Ilya Voilokov, Ph.D. tech. sciences

Currently, designers are implementing a large number of methods for industrial heating of enterprises, workshops, warehouses and other facilities with a large volume of air and high ceilings.

The most common methods of heating industrial facilities include:

- general ventilation and heating system;

- infrared gas or electric emitters;

- infrared ceiling water panels;

- heating with mobile heat guns - gas, electric, etc.;

- convection heating system (radiators or steel registers);

- air heating system using stationary gas air heaters;

- underfloor heating system;

- air heating with water fan heaters or air heating devices.

General ventilation and heating system

This is a classic air heating system. Air is taken from the room and through an air duct system enters the chamber, where it is mixed with fresh air from the street. Then all the air is supplied to a water or electric heater-heater, where it is heated to the required temperature. After this, the already heated air is returned to the room through the air duct system.

Advantages: combination of both heating and ventilation in one system; the system as a whole works efficiently, since warm air enters the comfort zone from the air ducts; fire safety - high-temperature elements of the system are located outside the working area.

Disadvantages: high cost of implementation, it is economically feasible to use it only where mechanical ventilation is necessary; complexity of installation, adjustment and maintenance; the system takes up a lot of space; difficult to manage, since finding a reasonable balance between the volume of air supplied and the required power for heating is quite difficult.

Results

Without warehouse insulation, no heating system will be effective. The best insulation is polyurethane foam (PPU). There are three heating options for the warehouse: air, electric, water. Air heating with heat pumps is convenient, it makes it possible to control air temperature and humidity, and circulation speed. The disadvantage is high initial costs. Electric heating is expensive to operate, but the devices can be moved to any other place. Water systems are a classic and are the most common.

We are a professional engineering design and installation company. On our website you can receive a commercial offer and find the necessary information.

Warehouse or hangar heating is provided by EuroHolod with turnkey installation. For questions related to heating, call +7(495) 745-01-41.

To receive a commercial offer

, write a request to e-mail [email protected] or send a quick request

See below

- Heating systems. Heat supply for buildings

- What is your object?

Infrared heating systems (system based on infrared emitters)

The basis of an infrared heating system is infrared heaters. The principle of their operation is based on the fact that the energy of burned gas or electricity is converted into thermal radiation energy.

Advantages: the ability to target heat to the desired zone and heat individual local zones on a large scale.

Disadvantages: if it is necessary to warm up the entire volume of air in the room, the efficiency of the devices is greatly reduced; radiating surfaces heated to high temperatures are located directly in the heated room, which can lead to a fire; emitters running on natural gas require a complex and extensive gas supply system, which greatly increases the cost of the entire project; Gas-powered emitters burn oxygen from the room, which leads to the need for ventilation; emitters running on electricity consume a lot of electricity, which is uneconomical; Possible deterioration in the well-being of personnel exposed to direct radiation.

Emitters are effective only when in a large volume room it is necessary to heat up several local working areas in a targeted manner; the effectiveness of their use for heating the entire volume of the room as a whole is extremely low.

Infrared Ceiling Water Panels

One of the most popular methods of local heating and cooling in the premises of large and medium-sized enterprises is infrared ceiling water panels. The method for producing infrared radiation in them is clear from the name: a liquid circulates through pipes enclosed in an aluminum shell (reflector), heated or cooled to a temperature that provides a sufficient level of radiation. Moreover, different types of liquids with corresponding physical characteristics can be used for heating and cooling.

Advantages: high productivity, as well as safety for human life and the environment; water is heated centrally, with heat distributed due to the active circulation of a special liquid through the pipes; heat flow can be adjusted, heaters operate silently, energy consumption is minimal; safe for health and environmentally friendly, easy to install and dismantle; have a direct and remote control system that turns off the heating when a violation of the cyclic movement of liquid or other malfunction occurs in the system.

Disadvantages: in the case of using main natural gas, heating will require a complex and branched gas supply system, which is extremely expensive both in installation and in design.

A feature of any infrared heating and, in particular, infrared ceiling water panels is that only a certain area in the room to which the radiation is directed is heated. In the rest of the space the temperature may even be below zero. Thus, infrared ceiling water panels are successfully used not only in industrial enterprises and warehouses, but also for heating open verandas at winter ski resorts, ice palaces and other places where it is necessary to provide appropriate conditions for comfortable work of people.

