In the wide range of shut-off valves used for heating systems, there is an element that is used quite rarely. Its shape resembles a tee, although the functions it performs are completely different. We are talking about a three-way valve, the operating principle of which will be discussed in this article.

Operating principle of three-way valve

- 1 How it works 1.1 Video – Three-way valve operating principle

- 2.1 Video – Device in a boiler group

- 7.1 Video - Three-way valve and its operating principle

What is this device and why is it needed?

How it works

The three-way valve is installed in those sections of the pipelines where it is necessary to divide the flow of circulating fluid into 2 circuits:

- with variable hydraulic mode;

- with constant.

In most cases, a constant flow is required by those who are supplied with liquid of high quality and in designated volumes. It is regulated in accordance with quality indicators. As for the variable flow, it is used for objects where quality indicators are not the main ones. The quantity coefficient is of great importance there. Simply put, the coolant is supplied there according to the required quantity.

Note! Shut-off valves also include an analogue of the device described in the article - a two-way valve. How is it different? The fact is that the three-way option works on a completely different principle. The rod included in its design is unable to block the flow of liquid, which has constant hydraulic parameters.

The rod is open all the time, it is adjusted to a particular volume of liquid. Consequently, users will be able to get the volume they need, both in terms of quantity and quality. In general, this device is unable to stop the flow of fluid to a network in which the hydraulic flow is constant. In this case, it may well block a flow of variable type, due to which, in fact, the possibility of adjusting the flow/pressure arises.

And if you connect a pair of two-way devices, you can get one, but three-way. But it is necessary that both work in reverse, in other words, when one valve closes, the next one must open.

Video - Three-way valve operating principle

Principle of operation

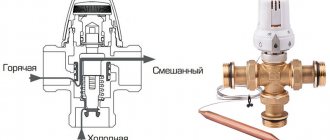

To start the mechanism, you need to connect two pipes for supplying cold and hot water. To successfully connect, you should study the diagram of a three-way valve, which shows various arrows and guides. The hot water that comes from the boiler is the main coolant, and the cold water is the remaining waste.

Systems may differ in position and method

Between both openings with inlets to the flows there is a valve that regulates the water supply. Depending on the position and connection method, the system can:

- mix two streams of water into one;

- divide one line into two outputs.

Many people mistakenly think that the tee blocks the water channels that are connected to it, but this is not the case. The purpose of the mechanism is only to redirect the fluid from inlet to outlet.

In a simple configuration, the radiator is connected to the boiler in a series or parallel manner. It is impossible to adjust each element individually, since only the temperature of the liquid in the boiler tank changes.

If there is a desire to regulate each battery, the system must be equipped with a bypass, as well as a regulating needle valve, which will allow you to regulate the volume of liquid passing through it.

The purpose of the bypass is to maintain the overall resistance of the installation to prevent malfunction of the pump. Unfortunately, this approach is expensive and complex to install, so it is not very popular.

Operating efficiency and final efficiency indicators may depend on the location of the valve. If it is half open, then the outgoing water flow will have an average temperature. If the valve is fully open, the temperature will reach its maximum. When it is completely closed, only cold water flows out.

Valves classification

Without lengthy introductions, we note that the device can be of two types according to the principle of operation. It could be:

- dividing;

- mixing.

The features of each type of action are clear from their names. The mixing device consists of two outputs and an input. In other words, it is necessary to mix fluid flows, which may be required in order to reduce its temperature. By the way, this is the most optimal option for setting the desired mode in the “warm floor”.

The procedure for adjusting the temperature regime is extremely simple. You just need to know about the current temperature indicators of the incoming liquid flows, accurately calculate the required proportions of each of them so as to obtain the required indicators at the output. By the way, this device, subject to proper installation and adjustment, can also function for flow separation.

But the separating valve divides one flow in two, therefore, it is equipped with one inlet and two outlets. This device is used primarily to separate the flow of hot water in hot water systems. Although quite often it is found in the piping of air heaters.

Externally, both options are almost identical. But if you look at their cross-sectional drawing, their main difference is immediately visible. The rod, which is installed in a mixing-type device, has one ball valve. It is located in the center and blocks the main passage.

