At the stage of installing a water supply or heating system using modern technologies, one cannot do without a distribution manifold. This device allows you to redirect fluid flows.

Thanks to the distribution manifold, you can easily turn off or limit the capacity of each heating or water supply circuit in a private house or apartment. This, in turn, allows you to significantly save money on heating those rooms in which maintaining a high temperature is not required.

This device also allows you to more evenly distribute the fluid pressure between consumers, which is almost impossible to do with a series connection.

Types of water combs

Combs come with a different number of branches, made of different materials, and several methods of fastening. Devices can have from two to six outlets; a larger number can be achieved by combining several collectors.

By material type

- Stainless steel. A very wear-resistant material that can withstand interactions with open fire and high humidity at any temperature. Stainless steel products are small in size, making them easy to integrate into any water supply system;

- Brass. The material is resistant to corrosion and elevated temperatures. The continuous service life of brass combs can be ten years or more. The only thing is that their cost is very high;

- Polypropylene. Products made from this material are very light, but have sufficient strength and do not corrode. Connection to pipes is carried out by soldering.

By fixation

According to the method of fastening, collectors can be:

- Combined;

- With Euro cone, suitable for systems with plastic and metal pipes;

- Threaded. Thanks to the threaded connection, the product can be easily and simply disconnected at any time;

- Under the solder. Used in systems with plastic pipes.

When installing a new system, you need to stock up on all the necessary components that match the parameters and features of the system, including fittings.

By design

The differences in distribution manifolds by design are determined by:

- Level of improvement;

- Material of manufacture;

- Number of bends;

- Distance between taps.

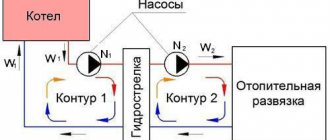

What is a hydraulic arrow

If pumping equipment of significant power is installed in a multi-circuit complex heating system, then even it will not be able to cope with the different conditions and parameters of the network operation. Such inconsistencies in the operation of different circuits will negatively affect the operation of the heating boiler and shorten the service life of expensive equipment.

Branched heating networks cannot work harmoniously due to the fact that each circuit has its own performance and pressure. But even if each circuit is equipped with its own circulation pump, taking into account the parameters of the main line, the problem of system fragmentation will only worsen. This will lead to unbalancing of the networks, because each heating circuit will have its own parameters.

To solve the problem, one common boiler must heat the required amount of coolant, but each circuit must receive the required amount of heated liquid from the collector. In this case, the functions of the hydraulic system separator are performed by the manifold. A hydraulic separator is needed to separate the boiler flow from the general circuit. Another name for a hydraulic separator is a hydraulic arrow or HS (hydraulic arrow).

The name of the device comes from the analogy with a railway switch. Just as a railway switch directs trains in the required direction, a hydraulic switch distributes coolant flows across separate circuits. Externally, the device resembles a piece of round or rectangular pipe with end caps. The device is connected through a pipeline to the collector and boiler and has several pipes in the side.

Complex design

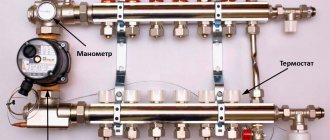

The most complex products also have a more complex design, some of which include:

- Ball Valves;

- Adjustment fittings;

- Mechanical or electronic sensors.

Installation of distribution manifold

When installing the distribution manifold inside the wall, a recess is made into which the comb and inlet and outlet pipes are placed. If it is possible to install the comb in a utility room, then this is the most suitable place to install this device.

The distributor installation process is very simple and is carried out in the following sequence:

- supply from the riser is turned off.

- The supply pipe is connected to the central inlet of the collector.

- If the device is not equipped with taps , then a ball valve is connected to each output of the distributor.

- is connected to each tap .

- If the number of taps exceeds the number of water supply circuits , then the extra outlets should be closed with plugs.

- After connecting all the pipes , the collector is fixed to the plane of the wall or box with clamps.

Advantages

Combs in water supply systems have their advantages, such as:

- Connection reliability;

- Well-functioning work;

- Pressure stabilization;

- Provides comfortable use of household appliances dependent on water supply;

- Makes it possible to install them on DHW;

- Prevents large changes in water temperature;

- Makes it possible to lay a water supply system using a hidden method;

- When repairing a separate area, it allows you not to completely shut down the system.

Select a manifold for the water supply of an apartment or house by company

Let me immediately note that the brands of collectors listed below by country may differ from the place of their production; everything needs to be clarified when purchasing.

VALTEC Russia

The Russian company of engineer entrepreneur Pavel Eduardovich Melnikov has been known since 2002. Low price, good quality.

Italian company Far

FAR Rubinetterie SpA was founded in 1974 by Alberto Alessina and Guerino Alessina and Nicola Rovaletti. QAVR quality certificate, Green Valve brand.

Italian Tiemme

On the market since 1990. It is proud to carry out its entire production cycle in Italy to ensure the quality, safety and reliability of its products.

Italian Luxor

Luxor Minuterie Idrauliche was founded in 1960 in Carpenedolo. All products comply with ISO 9001:2015 certification, Certified in Russia.

UNI-FITT Italy

The Italian brand has 19 enterprises in Europe and 9 factories in Russia. On the Russian market since 2010. Externally very similar to FAR.

General fittings

GF collectors come from Italy. There are manifolds with shut-off ball valves and control valves. Large selection of types and sizes, material nickel-plated brass.