Pressure water

| Pipe diameter | Wall thickness | Price for 1 p.m. VAT included |

| TU 6-49-53883187-01-05 SDR 17 | ||

| 16 t | 2 | 13,75 |

| 20 t | 2 | 16,82 |

| 25 s | 2 | 21,46 |

| 32 s | 2,3 | 31,61 |

| 40 s | 2,4 | 41,76 |

| 50 s | 3 | 65,25 |

| 63 s | 3,8 | 103,96 |

| 110 s | 6,6 | 291,82 |

| 160 s | 9,5 | 608,82 |

| 225 s | 13,4 | 1206,46 |

| 315 s | 18,7 | 2349,49 |

| 400 s | 24 | 4114,22 |

Pressure water

Heating with mobile fan heaters or heat guns

The principle of operation of heat guns is simple: air from the room is forced by a fan onto the heating element and the already warm air enters the room. The heating element is either an electric heating element, a diesel burner, or a liquefied or natural gas burner. Sometimes direct heating guns are used, and fuel combustion products enter the room along with the heated air.

Advantages: mobility – guns are relatively easy to move and do not require installation; relatively low price of equipment; high heating efficiency.

Disadvantages: the most expensive types of energy are used: electricity, diesel fuel, liquefied gas; the presence of toxic combustion products in the indoor air can lead to poisoning of personnel; the outgoing air flow heated to excessively high temperatures can lead to a fire; the location of air heaters at the bottom can lead to their accidental damage during business activities; occupy a significant part of the usable area of the room; system management is difficult to automate, which requires constant monitoring by personnel.

Thus, the use of mobile air heaters is justified only in cases where non-permanent or temporary heating is required. The use of guns for constant heating leads to excessive fuel costs and a decrease in the fire safety of premises.

Thermal insulation of warehouses and hangars

A building made of brick, blocks or concrete, or a metal hangar can serve as a storage facility. If in the first case insulation is not always required, then thermal insulation of the hangar is simply necessary. Without this, it will be cold in winter, and very hot in summer, even hotter than outside.

Heating of the hangar should be done only after high-quality insulation, since the main task of heating is to replenish heat loss. The less heat loss, the cheaper heating costs. Therefore, you need to carefully select the material according to its characteristics and correctly calculate the insulation layer.

As a rule, warehouses are insulated from the inside. Speed of work is of great importance. The price of the event is also important. What parameters should the thermal insulation layer meet:

- minimal thermal conductivity;

- non-flammability;

- moisture resistance;

- speed of application;

- operation without finishing.

The lack of finishing will not affect the operation of the warehouse in any way; beauty is not needed here, the main thing is practicality and reliability.

Taking into account all the above parameters, thermal insulation of a warehouse with polyurethane foam would be an ideal option.

PPU is a polymer insulation with a closed-cell structure, and for a hangar, foamed polyurethane foam is generally the only option. It has the lowest thermal conductivity coefficient compared to all modern insulation materials, which is 0.029 W/m*C. It does not allow steam to pass through and does not absorb moisture. The material does not burn, even if an open flame is directed at it, and therefore does not emit toxic gases. Polyurethane foam has high adhesion to almost all materials, that is, it holds tightly to any surface. The insulation is lightweight, does not shrink, and is not afraid of rodents.

Thermal insulation of a polyurethane foam warehouse is carried out in one day, depending on the area, but often no more than a day. The insulation is applied by spraying, using a special blow molding machine. No one carries out such work with their own hands; they hire contractors.

Autonomous gas heating of apartments is the norm for new buildings today. It's really very convenient.

Using a smart home system, heating is controlled remotely; all you need is the Internet.

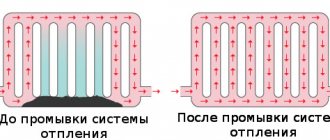

Convection heating system (registers, radiators or convectors)

The heating devices in such a system are radiators, convectors or registers made of smooth steel pipes.

Advantages: possibility of creating an electrically independent heating system; relatively low price of equipment and materials.

Disadvantages: extremely low efficiency of the system due to the fact that warm air from the registers immediately rises up, not down, and leaves the working area; heating equipment takes up a lot of space on the surfaces of walls and floors, thus, the usable area of the room is reduced and used irrationally; high inertia of the system (large volume of heated water in the pipes); the location of heating devices at the bottom can lead to their accidental damage during business activities; if commissioning work is poorly carried out, the system is poorly regulated; extremely low aesthetics of the register system, which does not meet modern requirements; Possibility of injury and burns due to direct contact with the surface of the register.

Taking into account all the above facts, we can conclude that it is advisable to use radiators or registers only for heating low rooms (with ceilings up to 3 m high). Otherwise, operating costs will be significant.