As for separating devices, the stem has two such valves, which are installed at the outlets. They function according to the following principle: one of them is pressed against the saddle, closing the passage, and the other, in parallel, opens passage No. 2.

According to the control method, modern models can be:

- electrical;

- manual.

In most cases, a manual device is used, which in appearance resembles an ordinary ball valve, but is equipped with three outlet pipes. But electric models with automatic control are used mainly in private homes, namely to distribute heat. For example, the user can set the temperature regime by room, and the working fluid will flow in accordance with the distance of the room from the heating device. As an option, you can combine it with a “warm floor”.

Video - Device in a boiler group

Three-way valves, as well as other devices, are determined in accordance with the pressure in the system and the diameter of the inlet. All this is regulated by GOST. And if the requirements of the latter are not met, this will be regarded as a gross violation, especially when it comes to the pressure indicator in the line.

Brass Fittings and HDPE Piping

We advise you to read our guide to the selection and installation of brass fittings for HDPE pipes, all the details are here

Useful tips

Before starting the heating system, you must make sure that the three-way valve and other components are in full working order, do not need repair or replacement, and also meet operational requirements. It is not recommended to install a tee on a pipeline with a pipe diameter of 40 millimeters or more. When operating in a hot environment, the valve must be opened with extreme caution, otherwise there is a risk of hydraulic valve failure.

The best material for a three-way valve is brass.

Experts recommend placing control devices or a turning handle with a rod so that they are freely accessible. When choosing a suitable faucet model, it is advisable to give preference to products made of brass. They are characterized by a long service life and resistance to all kinds of influences.

As for the control method, the best option would be a product with pneumatic control. Before making a choice and buying a tee, it is better to consult with a specialist, talk about the possible pros and cons of the available models, and also read reviews about them on thematic forums.

Among the huge variety of shut-off valves that are used on the heating system, there is a rather rarely used element - a three-way valve for heating with a thermostat. It is similar in shape to a tee, but it is designed for completely different functions. How a three-way valve with a servo drive works and why it is needed will be discussed in this article.

Areas of application

The three-way valve, the operating principle of which was discussed above, has a fairly wide range of applications. Thus, its varieties, such as an electromagnetic device or a device with a thermal head, are often found in modern pipelines, where it is necessary to adjust the proportions when mixing two separated liquid streams, but without reducing power or volume.

As for household use, the most popular here is considered to be a thermostatic mixing device, with which, as noted above, you can regulate the temperature of the working fluid. This liquid can be supplied both to the “warm floor” pipeline and to heating radiators. And if the valve also has automatic control, then you can control the temperature in your home without any problems!

Note! The use of a three-way valve in a heating system to balance temperature changes is extremely beneficial not only in terms of comfort and convenience, but also in terms of cost savings.

The fact is that by regulating the temperature of the liquid at the “return” of the heating device, you can significantly reduce the volume of fuel consumed, and this will have a positive effect on the efficiency of the system itself. In some systems, a valve is simply necessary. For example, in a “warm floor” system, this device prevents overheating of the floor covering above a given comfort level, thereby relieving users of unpleasant sensations.

Regulating devices of this kind are also used in water supply systems in order to obtain a permanent flow at the required temperature. The simplest example is an ordinary mixer, in which you can make water hotter/cooler by opening/closing a cold tap.

Safety valve for boiler

Previously, we described how to select and connect a safety valve for a boiler, talked about its areas of application and internal structure. In addition to this article, we recommend that you read: all the details here

Design features

The faucet looks like a tee with a T-shaped arrangement of tubes. For this reason, plumbers began to call it a tee. As for the design of the mechanism, it includes:

- A sealed metal case that is reliably protected from moisture penetration, corrosive processes and other negative influences. The material used to make the body is cast iron, bronze, steel or brass.

- A valve with several passage channels of different shapes.

- Three openings (outlet, with hot and cold water supply).

Three-way valves may differ in some additional characteristics.

