Solid fuel boilers operating on pellets appeared on the market later than wood and coal models. The material used is wood processing or agricultural waste. These are granules whose diameter is up to 10 mm. They are pressed into briquettes no longer than 7 cm.

When burning 1 kg of pellets, 4,500 kcal are released. This is a good indicator, so manufacturers can produce devices with high power and spacious bins (maximum volume - 500 l). Such devices heat large areas.

Equipment design

Pellet boilers are designed to consist of 3 main parts. This:

- The device itself, the body of which is standardly made of high-temperature resistant steel. It is equipped with a special burner for igniting fuel.

- A bunker where raw materials are stored.

- Mechanism for feeding pellets into the combustion chamber. Most models use a screw device. However, there are also those where the fuel enters the chamber under the influence of gravity.

Some units are equipped with automation that controls operation. The devices are characterized by reliability, but correspondingly high prices. Devices can be programmed for the desired turn-on time, support specified temperature parameters, etc.

What are pellets

The production technology was invented in the thirties of the last century. The birthplace of the invention is Idaho, USA. The essence of the method for producing pellets is to compress preheated wood waste. When heated, sawdust, wood chips or shavings release lignin. This substance has the ability to bind small wood particles together.

Under high pressure they are compressed into smooth granules. The finished product has high density and heat transfer during combustion.

No chemicals are used in the production of pellets. This makes them an environmentally friendly fuel. Granules are produced according to the DIN plus standard.

Agricultural waste can be used as a raw material for the production of pellets: corn cobs, husks, etc. The most common type of granules in the country are pellets, with a diameter of 6-8 mm and a length of up to 50 mm.

The efficiency of heating solid fuel boilers largely depends on the quality of the pellets: humidity, density, ash content. When burning 1 ton of pellets, thermal energy is released equivalent to 1.6 tons of firewood.

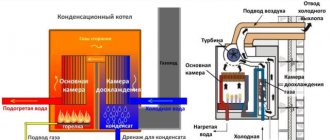

Operating principle of boilers

After pellets are loaded into the chamber, the ignition is turned on. The fuel burns and releases energy, which goes through the air to heat the water. Further from the coolant, radiators throughout the house are heated.

The operating principle differs little from the functioning of other solid fuel equipment. However, the efficiency of pellet models is higher than that of wood-burning appliances (on average 90%). This is due to the design of the combustion chamber, in which energy is directed to the heat exchanger under pressure.

Exhaust gases from the system are removed through the chimney. In high-quality models, fuel burns almost completely. The mixture of carbon dioxide and steam is removed using a smoke exhauster.

Criterias of choice

Many aspects are taken into account when purchasing. The boiler is selected based on several parameters:

- Power. It is generally believed that 1 kW is spent on heating 10 square meters. m of premises. But heat loss must be taken into account. They make up at least 10%. For a more accurate calculation of power, it is necessary to know the heat loss of the floor, walls, ceilings, etc.

- Dimensions. High power means that pellet equipment has a spacious hopper, which means a lot of weight and dimensions. House owners cannot always allocate space for such a complex.

- Pellet consumption. The smaller it is, the more profitable it is to install the equipment.

- Availability of automation. This makes the model more reliable, but increases the cost.

Rating of the best pellet boilers

To understand which boilers are considered the best, it is worth reading not only professional reviews, but also user reviews. It is recommended to get information about the most popular devices on the suppliers' websites.

Heiztechnik Q Bio Duo 35

Considered universal. The device is equipped with 2 fireboxes and can operate on wood and pellets. The power range is 12-35 kW, but the efficiency is slightly lower than most models - 88%.

The features of the model are:

- automatic air and fuel supply;

- adjustment depending on weather conditions;

- economical consumption of raw materials;

- microprocessor control.

The equipment operates automatically for up to 12 days.

Sunsystem v2 25kw/plb25 – p

This is a Bulgarian boiler, reliable and efficient. With a power of 25 kW, it heats large rooms.

The advantages include a self-cleaning function, automated operation, and a high-quality transport auger.

The fuel bunker can be installed on either side, which is convenient in limited space.

Stropuva P20

The model is the development of a Lithuanian brand. The main advantages are considered to be high efficiency and simplicity of design. The device does not have a fuel supply auger; pellets fall into the chamber under the influence of their weight and gravity. There is no automatic ignition system. You need to use a gas burner, but this is a safe and convenient way.

4 temperature sensors are responsible for monitoring the operation. The air supply is regulated using a built-in fan. The power of the unit is 20 kW. Taking into account heat loss, this indicator is enough to heat a room of up to 180 square meters. m.

Kiturami KRP 20a

This is a reliable and efficient boiler from a South Korean brand. The power of the device is enough to heat an area of up to 300 square meters. m. The capacity of the bunker is 250 l.

The unit is equipped with protection against overheating (the thermal valve is activated and cold water is supplied to the system). The equipment is characterized by a convenient vibration cleaning function, low noise level during operation, and piezo ignition.

A double-circuit boiler heats not only the room, but also water, and consumes 5 kg of fuel per hour. The advantage of the device is considered to be high efficiency for this category of equipment - 92%.

Disadvantages include weight (317 kg) and the absence of a circulation pump. In addition, there are no heating indicators.