Air heating system using stationary gas air heaters

Air heating using gas air heaters is carried out using air (recirculation and/or supply air). It is supplied inside the unit using a fan, after which it is heated and supplied to the room either directly or through an air duct system, passing around the combustion chamber and through the heat exchanger, and combustion products are discharged through the chimney.

Advantages: ability to use relatively inexpensive natural gas; the air duct system allows for the highest quality air mixing in order to reduce the temperature gradient and deliver it to the desired area; a heating, ventilation and air conditioning system based on indirectly heated gas air heaters can also be decentralized (from the boiler room); the ability to combine heating, ventilation and air conditioning in one system, thereby achieving low metal consumption; greater efficiency and economy due to the absence of an intermediate coolant – water, which eliminates the possibility of “defrosting” and leakage; low inertia of the system (air heating occurs in 20–40 minutes) and, as a result, rapid temperature changes during the day; the possibility of placement inside the heated volume without preparing a separate room (boiler room); does not burn oxygen in the room; there are no attachments in heated rooms; there are no harmful and toxic emissions in the premises; there are no coolant pipelines or additional cable systems.

Disadvantages: in the case of using main natural gas, heating will require a complex and branched gas supply system, which is extremely expensive both in installation and in design.

Room characteristics

When choosing a heating system, you should pay attention to some characteristics of the building. First of all, it is necessary to take into account the height of the ceiling and the area of the building. If the height from floor to ceiling is more than 3 m, then it is not recommended to use water systems, because they are unable to provide the required temperature in large rooms.

The second important indicator is thermal insulation. Insulated walls and ceilings will significantly save money spent on heating a workshop or warehouse. If it is not possible to avoid heat loss, it is recommended to use heat sources that heat certain work areas.

You should also take into account the technological temperature requirements for storing raw materials or products.

Air heating on air heating devices

Air heating devices are also called water fan heaters, heating volcanoes (from the name of the manufacturing company Volcano), as well as water heaters with fans.

The principle of operation is extremely simple: the fan pumps air through a water heat exchanger-radiator. Hot coolant from the water heating system flows through the same heat exchanger. They are usually hung on the wall at a height of 4–6 m from the floor. The air flow at the outlet is warmed up and has sufficient speed so that it does not go to the ceiling, but goes down to the comfort zone. Thus, the air gives off most of the heat not to the ceiling, but to the lower part of the room.

| Advantages | Flaws |

| The system is very effective due to the fact that the warmest air is always below in the comfort zone | There is a need for a boiler room or heating networks |

| Low power consumption. | Electrical dependence, but this is common to all systems |

| Relatively low cost of equipment | Imported systems are expensive due to exchange rates |

| Low operating costs due to the ability to use relatively cheap natural gas in the boiler room | When a boiler room operates on liquid (diesel) fuel, the cost of operation increases |

| Robust design | Russian analogues are unreliable |

| Simple and quick installation, the ability to assemble an air heating system with your own hands | The risk of incompetent assembly is high, the volume of pipelines is large |

| Low inertia of the system, which allows very precise dosing of heat without overheating the room | There is a risk of the room not warming up if the equipment is placed incorrectly |

| The location of the devices is at the top, i.e. outside the working area of the floor increases the usable area of the room and reduces the risk of damage to the device during business activities | A large number of pipelines, additional coordination of IP sections |

| The system is very simple and inexpensive to automate so that the desired air temperature is maintained in the room | Increased noise from fan heaters |

| Ease of calculation of an industrial heating system and its design | More equipment and heating networks require additional maintenance |

| Small size and weight of equipment | |

| The modern and at the same time discreet design of the units allows them to be used in sales areas and other places with large crowds of people. | |

| Does not burn oxygen in the room | |

| There are no harmful and toxic emissions indoors |

For electrical cable

| Pipe diameter | Wall thickness | Price for 1 p.m. VAT included |

| TU 6-49-53883187-01-05 SDR 17.6 | ||

| 16 s | 2 | 9,43 |

| 20 s | 2 | 12,10 |

| 25 s | 2 | 15,48 |

| 32 s | 2 | 20,26 |

| 40 s | 2,3 | 27,71 |

| 50 s | 2,9 | 42,99 |

| 63 s | 3,6 | 63,88 |

| 110 s | 6,3 | 149,75 |

| 160 s | 9,1 | 315,88 |

| 225 s | 12,8 | 619,44 |

| 315 s | 17,9 | 1890,00 |

| 400 s | 22,7 | 3138,75 |

For electrical cable