The tee may also differ in a number of additional properties, which are indicated on its packaging. Depending on the type of shutter mounted in the mechanism, conical, cylindrical or spherical products are distinguished. The fastening principle can be flanged, coupling, welded or end-fitting. The mechanism is controlled manually, by a drive system or by an electronic controller. As for the shape of the plug, it comes in three types - S, T, L.

Adjusting the flow of working fluid. What to look for when purchasing?

Manual adjustment is made using a conventional ball valve. Visually it is very similar to a simple valve, but has an additional output. Fittings of this kind are used for forced manual control.

As for automatic adjustment, a special three-way valve is used here, equipped with an electromechanical device to change the position of the rod. It should be connected to a thermostat in order to be able to regulate the temperature in the room.

Remember that when purchasing a valve, it is imperative to take into account the technical parameters of the device, which include the following.

- Diameter of connection to the heating main. Often this indicator varies from 2 to 4 centimeters, although much depends on the characteristics of the system itself. If a device of a suitable diameter cannot be found, you will have to use special adapters.

- The possibility of installing a servo drive on a three-way valve, the operating principle is discussed at the beginning of the article. Thanks to this, the device will be able to work automatically. This point is very important if the device is selected for use in water-type “warm floors”.

- Finally, there is the pipeline capacity. This concept refers to the volume of liquid that can pass through it in a certain time.

Buying a crane

When purchasing a three-way valve, you need to consider several features and selection criteria. First of all, you need to do the following:

- Measure the diameter of the pipes of the common line to which the tee will be connected. The optimal figures are 20-40 millimeters, but there are also non-standard situations when you have to purchase special adapters for an individual size.

- Understand the pipeline capacity in heating circuits. To do this, you need to carry out a simple calculation and determine how much liquid each pipe can pass through, as well as what period of time this process takes.

- Find out if it is possible to additionally connect a servo drive, which will make the system automatic. This option is especially in demand for rooms with heated floors.

When purchasing a 3 way valve, it is important to take some measurements

Also, when purchasing a tee, it would not hurt to carefully study its other characteristics. In most cases, they are indicated on the box with the product. If it is difficult for an inexperienced buyer to understand various terms and official data, then it is better for him to seek help from consultants.

Popular manufacturers

There are many manufacturers of three-way valves on the domestic market. The choice of one model or another depends, first of all, on:

- type of mechanism (and let us remember, it can be mechanical or electrical);

- areas of use (DHW, cold water, “warm floor”, heating).

The most popular device is rightfully considered Esbe - a Swedish valve from a company that has existed for more than a hundred years. This is a reliable, high-quality and durable product that has proven itself in many areas. A combination of European quality and modern technology.

Another popular model is the American Honeywell - a true brainchild of high technology. Simple operation, convenience and comfort, compactness and reliability - these are the distinctive features of these valves.

Finally, relatively “young” but promising devices are valves from the Valtec line - the result of joint cooperation between engineers from Italy and Russia. All products are of high quality and are sold with a seven-year warranty. They differ in that they have a very affordable price.

Mixing unit function

First, let's determine the main function of the valve used in the water heated floor system

It is important to note the fact that for underfloor heating it is extremely important to achieve an acceptable temperature. This is especially important if the underfloor heating is powered from a centralized heating system

As you know, in this system the coolant has a temperature of about 75 degrees Celsius. Of course, such a temperature for the floor will be very high. If a coolant with such a temperature goes into the underfloor heating system, then due to the high temperature the screed will begin to collapse. Of course, not immediately, but gradually over time. Moreover, at this temperature, the floor covering will experience serious stress. Moreover, walking on such a floor will not be comfortable at all.

Based on established standards, the temperature of underfloor heating should not exceed 26 degrees Celsius. Thanks to this, the indoor air will have a temperature of about 22 degrees Celsius. This is the temperature that is considered the most comfortable for living. So, in order to achieve such a temperature, the coolant that enters the heating circuit, laid in the floor screed, must have a temperature of up to 50 degrees Celsius. Remember that 50% of the thermal energy is taken by the heating cake. As heat begins to enter the room, the temperature will partially drop. This is also affected by the nature of the floor covering.