Froling p4 pellet 25

The model is characterized by high energy efficiency. The device can be equipped with a condensing heat exchanger with a recovery function. The latter means that thermal energy is returned to the technological cycle. Therefore, the efficiency of the equipment reaches 100%.

ACV Eco Comfort 25

The model of the Belgian brand has a power of 25 kW. This is enough to heat a room of 200 square meters. m. A special feature of the boiler is a heat exchanger made of copper (the most durable and durable material).

The tank has a capacity of 97 liters, which allows you to quickly transfer hot water to the pipes. The walls of the case are made of 5 mm thick alloy, so the heat is retained for a long time.

The advantages include smooth power control and operation with any pellets. But due to its dimensions and weight of 430 kg, it is difficult to find a place in the house for the device.

Pelletron 40 CT

The Russian brand boiler has good performance characteristics and a power of 40 kW. The efficiency is 92.5% - this is a high figure for this category of equipment.

Characterized by a built-in fire extinguishing valve and smoke exhauster, convenient cleaning of the burner. The granules are fed into the compartment under their own weight.

Economical fuel consumption is also noted - 230 g per hour. Therefore, when the bunker is fully loaded, the boiler operates for several days. The only drawback is the lack of automation. The device is controlled mechanically.

Teplodar Kupper PRO 22 with APG25

It is a modified Cooper PRO model. This is a single-circuit boiler with an APG-25 automatic burner. It comes complete, since the fuel hopper is equipped with a feeding mechanism and a control panel. A special feature of the device is the unusual location of the reservoir (directly on the boiler itself).

The advantage of the model is that it saves space. However, loading fuel is inconvenient compared to other boilers. The power range of the device is 4-22 kW. The unit runs on pellets and wood.

Zota Pellet 15S

This is a Russian-made boiler. The power is 15 kW, the device is used to heat rooms up to 120 square meters. m (including heat loss). Hopper volume – 293 l.

The advantages include reliable automation that regulates the amount of air supplied and the operation of the pumps. Users note a convenient control panel equipped with a display that displays important indicators. A remote-controlled module is also connected to the boiler.

The device has no disadvantages. But, like other devices in this category, the unit weighs a lot - 333 kg. This feature must be taken into account during installation.

This manufacturer also has a long-burning pellet boiler with a water circuit, the power of which varies from 3 to 400 kW.

Faci base 258 kW

An efficient device with a self-cleaning burner and a multi-pass heat exchanger allows you to achieve maximum results at relatively low cost.

The model is unpretentious to fuel quality and runs on pellets and wood. There is a function to control the air temperature in the room.

Reviews of various models

We have analyzed a very large number of reviews from real owners of pellet boilers, and we invite you to familiarize yourself with the most reasoned statements.

We installed a 20 kW Jaspi Pelletti system. The boiler is equipped with an EcoTek 25 retort-type pellet burner. I bought it for heating a private house with an area of about two hundred square meters. The equipment worked without problems for the season. Average fuel consumption is approximately 5 tons per season (I live in the Moscow region). Among the disadvantages, it is worth noting the need to clean the boiler twice a month.

As such, there are no serious complaints about the quality of assembly and operation of pellet boilers. Typically, dissatisfaction is due to the lack of certain functions.

On the advice of a friend who bought the same boiler, I purchased Kostrzewa Pellets 100 32 kW. The heated area is about 150 square meters. We love warmth, so we set the temperature to 24 degrees. Approximately 200 kg of pellets are consumed per week. I try to feed the boiler with light-colored granules; after two years of experiments, they showed their best side. I'm happy with my purchase - the boiler is simple and reliable.

The video below shows a review from the owner of a 30 kW Biokaitra boiler.

A frequent complaint is the violation or insufficiently efficient operation of equipment using low-quality fuel. This once again suggests that before purchasing a boiler you need to monitor the raw material base.

I would like to leave a review about the Zota Pellet boiler, with which we survived this winter. I also took it for the reason that it has a remote control function. Our family periodically lives either in an apartment or in a house. So being able to launch by phone is awesome. However, I will say one thing: a boiler works well only with light pellets. That is, only high-quality fuel is suitable for it.

The short video below shows a review from a service station owner who preferred equipment from the well-known Kiturami brand.

The efficiency of a boiler is determined by its efficiency. Very often the equipment of the Korean manufacturer Kiturami is praised for this.

We spent a long time choosing a boiler and settled on the Kiturami KRP 20. The advantages include high efficiency (the pipe leading from the boiler to the chimney has the room temperature), economical consumption of pellets. The automation works flawlessly. The price is steep compared to analogues, but we still preferred Kiturami. The review is positive - after 2 years of operation.

Installation Rules

Pellet boilers are installed only in a separate room. For such purposes, a basement with a special floor covering - durable and made of non-combustible material - is suitable. Simple options are poured concrete or a base lined with metal sheets. The device itself is installed at a height within 10-20 cm.

The boiler room should be heated and have moderate humidity. The unit is installed in accordance with the manufacturer's instructions (so that there is free access for cleaning, repair and maintenance).

Classification

Most models of pellet boilers are intended only for heating buildings, but there are designs that can also provide hot water. The units produced by manufacturers are classified according to various criteria.

Boilers are classified according to the method of fuel supply:

- automatic;

- semi-automatic;

- mechanical.

Automated models work according to a given program. When servicing semi-automatic boilers, you have to perform some functions manually. Mechanical units are fully human-serviced.