Calleffi

Another “Italian” from 12 companies and 5 representative offices. All 3 factories are located in Italy. There are no crafts.

Polish Solomon

Cheap Polish-Chinese brass miracle. You need to look in Russia.

STOUT

European brand with factories in Russia, Italy, Spain, Germany. Products in the mid-price range, with nice, unfolded white handles. More used for heated floors.

Tim

TIM company was founded in 1994. produces a wide range of manifolds for heating and plumbing. The TIM Group unites 6 factories in China and distributors throughout Europe, Russia and the USA.

German Rehau

A narrow range of brass distribution combs for sliding sleeves and nickel-plated distribution manifolds with continuously adjustable 4 outlets. Large selection of collector groups for heated floors.

Flaws

The disadvantages of the devices are their cost and some properties of the components necessary for its installation (valves, risers, fittings, etc.).

In addition, some connection methods make the system bulkier. Despite all these disadvantages, the costs and inconveniences are fully worth it.

Why is this necessary?

Why and when do you need a water supply comb?

Collector water distribution is necessary in two cases:

- If you need to ensure the disconnection of several plumbing fixtures or their groups from one point (manifold cabinet). This feature is very useful in a mini-hotel or hostel;

All plumbing is disconnected from one manifold cabinet

- If you need to ensure constant water pressure on all devices at any ratio of water consumption between them.

The second point probably requires some clarification.

Remember the cute communal scene: one of your family members is taking a shower in the bathroom, the other is trying to wash up the dishes in the kitchen. As soon as he opens the cold water tap further, an angry roar from the scalded body can be heard from the bathroom.

Why is this happening?

Because an increase in cold water flow with a constant hydraulic resistance of the water supply leads to a drop in pressure at all water collection points.

Open the tap on one mixer and the pressure on another will drop sharply

This is a common problem with so-called tee (or series) connections.

Tee (sequential) water distribution

It is worth providing each plumbing fixture with its own supply connected to a common collector - and the problem of pressure drop will be solved: regardless of the water flow in the kitchen, the pressure in the bathroom will remain unchanged.

Scheme of collector wiring in a house with a boiler

Installation

When drawing up a plumbing system project, you need to immediately decide on the installation location of the comb. Often it is necessary to integrate the product into an already laid highway.

The main criteria for choosing the location of the collector are:

- Free access for maintenance and repair;

- No high humidity;

- To attach the comb, you need to select a load-bearing wall;

- Good lighting so that you don’t have to work with the collector “blindly”.

Sometimes the water comb is installed in a separate room, or a special cabinet is installed for this purpose.

The nuances of installing the collector:

- Installation work must be carried out by a specialist with the necessary experience. Otherwise, difficulties may arise when installing the comb yourself.

- To securely fix the device, it is necessary to use fastening clamps.

- The assembly is installed without auxiliary seals.

- Cold and hot water combs are often installed separately.

- The location of the unit should be the filter element and the pressure reducer.

- The installation kit must contain control and shut-off valves.

- In two-story buildings, it is advisable to equip the water supply system with a circulation pump.

- Installation should be carried out only after drawing up the wiring diagram.

- To install the comb, you will need consumables: adapters, gaskets, seals. Having everything you need at hand, installing the collector will not require much time.

After some time, the system may need to be upgraded. Therefore, it is advisable to immediately install a comb with spare connection outlets, plugging them with plugs.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

Criterias of choice

Before purchasing a comb, it is advisable to familiarize yourself with the technical characteristics of various models, which will help you choose the best option for a particular water supply system.

Nuances to consider when purchasing:

- Device throughput;

- System pressure;

- Number of water consumption points;

- Purpose (DHW or cold water supply);

- Availability of free outlets for connecting additional equipment;

- Material of manufacture;

- Price for a water comb.

Products made from bronze and brass-copper alloy are considered high-quality and reliable, since they do not form build-up from sediment, which contributes to the development of corrosion.

Combs are a very useful functional device that provides stable water pressure, prevents leaks, and makes it possible to freely use several points of water consumption at the same time.

Therefore, installing such a device is not an extra expenditure of money, but rather ensures comfort in the building.

Pros and cons of collector systems

The main advantage associated with the use of collector-type systems is the ease of control and operation. This is due to the fact that each of the elements can be controlled both centrally and individually. Consequently, it is possible to set the temperature for each specific room, and, if necessary, completely deactivate a device or group of devices. Moreover, this will not affect other parts of the system.

Video – Collector heating system

Each of the branches that make up the node must power only one battery (or, alternatively, a separate group of batteries), so the diameter can be insignificant. If necessary, using a collector, you can equip several circuits with different temperature parameters at once. This became possible thanks to the advent of a hydraulic arrow - a type of comb, which is a similar tube, but of a larger diameter.

This arrow is installed differently from a standard manifold - a kind of short circuit is created in the gap between the “return” and the supply. The liquid in the initial circuit will be permanently heated by the boiler and smoothly move inside the hydraulic arrow, as a result of which different temperature and coolant pressure indicators are demonstrated.

But there are, of course, disadvantages. First of all, buying a distribution comb is a very expensive pleasure and this is probably the only reason why these devices scare away potential buyers. The fact is that high-quality steel is used in the production process, which is why the products are much more expensive than steel pipes. In addition, for installation you will also need high-quality shut-off valves (the number of them depends on the number of circuits).

Another drawback is the mandatory presence of a circulation pump, without which the comb simply will not be able to function (read: additional electricity costs).