So, in order to achieve the most comfortable temperature, a number of specialized equipment is used. In particular, the mixing unit plays an important role. And the valve plays an important role in this whole unit. Based on its name, it mixes cold and hot coolant. The result is a comfortable water temperature at the outlet. It is worth noting that such a faucet comes in several varieties, for example:

- Two-way.

- Three-way mixing valve.

So, now we invite you to take a closer look at the features of this device to understand which one is best to choose.

How to install a mixing valve yourself

This installation scheme is used mainly in boiler rooms of those heating systems that are connected to a hydraulic separator or to a free-flow collector. And the pump located in circuit No. 2 ensures the required circulation of the working fluid.

Note! If the three-way valve will be connected directly to a bypass heat source connected to port B, then it will be necessary to install a valve with a hydraulic resistance equal to the same resistance of this source.

If this is not done, then the flow rate of the working fluid in the segment A-B will fluctuate in accordance with the movement of the rod. We also note that this installation scheme provides for the possible cessation of liquid circulation through the source if the installation was carried out without a circulation pump or a hydraulic separator in the main circuit.

It is not advisable to connect the valve to heating networks or a pressure manifold in the absence of devices that throttle excessive pressure. Otherwise, the fluid flow in section A-B will fluctuate, and significantly.

If overheating of the return is allowed, excessive pressure is eliminated by means of a jumper installed parallel to the valve connection in the circuit.

Installation and operation

To ensure successful installation of a three-way valve, it is important to follow the drawings and step-by-step instructions. also need to pay attention to several nuances of the upcoming installation:

To properly install a three way valve, it is important to follow the drawings and step-by-step instructions

- On the body of the tee there is a special diagram with arrows that show in detail the direction of water flow. Its presence significantly simplifies installation work and allows you to quickly and accurately connect important components.

- When welding metal mechanisms, the temperature flow in the joint area must not be allowed to exceed +100°C. It is important to ensure that scale or dirt does not penetrate the system, otherwise this can lead to irreparable consequences.

- To install the tee, you need to choose a place that will be easy to reach for repairs or maintenance. If the tap has to pass insufficiently high-quality liquid, it is recommended to additionally equip it with filter units.

- The method of fixing the product can be either vertical or horizontal. This does not affect work efficiency in any way. As for the valve, it is installed directly in front of the circulation pump.

In order for the tee to function for a long time, reliably and efficiently, it is necessary to take into account the operating rules and maintain it on time. The service life of the device depends on proper and correct use.

How to install a dividing valve with your own hands

Providing quantitative regulation by changing fluid flow rates is the main function performed by such a three-way valve. Its operating principle is extremely simple and was discussed above. It is used where it is possible to bypass liquid to the “return”, but stopping circulation, on the contrary, is not allowed.

Note! This connection scheme has gained wide popularity in water and air heating units that are connected from individual boiler houses.

In order to link hydraulic circuits, it is necessary that the consumer's pressure losses be equal to the losses at the balancer valve in the bypass. The diagram presented here is intended for installation on those pipelines in which there is excessive pressure. In this case, the liquid moves due to the strong pressure generated by a circulation pump.

Mixing types: series and parallel

When all circuits are closed, a bypass with a bypass valve helps supply the pump with flow. The bypass valve is mechanically adjusted to the required pressure, under the influence of which it will begin to function. This option has a significant drawback - the temperature of the coolant at the outlet will be similar to that of the water entering the system (pro

Other types of industrial devices

The domestic industry produces many thermostats for water floors, which allows you to control fluid flows autonomously. Among the known varieties of valve mechanisms, the following types stand out:

- mechanical three-way valves for heated floors;

- the same models, but with a remote sensor;

- touch faucets;

- electronic devices;

- software controlled thermostats.

Mechanical devices are the simplest, cheapest and most reliable devices in operation, equipped with a protective casing made of durable plastic. To adjust the temperature with such a device, simply turn the thermostatic head in the desired direction. The exact value from the temperature range is selected by turning a special disk with a scale divided into divisions.

