistance to defrosting.

Important!

When installing polypropylene pipes, pay attention to the temperature, the maximum of which is typical for this pipe. The reinforcing layer will play an important role, which will help maintain the original shape of the pipes and protect against high temperatures.

But it is recommended that the return part of the pipe entering the boiler be made of steel. With its material, it will reduce the water temperature and help reduce hydraulic resistance.

Two-pipe heating system

There are two options for connecting radiators to the heating system:

The only advantage of a one-pipe system is the savings on pipes. But there is a significant minus - the radiator closest to the boiler is the hottest, and the farthest is the coldest. It is also problematic to turn off a radiator - they are all in the same circuit. If it's not critical, why not use this option? Quite a normal scheme.

The two-pipe scheme is more flexible:

- All radiators are in almost equal conditions. Water is supplied to each person at the same temperature;

- You can set your own temperature on each radiator by regulating the flow of water through it;

- You can safely shut off the water supply to any radiator, for example, when it is hot or you need to flush the radiator;

- More convenient for increasing the number of radiators.

For the sake of fairness, it must be said that in the two-pipe version, the last radiator is somewhat “offended”; it receives less heat. The reason is that the pressure difference between the supply and return is practically zero and the water flow is minimal.

So what choice did I make?

That's all for today. In the following articles I will bring to your attention a gas heating system, heated floors, and infrared heating. Comment, ask questions. Thanks, see you!

A centralized heating system does not always cope with the tasks assigned to it. Therefore, many strive for energy independence and worry about installing autonomous heating. This is especially in demand in private homes, where often there is simply no centralized heating system. There are various heating schemes for a private home, but you just need to choose the one that suits the specific conditions of your home.

Wiring

The instructions for wiring radiators are determined primarily by the number of floors in the house.

One floor

When wiring to one floor, the author strongly recommends not reinventing the wheel and using the time-tested Leningrad wire. In its correct implementation, it consists of a ring laid around the perimeter of the house, with heating devices embedded parallel to this ring.

Each radiator is connected from bottom to bottom or diagonally. The connections are equipped with two valves or a valve on the supply and a throttle on the return. Shut-off valves will allow you to disconnect batteries for repairs without stopping the entire circuit, or to throttle some heating devices to equalize temperatures.

Leningradka with bottom connection of radiators.

A simplified version of a heating system with natural coolant circulation

The boiler is installed, the place for it is determined in advance. The supply riser is removed from the boiler, and in a predetermined place upward, as far as possible in the building. As a rule, in the attic or some storage room on the top floor of a country house.

An expansion tank with an overflow pipe leading to a utility room where there is a sewerage system is installed at the top of the riser. If the expansion tank is supposed to be closed, then it is installed on the return line in the boiler room or other room, and an auto-ventilator is installed at the highest point. A security group is also installed in the boiler room on the 1st floor. The boiler must be installed as low as possible, in a pit or basement. It is prohibited to install a gas boiler in the basement. From the top point, where the open expansion tank or air vent was installed, a lowering is made. This creates a pressure loop. Next, we’ll talk about why a pressure loop is needed.

Water heating at home

In this case, the coolant is water or special liquids, for example, antifreeze. Here the heat sources are also very different depending on the fuel. But if warm air comes

into the room, then the water air of the room

is heated by devices

that give it

the heat accumulated by the water

.

And water accumulates a lot of heat. There is such a concept: “heat capacity”, remember? If in your own words,

So this indicator for water is very good. Look at the table on the right.

It turns out that we get a luxurious coolant for practically nothing.

Yes, the water system is somewhat more complicated, but it is also more flexible.

Imagine, heated water can be supplied through pipes anywhere and there it will release the accumulated heat.

And the pipes can be easily hidden in the walls, or not hidden at all; modern ones look very aesthetically pleasing.

How does water give off heat? Several types of devices have been created for this:

Radiators are massive, for example cast iron, sections assembled into batteries.

Hot water flows inside them. They give off thermal energy mainly due to infrared radiation (radiation).

They are usually steel or aluminum, less often copper. The surrounding air, heated by the convector, begins to naturally move upward. That is, a flow (convection) of air is created that removes heat from the convector.

Modern aluminum appliances also belong to convectors, although they are called radiators. It should be noted that now almost all thermal water heating devices are called radiators, although strictly speaking this is incorrect. But let's not be clever.

Air is pumped through them to be heated. They are often used in fresh air ventilation systems to heat cold air coming from outside.

“Warm walls” were used in panel housing construction in the seventies. A coil of steel pipe was embedded in the concrete panels, into which water was supplied from the heating system. I remember from childhood the warm walls of five-story panel buildings.

Let's take a closer look at the options for heating systems for low-rise buildings.

Video types, types of radiator heating systems

A gravity heating system is the only way out if there is no electricity or gas. This type of heating is practically never found these days, but there are times when it comes in handy.

Much will depend on the choice of heating scheme in the future, so this matter must be approached responsibly.

The type of heating you choose may depend on:

- room design;

- uniform heat distribution;

- ease of use;

- volume of work;

- price for materials.

On the Internet, if you wish, you can find many photos of drawings and even videos about different heating systems. But such schemes are difficult to understand, and besides, it will need to be adjusted to suit you.