Mechanical thermostats equipped with a remote temperature sensor are more advanced designs that allow you to control the value of the operating parameter. Their disadvantages include the need to constantly monitor the current parameter, which can only be changed manually. This forces specialists to install an additional thermometer in the system (especially for temperature control). Taking into account the difference in settings and instrument readings, it is possible to manually adjust this indicator with an acceptable error.

Touch valve

When using sensor mixers connected to the system using special adapters, the thermal parameters are adjusted from the remote panel. Some models use a manually controlled remote control for these purposes. This type of thermostats belongs to more modern models that significantly simplify the temperature control procedure. They provide several adjustment parameters, which guarantees accurate setting of the desired temperature. The reliability and safety of using these devices largely depends on the specific model, when choosing which you are faced with a wide range of price categories. In this situation, it is undesirable to save money and choose a cheaper sample, since the real losses will exceed the difference in the funds spent.

Wireless model

Wireless devices allow you to maintain the temperature in an apartment or private house only if people are present in them. At other times, the floor system is switched to standby mode. Due to this, the costs of heating premises during the heating season are reduced. Such devices can be connected to a smart home control system, when working with which heat savings reach 30 percent. Due to the fact that the modes can be controlled manually (when the user is present in the house), the efficiency indicator will be even greater.

A special feature of programmable devices is the ability to simultaneously control several water heating systems located in different rooms. Their disadvantages include:

- high cost of equipment;

- complexity of setup;

- the need to call service center specialists during startup work.

In addition, the user will have to study the attached instructions and follow its instructions in the future.

Radio-controlled models used to regulate the temperature of the medium are used extremely rarely, which is explained by their unreasonably high price. In terms of their functionality, they practically do not differ from those already described, and the price increases several times. The only difference is that the mechanisms are controlled not via a cable, but via radio signals. When such a system operates, the thermostat receives signals with information about the indicators of the sensors and transmits them to the controller. The latter processes the parcel and sends radio signals to the hot or cold water supply servos.

The disadvantages of these systems include the need to equip each of the individual devices with transmitters and receivers. The increasing complexity of process control circuits leads to frequent breakdowns of electronic components and difficulties in restoring devices.

Variety of water floor structure regulators

The fundamental difference between different control devices lies in the method of setting the required temperature:

- Mechanical modifications. These devices rarely break down and are affordable. This type of water heated floor regulator has a simple scale that makes the setting process easy and understandable. The required temperature is set using a rotating disk. Sometimes on the front panel of thermostats for heated water floors there is a lever designed to turn it on/off. These devices have no other functions. The average price for them is 15 euros.

- Electronic devices. Their functionality is similar to the mechanical version, but it is implemented differently. The electronic model provides a digital screen on which current or set parameters are displayed. You can also see several buttons on the devices. They may contain arrows with “up” and “down” signs, which serve to gradually change the temperature regime. Estimated cost – 20 euros.

- Models with programming. Adjusting the temperature of a heated floor using such a device allows you to both maintain stable heating and change it automatically depending on time. Models are sold that have the ability to program the temperature during the day and by day of the week. This function allows you to save energy resources, and therefore money, and at the same time live in comfortable conditions. For example, the temperature can be lowered when all family members are away from home, and raised before they return. Some modifications, in addition to the stationary unit located on the wall, are equipped with portable control panels. There are now models on sale that can be used to correct work using a computer or tablet. The simplest modification, which provides the ability to set the floor temperature over time, will cost no less than 40 euros, and a sophisticated device can cost more than one thousand.

- Multizone modifications. Such thermostats control several circuits and maintain individual parameters in each of them.

- Touch models. The list of functions performed by these devices is the same as that of electronic models. But they are equipped with touch buttons, not tactile ones. The cost is higher.

- Radio thermostats and controllers. Similar systems supplied by European manufacturers are new to the domestic market. For example, Uponor systems consist of servomechanisms controlled using radio signals, a radio thermostat that monitors sensor readings, and a radio controller that receives data from the thermostat and transmits it further to servos. The kit also includes an SMS module that allows you to control the system via mobile communications and monitor its status.

Criteria for choosing thermostats for heated floors

In order to make your heating system as efficient and controllable as possible, you should not neglect expensive device models. In most cases, the choice of device is influenced by living conditions and the intensity of use of heating equipment.

It should be said right away. Mechanical thermostatic valves are simple and convenient. They are usually used in residential areas where people are constantly present. Even in a room where children are, installing such devices is not prohibited. The devices have appropriate protection.

In cases where there is often no one at home, and the need for heating exists constantly, the best option would be to use a programmable thermostat. By setting the necessary time and temperature parameters in advance, you will organize automatic operation of the heated floors. For those who are planning to install heated floors at home, when purchasing a thermostatic regulator, a number of nuances should be taken into account:

- when relying on automated devices, it is necessary to have a constant voltage in the home electrical network;

- the permissible temperature threshold for the thermostat is 60C;

- Installation of devices is carried out in two versions, using a panel installation or wall mounting. The panel mounting option is used in large premises. The wall-mounted version is mounted next to an outlet or electrical panel and is more suitable for working in small spaces.

Thermal valve - the main element of a water heated floor

The device allows you to significantly simplify and optimize the operation of the heating system by adjusting the flow of hot and cold water into the pipeline. Thus, the thermal valve is the element through which the coolant passes. The microclimate in the house essentially depends on its performance.

A simple way to adjust the temperature of a heated floor

Design features of the thermal valve:

The thermal head is a separate unit that is mounted on the valve stem. This part is responsible for adjusting the air temperature by changing the position of the valve box;

Characteristics of the thermal head from the thermal valve

Adjustment mechanism

Thermostatic mixing valve

A thermostatic mixing valve is also used in radiator-type heating schemes, but convective air circulation (even with balanced ventilation and careful insulation) still leaves the lower layers as the coldest part of the room.

The source of thermal energy can be either a central heating plant or an autonomous boiler. In any case, boilers operate effectively in stable modes and will not provide smooth adjustment of coolant flow in each individual room.

For this purpose, special fittings with selected operating parameters and a specific type of design are included in the system. Installing a mixing valve for underfloor heating gives the following stabilizing result in normalizing the temperature in the house:

Mixing valves perform the task of combining a high-temperature heating circuit with a low-temperature underfloor heating distribution, since the recommended temperature in the pipes under the floor is 40°C, and for the water leaving the boiler 70 - 90°C.

Work principles

If the coolant is too hot, a cold stream is mixed into the water

The three-way valve for heated floors performs its function in the following order:

- the hot coolant from the boiler is directed to the distribution manifold, from which it diverges through the loops of the underfloor heating system;

- a thermo-mixing valve is installed along the path of movement, reacting to the heating temperature of the water;

- when the flow temperature exceeds the set value on the regulator, the latter opens a passage for mixing cooled water from the return pipeline;

- in the tee, two converging flows are mixed and the coolant of the desired temperature is released into the system;

- When balance is achieved, the change in the internal sections of the valve stops.

The valve body is made of brass and consists of 3 channels converging to the adjustment mechanism. The use of 3 different methods of mixing water flows distinguishes 3 types of three-way valve designs.

Three way thermostat

The thermostat mixes hot and cold flow

The set temperature is maintained by a three-way thermostatic valve, which automatically mixes the hot liquid flow from the heater and cooled water from the return pipeline. The need for quantitative changes in flows is determined by the thermostat settings.

This product can be used in underfloor heating systems (especially complex configurations), on radiator wiring and in the internal hot water supply circuit.

Automatic change in the temperature of the outgoing coolant protects a person from elevated temperatures in the event of a pipe rupture. If for some reason the flow of cold water stops, the valve will automatically close the flow of hot pressure from the boiler. The temperature-sensitive unit responds to the amount of heating and, accordingly, changes the cross-section of the inlet holes, achieving the required balance.

The layout of the thermostatic valve for a heated floor looks like this:

A pressure throttle is a device that provides fluid pressure regardless of the pressure difference at the inlet and outlet. Paired with a thermal head for a heated floor, it stabilizes the operation of all system circuits when incoming conditions change.