We remind you that there are two basic heating system designs:

with forced circulation (using a pump);

These two types of heating systems are successfully used in both two-pipe and single-pipe systems. Let's talk in detail about the latter.

Warm floor or radiators

You also often hear the question of which heating is better for your home: heated floors or radiators. In fact, there is no answer to this question. It all depends on your preferences. Both heating systems will do an excellent job of heating your home. Therefore, let's highlight several criteria and focus on them.

- Installation price. Heated floors are more expensive in terms of installation cost than radiators, and the materials are also more expensive. The difference is 20%-30%

- Your operating costs will be approximately the same. Heat loss is a constant value for any heating system. And each system will spend the same resources to compensate for them.

- Comfort. Warm floors will be more comfortable than radiators. Heat is distributed more evenly throughout the room, walking on the floor is more comfortable, and heat distribution is also more rational.

When choosing a heating system, rely on your preferences. The only thing to keep in mind is that not everyone will have enough heated floors for proper heating.

Basic diagrams for home heating systems

Heating system of a private house

Despite the fact that heating systems differ in the type of energy source used, they have only two basic schemes. Correct measurements of the house and surrounding area will help you decide on the choice of heating scheme. The size of the building is the main indicator that determines the choice of scheme. Consider these diagrams:

- Scheme using gravity coolant flow;

- A circuit operating with forced circulation of coolant.

Let’s try to figure out what the fundamental differences between these schemes are. It should immediately be noted that both heating schemes can have a single-pipe or two-pipe design. Regarding gravity systems, it can be said that they have a number of disadvantages, and therefore they are used much less frequently than heating systems with forced circulation. These are the disadvantages:

- High cost of the system. Considering the fact that the supply line is located far from the cooled water return line, and everything happens under the influence of gravity of the coolant, it is necessary to install a pipeline of sufficient length.

- The complexity of installation due to the need to strictly adhere to the slope angle to ensure natural coolant flow in both directions.

- The unesthetic appearance of the system is due to the fact that it is not always possible to use modern materials, since the temperature of the water in the system can reach quite high temperatures, up to the boiling point.

- Difficulty in regulating the temperature of individual heating devices.

- Low efficiency due to large losses arising from the large length of the system.

- Large volume of coolant used.

Among the advantages of a gravity heating scheme, two facts can be noted. Firstly, such a system can work without power supply, although it is rare now to find an area where there is still no electricity. Secondly, the system has high inertia, that is, heat spreads evenly and external factors have little effect on the state of the coolant.

What will we talk about

I suggest not going into a detailed study of various heating schemes.

Let's look at them from the point of view of application in a private home.

After all, a private house can be for permanent residence, or temporary, like a summer house, for example.

So to speak, let’s narrow our topic and get closer to practice.

I was probably wrong about ten years. I started servicing my first heating system 33 years ago, when I was a student at the Ural Polytechnic Institute. I was lucky to get a job in the boiler room of the institute as a mechanic on duty. True, then I didn’t even think about what it was like, this system? It worked and that's it.

The work was sometimes difficult, when there was some kind of accident. And if everything is fine - beautiful, sit and study your notes. I spent the night on duty, in the morning I went to school, “to school,” as we used to say then. Two nights later, back on duty. And most importantly, they paid 110 - 120 rubles! At that time, young specialists received the same amount. Yes, plus a scholarship of 40 rubles. Gorgeous life! But let's get closer to the warmth.

Types of gravity heating schemes

There are dozens of schemes for gravity heating systems. A knowledgeable specialist, and even a beginner, can independently come up with a new scheme based on the specific conditions of the structure. In a general understanding, it looks like this: the coolant, heating up in the boiler under the influence of high temperature, rises through the riser and enters the heating radiators. There the coolant gradually cools down and, according to the laws of physics, is sent back to the boiler

It is very important here that the supply line from the boiler to the radiators does not have sharp turns or significant slopes

Gravity single-pipe heating circuit

The considered heating scheme works without interruptions, but it lacks the main thing - the ability to regulate the temperature in a single device. There are schemes in which this problem, although at a primitive level, is solved. In some cases, it is possible to turn off one or more heating radiators. More modern schemes, if one can say so about gravity systems in principle, offer not only the ability to turn off individual devices, but also the possibility of installing thermostats.

Typical gravity heating schemes in a single-pipe design were discussed above. As for its two-pipe version, the last option is an example of a typical two-pipe design. Although such a scheme is still gravity-fed, the ability to regulate the temperature in individual devices increases its authority. However, the consumer still makes the main choice in favor of a scheme with forced coolant circulation.

Radiator location

They say that with natural circulation of the coolant, radiators must be located above the boiler.

This statement is true only when the heating devices are located in one tier. If there are two or more tiers, the radiators of the lower tier can be located below the boiler, which must be checked by hydraulic calculations.

Specifically, for the example shown in the figure below, with H = 7 m, h1 = 3 m, h2 = 8 m, the effective circulation pressure will be:

g = 9.9 [ 7 (977 – 965) – 3 (973 – 965) – 6 (977 – 973)] = 352.8 Pa.

Here:

ρ1 = 965 kg/m3 – density of water at 90 °C;

ρ2 = 977 kg/m3 – density of water at 70 °C;

ρ3 = 973 kg/m3 – density of water at 80 °C.

The resulting circulation pressure is sufficient for the operation of the above system.