3-way thermostatic valve

The operation of this valve is not as complicated as a thermostat. Only the incoming hot media is regulated. For more information about the operation of three-way valves, watch this video:

To analyze changes in temperature indicators, the kit includes a thermal head for heated floors, which acts as an executive body based on a signal from an external sensor.

Mixing valve

Manual valve adjusted manually

The three-way mixing valve, which is not equipped with sensors and automation, is even simpler. The manual valve needs to be forced to set the position of the regulator to obtain the desired outlet temperature.

This crane is manufactured in 2 types:

- has a T-shaped passage (symmetrical design);

- internal L-shaped passage, (asymmetrical).

The differences are that with a symmetrical scheme, 2 jets meet from opposite arms of the valve and go into the side branch already in a mixed state.

Making a planting plan

Having acquired a plot of land, the owner feverishly begins to develop it and makes a major mistake. Trees and shrubs, planted without taking into account their characteristics and compatibility, will over time begin to oppress each other, infect each other with diseases and pests, and get sick due to lack of lighting, nutrition, and moisture. It is more practical to draw several diagrams indicating the main landmarks:

- mark the boundaries of the site,

- indicate the area that residential and outbuildings will occupy,

- for proper lighting of future crops in the garden, it is necessary to draw the location of the site in relation to the cardinal directions: south, north, west, east and note what time of day the individual zones will be illuminated by the sun (for sun lovers and shade-tolerant crops),

- indicate the type of soil - chernozem, loam, sandy loam, etc.,

- be sure to indicate the depth of groundwater.

The following entry is a list of garden and berry crops for the garden and berry garden. This list is not very large, but the wrong location of trees in the garden, unwanted proximity, competition - all this can, over time, reduce all worries to zero.

So, 1-2-3 trees of each of the desired crops are placed in the garden, taking into account the ripening time, biological characteristics of the variety or hybrid. Usually these are apple trees, pears, plums, cherries, cherries, apricots, peaches, and nuts. Experienced gardeners additionally plant exotic crops. Among the shrubs, berry gardens are most often occupied by black and red currants, gooseberries, raspberries, chokeberries, sea buckthorn, serviceberry, and blackberries.

Having determined the assortment of fruit and berry crops, they enter the data into a table of competitors and unwanted neighbors. The diagram clearly indicates where and what garden crops will be planted, taking into account compatibility, competition and protection measures.

Orchard

Equipment characteristics

The coolant from the boiler passes through the pipe line to the collector. From it the liquid flows into the floor pipeline. Giving up heat, it returns back to the collector, which has a separate return outlet for the cooled coolant. The circulation pump forces water back into the boiler.

When manually controlling the temperature regime, valves are installed on the circuit with cold water and high-temperature coolant. If the room has warmed up well enough, then the hot water valve is closed. If the room is cold, the valve is opened.

To automatically regulate the heating mode, install a three-way mixer with a thermostat and an external temperature sensor. This system forms a thermostatic valve. It is installed at the entrance to the collector. The equipment is made of brass or bronze.

- The three-way valve has 3 outlets for hot, cold water and coolant, which is supplied to the floor line. Markers on the body indicate the direction of flows of different temperatures.

- A mixing chamber is provided to mix liquids of different temperatures.

- On the body there is a thermostat with a temperature regulator.

- The temperature sensor is located on the thermostat.

- The valves close the outlets for cold and hot flow. They can be disc-shaped or needle-shaped. Their operation depends on the thermostat.

- The thermostat is a system that consists of a capsule with liquid and a spring-loaded rod. Valves are attached to it.

- The temperature sensor has a digital panel on which the heating modes are indicated.

We recommend: What characteristics does a two-core heated floor have?

The thermostat can be located in the thermal head or in the servo drive. The devices have different circuits, but the same principle of operation. The thermal head is a thermostat, the operation of which is carried out using a liquid: it is sensitive to temperature changes.

Servo drives operate from the electrical network. The liquid is contained in a container. It contains a heating plate. The servo drive is installed on the manifold.

The three-way mixer is designed for heating systems of large areas. In separate rooms or in country houses, a two-way valve is connected to the collector. It is installed on a circuit with a high temperature coolant. Water flows through it in only one direction.